Top Workshop Owner Mistakes When Choosing Battery Chargers

In This Article

- Always verify voltage and battery type compatibility before purchasing a charger.

- Never buy workshop chargers lacking proper UK safety certification like UKCA or CE marks.

- Avoid sharing one charger among many technicians in busy environments—invest in multi-slot chargers.

- Choose rapid chargers if high tool usage frequency is part of daily operations.

- Select charger brands offering warranty, support, and recognised reputation to reduce risk.

- Multi-bay charging systems eliminate bottlenecks and improve tool availability.

- Standard vs rapid-speed choice should be based on practical use patterns, not assumptions.

- Always verify seller credentials and charger legitimacy to avoid counterfeit products.

- Don’t overlook aftersales tech support—it often sets good brands apart from poor ones.

- A solid charger infrastructure should align with your workflow, not complicate it.

Why Charger Choice Matters More Than You Think

Bad Charging Decisions Can Compromise Efficiency

When it comes to everyday productivity in a modern automotive or tools-based workshop, few realise how pivotal a role battery chargers play. Workshop battery charger mistakes don’t just stem from selecting poor-quality equipment—they result from misunderstanding the workflow implications of inadequate charging infrastructure. If you’re constantly switching out batteries, waiting for sluggish chargers, or juggling incompatible units, efficiency and throughput take a hit. Ultimately, wrong choices here hinder technician productivity, reduce tool uptime, and increase equipment deterioration.

Common Mistake #1: Prioritising Price Over Compatibility

Why Compatibility with Voltage and Battery Type Matters

One of the most frequent workshop battery charger mistakes is buying a charger based solely on cost savings without verifying compatibility with the batteries in use. Tools and machinery often rely on either lithium-ion, NiMH, lead-acid, or newer battery technologies—all requiring specialised charging standards. Mismatch your battery chemistry or voltage requirements, and not only do you risk inefficient charging, but you could also damage battery cells or even compromise safety. Investing in the cheapest unit that ‘fits the plug’ may end up costing far more in equipment damage, staff frustration, and productivity setbacks.

Common Mistake #2: Ignoring Certification and Safety Standards

CE Ratings and What They Really Mean

Another critical yet overlooked aspect is ensuring the charger is certified to meet UK and international electrical safety regulations. Choosing low-cost imports that lack clear CE markings or BS EN conformity can result in substantial risks. Not only are uncertified chargers more likely to overheat or deliver unstable current, but fault currents can also damage tools or start electrical fires. Workshop battery charger mistakes of this nature can void insurance claims and increase liability exposure. Between regulatory non-compliance and risks to worker safety, skipping registration details on product datasheets is a major operational oversight.

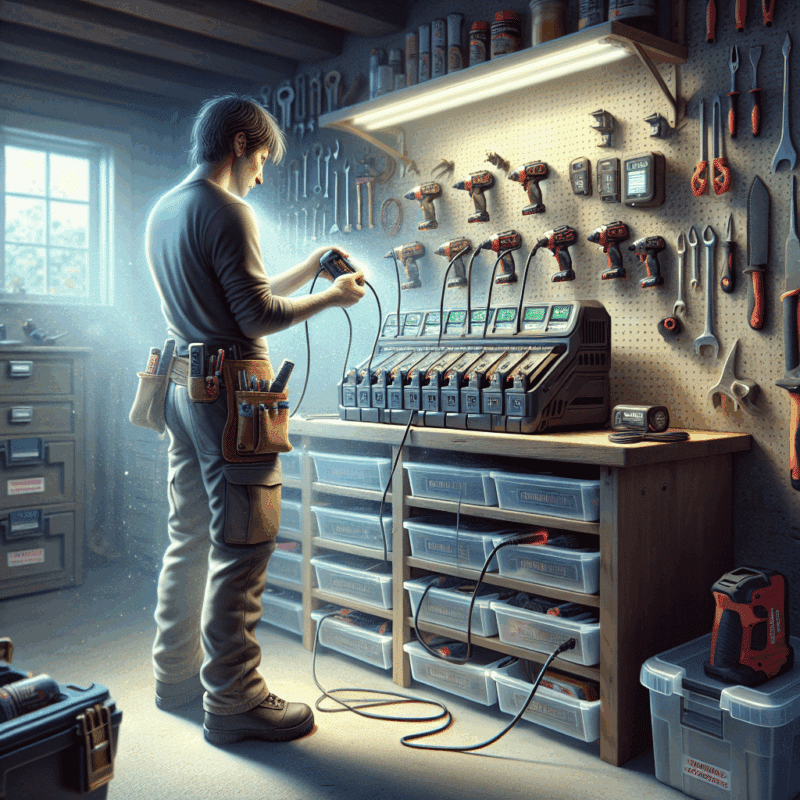

Common Mistake #3: Buying Just One Charger for a Busy Team

How Workflow Bottlenecks Start

Trying to multitask with a single charger across multiple technicians is another classic mistake. Workshops with high tool turnover rates or simultaneous tasking need charging stations that can accommodate parallel usage. Expecting staff to “take turns” plugging batteries into a lone charger not only wastes time but interrupts job flow. Prolonged queuing for battery charging leads to discontent, missed SLAs, and poor resource balancing. To avoid these workshop battery charger mistakes, workshops should assess peak usage hours and align charger availability accordingly with multi-slot units.

Common Mistake #4: Overlooking Charge Speed Requirements

The Real Impact on Workday Efficiency

Different chargers offer vastly different refill speeds—standard trickle chargers may need hours, while rapid chargers cut that time dramatically. Some workshop owners buy chargers based on outdated specifications, unaware that modern high-amperage units drastically improve turnaround time. Consider the cumulative savings of even shaving 20 minutes off each battery’s charge cycle across dozens of batteries daily. Failing to match charge speed to operational needs results in idle staff, reduced tool usage, and lagging throughput. Avoiding these time-drain workshop battery charger mistakes can yield immediate gains in efficiency.

Common Mistake #5: Ignoring Brand Reputation and Support

What Happens When Support Isn’t There?

It may be tempting to purchase an off-brand or unknown charger to reduce short-term costs. However, workshop battery charger mistakes often compound when those units fail—and there’s no warranty or technical support available. Reputable brands not only guarantee conformance to safety standards but also provide replacement parts, firmware updates, and expert advice. In a commercial environment, aftersales service is critical. Equipment failure is never ideal, but without brand-backed support, you may face operational downtime with no clear resolution path. Cheaper doesn’t mean cheaper long-term.

“Choosing the right battery charger isn’t just a technical decision—it’s a strategic advantage that impacts your entire workflow.”

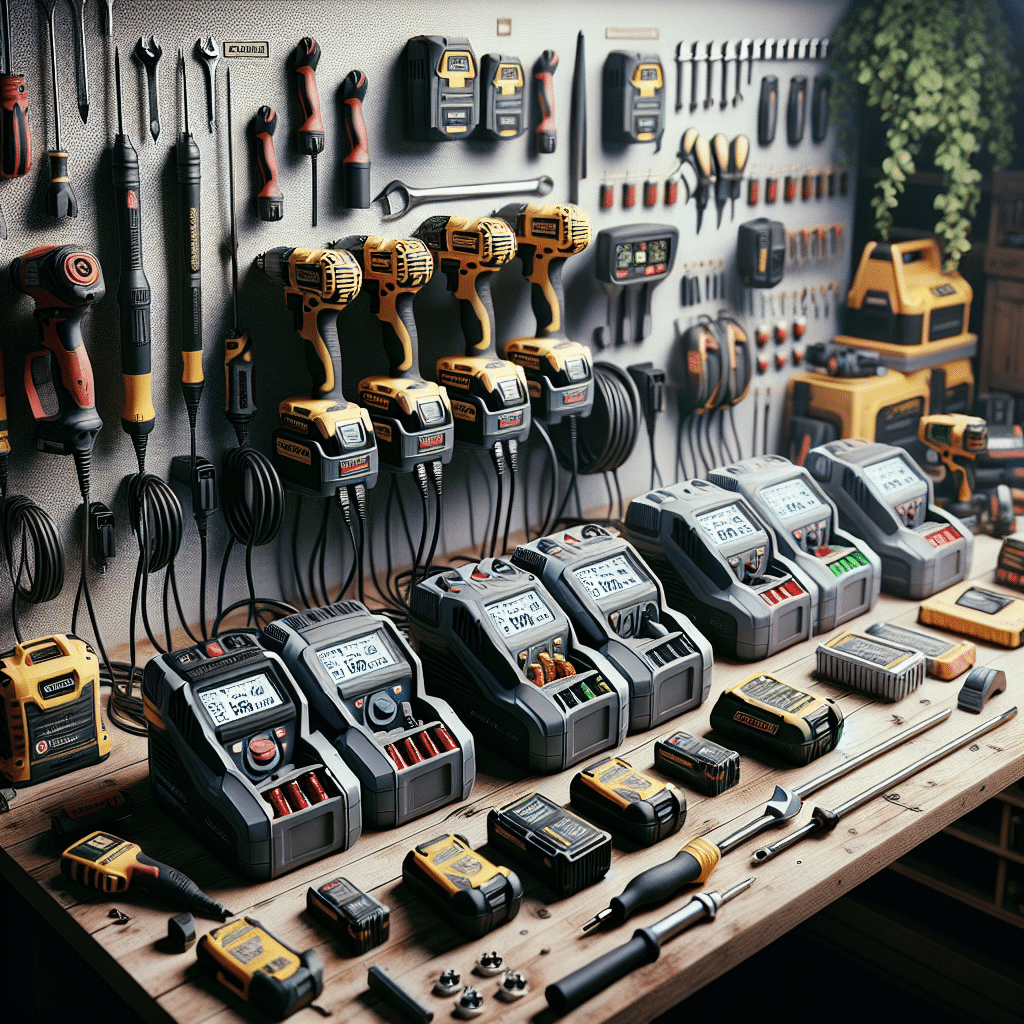

How to Choose the Right Charger Type for Your Shop

Rapid Chargers vs Standard | Solo vs Team Use

Deciding between rapid and standard-speed chargers depends largely on your throughput demands. For workshops engaged in continuous multi-tool tasks, rapid chargers are a no-brainer. And yet, for occasional or backup-use batteries, standard chargers may suffice and conserve energy. Single-slot chargers can be viable for one-man operations, but larger teams require distribution planning. Determine battery demand during hourly peak use and invest in chargers that accommodate those figures. Don’t fall into workshop battery charger mistakes around under-purchasing or mismatching your chargers’ quality to your workload intensity.

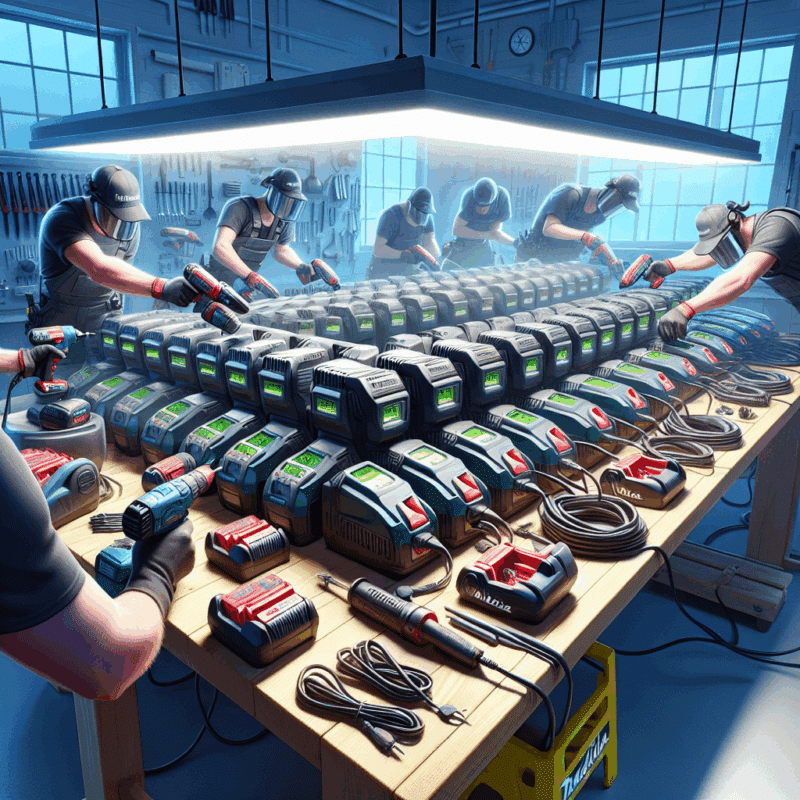

Why Multi-Bay Chargers Can Save Time and Frustration

Preventing Tool Downtime

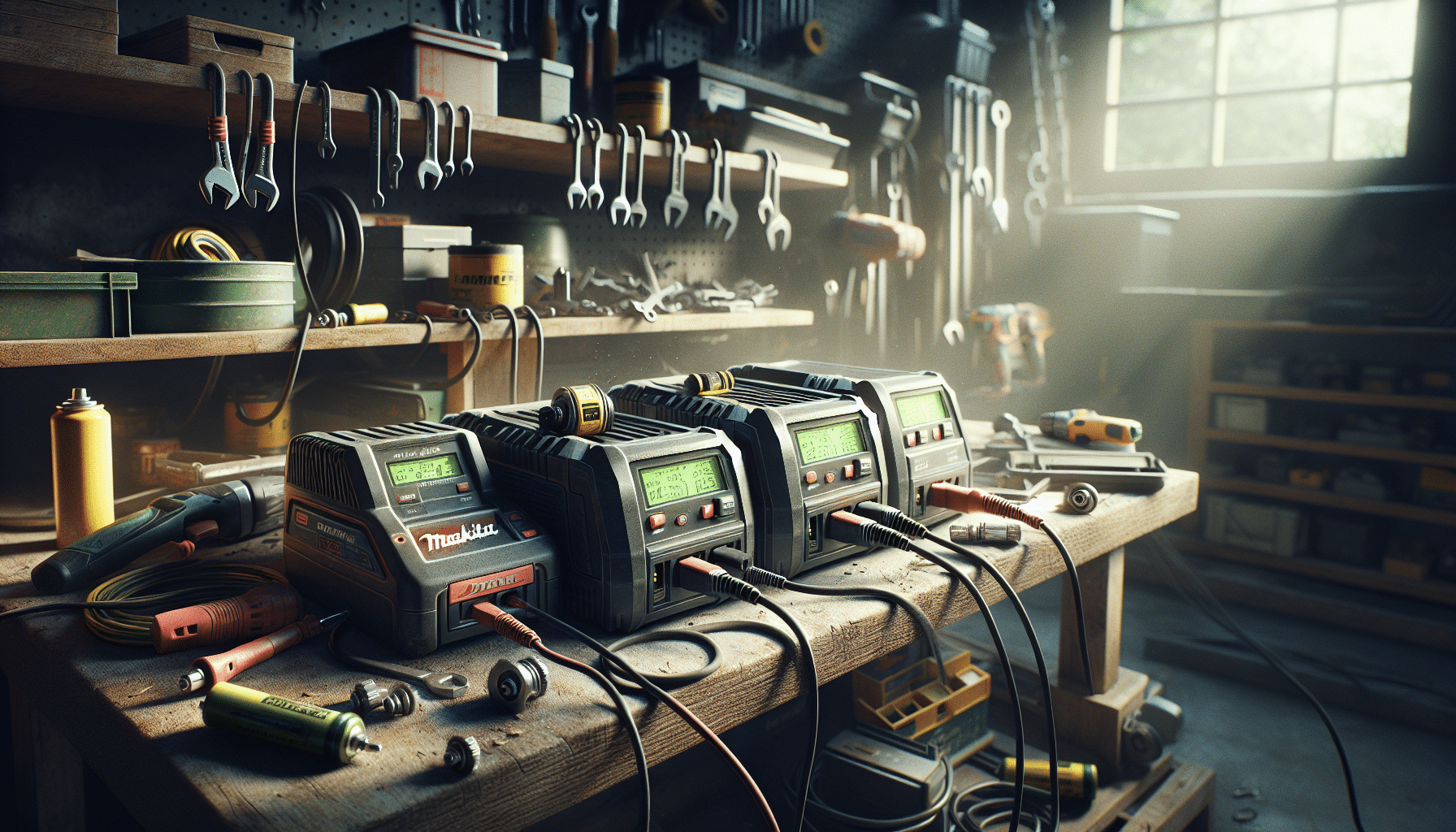

Multi-bay battery chargers are often seen as luxuries or unnecessary spend. In truth, they are workflow enhancers. Charging hubs that allow 4, 6, or even 10 batteries to be charged simultaneously prevent scheduling conflicts and tool shortages. Technicians stay productive, and equipment remains cycling without hitches. Workshop battery charger mistakes occur when owners fail to consider production flow as a design requirement for charger infrastructure. Modern workshops need scalable, centralised solutions to eliminate downtime and ensure every tool is always ready to go. Consider ergonomic layout for charger stations to optimise space and easy accessibility.

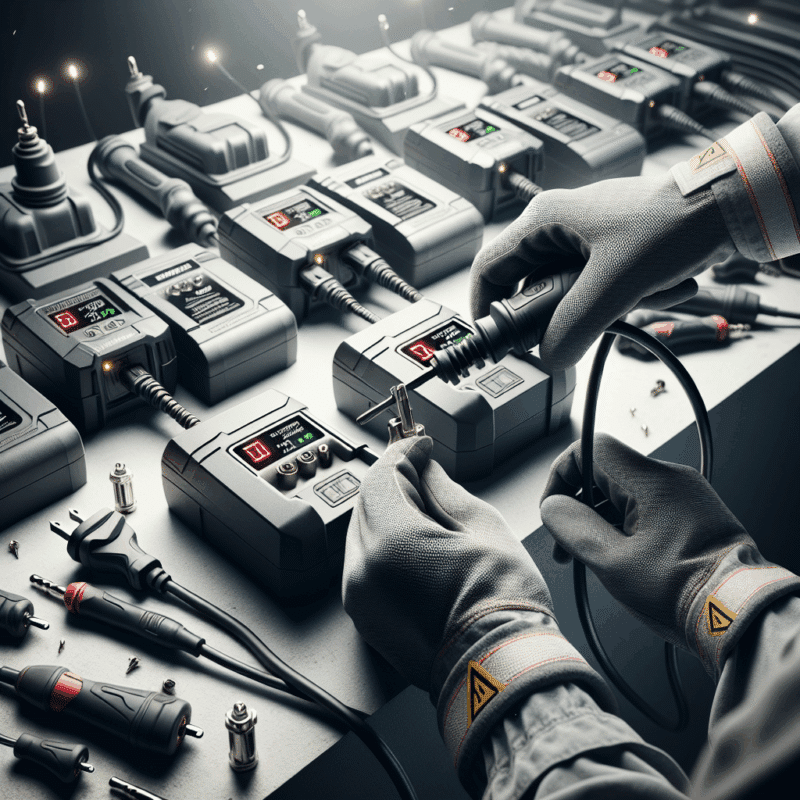

Expert Tips on Verifying Charger Legitimacy Before Purchase

Red Flags & Guarantee Checks

To avoid costly pitfalls, business owners must vet potential chargers before placing orders. Start by checking for BS EN 60335 conformity and a UKCA or CE mark. Investigate the brand’s response time to support queries or part replacement. Legitimate suppliers provide datasheets, warranties, and purchase guarantees. Check address listings and avoid sellers who only trade via third-party platforms with no surface-level identifiers. One common workshop battery charger mistake is buying from unverified online sources, leading to defective stock and no recourse post-purchase. Counterfeit chargers may mimic branding but lack basic safety integrity. Vetting is not an optional step—it’s essential.

Conclusion: Effective Charging is a Business Advantage

Workshop battery charger mistakes can derail even the most well-organised operations. From underperforming equipment to safety hazards and inefficient workflows, the consequences ripple across your business. By understanding the key selection metrics—compatibility, charging speed, safety compliance, and support availability—you empower your team to deliver quality service without interruption. Viewing charging infrastructure not as an expense but as an efficiency asset allows you to future-proof productivity. You can decrease tool downtime, increase staff morale, and improve case resolution speed—all by making better decisions at the charging station.

Great guide on workshop-owner-battery-charger-mistakes – Community Feedback

What is the main mistake to avoid when buying battery chargers for a workshop?

The biggest mistake is choosing chargers without checking compatibility, CE certification, and appropriate charging speed for your tool fleet. Always assess both safety and charging performance.

How can I ensure a battery charger is safe and reliable?

Look for CE-certified chargers from trusted suppliers. Check user reviews, product documentation, and whether it offers protections against overcharging and overheating.

Should I invest in one fast charger or multiple standard chargers for my workshop?

It depends on team size and workflow. Multiple chargers can prevent bottlenecks, while a single high-speed charger suits solo users. Assess your daily needs for the right setup.