Why Workshops Need LCD-Equipped Chargers for Maximum Efficiency

In This Article

- LCD charger benefits include real-time display of charge status, heat, and error codes.

- Workshops reduce waste and boost efficiency by switching from basic to smart charging stations.

- LXT users see the most benefits thanks to Makita compatibility and fast-charging capabilities.

- Safety improvements like thermal shutdown drastically reduce risk.

- LCD chargers future-proof your tool setup for upcoming battery technologies.

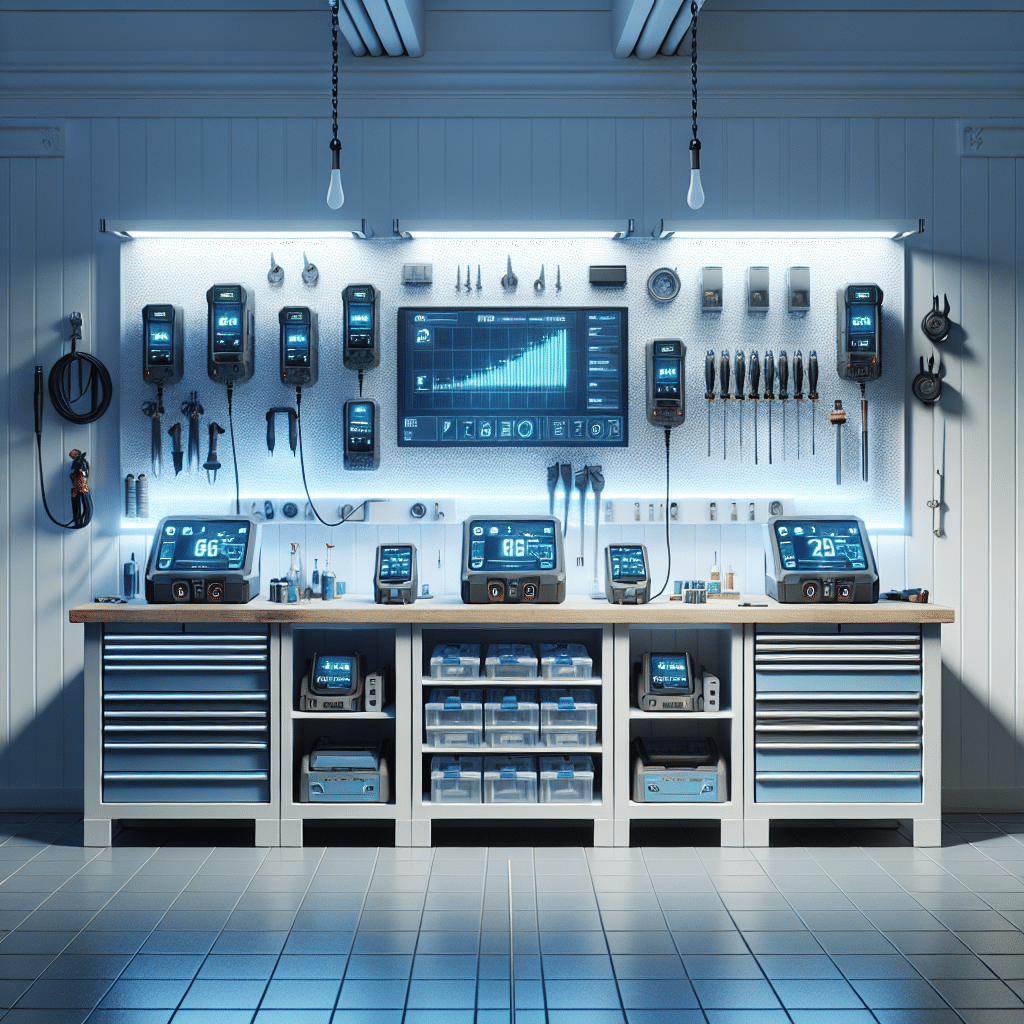

The Evolution of Power Tool Charging

From Analog to Smart LCD Systems

The landscape of power tool charging has transformed dramatically over the past decade. Traditional analog chargers—once the standard in workshops—provided basic functionality with limited feedback. These early chargers offered little more than a single LED indicator to signal when a battery was charging or fully charged. While functional, they dramatically lacked transparency, creating increasing demand for smarter, more informative solutions.

The introduction of smart LCD chargers marked a pivotal moment in tool power management. With digital displays capable of outputting vital charging data, users gained access to real-time feedback on battery status, charge levels, voltage, temperature, and estimated time to full charge. As workshop efficiency gained defence against both human error and equipment failure, technicians and tradespeople began to understand what LCD charger benefits truly meant.

LCD Displays: Real-Time Charger Insights

How Visibility Translates to Efficiency

LCD screens on chargers offer far more than aesthetic appeal—they deliver crucial, actionable information. For professional users, the greatest of all LCD charger benefits lies in this transparency. With easily readable data, workers can schedule usage around charge cycles. Users know which battery is charging, how far along it is, its temperature, and whether any faults are detected. This level of insight helps minimise idle time and improves power tool availability across multiple workstations.

In practice, the real-time display prevents guesswork and mismanagement. When technicians can see an exact percentage or time remaining, planning becomes proactive rather than reactive. This advantage is particularly significant in high-output environments where scheduling impacts deadlines or billable hours. Teams that once juggled batteries without context now work with streamlined workflows—and that difference is transformative.

“The integration of LCDs into chargers has eliminated our downtime. It’s like having a roadmap for our tools.” — Lead Supervisor, London-based Carpentry Firm

Reducing Battery Waste and Downtime

Improved Lifecycle Management

One of the often-overlooked LCD charger benefits is its significant role in extending battery lifecycle. Older chargers lack the diagnostics required to monitor a battery’s health. As a result, users might continuously cycle deteriorating batteries, degrading performance or even causing irreversible damage. LCD chargers, on the other hand, notify users of battery faults, temperature irregularities, and overvoltage risks before they worsen.

This capability allows workshop managers to proactively swap or retire batteries with early warning data. Consequently, budgets are protected, and battery supply chains stay leaner. Even simple insights like charge count or thermal history prevent avoidable downtime due to overworked cells or incorrect charging practices. Furthermore, the reduction in wasted energy during overcharging cycles contributes positively to sustainability goals, making them a practical choice for eco-conscious trades.

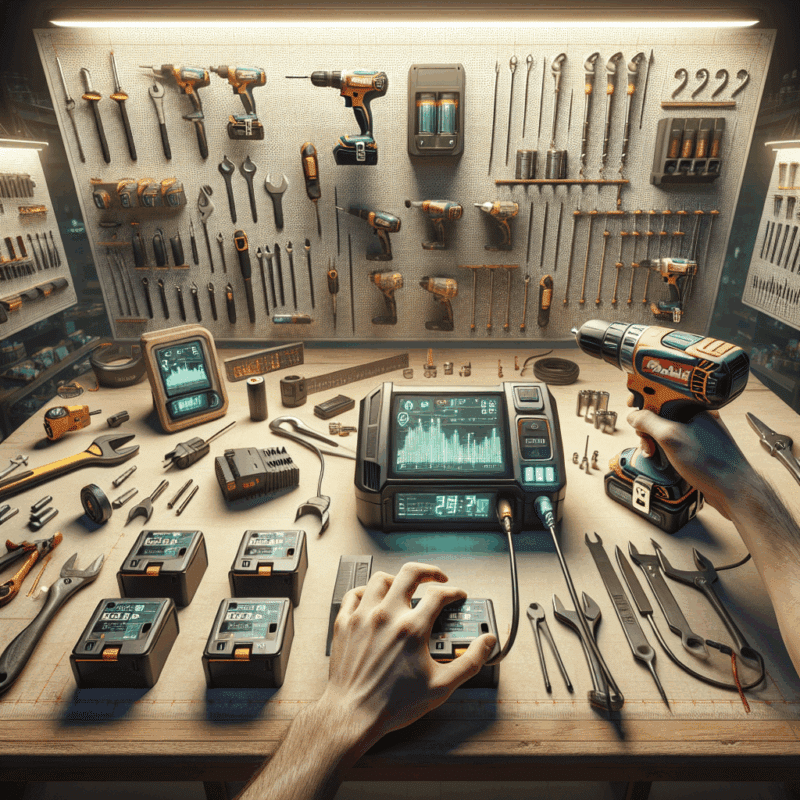

Voltage, Amps, and Smart Metrics

What Workshop Teams Rely On

Modern LCD-equipped chargers provide numeric data about voltage and amperage that goes well beyond simple battery levels. Accurate readouts allow users to understand the speed and safety of their current. If a battery is charging slowly due to low input voltage or high tool drain, this becomes immediately visible. Overcharging? High temperature? Chargers display it—and they act if required.

This granular insight is especially helpful in mixed-tool environments. If a workshop uses both 18V and 40V batteries, ensuring proper usage is essential. Smart LCD chargers adaptively match charge settings per battery and confirm compatibility through display diagnostics. In job site conditions where power performance affects safety and timing, access to these metrics reduces misapplication and boosts confidence in the powered equipment.

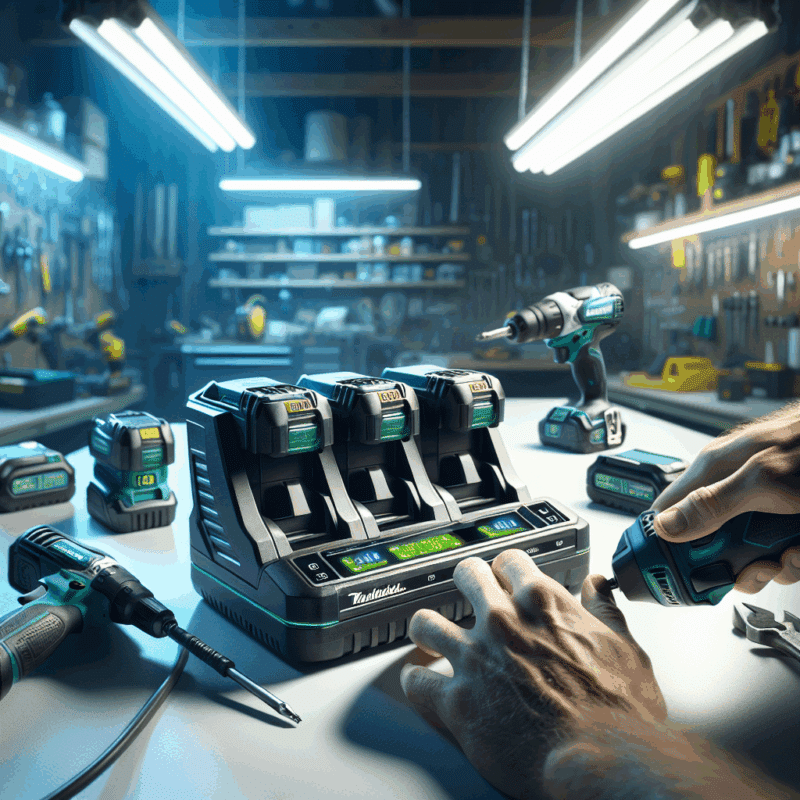

Compatible with Makita Tools

Why LXT Users Benefit Most

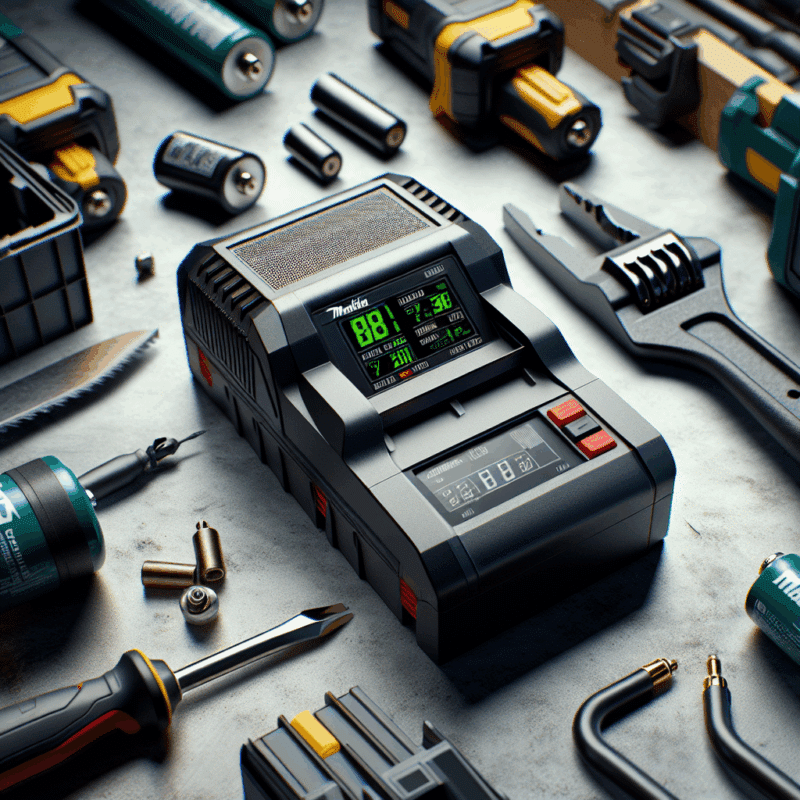

Makita’s LXT platform thrives in both domestic and professional toolkits, and LCD charger benefits are especially meaningful to this expansive battery ecosystem. LXT batteries vary in size, output, and age—an LCD charger ensures that each is charged optimally. Instead of inserting batteries into standard “dumb” docks, LXT users now receive verifiable battery health reports and power insights, allowing confident deployment.

Furthermore, some Makita-compatible LCD chargers can simultaneously fast-charge multiple LXT batteries at different stages, optimising energy use and reducing bench clutter. The time saved by not rotating units manually is substantial. Of course, modern LCD models with built-in cooling fans and fault detection even ensure that older LXT units can be revived or safely taken out of commission.

Upgrading Beyond Basic Chargers

Fast-Charging + Smart Displays

The basic charger solutions bundled with most tools serve minimal needs. In contrast, LCD-equipped alternatives introduce sophisticated, multi-phase charging techniques. Many units use input analysis to adjust charge intensity by evaluating temperature, battery age, and expected usage. As a result, they often reduce cumulative charge time by 30–40% compared to legacy systems.

Moreover, some LCD chargers include firmware that can be updated, making them useful across future battery generations. That forward compatibility becomes critical when investing in workshop infrastructure long-term. Teams working long shifts or across multiple locations benefit vastly from intelligent fast-charging that doesn’t sacrifice safety or integrity—for them, upgrading is no longer optional, but essential.

LCD Chargers and Safety Improvements

Protecting Users and Batteries

One of the underestimated LCD charger benefits is improved safety. In traditional chargers, thermal runaway or overvoltage went unnoticed until performance suffered or tools failed. By contrast, LCD chargers include thermal sensors and voltage monitors with threshold alerts. Some brands even auto-shutoff or inform users through fault codes to isolate higher-risk batteries before they cause harm.

When dozens of devices are charging simultaneously, unchecked systems can reach dangerously high temperatures. LCD chargers reduce this risk by regulating load and reporting charge conditions to one glance. Additionally, bright error indicators prevent faulty batteries from returning to service. The result? A safer, more predictable working environment and fewer liability concerns for managers and employers alike.

Workshop Efficiency Case Studies

Data from Power Tool Pros

Several UK-based workshops that shifted to LCD-output charging systems have reported impressive operational gains. For example, a Birmingham-based joinery reported a 28% increase in charging turnaround speed after replacing all standard chargers with smart LCD models. In Glasgow, a renovation firm slated for government housing said its replacement rate on degraded batteries dropped by 35%, thanks to earlier detection of cycles nearing fatigue.

In another highly specialised case, a film studio’s prop department adopted LCD chargers to prevent downtimes during complex construction builds. By visualising charge levels and leveraging rotational charging protocols, the team extended continuous tool readiness throughout intensive filming periods. These practical use cases cement the real-world value of making the switch to smarter charging solutions.

Recommended Products and Features

What to Look for in 2024

If you’re shopping for smart LCD chargers in 2024, ensure the product includes these essentials:

- Multi-battery support with independent readouts

- Dynamic voltage and amp monitoring

- Overheat protection and auto-shutdown

- LXT battery compatibility (especially for Makita users)

- A minimum charge speed of 4A per port

- Upgradeable firmware and USB-output features

Leading charger models by trusted names such as Makita, DEWALT and Milwaukee support most of the above while including extended warranties backed by Industry insights into LCD charger technology. Additionally, consider reading Learn more about Advanced power tool charging solutions for workshops to explore charger comparisons relevant to your tool kit size and type.

Voices from the Field

Community Use Cases

Tradespeople across the UK have reported transformative differences after switching to LCD-equipped chargers. One carpenter in Leeds commented on Reddit that “I save nearly 20 minutes per project now—no guessing whether I’m ready to work.” Another testimonial through a user survey organised by Read a related article echoed similar sentiments: 91% of users found LCD-based charging improved their workshop flow significantly.

Forums such as Screwfix and ToolTalk also feature hundreds of discussions praising fault-detection capabilities unique to LCD devices. You can follow these conversations at sources like Automating digital efficiency in your workshop to see what real users are discovering in their daily workflows. The adoption wave is spreading fast, and for a good reason.

Conclusion: Ready to Maximise Tool Power?

The all-encompassing LCD charger benefits span from efficiency and safety to battery longevity and workshop intelligence. As the demands for smart tools and lean operations grow, investing in intelligent charging solutions shifts from luxury to necessity. LCD-equipped chargers are the clear next-step for workshop professionals upgrading their charging infrastructure—with tangible returns in both time and productivity.

Instead of working reactively, future-focused professionals are using technology to work smarter. Say goodbye to blind charging and hello to transparent power management. Your tools—and your projects—deserve it.

Great guide on lcd-equipped-chargers-workshop-productivity-benefits – Community Feedback

What is the main advantage of LCD-equipped chargers in workshops?

LCD-equipped chargers provide instant visibility of charging status and critical metrics, allowing teams to monitor battery health in real-time and optimise workflow, which minimises downtime and boosts productivity for busy workshops.

Do LCD charger displays improve tool safety or longevity?

Yes. LCD displays allow users to watch battery voltage and current precisely, helping to spot faults or overcharging issues early, protecting both batteries and tools from damage.

Are Makita-compatible LCD chargers worth the investment?

For workshops seeking maximum productivity and battery protection, Makita-compatible LCD chargers offer clarity, reliability, and advanced features—making them a valuable upgrade over standard models.