The True Cost of Slow Charging: Lost Work Hours On Site

In This Article

- Slow charging loss leads to significant hidden downtime and financial impact on jobsites.

- Even minor delays in battery charging can aggregate into dozens of wasted labour hours monthly.

- Upgrading to Makita-compatible fast chargers can recoup investment within a month.

- Modern chargers offer thermal management and safety features for rapid, safe power delivery.

- Strategic battery charging increases overall jobsite productivity and team morale.

What’s Hiding in Your Charging Setup?

Understanding Invisible Downtime

At first glance, a minor inconvenience like slower tool charging may not seem catastrophic. But when we take a magnifying glass to the situation, the true effects of slow charging loss become painfully evident. For contractors and site managers, every unproductive minute adds up across labour logs, missed completion windows, and increased overtime. While workers wait around for batteries to reach full capacity, jobs stall. Ironically, it’s not the tasks that are slowing the day—it’s the tech that powers them.

This issue, known as slow charging loss, refers to the wasted time and financial cost caused by outdated or underperforming charging solutions. Think of it as an unseen leak in your project timeline. It’s not just about battery downtime; it’s the domino effect that throws off crew productivity, project scheduling, and ultimately your bottom line.

How Slow Charging Disrupts Workflow

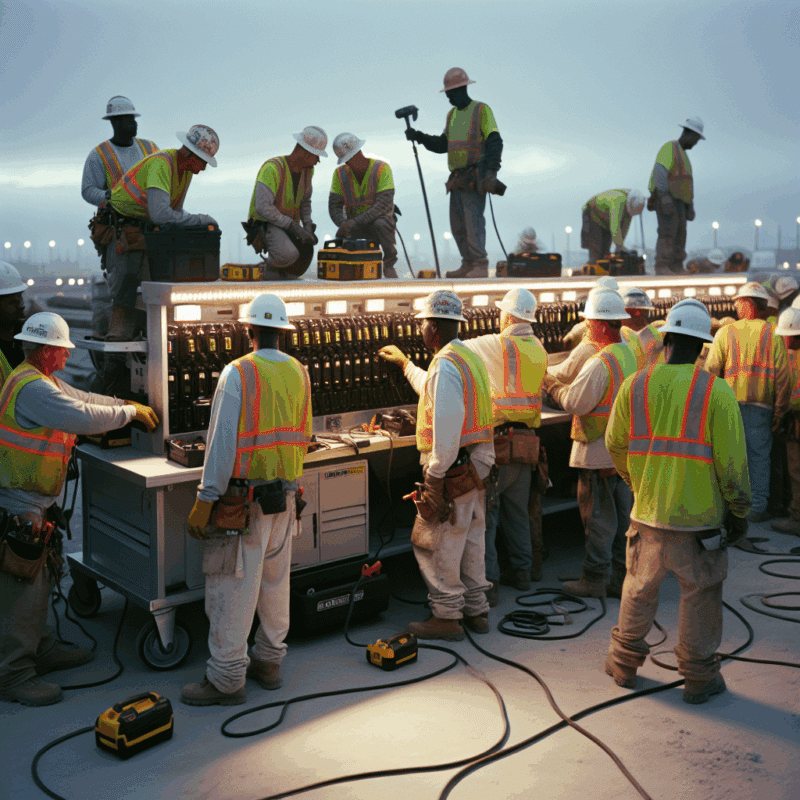

Jobsite Realities from Trade Pros

Ask any seasoned tradesperson or foreperson, and you’ll hear the same story: work grinds to a halt when your batteries can’t keep up. Imagine an eight-person crew waiting on two batteries. You’re paying daily rates for multiple idle workers—costing potentially hundreds before lunchtime. It’s not just inefficient; it’s unsustainable in competitive project cycles.

Slow charging loss creeps into all aspects of site management: from delayed cutting and drilling tasks to extra site visits for unfinished work. Everyday tools like circular saws, impact drivers, and SDS drills become bottlenecks when they’re sitting useless on the charger. And the fallback solutions? Either buy more batteries or delay the job—each with its own expensive consequences.

“We used to think buying more batteries was the fix. But when charging was the choke point, we realised we needed faster chargers, not more packs.”

Calculating the Cost of Inaction

Every Uncharged Minute Adds Up

If your crew experiences just 15-20 minutes of idle time a day due to slow battery charging, you’re looking at nearly 6-8 hours of lost labour per month per employee. Multiply that across a five-person team and you’re facing upwards of 40 hours wasted a month—essentially one employee’s full-time hours paid for zero productivity.

This slow charging loss typically translates to increased labour costs, delayed invoicing, and a compromised reputation. When calculating actual cost impacts, consider not just hourly wages, but also fuel costs for return trips, the opportunity cost of equipment lying idle, and penalties from missed deadlines. That’s not a background operational hiccup—it’s a direct hit to your company’s P&L.

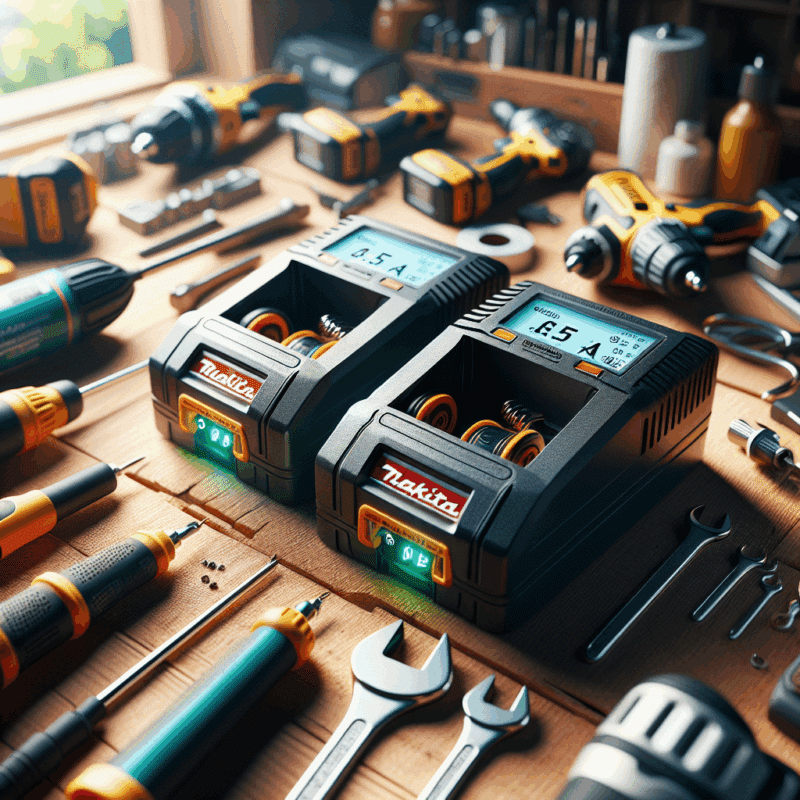

The Break-Even Point of Fast Charger Upgrades

ROI in Time Saved

Transitioning to high-speed charging solutions immediately puts time back into your team’s hands. A Makita-compatible rapid charger, for example, can fully restore a standard 5.0Ah battery in under 45 minutes—compared to over 90 minutes using older models. That’s more than 50% time recouped on every cycle.

Based on usage cycles and real jobsite productivity improvements, most upgraded charging solutions reach ROI within the first 3 to 4 weeks of use. Why? Because fewer idle hours, lower overtime costs, and more streamlined project progression significantly outpace the initial hardware investment. For many crews, it’s not just a break-even—it’s a revenue catalyst.

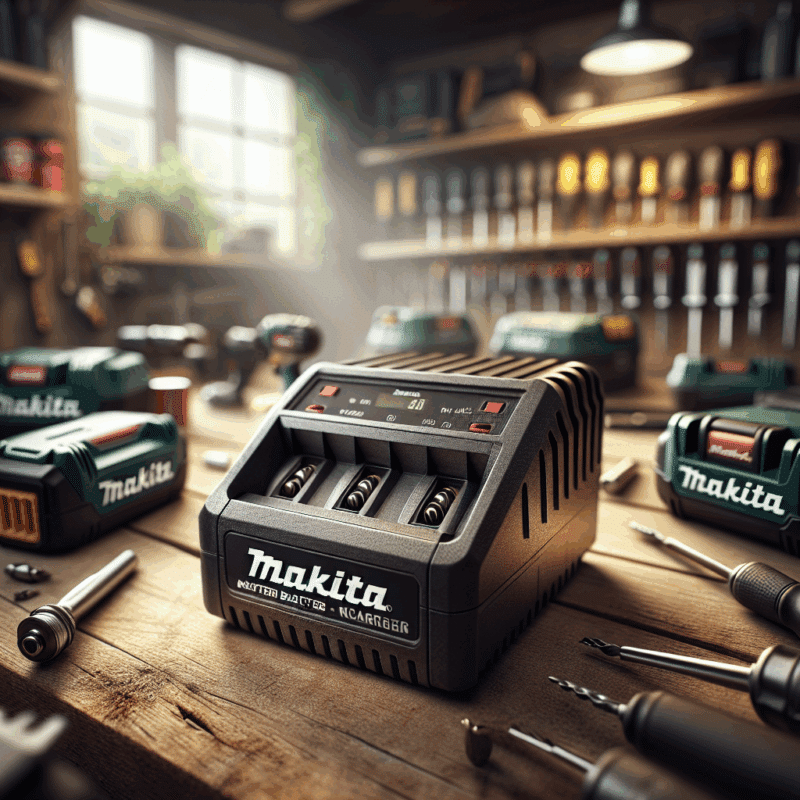

How Makita-Compatible Fast Chargers Help

Power Meets Practicality

Modern Makita-compatible chargers do more than simply recharge; they’re complete power management systems. These advanced units use active cooling fans, optimal voltage regulation, and integrated charging indicators. That cuts the risk of thermal throttling and reduces the time between cycles.

Additionally, multi-port chargers allow teams to charge several batteries simultaneously—no more overnight rotation delays or last-minute hunts for prepared tools. With backward compatibility for existing Makita battery systems, you won’t need to overhaul your current inventory either. This seamless integration means faster adoption, fewer disruptions, and maximised workflow continuity.

Safety First: Fast Charging Without the Risk

Smart Tech and Thermal Management

One of the common misconceptions is that faster charging inherently sacrifices battery lifespan or safety. In reality, well-engineered fast chargers employ smart monitoring systems to regulate heat, voltage, and internal cell status. These technologies ensure every charge cycle operates within optimal safety margins.

Makita-compatible chargers use active cooling, automated cut-offs, and LED readouts to make thermal and electrical parameters transparent. This innovation eliminates overheating issues that once plagued older rapid-charging systems. As a result, slow charging loss is avoided without exposing users or tools to unnecessary hazards.

What the Data Says About Lost Hours

Case Studies and Research Insights

Recent studies from construction workflow analysts extrapolate that slow charging loss contributes to an average of 8-12% of total project downtime on typical contractor jobs. In a groundbreaking assessment by Tool Efficiency UK, crews who adopted rapid charging reported a 16% increase in daily productivity and a 27% drop in cumulative tool wait time over three months.

Furthermore, a case study involving a commercial build site in Manchester revealed that fast charging implementations reduced final-phase labour overage by nearly £2,200. That’s not hypothetical—it’s data-backed impact in real-world conditions.

Insights from the Field: Trade Voices

Community Commentary

Seasoned tradespeople emphasise that charging solutions have finally become a frontline tool planning consideration. “We used to rate a cordless tool by its torque or run-time—but now it’s about how quickly we can get back in the game,” said Marcus, a joiner from Leeds. “Fast charging completely reshaped our approach on site.”

The trade has spoken clearly: fast charging isn’t just a luxury—it’s becoming a necessity. In forums and peer learning events, the most successful contractors build fleet charging strategies into their job cost projections. Learn more about Optimising Power Tool Charging for Worksite Productivity

Better Charging. Better Workflow.

Optimising Productivity End-to-End

Implementing high-speed chargers isn’t just a tactical fix—it’s a strategic improvement across jobsite logistics. Reduced downtime gives forepersons the confidence to schedule tasks tighter while enabling simultaneous multi-role operations. If your framing team isn’t waiting on drills and your electricians stay powered during long wiring sessions, you hit milestones faster with fewer bottlenecks.

It also boosts morale. Nothing frustrates skilled tradespeople more than standing idle due to tech issues. Providing adequate charging infrastructure shows respect for their time and improves retention by removing friction from daily work.

Next Steps: Choosing the Right Charger

What to Look For

When selecting your next charging system, assess charge speed, tool compatibility, safety features, and long-term cost efficiency. Smart capabilities such as temperature control, overcurrent protection, battery diagnostics, and multiple port simultaneous charging can significantly reduce slow charging loss. Understanding infrastructure’s impact on lost time

Don’t forget future-proofing. A charger that only handles current tools limits your adaptability. Invest in models that accommodate Makita’s broader platform evolution. And always check the charger’s warranty and service support options to guarantee uninterrupted usage. Read a related article

Final Thoughts: Work Smarter, Not Slower

Every tool in your kit contributes to your final deliverable—but none has a more underappreciated role than your charger. Weaponising your charging setup against productivity leaks gives you a competitive edge. Now that you understand the true cost of slow charging loss, it’s not a question of if but when you’ll upgrade.

Invest smartly. Reclaim your hours. And ensure that the only thing slowing your crew is the coffee break, not a flat battery. Unlocking business growth with automation strategies

Great guide on true-cost-slow-charging-jobsite-lost-hours – Community Feedback

How much time do slow chargers cost on a typical jobsite?

Slow chargers can cost crews several hours per week due to extended recharging, disrupting workflow and resulting in costly downtime.

Do fast chargers reduce overall expenses?

Upgrading to fast chargers reduces downtime and labour costs, offsetting initial expenses and increasing total productivity on site.

Will switching to rapid charging shorten battery life?

With the right charger and thermal management, quality fast charging does not significantly reduce modern battery lifespan.