The Smart LCD Advantage: Real-Time Battery Data for Pros

In This Article

- Smart LCD chargers provide real-time battery data, reducing downtime on site.

- Live monitoring increases safety and prolongs lithium-ion battery life.

- Makita-compatible models integrate seamlessly into professional workflows.

- Choosing the right charger involves reviewing display functions, port counts, and brand compatibility.

- Proper usage and maintenance maximise your charger’s effectiveness and longevity.

Why Real-Time Battery Data Matters On Site

Reducing Downtime with Immediate Power Insights

In the fast-paced environment of modern construction and technical trades, timing and efficiency are everything. A dead battery at the wrong moment can cause operations to grind to a halt. That’s where a smart LCD charger becomes a game-changing asset. With the ability to display live battery data, this intelligent device offers trades professionals real-time visibility into battery health, charge status, and potential faults.

Through clear, readable LCD screens, these chargers eliminate the guesswork that often plagues traditional models. Workers can quickly determine if a battery is fully charged, needs more time, or may be failing altogether. This proactive information prevents costly project delays and enables better scheduling for tool usage and charge rotations. By optimising battery availability, on-site productivity is protected.

Moreover, rechargeable batteries are not created equal. Lithium-ion batteries, while powerful and compact, can degrade if not managed correctly. A smart LCD charger presents an advanced ability to safeguard these assets through data-driven charging. For example, chargers can display voltage, temperature readings, or even battery cycle counts in some models. This transparency not only protects the workforce’s power supply—it also extends the usable lifespan of expensive equipment.

Understanding Smart LCD Charger Technology

Built-In Features that Empower Tradespeople

At the heart of every smart LCD charger is an embedded microprocessor. Unlike basic plug-and-play units, these high-performance chargers are equipped with software that actively regulates the charging process. This intelligent system can detect battery chemistry, assess charge levels, and adjust the current flow accordingly. The visual LCD output keeps the user informed at every stage.

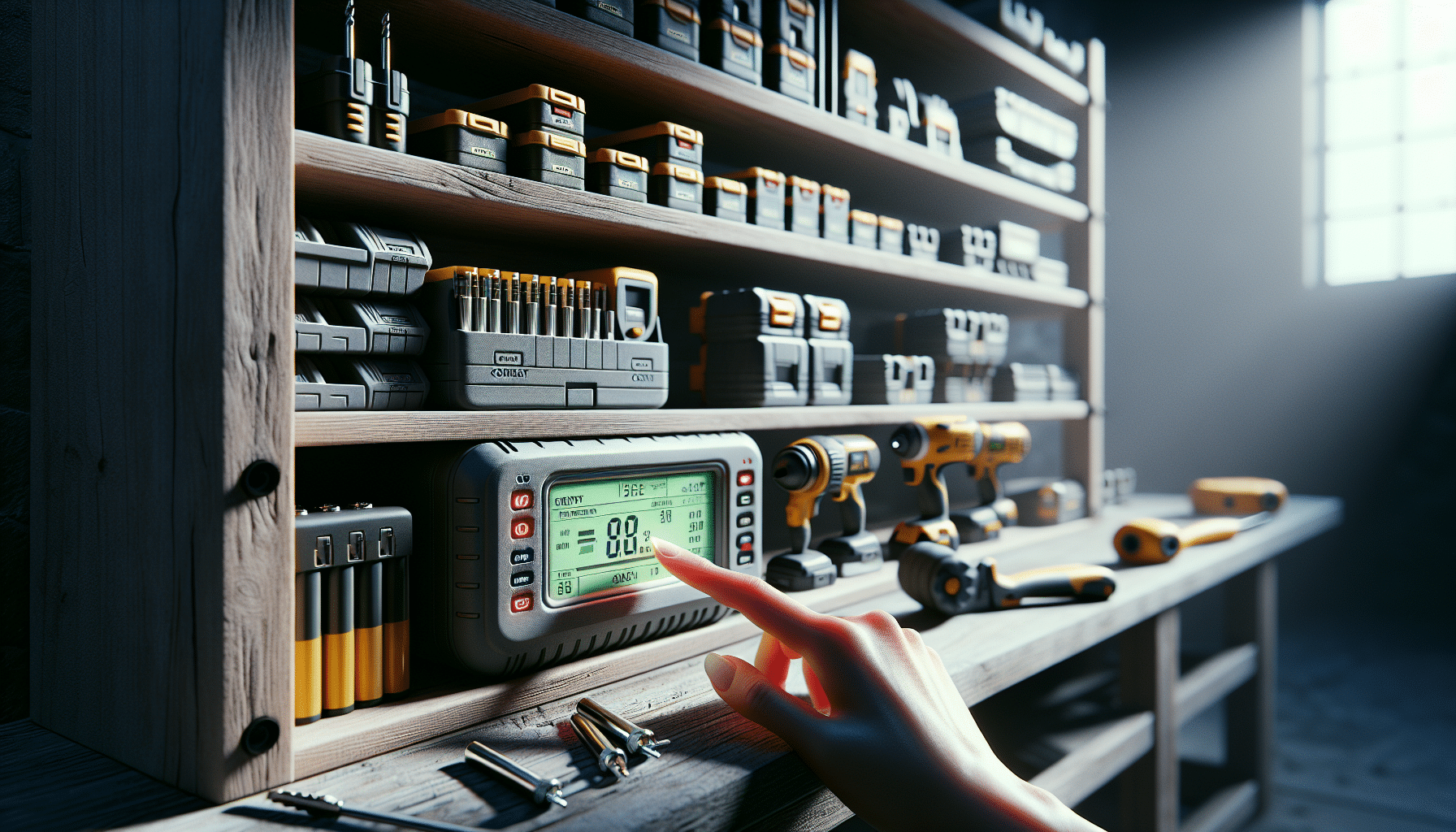

Key features include digital readouts of charging percentage, precise voltage output, and indicators for battery health. Some advanced units also offer multi-slot functions, allowing several batteries to be charged and monitored simultaneously. Error codes appearing on the screen flag issues such as overheating, reverse polarity, or non-compatible battery packs—thus improving both safety and efficiency.

Importantly, many smart LCD chargers are designed with tool ecosystem compatibility in mind. For professionals using brands like Makita, there are dedicated LCD models that maintain full integration with existing 18V or 40V battery systems. This ensures seamless workflow implementation without compromising on power requirements or device warranties. While the screen might seem like a simple visual add-on, it actually represents a powerful interface between the user and the battery’s real-time condition.

“Access to real-time battery stats through an LCD charger has completely transformed our team’s approach to on-site power management.”

Top Benefits of Live Battery Monitoring

Smart LCD chargers bring several measurable advantages to the jobsite. Firstly, they reduce the uncertainty surrounding charge levels. Battery monitoring is no longer a guessing game. Teams can arrange their schedules and tool usage based on precise information, ensuring that devices are ready when needed.

Secondly, these chargers help extend battery life cycles by preventing overcharging. Older chargers often continued to deliver current to a fully charged battery, which could degrade the internal cells over time. A smart LCD charger uses algorithms to detect full saturation and automatically switch to trickle charge or terminate the session altogether to prevent excess heat.

Another critical benefit lies in safety. High temperatures or damaged battery packs can be dangerous, particularly with lithium-ion cells. LCD readouts can alert technicians before a potential fault becomes a hazard. This data-first approach allows problems to be addressed proactively and accidents to be avoided.

Integrating LCD Chargers Into Professional Workflows

Adopting a smart LCD charger into daily operation isn’t just about technological upgrades—it’s about strategic efficiency. For contractors handling large-scale projects, keeping tools operational is mission-critical. With real-time data, supervisors can implement charging cycles based on actual usage, preventing idle time.

Fleet management also becomes more intelligent. Chargers with USB-C or Bluetooth functionality can link to software platforms that track multiple batteries across sites. From facility managers to individual operators, everyone benefits from greater visibility and control. Time saved from troubleshooting battery issues can instead be spent on productivity and task completion.

Integration with existing power systems is typically straightforward. Most smart LCD chargers are compatible with standard electrician-grade outlets and storage cases. Their rugged construction ensures they endure site conditions while providing a clear digital pulse on the battery ecosystem. To learn more about optimising workflow integration, see our guide: Learn more about Advanced Battery Charging Technology for Professional Tools

Prolonging Battery Life with Accurate Data

Every lithium-ion battery has a finite number of charge cycles before performance diminishes. However, the conditions under which these batteries are charged can significantly impact that lifespan. Smart LCD chargers are designed with algorithms that mitigate common factors of degradation.

For instance, many models use temperature sensors to delay charging until batteries cool down. This is important because charging overheated batteries can cause cell stress. Some chargers go further by allowing users to select charge speed—normal, fast, or regulated—depending on battery state and project urgency.

Routine data like voltage and internal resistance informs technicians when it’s time to retire old packs or replace problematic ones. Instead of relying on trial-and-error troubleshooting, professionals can make informed purchases and avoid unexpected downtime. Proper use of smart LCD technology therefore equals greater ROI on battery investments, especially in high-demand sectors like construction or manufacturing.

Are Smart Chargers Safe for Lithium-Ion Batteries?

Safety is often a concern when introducing advanced electronics to high-power tools. The good news is that smart LCD chargers are built with safety as a core feature. They include built-in protections against over-voltage, short-circuiting, and overcurrent. Once a battery reaches full charge, the system terminates charging automatically, protecting both the charger and the pack.

LED warnings and on-screen messages provide preemptive alerts if a battery is at risk. This real-time checking is vital for lithium-ion systems, which, while efficient, are known for their sensitivity. A smart LCD charger reduces the likelihood of unsafe situations by preventing overcharging and overheating, and identifying damaged cells before they’re used on heavy-duty equipment.

From workshops to mobile vans, this class of charger brings peace of mind. Professionals can focus on tasks without second-guessing battery status. More guidance on safe use of these units with various battery types can be found via How smart batteries communicate charge data

Comparing Traditional vs Smart Site Charging Setups

The difference between conventional chargers and smart LCD models is monumental. Traditional chargers typically offer a single LED to indicate that a charge is occurring—if that. There’s no easy way to know the battery’s current state, performance history, or fault condition. Technicians often discover problems only when a fully charged battery fails under load.

Smart LCD chargers reverse this reality. They empower users with granular data, displayed clearly and updated in real-time. Charging time is optimised, faults are caught early, and tool readiness is dramatically improved. In essence, the smart LCD charger transforms power management from reactive to proactive.

This fundamental shift in approach not only boosts uptime but also leads to better decision-making across a team. Whether you’re operating a large warehouse or a mobile service van, investing in smarter charging infrastructure is crucial. For deeper insights, read our breakdown here: Read a related article

The Makita-Compatible Advantage

Professionals loyal to the Makita ecosystem will appreciate that many smart LCD chargers offer direct compatibility with 18V LXT and even 40V XGT platforms. This compatibility ensures seamless upgrades without having to replace your entire battery inventory. The connection points and charging profiles are optimised to the brand’s specifications, ensuring safe and effective charging every time.

The LCD display works in harmony with Makita battery chips to read and display accurate diagnostics. Some chargers even use Makita’s own algorithm to offer fast and cool charging, further extending battery life. Tool fleet managers keen on preserving warranty coverage and performance reliability should always choose smart LCD chargers certified as Makita-compatible.

For a curated list of recommended compatible chargers and power tools, you can explore reviews at Comparing automation for smarter workflows

Choosing the Right Smart LCD Charger

When selecting a smart LCD charger, tradespeople should assess several criteria beyond just price. Compatibility with current battery brands and voltages is key. Additionally, evaluate the number of charging ports, the presence of fast-charging modes, and whether the screen offers diagnostic fault codes as well as charge levels.

Some models provide data logging features or Wi-Fi connectivity for fleet use. Others prioritise rugged casing for field conditions. Recommendations vary depending on your role—onsite construction may have different needs than workshop fabrication. Aim for chargers backed by warranties and trustworthy customer reviews.

User Tips: Getting the Most from Smart Charging

To leverage the full value of your smart LCD charger, always position units in ventilated locations and keep charging bays clear of dust or metal debris. Avoid stacking batteries or overloading power points. Clean terminals periodically using soft brushes to maintain consistent connection and charging rate.

Check the LCD screen every day to monitor trends. Batteries that charge slower, fail to reach 100%, or show temperature warnings should be ruled out or tested further. Updating firmware (if available) ensures you benefit from the latest safety protocols and software improvements. Finally, set a schedule to rotate batteries weekly to balance wear and maximise utility across the fleet.

Conclusion: Empowering On-Site Productivity

[CONCLUSION_CONTENT]

Great guide on smart-lcd-live-battery-data-pro-workflows – Community Feedback

How does a smart LCD charger improve workflow efficiency?

Smart LCD chargers provide real-time battery status and charge data, enabling professionals to plan tool usage and charging cycles for maximum productivity without downtime.

Is live battery monitoring beneficial for battery life?

Yes, live monitoring helps prevent overcharging and deep discharging, both of which shorten battery lifespan. Keeping aware of charge levels optimises usage and prolongs battery health.

Are smart LCD chargers safe for lithium batteries?

Modern smart LCD chargers are designed to safely charge lithium batteries by regulating voltage, current, and automatically stopping once fully charged, ensuring battery safety.