The Contractor’s Interactive Checklist for Purchasing Workshop Chargers

In This Article

- Ensure charger compatibility with existing battery types.

- Prioritise safety features including CE certification.

- Do not compromise display clarity and cable management.

- Multi-bay solutions boost onsite productivity.

- Match charging speed with tool demands—balance is key.

- Never sacrifice build quality for cost savings.

Why Efficient Charging Matters

Powering Productivity on Every Jobsite

Any electrician, carpenter, or builder knows that downtime from dead batteries can grind productivity to a halt. That’s why selecting the right solution must start with a comprehensive workshop charger buying guide. Your tools are only as dependable as the batteries that power them, and your charging station underpins that reliability. A contractor’s success often hinges on every tool and battery being ready when needed. Efficient charging stations ensure minimal wait times and optimal battery life—providing consistent, uninterrupted workflow on any project. Rapid but stable charging translates directly to increased output over the course of a day or a project.

Checklist for Choosing a Workshop Charger

Interactive Contractor Considerations

The ideal charger for one contractor’s needs may not suffice for another. To navigate the market effectively, follow this structured workshop charger buying guide checklist:

- Battery Brand Compatibility: Does the charger match your primary tool battery types?

- Voltage and Amp Ratings: Do the outputs match your battery specs efficiently and safely?

- Charging Speed: Does it align with your workflow expectations?

- Multi-Port Options: Essential for teams or high-rotation tool use.

- Build Quality and Safety Certifications: Look for CE marking and thermal protection features.

- Display Clarity: Can users quickly read status and diagnostics?

- Ergonomic Cable Management: Vital for organised workspaces.

- Smart-Charging Capability: Features like battery health monitoring add long-term value.

Use this checklist as your must-have reference before making any purchase. Ensuring each box is ticked means your investment yields optimal efficiency, durability, and reliability.

“A strategic charger purchase isn’t an expense—it’s a force-multiplier for operational readiness.”

Compatibility and Tool Battery Types

Know What Works with What

Among the most critical steps in any workshop charger buying guide is ensuring compatibility between the charger’s ports and your battery ecosystem. Contractors tend to accumulate tools from different brands over time—some favouring Makita, others DeWalt, Bosch, or Milwaukee. Unfortunately, there’s no industry-standard charging connector. Most brands intentionally design proprietary systems, creating the need to either standardise your batteries or invest in chargers designed to accommodate multiple battery types.

Look for chargers labelled as “universal” or those provided by tool manufacturers specifically to match multiple voltages and battery chemistries such as NiMH, NiCd, and lithium-ion. Pay particular attention to battery slots that auto-detect battery type and voltage to safely deliver the ideal current. This prevents overheating or premature battery degradation. You may also consider modular charger banks featuring interchangeable ports—highly useful for diverse battery inventories.

Comparison of Top Workshop Chargers

Side-by-Side Charger Insights

To better understand the market, here is a condensed comparison of highly rated workshop chargers:

- Makita DC18RD Twin Port Fast Charger: Dual-slot system, active cooling, charges two 18V Li-ion batteries within 45 mins.

- DeWalt DCB104 Multiport Charger: Charges four batteries simultaneously, includes intelligent charging control, ideal for fleet tools.

- Einhell PXC Twincharger: Fast 3A output, LED indicators for both batteries, affordable for small operations.

- Metabo ASC 145 Duo: Multi-volt, rapid charging capabilities, intelligent battery management for prolonged cell life.

These chargers represent diverse needs—individual to multi-user environments, price-sensitive setups to high-capacity professional stations. Reviewing such side-by-side options in any expert workshop charger buying guide saves both time and future frustration.

Understanding Charging Speed vs. Needs

Faster Isn’t Always Better

In workshop charger terminology, faster may not always translate to better. While speed surely matters, it must be balanced against thermal stability and battery longevity. Ultra-fast chargers often push higher currents, which generate excess heat. This is especially risky with lithium-ion cells, which degrade rapidly if not properly cooled or monitored.

Choose chargers that feature fan-assisted cooling or thermistor-controlled circuits. These allow for prompt charging without exposing your batteries to damaging cycles. Your workshop charger buying guide recommendation: understand your operational tempo and balance it with real charging requirements. For example, a framing crew might need faster cycles compared to a cabinetry workshop dependent on lower-drain tools.

Safety and CE Certification Factors

Smart Charging with Protection

All quality workshop charger solutions must adhere to local electrical safety requirements. CE certification ensures the charger has passed stringent conformity testing across EU countries, verifying that it meets electrical protection norms. Look for additional protections such as reverse polarity protection, thermal cutoffs, short-circuit resistance, and over-voltage shields.

Also noteworthy are chargers with “sleep mode” or idle shutdowns, which prevent phantom load draw and fire risk. Some smart chargers additionally alert users to faulty or end-of-life cells that should be replaced. Following the safety guidance within the workshop charger buying guide shields your site from unexpected liabilities or tool failures.

Multi-Bay Chargers and Team Efficiency

Charging Multiple Batteries Seamlessly

Contractors managing more than one team member or a larger suite of cordless tools will particularly benefit from multi-bay chargers. These units simultaneously service two, four, or even six batteries, depending on the make. For example, the Bosch GAL 18V6-80 houses six 18V batteries in one base, charging each in sequence without manual intervention.

A workshop charger buying guide should always prioritise this feature for multi-user environments. Reducing rotation time and eliminating queuing of dead packs maximises tool availability. Additionally, it provides cleaner load balancing to your site’s power circuits by spreading demand across time-managed charging slots.

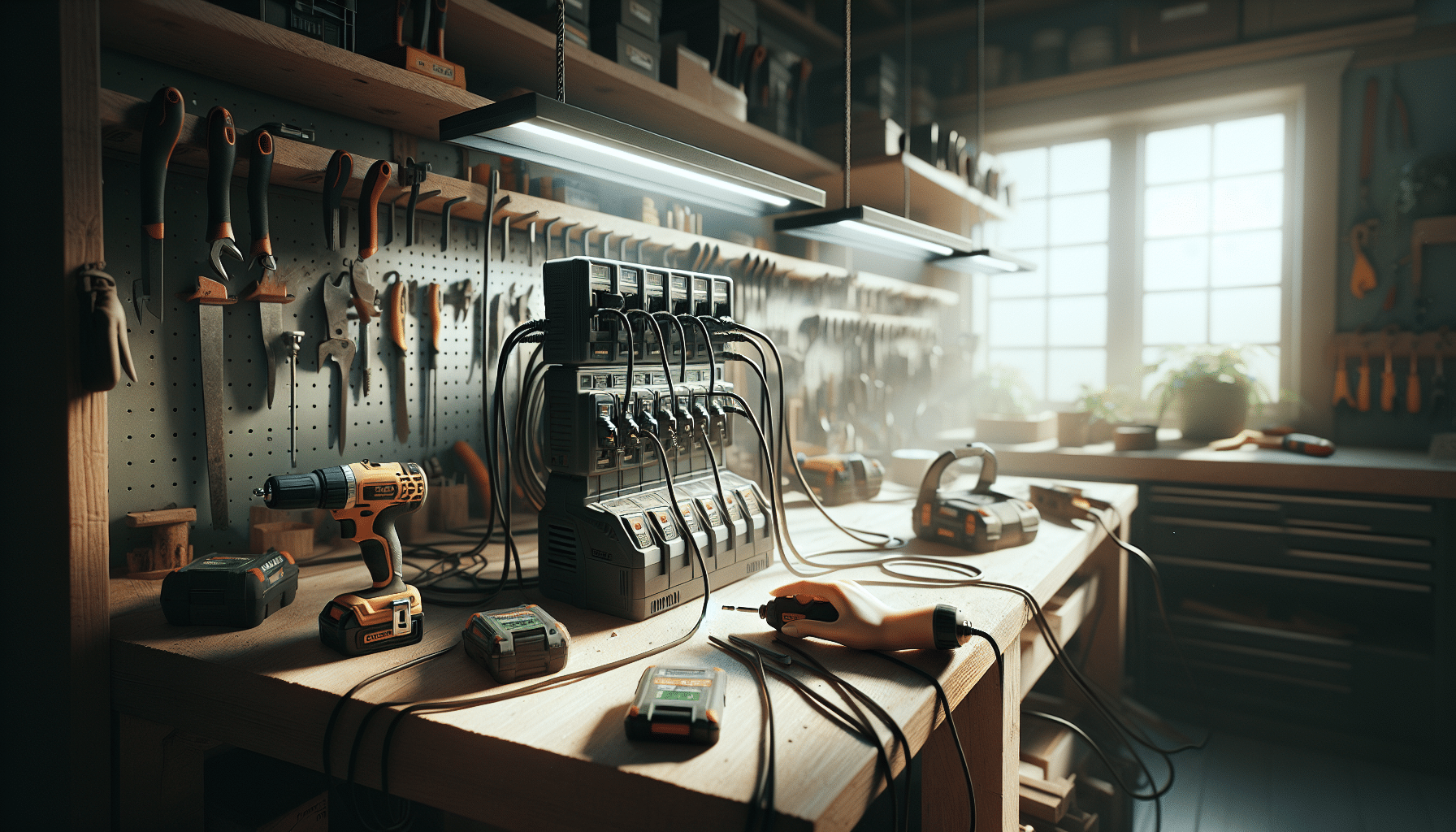

Charger Ergonomics and Cable Management

A Clean Setup Boosts Workflow

While performance and speed grab the headlines, charger ergonomics are equally vital. Look for rugged enclosures, rubber feet for anti-slip positioning, mountable holsters, and wall brackets. Consolidated cable routing paths and optional cable ties reduce trip hazards, a common safety concern in improperly configured workshops.

By incorporating cable trays or charger docking stations into your setup, you streamline your workspace and enhance safety. A good workshop charger buying guide should always recommend chargers with accessible design, clearly positioned LED indicators, and robust casing against dust and accidental knocks. Ergonomics should never be underestimated in daily workshop realities.

Understanding Display Information

Reading Voltage and Amperage Correctly

Advanced chargers come equipped with digital displays or LED bar arrays. Knowing how to interpret these interfaces helps avoid operational errors. Voltage values inform if a battery has reached its nominal state, while amperage indicates charging current.

Overloaded chargers may display fault codes or flashing warnings. Others might visually represent “ready”, “charging”, or “error”. Ensure your crew is familiar with your particular charger model. Documentation is often overlooked, which is why a reliable workshop charger buying guide stresses reading the manual and fully understanding the display system. This guarantees informed usage and early error detection.

Signs of a Poor Quality Charger

What Not to Buy

Understanding what to avoid is just as vital as knowing what to buy. Here are red flags to watch for during your selection process:

- No safety certification marks: Missing CE, GS, or compliant symbols.

- Thin, unshielded cables: Increased fire risk and reduced durability.

- Generic branding with no service support: Untraceable OEM manufacturers or sellers.

- Cheap price without specifications: No listed voltage, amperage, or battery compatibility.

- Overly bulky but light weight: Indicates poor internal components.

Follow the steps highlighted throughout this workshop charger buying guide to steer clear of ineffective or even dangerous products that cost you more in replacements and lost time.

Final Thoughts and Expert Takeaways

Selecting the proper charging system is not a trivial choice—it’s a foundational decision that affects workforce efficiency, jobsite safety, and overall project momentum. As detailed in this workshop charger buying guide, informed buying decisions stem from understanding your entire battery ecosystem, compatibility requirements, and power management needs.

Smart investing in quality chargers pays dividends by extending battery life, keeping tools available, and reducing potential electrical hazards. Aim for solutions that blend high performance with certifications, intelligent diagnostics, ergonomics, and charging capacity tailored to team size. For related tool selection strategies, explore Learn more about Workshop power solutions and charging systems or review comparative battery guides at Read a related article. For brand-quality reports and technical specs, begin at Comprehensive project checklist for EV infrastructure and Automate translations for technical product sites.

Great guide on contractor-workshop-charger-buying-checklist – Community Feedback

What features are most important when buying a workshop charger?

Key features include charging speed, safety certifications, multi-bay support, compatibility with your tool batteries, and clear voltage/amp displays to optimise workflow.

Should contractors choose rapid or standard chargers for a busy workshop?

Rapid chargers save time on high-turnover sites, while standard chargers may suit lower usage. Consider team size, project pace, and battery stock to match charger type to requirements.

How do you ensure workshop chargers meet safety standards?

Select chargers with CE certification and proven safety features (overcharge, short-circuit protection). Always follow manufacturer guidelines and inspect equipment regularly for signs of damage.