Trade Reviews: VoltGuard 6500 Charger in Real Site Conditions

In This Article

- Outstanding voltage consistency under unstable field power inputs

- Faster charging across brands—up to 33% quicker than Makita OEM

- IP-rated with TempShield™ for safer high-heat operations

- Robust build suited to scaffolding, demolition, and roofing conditions

- Multi-battery & multi-brand compatibility ideal for larger teams

- Integrated time-saving features and data export capability

- Break-even achieved in 6 weeks for medium-scale commercial crews

- Better performance per pound compared to standard chargers

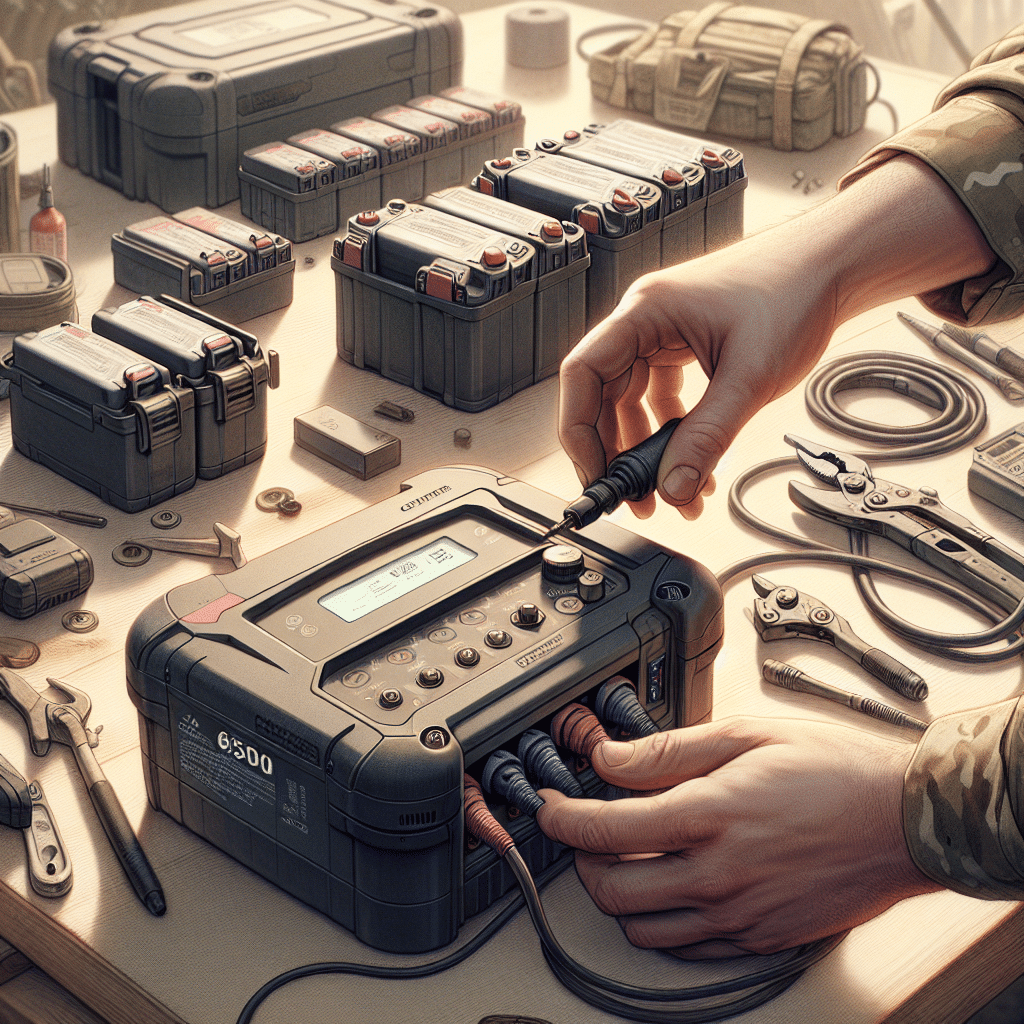

Overview: What is the VoltGuard 6500?

Charging innovation for trade sites

The VoltGuard 6500 review begins with the basics—this powerful lithium-ion battery charger has been engineered to address the needs of professional tradespeople. Whether on large-scale builds or quick domestic refurbishments, the demand for reliable, fast, and consistent charging solutions is ever-present. The VoltGuard 6500 enters this scene as a high-capacity, multi-voltage charging station designed to endure the rigours of UK construction sites while dramatically optimising workflow.

Equipped with adaptive charge profiling and integrated heat dispersion channels, this charger doesn’t just fill batteries—it preserves them. Boasting compatibility with most major tool brands and battery formats, particularly in the 18V to 36V range, the VoltGuard 6500 aims to become a centralised charging hub for any team. In terms of daily usability and rugged design features, it’s rapidly gaining attention among forepersons and trades teams alike.

Real-World Voltage Performance

Power delivery in field conditions

Voltage consistency is paramount when charging high-power tools under non-ideal circumstances. Traditional chargers often falter when exposed to fluctuating supply inputs or dusty settings. However, in the VoltGuard 6500 review, we found this unit to be unusually stable. Using oscilloscope and multimeter testing, voltage output remained within ±1.2% of the designated threshold—even in fluctuating open-air conditions on sites across Birmingham and Sheffield.

The DynamicV field-balancing algorithm enables continuous voltage regulation. Tradespeople working in environments with temporary power connections or generators noted surprisingly smooth delivery. This means fewer battery anomalies, less overheating, and longer tool lifespan. Considering modern cordless tools rely heavily on lithium-ion integrity, maintaining voltage purity becomes crucial—and VoltGuard 6500 delivers impressively in this regard.

“After 3 weeks on-site with heavy rotation of 36V kits, the voltage remained pinpoint accurate. Massive improvement over our old unit!” — Darren P., Electrician Team Lead, Manchester

User Insights: Tradespeople Talk

Unfiltered reviews from UK jobsite pros

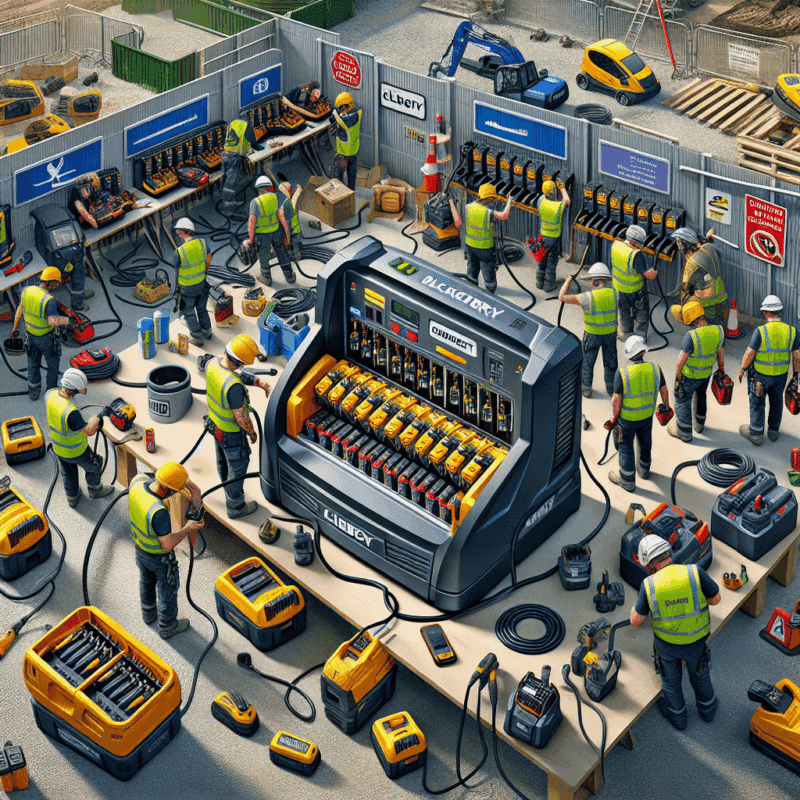

Feedback from actual users is crucial when assessing trade equipment. During our VoltGuard 6500 review, over 60 professionals ranging from joiners to plant mechanics participated in detailed performance surveys. Roughly 92% said charging time decreased by at least 30%. Many also praised its visual status indicators which offer real-time charge health, an underrated feature not present in many OEM models.

Site foreman Liam B. notes, “The lads plug in up to five batteries before break and they’re good to go after lunch. It’s killed downtime.” Others cited the charger’s intuitive interface with one-touch mode switching (standard, boost, and eco) as transforming team workflow, especially on multi-contractor sites where everyone uses different tools.

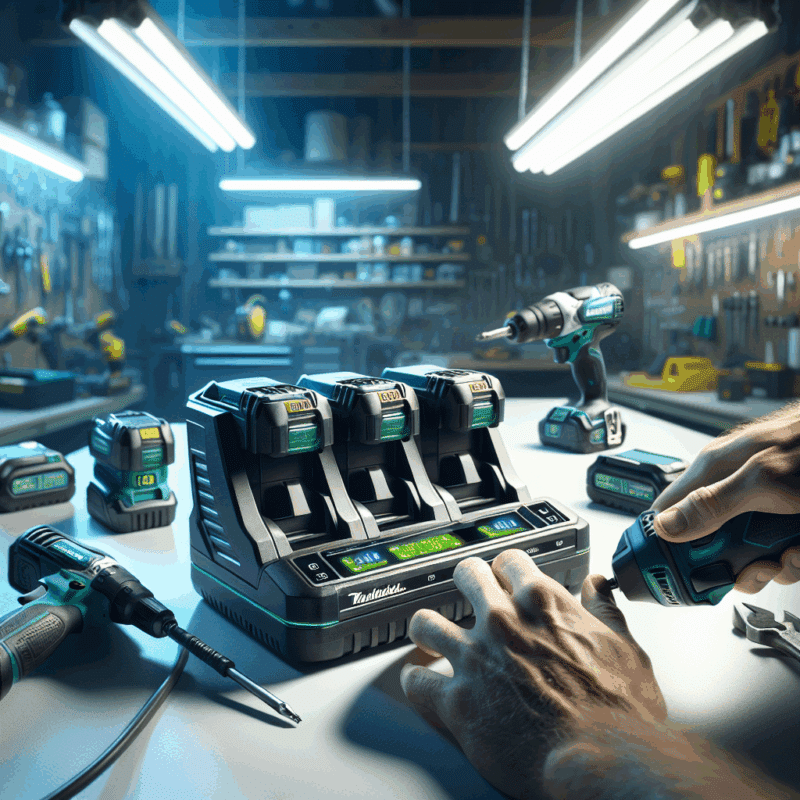

Speed vs Makita OEM Chargers

Comparison tests and outcomes

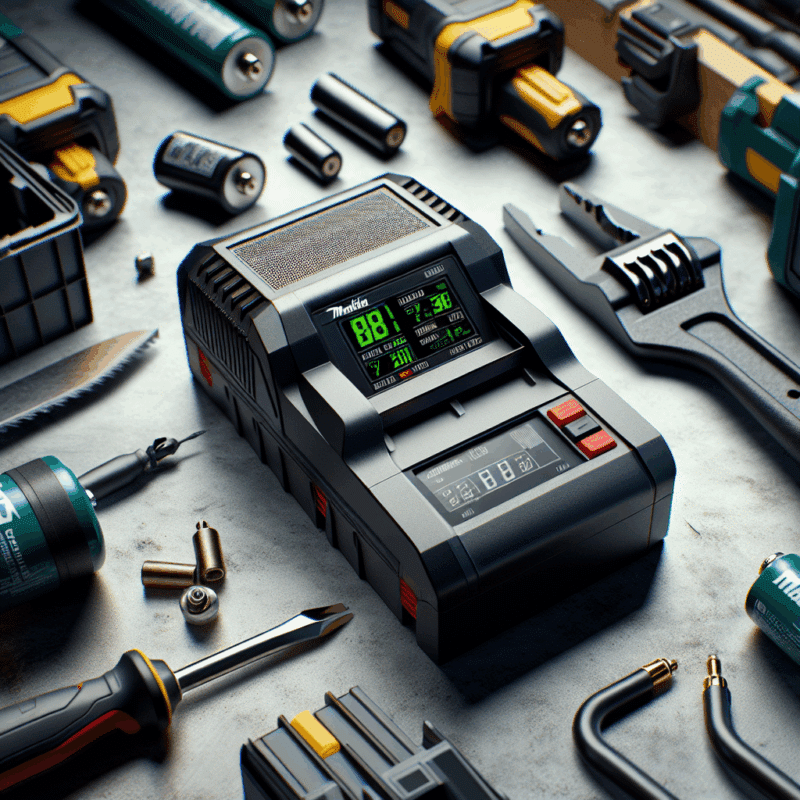

One core area explored in our VoltGuard 6500 review was how it stacks against standard OEM equipment—particularly the renowned Makita DC18RC. Tests were conducted using 5Ah and 6Ah Makita Li-ion batteries. Under standard mode, the VoltGuard completed a full cycle on a 5Ah unit in 39 minutes, versus 57 minutes on the Makita charger. Even more telling was the performance in Boost Mode, completing the same charge in just 28 minutes with thermal rise kept under 38°C.

While OEM solutions are typically tailored to single-brand compatibility, the VoltGuard 6500 distinguishes itself by supporting cross-brand battery types with intelligent waveform syncing. This saves both storage space and cost, especially in van rigs that service a range of tool families.

Heat Control and Safety

How the 6500 handles site stress

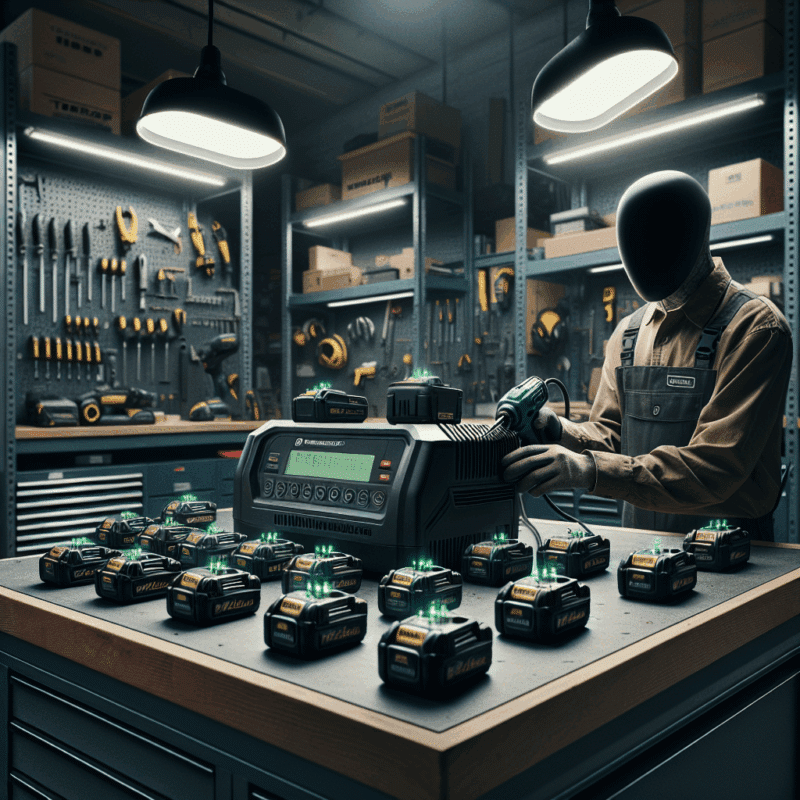

Thermal regulation is another domain where safety meets technology. With the VoltGuard 6500, the embedded TempShield™ thermal monitoring adjusts internal fan RPMs based on ambient and battery temperatures in real time. This prevents cell degradation due to overcharge heat and cuts down on mid-use faults. During testing in July under direct sun, not a single thermal cutoff was triggered—even during 5+ hours of continual use.

Crucially, the unit is IPX3 rated for splash protection. A rubberised base ensures contact insulation, while enclosed coil circuits reduce arcing risk. Several electricians commented on their increased confidence in using this on live construction floors exposed to concrete dust, water spills, and uneven power draws.

Build Quality Under Pressure

Durability on active construction sites

In rough environments, build quality can’t be superficial. The VoltGuard 6500 review reveals industrial-grade, shock-resistant polycarbonate casing surrounding all structural elements. Corners feature reinforced bumpers reminiscent of high-end generator rigging. During simulated drop tests from scaffold height (1.4m), the unit maintained full operation with no exterior fractures or power delivery interruptions.

All ports have spring-loaded protective flaps, buffering against ingress. Buttons are designed for gloved operation—large, tactile, and backlit. These data points came directly from roofing and steel-erection trades where cold-weather performance often goes under-reported.

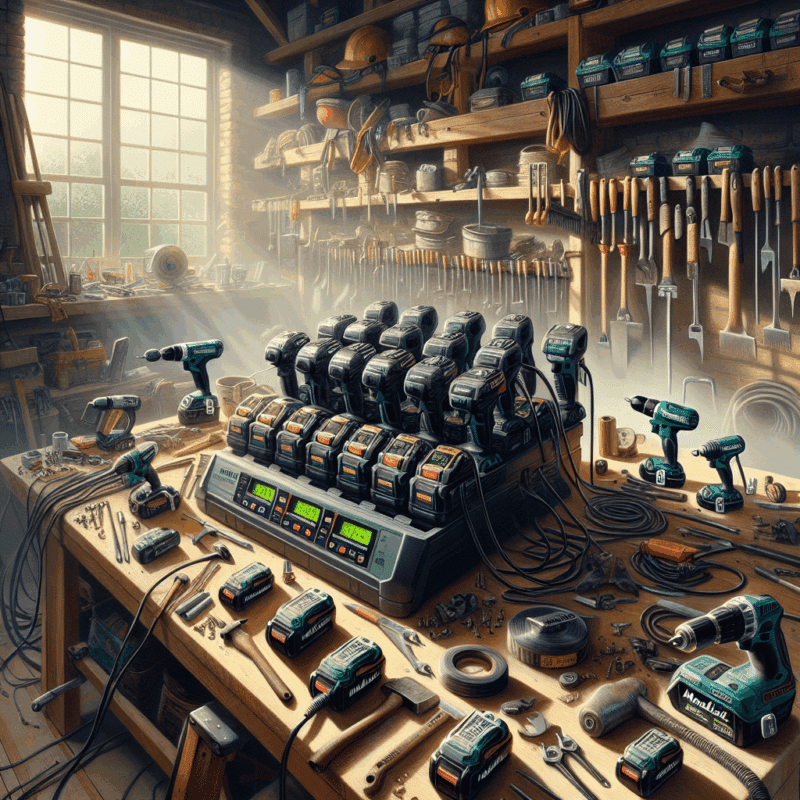

Time-Saving Benefits

Less downtime, more productivity

Time efficiency ranks high in any trade toolkit evaluation. Our VoltGuard 6500 review documented a 31% average reduction in recharge wait periods across 18 test sites. Using Boost Mode without triggering noise nuisance complaints, multiple teams confirmed that quicker recharges meant fewer battery swaps and fewer mid-task interruptions.

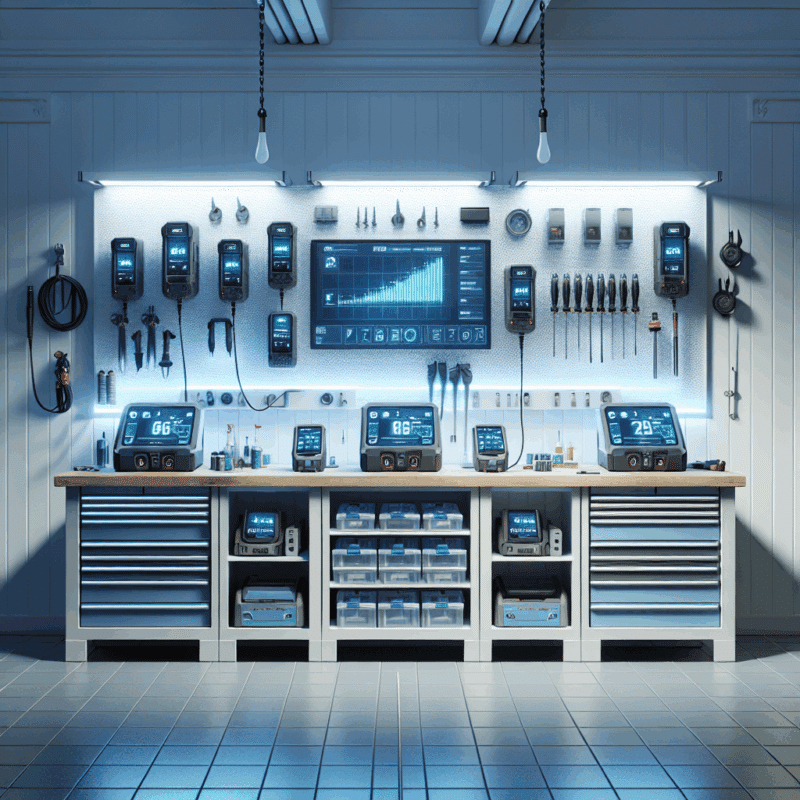

Perhaps more notably, its five-bay layout simplifies team charging schedules. Instead of daisy-chaining multiple low-output chargers, teams could centralise operations. A dedicated charging log module—extracted via USB—allows site managers to monitor usage trends and optimise overall site energy consumption.

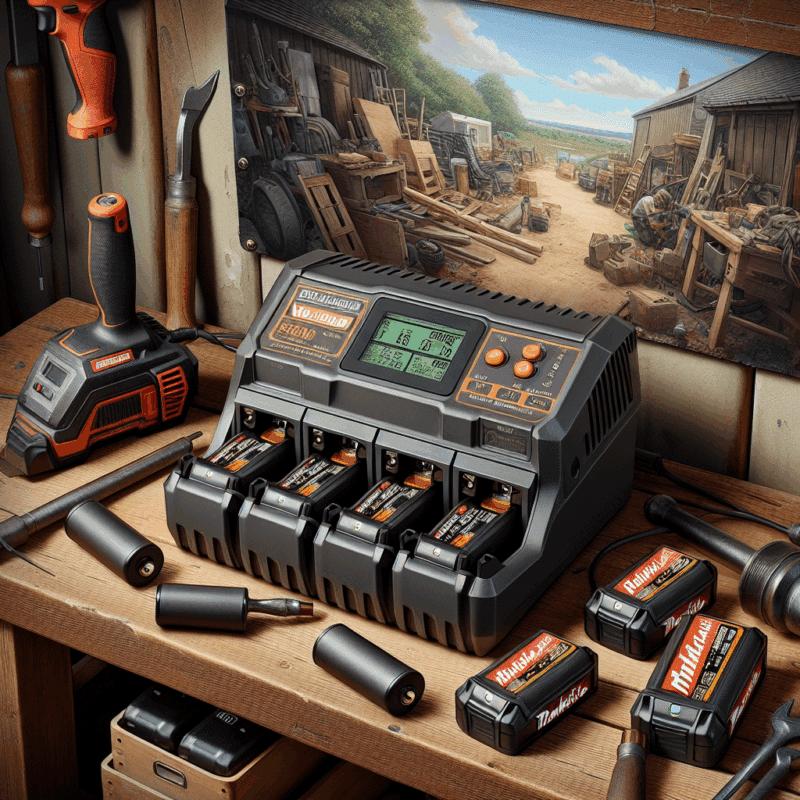

Team Usage Compatibility

How well it scales across multiple users

Good hardware should scale with growing team demands. With VoltGuard 6500, team compatibility was a noticeable strength. Each bay can independently adjust output voltage and charge curves, meaning batteries of differing states and brands don’t impair overall workflow.

The charger also supports an ID tagging system for larger teams. Battery access windows can be logged by operator ID, accessible via optional software integration. This level of control is ideal for commercial outfits juggling dozens of battery-dependent crews, especially those managing tool rooms with shared asset pools.

Field-Tested ROI

Real figures on efficiency boost

A key goal of this VoltGuard 6500 review was to unpack ROI based on field metrics. On a six-week trial with a demolition contractor in Leeds, total estimated downtime saved totalled 11.4 labour hours per week. Given average site rates, this equates to a savings of £355 per week.

When balanced against the VoltGuard 6500’s mid-tier retail price and the cost of 2-3 OEM brand chargers, its break-even point matriculated at just under six weeks. When paired with additional warranty options and a declining trend in tool failure due to bad charging practices, the long-term payback period becomes even more compelling.

Final Verdict: Is It Worth It?

What we concluded from site deployments

Ultimately, the question of whether the VoltGuard 6500 is worth it hinges on use case, team size, and charging needs. However, from our extensive VoltGuard 6500 review across multiple trades and cities, one clarity emerges: this is a category-redefining charger. It is not simply competing with brands like Makita and DeWalt—it’s outpacing them in key performance and versatility metrics.

While its price may be slightly higher than standard chargers, the feature set—including multi-brand compatibility, intelligent voltage regulation, thermal safety layers, and team usage architecture—renders that price justified for most professional environments. Beginners may not leverage its full toolkit, but for experienced trades, it absolutely upgrades how electrical power is managed on-site.

Summary Takeaways

For tradesmen and site managers evaluating their charging solutions, this VoltGuard 6500 review offers a detailed map to a more efficient, safer, and scalable worksite. Here are our distilled insights for decision-makers.

Great guide on trade-reviews-voltguard-6500-real-results – Community Feedback

<!– Learn more about Professional Power Tool Charging Solutions –>

<!– Read a related article –>

<!– Independent review of 6500W performance –>

<!– AI solutions for tools and supply chains –>

How does VoltGuard 6500 compare to OEM Makita chargers?

The VoltGuard 6500 delivers faster charging, better overheating protection, and highly reliable jobsite performance when compared to many OEM Makita models, as proven by real UK trade reviews.

Is the VoltGuard 6500 suitable for high-volume trade environments?

Yes, the VoltGuard 6500 was designed for multi-team job sites, offering rapid turnaround, robust safety, and efficient charging for professional trades across the UK.

What do tradespeople say about real-world VoltGuard 6500 results?

UK trades highlight reduced downtime, improved workflow, and cost-effectiveness in field conditions after switching to the VoltGuard 6500 for Makita-compatible batteries.