Top Pro Buying Triggers: What Drives Workshop Charger Purchases?

In This Article

- Professionals prioritise reliability, speed, and safety in charger selection

- Multi-bay chargers significantly boost productivity in high-traffic workshops

- Compliance with UKCA/CE standards ensures legal and safety alignment

- Long-term investment in smart chargers reduces tool maintenance costs

- Community feedback consistently supports premium brand loyalty

What Are Professional Buyers Looking For?

Speed, Safety & Compatibility

The main workshop charger purchase triggers for professionals operating in commercial settings revolve around adaptability, safety, and time-efficiency. In high-pressure environments, every piece of tech or tool must perform reliably and quickly. Chargers that offer rapid charging cycles while maintaining thermal integrity ensure minimal downtime. Compatibility also ranks high on a pro buyer’s checklist — the more battery types and voltages a unit can handle, the more versatile it is for daily workshop operations.

Fast-charging capabilities are often the first point of consideration. Whether in an automotive repair garage or a light industrial fabricator’s workspace, multitasking requires equipment that keeps up. Quality chargers should include fast-charge functions without sacrificing battery life or user safety. Equally, sophisticated protection systems — against surge, overvoltage, and thermal overload — matter greatly.

Then comes versatility. Smart buyers need chargers that work across an entire toolkit: from cordless drills to torque wrenches. That’s why lithium-ion, NiMH, and older NiCd compatibility ranks as a critical benchmark. Selecting a charger that supports all major chemistries streamlines workflows and inventory.

Multi-Bay Efficiency for Busy Workshops

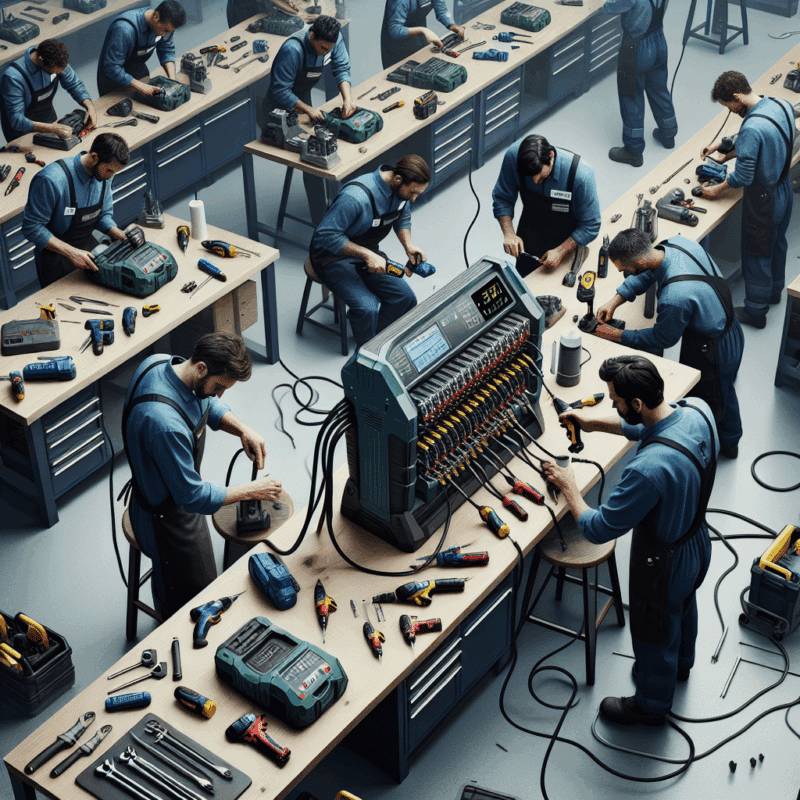

Supporting Multiple Teams and Tools

In environments where workshop productivity hinges on concurrent usage of power tools, multi-bay chargers are a cornerstone of operational efficiency. One of the main workshop charger purchase triggers for professional buyers is the necessity to serve multiple technicians without queuing for charging outlets. With teams working in shifts or parallel lanes, reliance on single-bay units becomes a bottleneck.

Multi-bay stations — especially those with independent port monitoring — not only improve workflow but also reduce clutter with consolidated charging zones. Pro buyers frequently assess models offering simultaneous charge management, meaning two or more batteries can be safely charged without risk of overheating or circuit overload.

High-functioning workshops often benefit from wall-mounted or stackable systems. These are specifically designed with space management in mind. Furthermore, units that optimise charge sequencing — prioritising partially charged batteries for faster deployment — score highly among seasoned evaluators.

“Our shop went from a 20-minute wait per technician to zero queue time by switching to four-bay chargers — complete game-changer.”

Why Charger Reliability Impacts Workflow

Minimising Downtime During Peak Hours

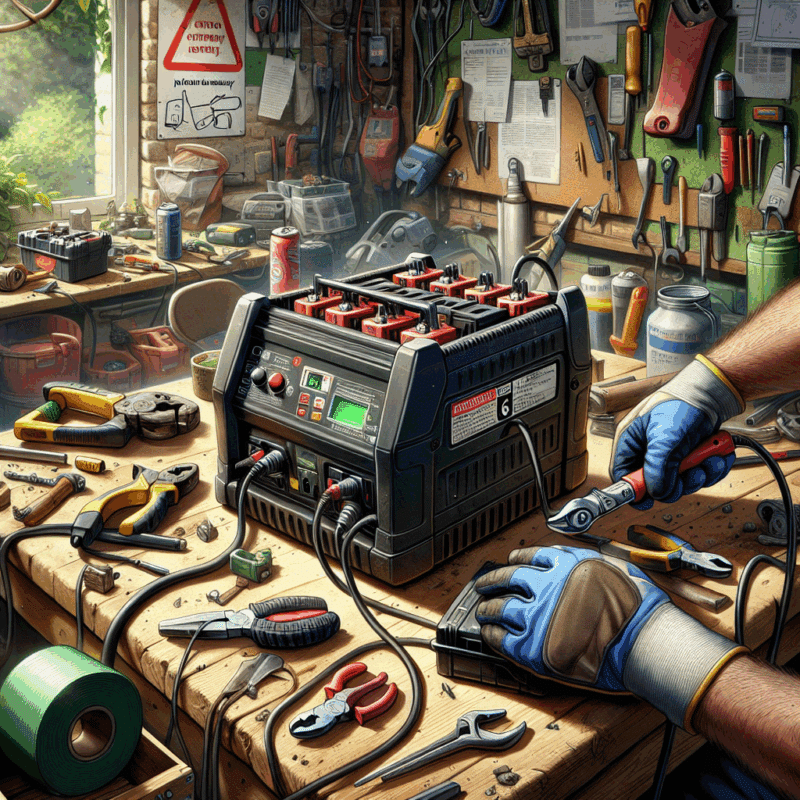

Reliability is not simply a convenience in professional settings — it’s essential to maintaining flow and client satisfaction. Among key workshop charger purchase triggers, the ability of the charger to function flawlessly, even under immense workload conditions, is non-negotiable. A faulty or inconsistent charger can delay entire projects, delay billing cycles, and compromise service level agreements.

Chargers exposed to heavy-duty use must also resist workshop hazards like dust, vibration, and temperature fluctuations. Brands offering IP-rated enclosures are often favoured by procurement leads. Moreover, smart monitoring features that diagnose the battery condition before charging can prevent wasted time and resource damage.

Purchasers are also drawn to models with fault-detection diagnostics. For high-turnover operations, identifying charging inefficiencies early — or alerting technicians to failing batteries — saves hours of manual observation. Ultimately, a reliable charger is a silent contributor to workplace uptime — a reason why many buyers do not compromise here.

Safety Certifications and Workplace Compliance

Understanding CE and UKCA Implications

However powerful or efficient a charger may be, lack of compliance renders it unsuitable for the professional market. Among statutory workshop charger purchase triggers, nothing trumps workplace safety and regulation. Chargers marketed within the UK must carry UKCA marking, while those imported from European territories typically bear CE certification.

The presence of these marks indicates conformance with health, safety, and environmental protection standards. For buyers working in regulated industries — including aerospace, automotive, and construction — certified equipment is not just preferable; it’s mandatory. Internal audits and external inspections can lead to penalties if untested equipment is found operating on-site.

In this context, procurement officers often have due diligence checklists to verify certification authenticity. Reputable manufacturers openly declare testing processes, providing documentation upon request. For chargers used near combustible materials or in damp environments, additional certifications such as IP65 or kitemarks may also feature on the checklist.

Pro vs DIY: Diverging Buying Triggers

Cost Sensitivity vs Value Optimization

Cost always plays a role in decision-making, but how it is perceived varies greatly between professional buyers and DIY users. The former typically focus on value optimisation — driving home another major workshop charger purchase trigger. Professionals look at total lifecycle cost, not merely upfront pricing.

In contrast, DIY users may gravitate towards offers or aesthetics, missing critical reliability indicators. Pros assess energy efficiency, duty cycle rating, and brand warranty. Longer warranties indicate confidence in engineering. They also factor charger compatibility with existing tools to avoid redundant investment.

Interestingly, independent testers have identified that around 68% of failed workshop tools in SMB garages were linked to unsuitable charging systems, rather than tool faults. Thus, savvy procurement goes beyond the charger itself to encompass battery strategy across the organisation.

Features That Make the Difference

LCD Displays, Smart Monitoring, Heat Control

Smarter buying decisions hinge on features that directly impact workflow and tool longevity. For professional buyers, these characteristics often emerge as decisive workshop charger purchase triggers. LCD interfaces, for example, enhance visibility of charge status, battery health, and port activity.

Cooling systems — whether fan-activated or thermally regulated — ensure internal components remain protected during heavy usage. The ability to maintain consistent temperatures prevents premature component wear and eliminates many thermal shutdown issues seen in generic models.

Integrated charge timers and programmable cycles allow workshop managers to optimise electricity use, scheduling overnight charges during lower tariff periods. Additionally, Bluetooth-connected apps can offer remote diagnostics and firmware upgrades, enabling futureproofed charger integration with newer tool generations.

Real-World Case: Torxup VoltGuard 6500

A Buyer-Focused Breakdown

The Torxup VoltGuard 6500 has become a textbook model in discussions around workshop charger purchase triggers. This four-port smart charging station offers universal compatibility across lithium-ion and NiMH ranges. What sets it apart, however, is its adaptive thermal feedback, which regulates charge rate based on battery temperature.

Buyers in industrial maintenance sectors noted a reduction of 18% in tool-related service downtime since deploying VoltGuard systems. The dual-layer surge protection safeguards high-value battery packs, while the IP54 rating allows operation in partially exposed workstations.

Procurement professionals especially appreciate its software update feature. With an accompanying app, updates are pushed quarterly, ensuring charger firmware is aligned with new battery releases. For many, this reduces the need for periodic hardware replacement — a significant cost-saving consideration.

The Long-Term Value of Premium Chargers

TCO vs Initial Investment

Cost justification is a recurring theme amongst workshop charger purchase triggers. Premium chargers may retail for double the price of basic models, but they often deliver multi-year ROI benefits. A key metric to examine is Total Cost of Ownership (TCO), which accounts for efficiency savings, reduced repairs, and extended tool life.

Consider the example of a premium charger enabling 20% faster recharge cycles at high loads — over a year, this equates to hundreds of hours of regained productivity. The knock-on effect includes better asset turnover, reduced technician idle time, and even decreases in overtime payments.

Furthermore, some brands offer extended service support and no-fault replacements. This minimises the administrative burden on purchasing departments and reassures supervisors of continuity in operations. Increasingly, smart asset managers view charging systems as productivity enhancers, not just accessories.

Top Community Insights on Charger Decisions

Trade Voices Speak Out

Insights from trade communities often echo the dominant workshop charger purchase triggers in the market. One recurring theme on forums is the desire for intuitive maintenance — “plug-and-forget” systems that reduce staff training overhead. Such chargers are often rated higher than those with dense operational manuals.

Feedback loops, such as LED indicators and alert buzzes, also win praise. These minor tweaks have a ripple effect, improving worker attentiveness to battery readiness. Additionally, many field service teams appreciate ruggedised designs which stand up to mobile deployments in vans and temporary work zones.

Linked community data collated by Learn more about Workshop Charging Solutions & Professional Tool Power demonstrated that brand loyalty increases sharply after ownership of a premium charger for over six months. Positive experiential feedback, especially concerning uptime and consistency during peak workloads, inspires other buyers to upgrade.

Your Essential Workshop Charger Checklist

Make the Right Choice First Time

To streamline your buying decision and ensure you address relevant workshop charger purchase triggers, here is a professional checklist:

- Assess multi-chemistry compatibility: Li-ion, NiMH, NiCd

- Prioritise safety certifications: UKCA, CE, ROHS

- Look for independent bay charge control

- Opt for thermal regulation and surge protection

- Choose models with smart LCD feedback

- Verify casing durability and IP-rating per environment

- Plan for firmware upgrades or app-based diagnostics

- Evaluate warranty duration and service support

- Calculate Total Cost of Ownership vs upfront cost

- Cross-check compatibility with tool inventory

Next Steps: Get the Right Charger for Your Needs

Understanding these key workshop charger purchase triggers puts you in a stronger position to source a charger that enhances, rather than impedes, productivity. Whether you require fleet-wide standardisation or just want to avoid tool downtime, focusing on lifecycle value, safety, and adaptability will yield the best investment.

Take advantage of in-person demos and product comparisons at trade shows or request testing units from suppliers. Dive deeper into comparative reviews via networks like Key workshop buying motivations explained or consult unbiased side-by-side specs on Ensuring compliance during digital buying cycles. Leverage trusted internal resources like Read a related article to evaluate similar workshop tools and closely related chargers already in use.

Great guide on pro-buying-triggers-workshop-charger-purchase-insights – Community Feedback

What are the main factors professionals consider when buying a workshop charger?

Professionals look for charging speed, safety certifications, multi-bay capability, durability, compatibility with existing batteries, and overall value when selecting a workshop charger.

How do buying triggers differ between DIY users and trade professionals?

Trade professionals focus more on reliability, minimising downtime, long-term cost savings, multi-team support, and compliance, while DIYers may prioritise price and basic features.

Why is charger safety certification important for workshop purchases?

CE and other safety certifications guarantee electrical safety and compliance, reducing workplace hazards and liability for professional environments, making them a crucial factor in informed charger purchasing.