Why 6.5A Charging is Essential for High-Volume Work Crews

In This Article

- 6.5A charging cuts downtime and increases tool productivity significantly.

- Modern rapid chargers offer advanced battery protection and diagnostics.

- Teams report fewer idle periods and reduced battery inventory requirements.

- Smart charging stations enhance safety and scheduling efficiency.

- ROI on 6.5A units often surpasses traditional charging investments in under a year.

Why Fast Charging Matters on Busy Jobsites

Tools Don’t Wait—Neither Should Batteries

On construction sites and other high-demand industrial settings, productivity depends on continuity. The importance of uninterrupted workflow cannot be overstated. This is where 6.5A charger benefits emerge as a game-changer. Waiting for batteries to charge using low-amperage systems not only delays tasks but can also cascade into missed deadlines and increased labour costs. Serious crews can’t afford that.

Professional teams often rotate tools between workers and tasks, necessitating a constant cycle of charged batteries. A lag in this process creates bottlenecks. When batteries are charging with only 3.0A or even 4.0A outputs, the delay is measurable. In contrast, the upgrade to a 6.5A charger slashes average charge times and restores tool readiness at just the pace modern workloads demand. Learn more about Optimising battery charging for professional tool users

Time is money in construction environments. The quicker a battery comes off the charging bench fully restored, the sooner power tools return to hands and work resumes. As projects grow larger and deadlines become tighter, adopting faster charging platforms is a matter of operational survival—not indulgence.

How 6.5A Speeds Up Tool Rotation

Twice the Power, Half the Wait

One of the most impactful 6.5A charger benefits is the dramatic acceleration of battery readiness. Whereas a 3.0A charger may take 60 minutes or more to reach 100% battery capacity, a 6.5A device can reduce this time by up to 50% depending on battery size. For tools in constant rotation, this improvement is repeatedly felt throughout every shift.

The maths is simple—the more amperage, the faster the power can be restored. High-output chargers deliver increased current without compromising battery health. With regulated output and intelligent charging circuitry, professionals enjoy not only speed but also efficiency that matches OEM standards. It’s not just about filling up cells faster; it’s about protecting them while doing so.

“Since upgrading to 6.5A charging, our tool downtime has nearly vanished—it felt like doubling our battery stock overnight.” – Site Manager, Midlands Crew

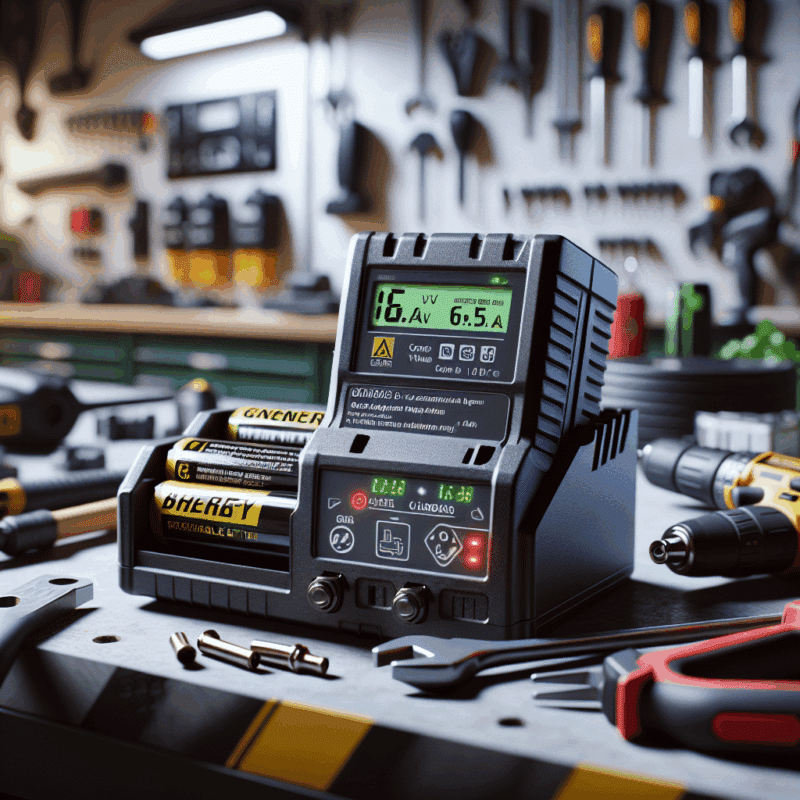

6.5A vs 3.0A: Real Time Savings Compared

To put things in perspective, consider a 5.0Ah lithium-ion battery. On a 3.0A charger, it typically takes about 100 minutes to charge fully. On a 6.5A charger, the same cell can be restored in approximately 45 to 50 minutes. That equates to over 50% savings in wait time on every single cycle.

Implementing 6.5A chargers across an entire team means each technician gains potentially one more productive hour per shift. Multiply that across a month, and you’re looking at dozens of additional man-hours gained—without hiring more personnel or increasing your fleet. This direct performance gain reflects precisely why the 6.5A charger benefits are fast becoming indispensable in professional setups.

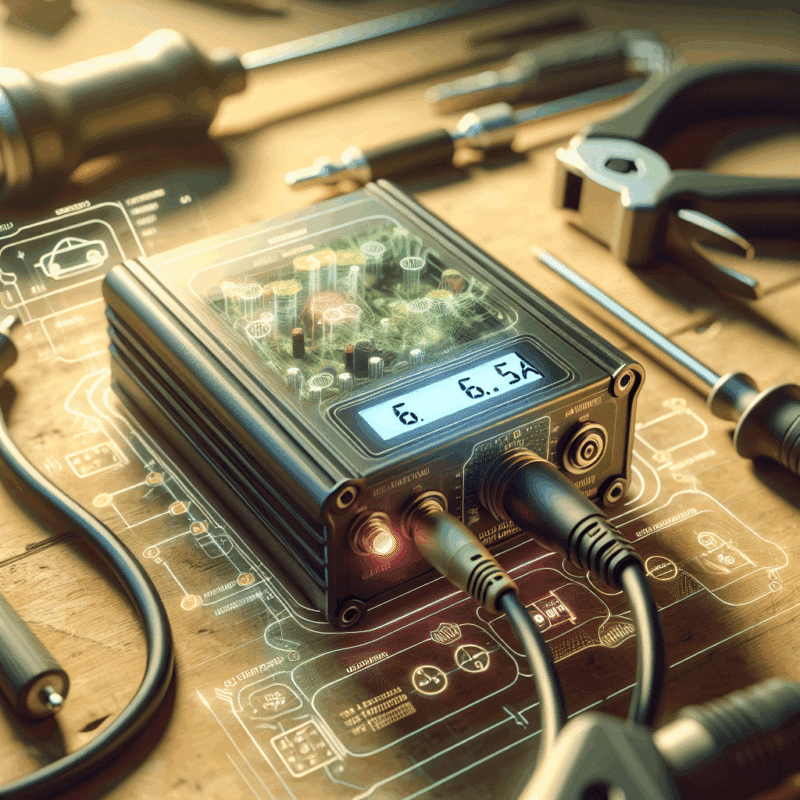

The Safety Science Behind 6.5A Charging

There’s a common misconception that faster charging equals higher risk. However, that belief neglects the sophisticated battery management systems (BMS) built into modern lithium tools and rapid chargers. 6.5A charging platforms often include smart temperature monitoring, overload protection, and adaptive voltage regulation.

When deployed correctly, these systems not only prevent overheating but can also extend the battery’s usable life by maintaining ideal charging conditions. The regulated nature of 6.5A output avoids voltage spikes that might otherwise degrade cells. Many units are certified by third-party agencies to meet or exceed safety standards, offering peace of mind for crews and site safety officers alike. Understanding safe high-amperage charging

Boosting Battery Uptime With Smart Charging Routines

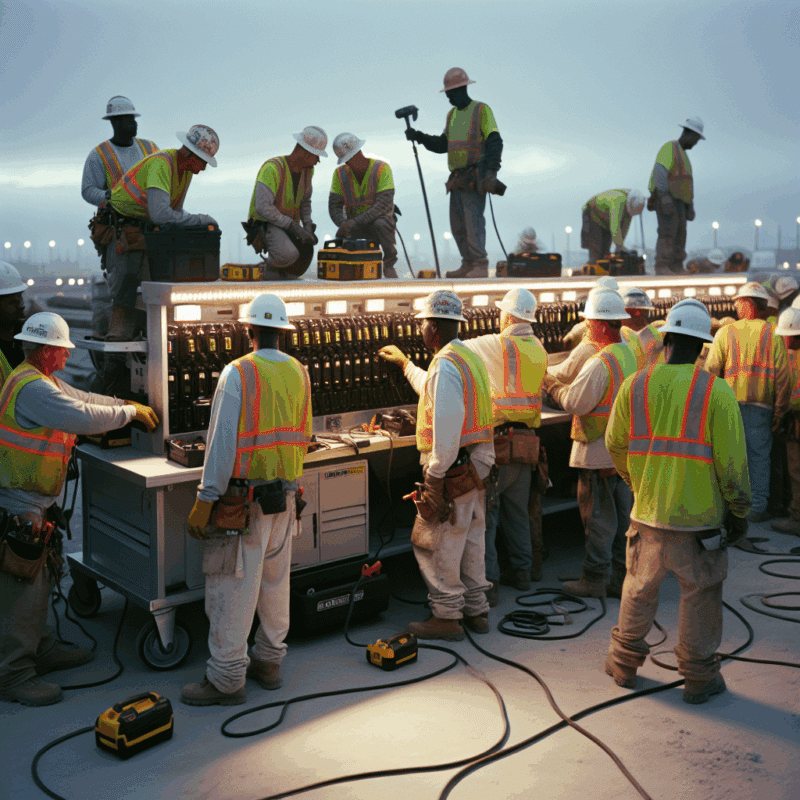

Another key aspect of 6.5A charger benefits is the ability to establish smart charging rotations. In high-volume teams, charger efficiency is only part of the equation—charging discipline is the other. With residential setups, it’s often acceptable to forget a battery for hours. Not so on a commercial site. A comprehensive charging bench, anchored by high-output units, enables scheduled rotation so that batteries are always ready, never stale.

Cycle Planning Made Simple

Operators often employ tiered battery stations: one for charging, one for standby, and one for active use. With 6.5A chargers replenishing units in under an hour, this strategy works seamlessly even in small spatial footprints. Integration with LED indicators or app-based alerts (on select models) takes the planning even further, offering real-time insights into battery availability.

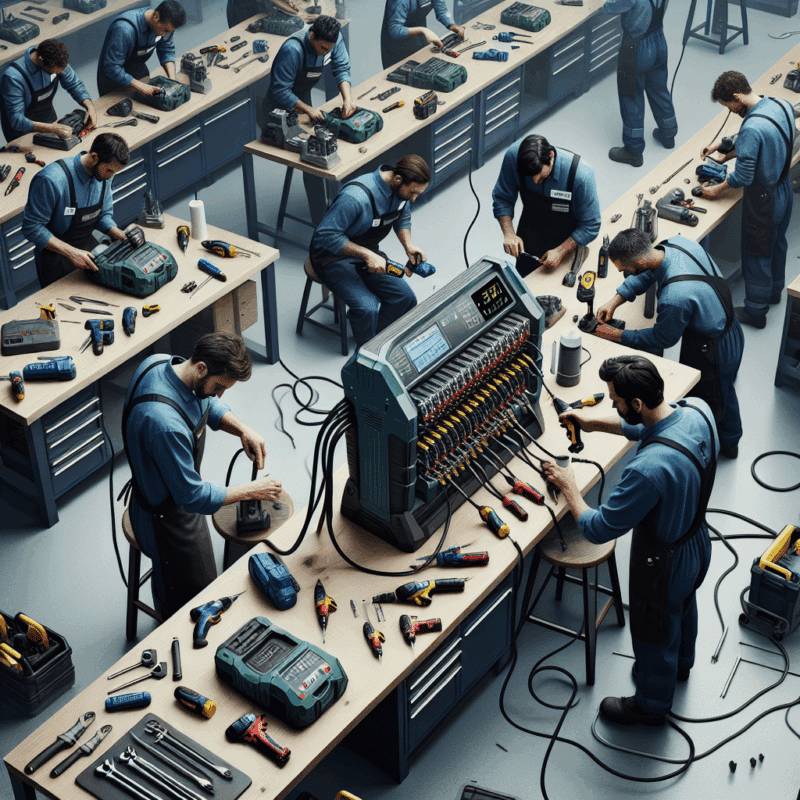

Real Crews, Real Results: Testimonials and Reports

Feedback from field crews using 6.5A systems is overwhelmingly positive. Many report reduced tool downtime, faster job completion, and a surprising realisation: they don’t need as many spare batteries as before. Instead of stockpiling duplicate packs to cover for slow charging, teams invest in fewer batteries and more high-output chargers. The result is not just better workflow but better budget management too.

Take Damon Construction, for example—a 20-person crew working primarily on high-rise refurbishments in Manchester. After adopting 6.5A chargers across their van fleet, they recorded a 30% reduction in lost time due to uncharged tools. Another crew in Leeds noted that switching meant they could downsize their battery inventory from 50 to 32 units without sacrificing uptime. Read a related article

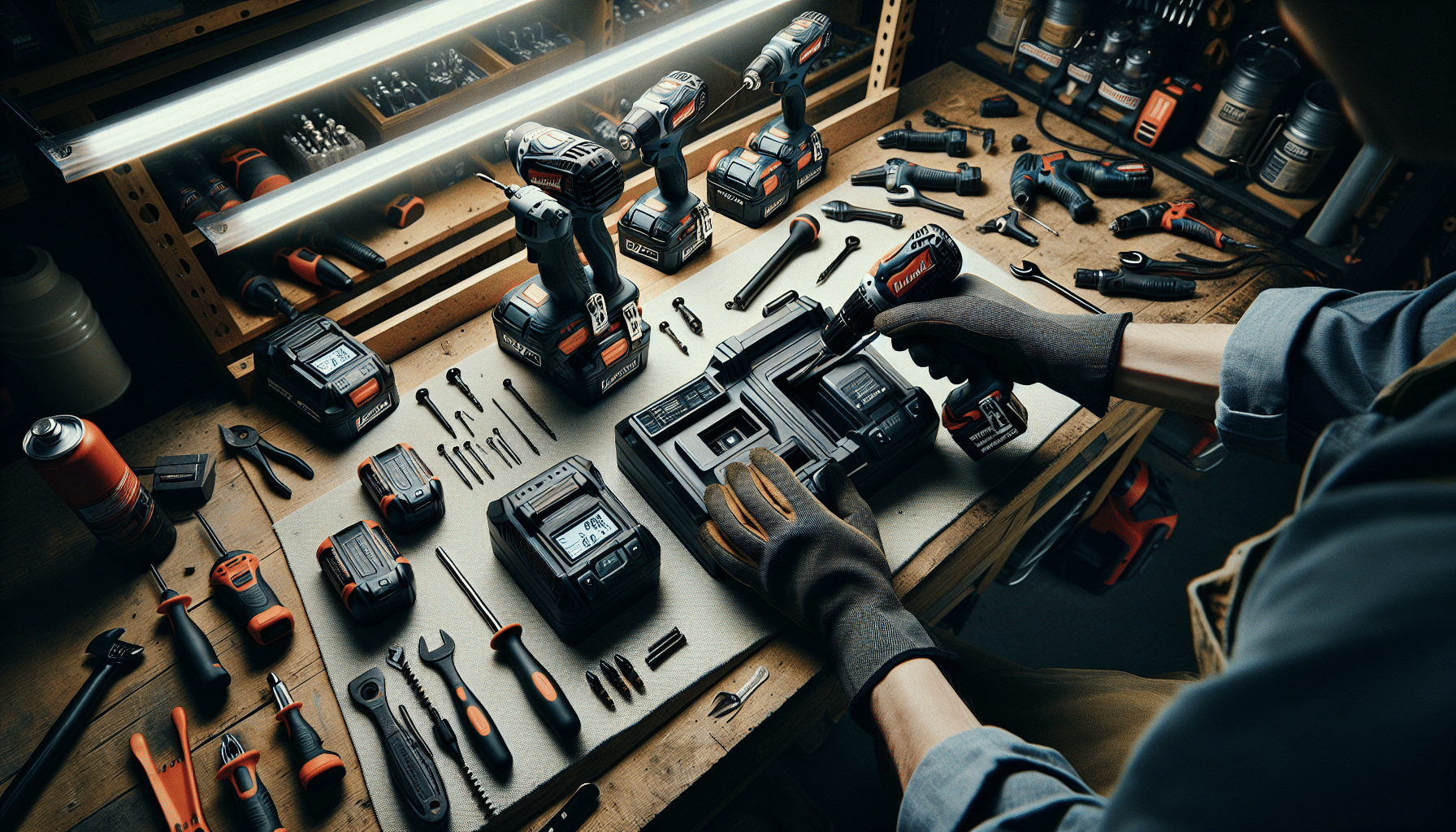

What To Look For in a Professional-Grade Rapid Charger

If you’re investing in 6.5A charging infrastructure, look beyond amperage alone. Critical features should include smart diagnostics, compatibility with multiple battery voltages, rugged housings for tough jobsite conditions, and ideally, stackable or wall-mountable designs for space efficiency.

Some models even include dual charging ports or pass-through USB functions, allowing you to power handheld diagnostics as well as tools. Prioritise chargers with cooling fans or heat sinks to avoid thermal throttling during back-to-back sessions. Advanced SEO and workflow automation solutions

Charging Bench Setup Ideas for Volume Users

Efficient charging doesn’t exist in a vacuum. For volume crews, workspace plays a vital role. Consider modular bench setups that allow vertical stacking of chargers, integrated cable management, and labelled battery trays for each user or tool set.

Wall-mounted pegboards with charge indicators and QR-coded maintenance tracking also enhance oversight. For site managers, establishing clear charging policies prevents hoarding and encourages shared responsibility. Safety stations equipped with fireproof bags or steel boxes further mitigate thermal incident risks.

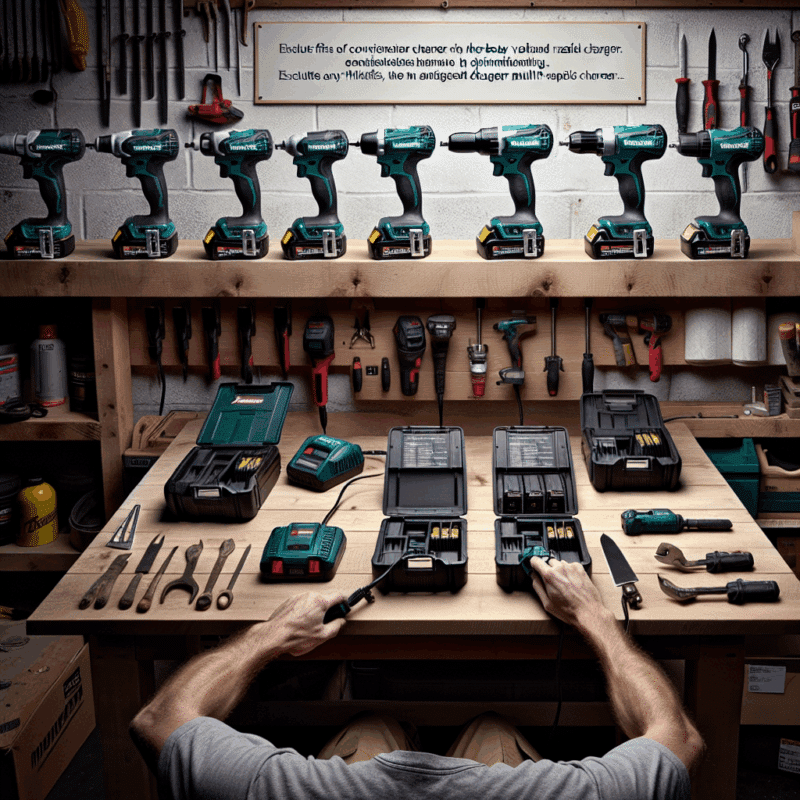

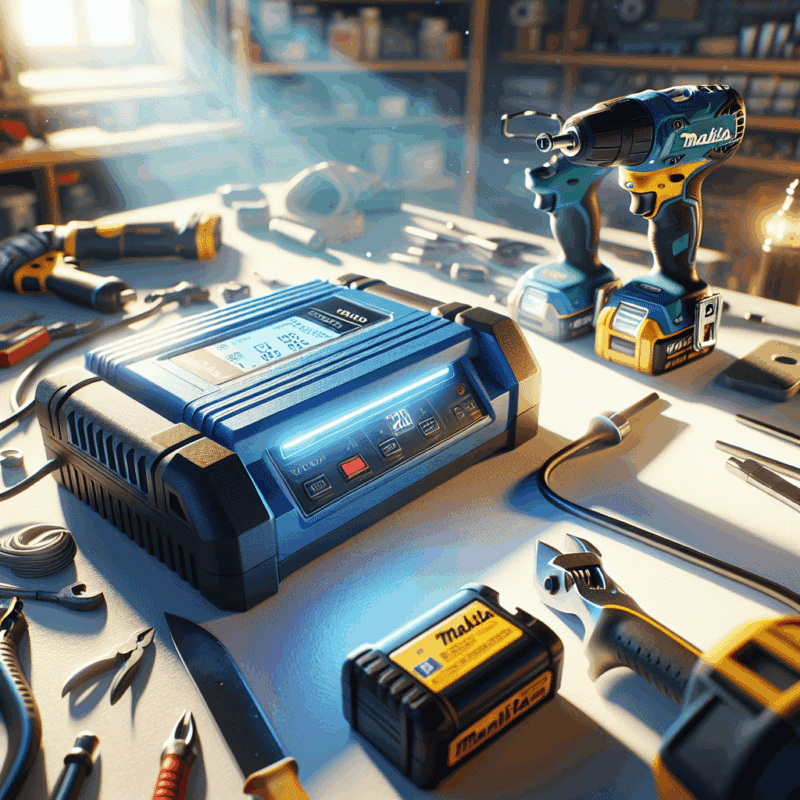

Makita Compatibility Overview: What Works Best

For users of Makita tools, understanding charger-to-battery compatibility is crucial. While most modern Makita lithium-ion batteries will work with newer high-output chargers, optimal performance is achieved by matching voltage range and BMS support.

Makita’s DC18RC and DC18RD chargers are good examples of reliable units that approach 6.5A output on select models. However, emerging professional-grade chargers have pushed further, offering smart integrations to sync with Makita’s LXT and XGT battery lines. Always refer to model specifications before mixing older batteries with newer chargers to avoid efficiency loss or damage.

FAQs: Clearing Up Myths About Fast Charging

Does fast charging ruin battery life?

No, not when performed with a regulated charger. Modern rapid chargers manage voltage and temperature carefully to protect cell integrity.

Can I use a 6.5A charger on older tools?

Generally, yes—provided the battery supports higher amperage intake and the charger is voltage-compatible.

Is it possible to overcharge with a 6.5A unit?

Not with properly regulated systems. Once full charge is reached, most systems switch to maintenance or shut-off modes.

Do I need more than one 6.5A charger?

For large crews, absolutely. The more stations available, the more you improve your rotation availability.

Buying Advice for Teams: ROI and Efficiency Gains

From a financial lens, 6.5A charger benefits translate directly into reduced tool redundancy, lower downtime, and improved return on investment over time. Purchasing multiple lower-output chargers may seem cheaper initially, but ongoing delays and battery inefficiencies stack up. Premium rapid chargers recover their cost quickly in man-hours saved alone.

Teams should plan their charging strategy based on tool usage intensity, the size of the crew, and shift scheduling. A mix of fast chargers combined with an organised bench layout provides maximum uptime with minimum clutter. Volume discounts are available from many manufacturers for businesses or contractors investing in multiples—don’t hesitate to explore those options.

Conclusion: Why 6.5A Is the New Standard in Charging

The modern worksite is too fast-paced and demanding for outdated charging methods. As this exploration of 6.5A charger benefits illustrates, the value lies not only in speed but in smarter, safer, and more strategic power delivery. With reduced tool downtime, extended battery lifespan, and streamlined crew operations, the case for upgrading to a 6.5A charging ecosystem is compelling.

Whether you’re managing a large commercial project or operating a small trade team, leveraging advanced charging solutions maximises your crew’s potential. The future of mobile power is fast, efficient, and undeniably 6.5A.

Great guide on what-makes-6-5a-charging-essential-for-high-volume-crews-interactive – Community Feedback

Why does 6.5A charging matter for high-volume teams?

6.5A charging drastically reduces battery downtime, allowing crews to rotate tools and batteries with maximum efficiency. This keeps work flowing, minimises waiting, and sustains productivity for large teams or demanding sites.

Does faster charging harm battery life?

Certified 6.5A chargers for pro-grade batteries manage heat and voltage safely, preventing premature wear. For approved batteries, the speed boost of 6.5A does not significantly impact overall battery lifespan.

How does 6.5A compare to 3.0A chargers?

6.5A chargers are over twice as fast as 3.0A models, cutting charge time and boosting tool availability. For large or simultaneous jobs, this rapid turnaround makes a measurable difference to site output.