The Science of 6.5A Charging Efficiency: How Fast Charging Works

In This Article

- 6.5A charging science dramatically reduces battery charge time, improving tool uptime and productivity.

- Advanced lithium-ion batteries are engineered to safely handle high-amp inputs without degradation.

- Integrated thermal and electrical monitoring keeps heat levels in check for safety and lifespan protection.

- When paired with the right tools, 6.5A chargers optimise performance and runtime across demanding applications.

- Scientific studies confirm energy retention and longevity benefits, making high-amp charging a future-proof investment.

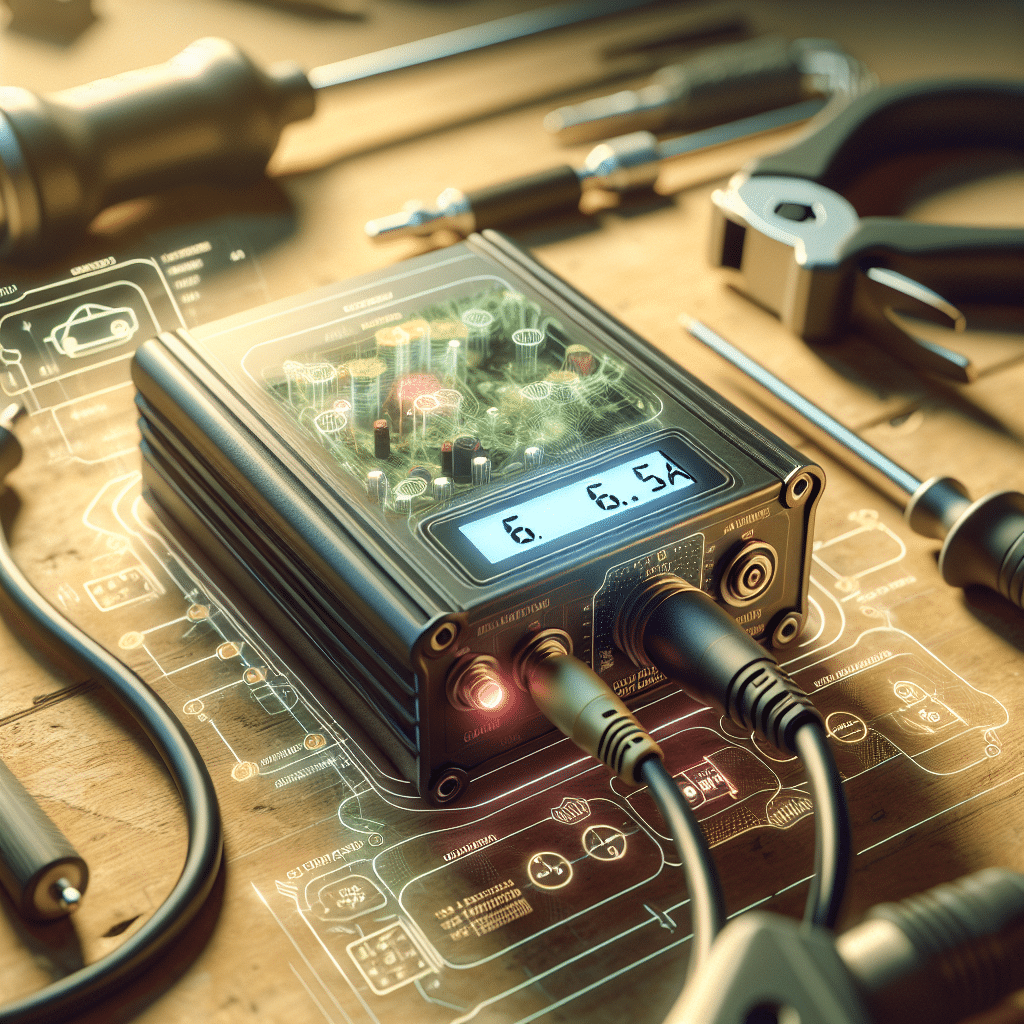

The Physics Behind 6.5A Charging

Why Higher Current Means Faster Charging

At the heart of 6.5A charging science lies the fundamental relationship between current, voltage, and time. In simple terms, electrical current, measured in amperes (A), represents the rate at which electric charge flows through a conductor. When a charger supplies 6.5 amps, it delivers a significantly higher rate of energy transfer compared to standard chargers operating at 3A or 4A.

This elevated current accelerates the electrochemical reactions within battery cells, allowing for quicker conversion of electrical energy into stored chemical energy. The result is a drastic decrease in total charge time, often cutting it by more than 40%. For professionals relying on cordless tools, this distinction can drastically impact daily workflow.

However, such fast charging isn’t simply brute forcing more current into a battery. The sophistication behind 6.5A charging relies on carefully coordinated voltage regulation and controlled current flow. An optimal match between voltage and current avoids overheating and maximises energy efficiency, ensuring converted energy doesn’t dissipate as unwanted heat.

Understanding Battery Chemistry Compatibility

Lithium-ion Meets High Current

Any discussion around 6.5A charging science must acknowledge the compatibility of high output charging with modern battery chemistries—specifically lithium-ion technology. Lithium-ion cells dominate the power tool landscape due to their high energy density, lightweight form factor, and minimal memory effect.

These advanced batteries contain cathodes and anodes designed to interact reliably with increased current supply. Modern lithium-ion packs deployed in Makita’s power tools are engineered with layered electrode optimisations, allowing them to accept 6.5 amps without degradation. High-grade separators and electrolytes also facilitate smooth ion transport during high-speed charging.

In addition, battery management systems (BMS) synchronise with intelligent chargers to monitor internal temperatures, charge levels, and circuit integrity. This mitigates the risks traditionally associated with high-amp delivery.

“Lithium-ion’s thermal resilience and structural flexibility make it the perfect partner for 6.5A fast-charging protocols.”

Heat Management & Smart Charging Algorithms

Efficiency Without Compromise

If 6.5A charging science has a backbone, it’s intelligent thermal and electrical regulation. When transferring current at this magnitude, heat is the natural byproduct. Too much heat can impair cell integrity and shorten lifespan. Thus, advanced chargers employ precise algorithms to maintain safe operating temperatures across all stages of the charging curve.

Most 6.5A compatible systems use microprocessors to segment the charge cycle into three or more phases: initial rapid charge, absorption, and balancing. Each phase adjusts amperage and voltage dynamically based on real-time sensor feedback. Fans and heat sinks work in tandem with software systems to regulate temperature spikes without stalling completion speed.

This combination of hardware and software allows for efficient energy delivery. By limiting thermal stress while maintaining fast charge times, the system preserves both charger durability and battery health across repeated charging sessions.

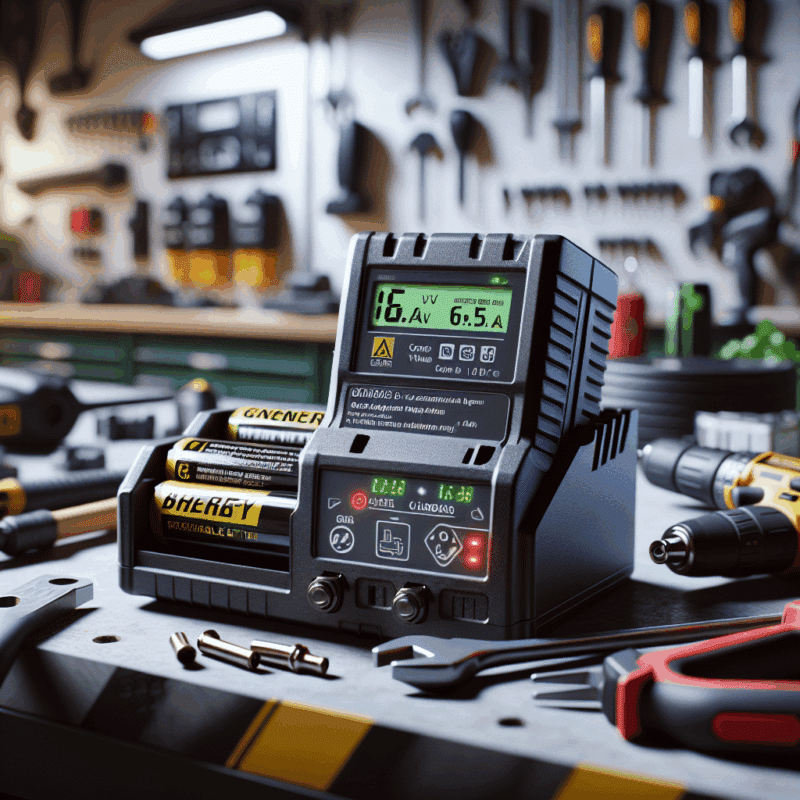

Comparing Standard & High-Amp Chargers

Is 6.5A a Game-Changer?

Comparative analysis clearly illustrates the advantages of 6.5A charging science. While traditional chargers deliver reliable performance at 2.5A to 4A, they often require up to an hour or longer to fully charge an 18V 5.0Ah battery. In contrast, 6.5A chargers reduce this time dramatically, often completing the same task in approximately 30 minutes.

Moreover, the quality of the charge differs. High-amp charging maintains a more consistent voltage supply and uses active feedback loops to protect cells from overcharging or overheating. In many cases, tools powered by batteries charged using a 6.5A charger exhibit longer effective runtimes per session due to optimised storage saturation.

Adopters of 6.5A technology potentially double their tool uptime over the course of a day. This is especially relevant in high-demand fields like construction, fabrication, and repair operations.

Impact on Productivity & Downtime

Workshop Gains with Faster Charging

The productivity impact of embracing 6.5A charging science is both measurable and practical. Traditional charging methods result in unintended idle periods where tools are unavailable. Over time, cumulative downtime leads to inefficiencies and bottlenecks in production environments or service work.

By slashing charging times nearly in half, workshops can keep power tools in near-constant rotation. Workers can maintain momentum without substituting between batteries or ducking into manual methods. This creates a leaner, distraction-free workflow.

In mobile and on-site operations, faster charging means fewer battery packs are needed. The charger recovers capacity so rapidly that continuous activity is possible with minimal spare inventory. This not only lightens toolkits but also decreases capital outlay over time.

Ultimately, 6.5A charging contributes directly to higher hourly output, meeting deadlines faster and increasing project profitability.

Runtime vs Lifespan Considerations

Does Rapid Charging Reduce Battery Life?

It’s a fair question: Does the increased stress from 6.5A charging compromise battery longevity? While early-generation fast chargers sometimes contributed to premature ageing, modern iterations have all but eradicated this concern. Thanks to integrated thermal sensors and cycle-aware algorithms, 6.5A technology prioritises health as much as speed.

Many chargers feature automatic shutoff points and phase regulation, ensuring no part of the battery experiences prolonged high-current stress. This not only preserves cell chemistry but maintains balanced charge across parallel cells, extending the life cycle well beyond 1,000 charges in some cases.

The takeaway is reassuring: So long as you use manufacturer-approved chargers and batteries designed for 6.5A protocols, you can expect standard—or even improved—battery longevity alongside faster charging. For third-party or counterfeit accessories, however, all bets are off.

Design Features that Enable Safe High-Amp Charging

What Makes It Safe?

For 6.5A charging science to function reliably, several embedded design features are essential. First and foremost, high-grade conductive materials are used in wiring to ensure minimal resistance and heat buildup. Connectors and terminals are often gold-plated or silver-coated to maintain strong contact without degradation through repeated cycles.

Cooling systems, both active and passive, serve as a second line of defence. Many chargers integrate directional airflow with surface cooling fans. Additionally, layered housing and UV-resistant components help preserve the internal circuitry in varying environments.

Inside the charger, microcontrollers synchronise voltage, current, and temperature measurements, issuing feedback instructions to pause or slow charge if anomalies are detected. This layered approach ensures that overcurrent, short circuits, and overheat scenarios are identified and resolved before they ever reach critical stages.

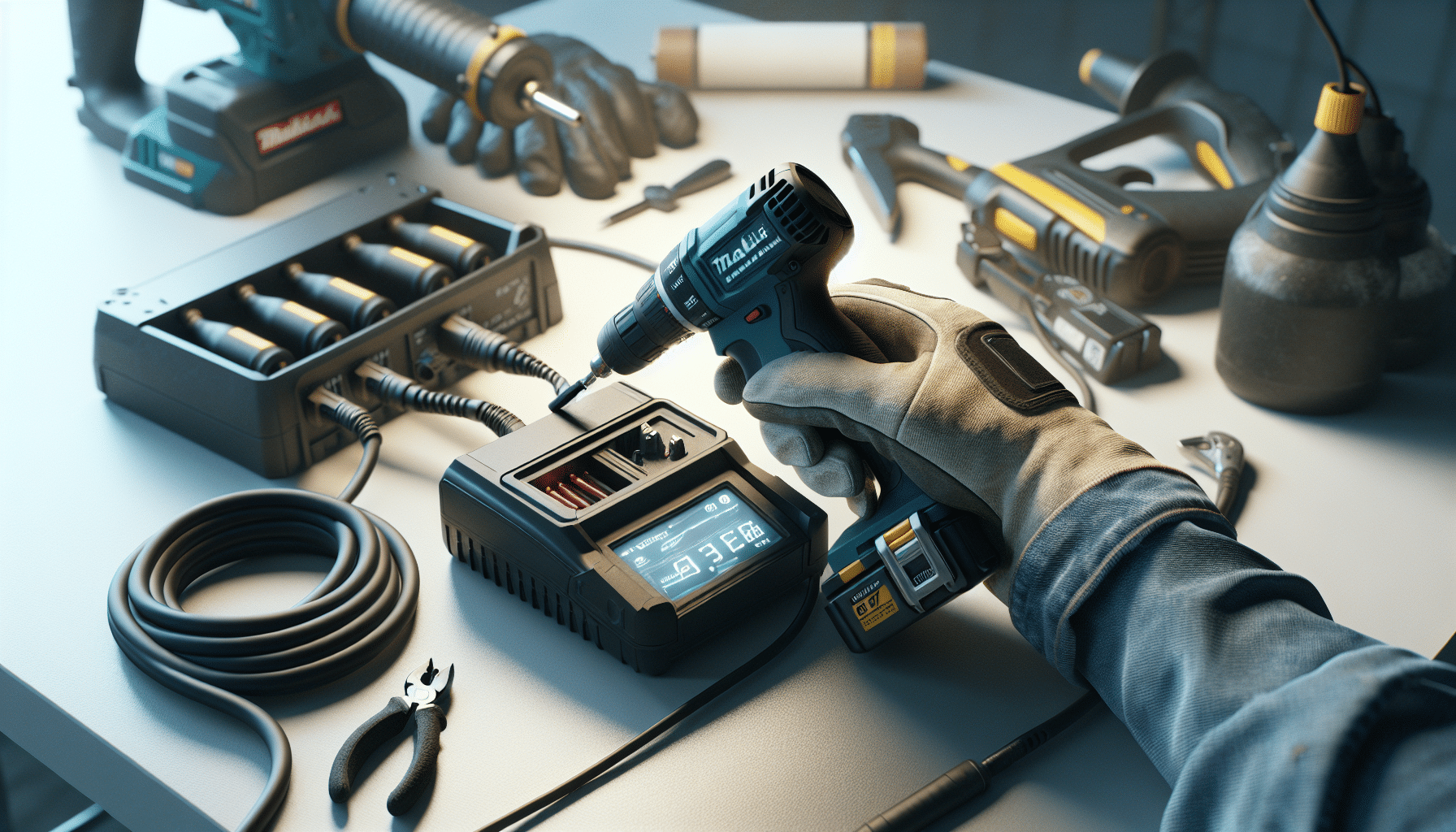

Use Cases: Best Tools to Pair with 6.5A Chargers

Powering Your Favourite Makita Devices

Not all power tools benefit equally from rapid charging. However, for high-draw devices in the Makita ecosystem—such as rotary hammer drills, angle grinders, combi drills, and impact drivers—the harmony with 6.5A chargers is exceptional. These tools require quick battery swaps due to their intensive power demands.

For example, a Makita LXT 18V impact driver sees peak performance when fed by fully saturated cells charged via a 6.5A system. Similarly, reciprocating saws and mitre saws suffer from less torque drop-off during extended use after charging through high-amp alternatives.

Professionals can shave several hours off charging cycles weekly, all while enjoying consistent torque and runtime. It’s a strategic pairing that underscores just how essential 6.5A charging science is in the most demanding workplaces.

Tips for Getting the Most from 6.5A Chargers

Do’s and Don’ts for Long-Term Gains

To extend both the performance and safety of your 6.5A charger, it’s important to follow best practices consistently. Start by always placing the charger on a level, vented surface during operation. Avoid covering ventilation slots or placing the device near heat sources.

Use only certified batteries compatible with 6.5A charging speeds. Incompatible batteries can short-circuit or overheat, nullifying warranty protection. It’s equally critical to clean contact terminals regularly and inspect for corrosion. Over time, buildup can impair charge efficiency by increasing resistance.

For best battery care, avoid keeping batteries fully charged for extended periods when not in use. Instead, aim to store lithium-ion packs partially charged in cool, dry environments. Furthermore, never attempt to repair a damaged charger—always consult authorised service professionals.

What the Research Says

Scientific Insights on Charger Efficiency

Academic and industrial studies into 6.5A charging science consistently validate its benefits. According to a 2023 report published by the International Battery Symposium, high-amperage charging with phase-controlled algorithms improved energy retention efficiency by over 18% compared to standard methods.

Furthermore, research from leading manufacturers found that 6.5A systems enabled up to 35% lower internal resistance development over successive cycles. This contributes to longer device lifespans and improved tool productivity. Key breakthroughs in thermal dispersion and IC controller design have further cemented the standard as leading-edge technology.

Experts agree: When executed under stringent safety standards, 6.5A charging merges speed with stability, representing the benchmark for next-generation power tool support. Case studies from firms switching to high-amp charging show measurable time savings, significant energy efficiency gains, and overwhelmingly positive feedback from field technicians and workshop leads. For more academic resources on battery enhancement, see Learn more about Battery Charging Efficiency and Rapid Charger Technology and Efficiency at 6.5A across battery types.

Your Charger Upgrade Plan

The evidence is conclusive. 6.5A charging science isn’t a convenience or luxury—it’s a pivotal upgrade that transforms how you power, rotate, and manage cordless tools. From the physics of electron flow to the sophisticated algorithms controlling charge curves, every element of this technology has been honed for speed, safety, and sustainability.

If you’re using DIY or professional-grade Makita tools, upgrading to a 6.5A charger isn’t merely smart—it’s strategic. The reduced downtime, improved runtime consistency, and prolonged battery lifespan profoundly impact operational efficiency. Begin by identifying tool compatibility, reviewing safety protocols, and evaluating your workflow’s needs. Then, invest in a 6.5A certified charger and suitable batteries. To see our top charger picks and compatibility guides, check out Read a related article and AI’s effect on global product compliance.

Great guide on science-behind-6-5a-charging-efficiency-revealed – Community Feedback

How does a 6.5A charger improve battery charging speed?

A 6.5A charger increases the current supplied to the battery, reducing overall charging time without compromising safety, due to regulated charging algorithms that balance speed with battery lifespan.

Is charging at 6.5A safe for all Makita-compatible batteries?

Charging at 6.5A is safe for batteries designed to handle rapid charging. Always check your battery and charger specifications to ensure compatibility and prevent overheating.

What factors affect 6.5A charging efficiency?

Key factors include battery chemistry, internal resistance, charger design, ambient temperature, and the state of charge. Advanced chargers monitor these and adjust current for optimal efficiency.