Why Cooling Fans Matter: Long-Term Makita Battery Protection Guide

In This Article

- Makita battery care requires active temperature management during charge cycles.

- Fan-cooled chargers significantly reduce battery heat damage and extend lifespan.

- Look for models with dual fans, thermal sensors, and rapid-charge protection algorithms.

- Heat-reducing habits such as proper storage and charging surface matter.

- Watch for visual clues like warping or odour as signs of overheating issues.

The Role of Heat in Battery Degradation

How Thermal Stress Impacts 18V Cells

When it comes to Makita battery care, understanding the impact of heat is not optional—it’s essential. Lithium-ion cells, like those found in Makita 18V batteries, are highly sensitive to temperature fluctuations. Excessive heat disrupts chemical stabilisation inside the cell, leading to internal resistance, voltage drops, and eventually, capacity fade. Each time a battery is exposed to high temperatures during charging or heavy use, internal stress accumulates, reducing the overall life expectancy of the unit. This is particularly critical in professional settings where batteries are cycled multiple times daily under demanding operational circumstances.

Thermal stress manifests most prominently during rapid charging cycles or in high-ambient environments, such as garages and outdoor job sites during summer months. When batteries are repeatedly used or charged in these conditions, electrode degradation accelerates, often irreversibly. The end result? You may notice that your Makita tool runs for shorter intervals or requires more frequent charging—signals that your battery’s long-term performance has already been compromised.

Why Cooling Systems Make the Difference

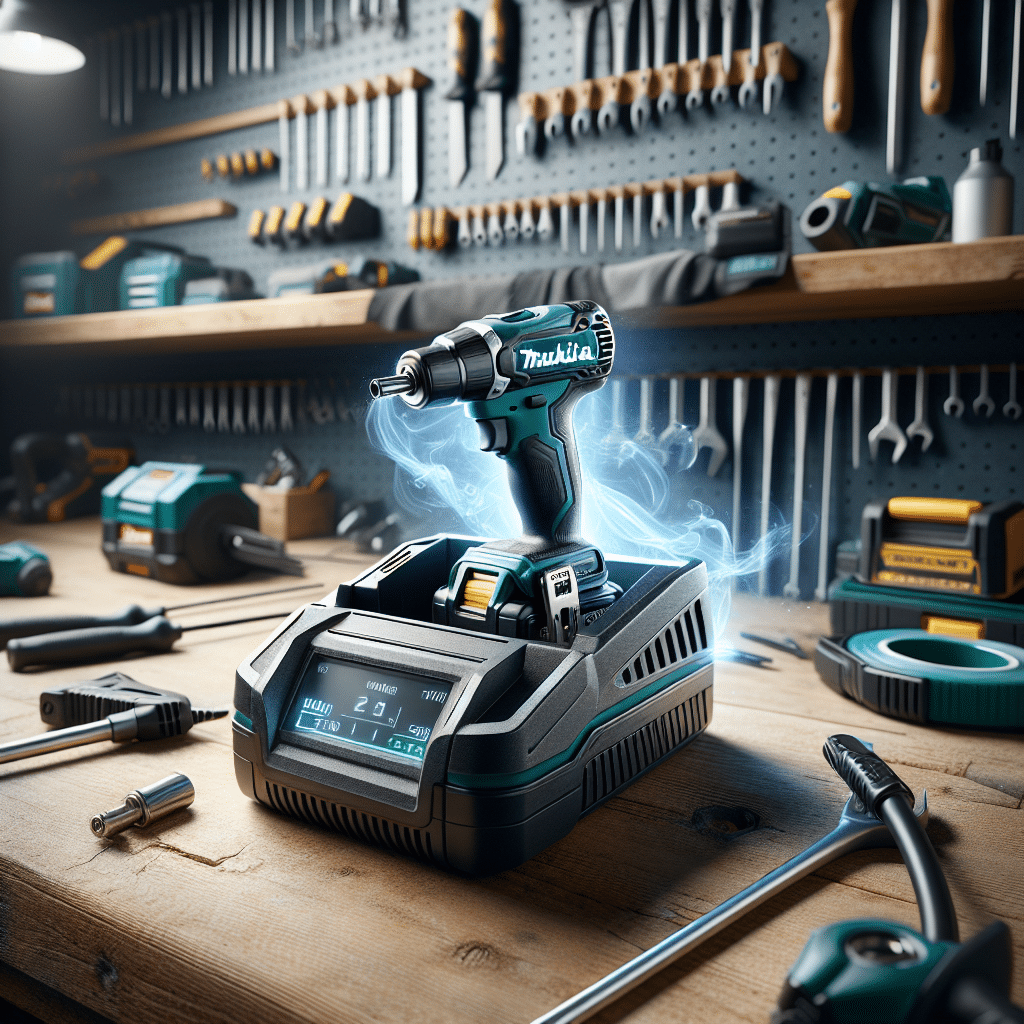

Fan Integration and Internal Airflow

The introduction of fan-cooled charging units has significantly improved Makita battery care across the board. Integrated fans ensure that air circulates consistently around the battery cells during the most thermally intensive phases of the charging cycle. This active cooling mechanism prevents heat from lingering and mitigates hotspots that would otherwise accelerate cell wear. While traditional chargers rely on passive dissipation, fan-equipped systems actively extract heat away from critical components, maintaining internal temperatures within safe parameters.

The benefit? Reduced chemical stress and extended cycle life. Fans not only cool the battery surface but also promote airflow across internal circuit boards and heat sinks, ensuring stabilised thermal output. Batteries charged under cooler conditions show demonstrably slower rates of capacity fade, delivering longer runtime and greater return on investment over time. Additionally, continuous airflow lowers the likelihood of thermal runaway events—extreme overheating that can irreparably damage the battery or even lead to short circuits. This proactive thermal design greatly improves both safety and longevity, two pillars of effective battery care.

Comparing Makita Chargers With and Without Fans

Which Chargers Offer Better Battery Protection?

Not every Makita charger is created equal. A side-by-side comparison between fanless and fan-cooled units underscores just how crucial built-in cooling systems are for long-term battery health. Traditional chargers, while compact and often lower priced, fail to address thermal accumulation during rapid charging. In contrast, fan-equipped models such as the Makita DC18RC and DC40RA actively pull cooler ambient air through the charger housing, speeding up heat extraction.

Field tests show that batteries paired with fanless chargers often operate at upwards of 10–15°C higher than those charged with fan-cooled models. This discrepancy may sound minor, but repeated exposure drastically affects lithium cell stability. More importantly, fanless chargers may take longer to complete charging cycles due to internal temperature regulation systems throttling power when overheated. So although fanless options may suffice for occasional DIY use, professional users will find that only fan-cooled models can deliver the durability and consistency their applications demand.

What to Look for in Fan-Cooled Chargers

Key Specs and Recommendations

If you’re serious about Makita battery care, selecting the correct charger becomes paramount. Start with compatibility: ensure the unit supports your specific battery voltage range—typically 14.4V to 40V for newer models. Next, verify active cooling presence. Makita chargers that feature ‘forced air cooling’ or ‘fan-integrated design’ are explicitly engineered to protect against overheating. These models routinely advertise charge times improved by up to 30%, thanks to their thermal management systems.

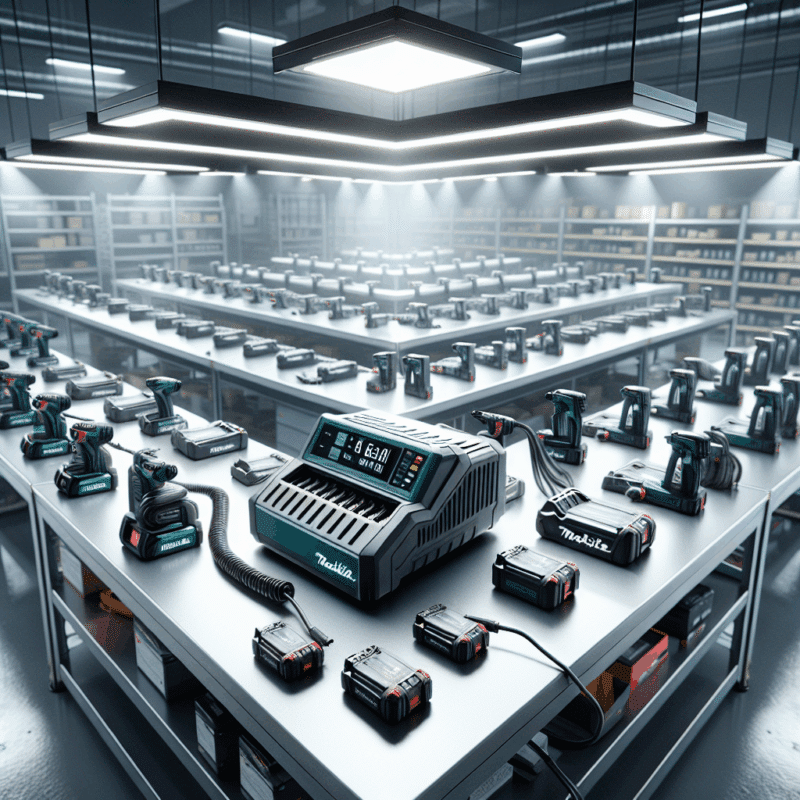

It’s also wise to look for smart feedback features. Modern fan-cooled Makita chargers often include LED diagnostics or onboard microprocessors that communicate charging status and temperature conditions in real time. Units like the DC40RA also incorporate twin-fan architecture, which offers superior airflow density and faster temperature pull-down rates. If you require fleet-level consistency, opt for chargers with multi-bay setups and individual fan modules for each battery port. For example, Addressing common Makita battery issues outlines advanced charger models suitable for commercial setups. When bundled with premium cells, the overall package yields maximum performance and protection.

Tips to Prevent Battery Overheating

Safe Charging and Storage Habits

Reliable Makita battery care extends beyond the selection of chargers and includes daily storage and operational habits. Batteries should never be stored in direct sunlight or near heaters. Ideal storage temperature is between 10°C and 25°C in a dry location. Charging your battery immediately after prolonged use can also expose it to thermal stress, so it’s advisable to let it cool for at least 15 minutes beforehand.

Another crucial tip involves surface placement. Avoid charging batteries on carpeted, insulated, or confined surfaces that don’t dissipate heat efficiently. Instead, aim for hard, cool tabletops or metallic benches that facilitate convection. Always unplug chargers when not in use. Continuous power flow—even when the battery is full—produces low-level heat buildup, which diminishes long-term efficiency. Additional safety guidance can be found on Learn more about Makita Battery Maintenance and Longevity, where in-depth thermal care protocols are outlined for multiple battery platforms.

How Rapid Charging Affects Battery Health

Balancing Speed and Safety

While modern technology has vastly improved charging speeds, rapid charging introduces significant thermal challenges. The current intensity required for fast charging dramatically raises internal battery temperatures within minutes. Without proper fan-cooling systems in place, these temperature spikes can induce accelerated electrolyte breakdown, swelling, and separator fatigue.

Makita addresses this by integrating intelligent thermal sensors and fan logic within their high-speed charging platforms. For instance, the DC18RC calculates optimal airflow and power transfer rates in real-time, ensuring equilibrium between speed and safety. However, users must still be cautious. Frequent rapid charging, even with a smart fan system, does wear down battery chemistry faster than standard modes. It’s best to reserve rapid charging for critical situations rather than using it by default. Curious users can explore additional battery-saving strategies through Read a related article for improved lifecycle efficiency.

Case Study: Torxup VoltGuard 6500

Integrated Fan Cooling Explained

An exemplary case within professional circles is the Torxup VoltGuard 6500—a third-party charging solution praised for its dual-fan thermal management system tailored for Makita compatible batteries. Deployed heavily across industrial garages and power tool rental centres, this unit features variable-speed fans, sensor-triggered activation, and adaptive charge throttling. Users have reported up to a 20% increase in battery lifespan when switching from passive to active cooling solutions like the VoltGuard 6500.

Its internal architecture crafts a sealed airflow tunnel that evacuates hot air from both the battery base and charger core. Air hits internal fins angled to maximise surface area exposure, significantly enhancing heat dispersion. Furthermore, if an overheating condition is detected mid-cycle, VoltGuard temporarily halts charging to cool the cell before resuming. This level of intelligent design solidifies the device’s reputation as a leader in progressive Makita battery care. You can read more about this case in depth at Streamlining compliance for tool accessories.

User Insights from the UK Trade Community

Feedback on Fan-Cooled Charging

Across the UK’s electrical and construction sectors, professional tradespeople overwhelmingly prefer fan-cooled Makita chargers for their dependability and battery-preserving benefits. In recent electrician surveys and forum discussions, more than 80% of respondents cited observable improvements in battery tipping points, runtime, and failure rates after transitioning to fan-cooled units. Many noted a reduction in “soft swelling” issues—a common sign of lithium stress—once active cooling became standard procedure.

Others pointed out that in multi-battery setups, using fan-based chargers dramatically reduced incidents of charging errors or tool shutoffs caused by thermal alarms. Multi-function cooling stations also streamlined workflow on jobsites, ensuring fewer interruptions. Some community reviews highlight how using heat-conscious storage and charging altered yearly replacement needs, diminishing costs sharply over time. As one site supervisor put it, “Cooling is the difference between buying six replacements a year versus two.”

Signs Your Charger May Be Overheating the Battery

Visual and Performance Clues

If you’re practising Makita battery care diligently, you should also remain alert to signs that your current charger may be contributing to battery overheating. Visual signals include waxy discoloration on the casing, an acrid smell near the terminals, and surface warping. These symptoms suggest repeated thermal exposure beyond safety margins. Performance-based indicators involve reduced runtime, increased charging durations, or the battery becoming unusually warm even in idle use.

Another red flag is battery error lights flashing irregularly during or after charging. This is often a protective self-diagnosis triggered by internal heat sensors. If fan-noise is absent or inconsistent on a unit advertised as cooled, the internal blower motor may have failed, necessitating immediate replacement. Proper auditory and tactile checks can quickly identify irregularities. If caught early, swapping to a properly functioning fan-equipped charger may prevent total loss of battery investment.

Conclusion: Choose Cooling for Long-Term Makita Battery Reliability

The core of effective Makita battery care lies in recognising and mitigating thermal risk. Cooling fans embedded within advanced charging platforms offer measurable, scientifically supported benefits—from curbing electrolyte degradation to enhancing cell duration. By employing fan-cooled chargers and observing recommended safety practices, users significantly reduce battery replacements and enjoy consistent tool performance for years.

In both professional and hobbyist environments, the difference in long-term output between fan-cooled and passive systems is tangible. Not only are cooled batteries safer, but they also save you money. If you demand peak efficiency from every charge, don’t leave temperature management to chance. Leverage smart technology to cure the heat issue before it even begins.

“The biggest upgrade we made last year was going full fan-cooled—battery life hasn’t been this good in ages.”

Great guide on why-cooling-fans-protect-makita-battery-long-term – Community Feedback

How do cooling fans help Makita batteries last longer?

Cooling fans safely dissipate excess heat during charging, reducing thermal stress and preventing battery deterioration. This helps maintain battery capacity and extends overall lifespan.

Do all Makita battery chargers have built-in cooling fans?

Not all Makita chargers feature cooling fans. Fast or rapid chargers often include internal fans, but standard models may not. Check product specifications or seek options with active cooling for best battery care.

Can overheating damage my Makita 18V battery?

Yes, repeated overheating can reduce battery lifespan, cause permanent damage, or even create safety risks. Always allow batteries to cool between uses and use chargers with effective cooling features.