Step-by-Step Guide: Set Up a Rapid Charging Bench for Best Results

In This Article

- Choose a stable, spacious, and ergonomic charging bench.

- Map power sources to avoid overheating and avoid shared multi-plugs.

- Maintain clear airflow between all chargers.

- Sort batteries by voltage and label storage areas accordingly.

- Use cable routing systems to avoid tangles and fire risks.

- Only use CE-certified rapid chargers with diagnostic functions.

- Implement weekly safety checks and charger maintenance routines.

- Facilitate team coordination with access slots, status boards, and rotations.

Why a Rapid Charging Bench Matters

Boosting Productivity & Safety

A dedicated rapid charging setup is no longer a luxury in today’s high-efficiency workshops—it’s a necessity. As power tool usage increases and turnaround times shrink, having a purposely designed bench for quickly recharging batteries improves productivity immensely. Workers spend less time idle and more time generating output. Beyond speed, there’s also the safety component. Poorly managed charging environments can result in equipment overheating or electrical hazards, which not only compromise personal safety but also reduce the lifespan of your batteries and tools. By implementing a proper rapid charging setup, you create a structured, reliable, and safe space that matches the modern pace of work. Not to mention, well-maintained equipment boosts overall project outcomes and lowers replacement costs.

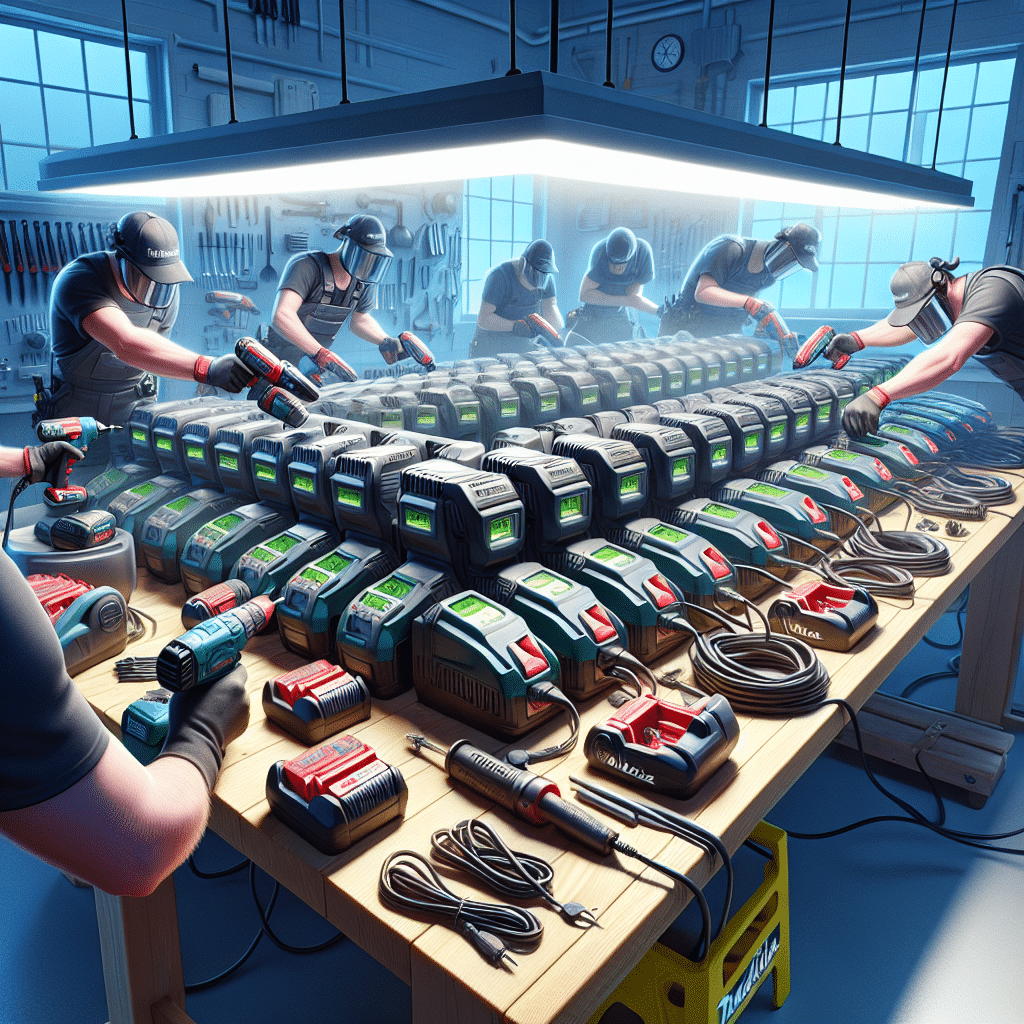

Choosing the Right Workbench for Charging

Stability, Surface Area & Accessibility

The foundation of your rapid charging setup starts with selecting an appropriate workbench. Stability is non-negotiable—it must endure the weight of multiple chargers and batteries without swaying or bowing. Look for heavy-duty steel-framed benches with anti-slip feet. Surface area is another critical factor. Ensure ample space to accommodate various voltage-specific charging stations, allowing clear separation between devices. A cluttered workspace is not only inefficient but also risky. Accessibility should also guide your decision. Opt for a bench height that promotes ergonomic use while minimizing strain. Integrated shelving or drawers can help neatly store cable organisers and battery test kits, effectively reducing reaction times during tool swaps.

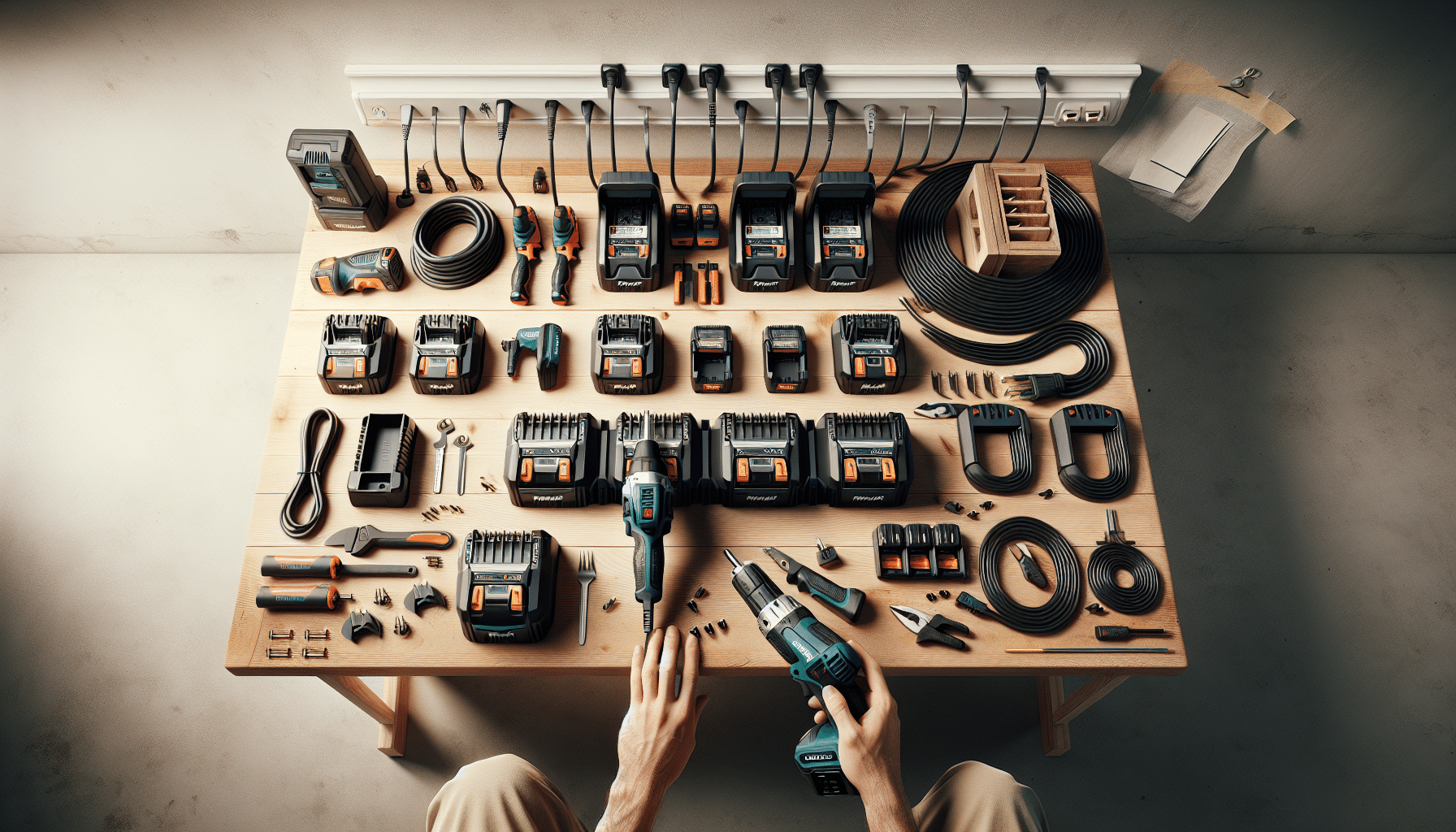

Mapping Out Power Distribution

Preventing Overloads and Cable Chaos

When it comes to intensive power usage, you must plan your power distribution with precision. Begin by calculating the total amps required across all charging units. Avoid daisy-chaining multi-gang adapters which can lead to current overload and fire hazards. Use industrial-grade extension leads rated above your peak load requirements. Each charger should ideally have its own socket on a surge-protected power board. Consider using a mounted vertical panel with labelled outlets to better organise access. It’s also advisable to map your charger layout close to mains outlets to reduce cabling lengths, which enhances charge efficiency. Thoughtful power planning is a core pillar of a safe rapid charging setup.

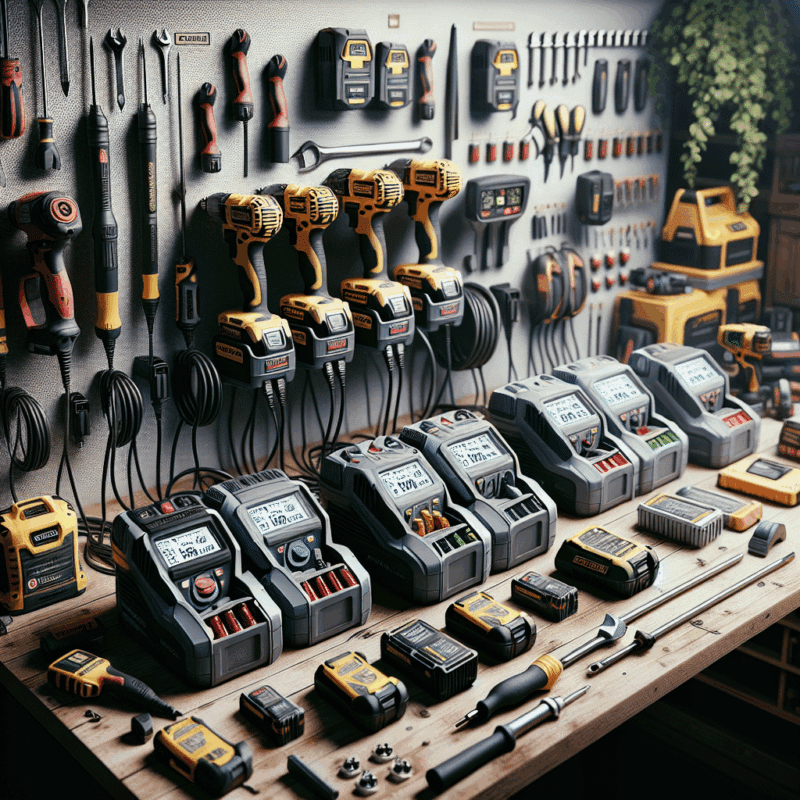

Spacing and Ventilation Best Practices

Airflow for Charger Performance & Longevity

Charger performance declines rapidly in poorly ventilated conditions. Most rapid chargers generate considerable heat, and if placed too closely, they restrict air circulation. Place each charger at least 10cm apart, and avoid stacking batteries atop one another during charging. Invest in aluminium mesh backboards to improve rear airflow. If your bench sits in a confined space, mount a desktop extractor fan or install crosswise vents to facilitate constant air movement. Extended overheating can cause premature degradation not only of batteries but also of the internal charging circuits. Proper spacing and ventilation form the backbone of a future-proof rapid charging setup. Learn more about Battery Charging Solutions for Power Tools

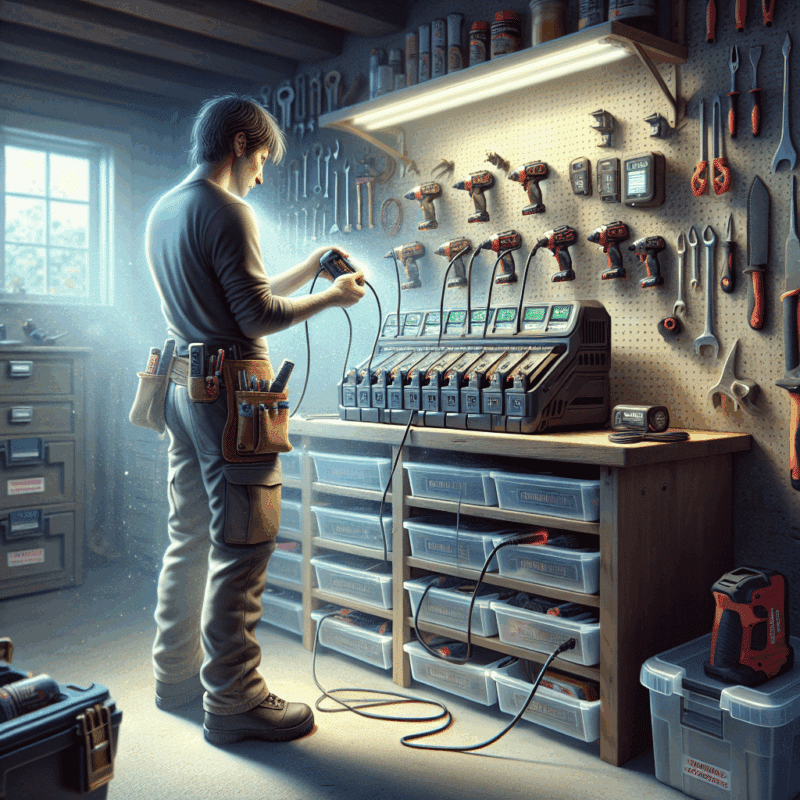

Organising Your Batteries by Voltage Type

How Separation Optimises Workflow

Efficiency comes down to knowing precisely where each battery type resides and is recharged. Group your battery packs by voltage—e.g., 12V, 18V, 40V—and designate marked sections on your workbench for each category. Use colour-coded trays or labelled shelves to avoid misplacement. This process dramatically reduces time spent on searching or rectifying a charging assignment mistake, as placing a battery in the wrong charger can lead to failure or hazardous charging. Beyond workflow gains, this segmentation safeguards the compatibility integrity between batteries and chargers, minimising wear-and-tear risks. It’s a small implementation with big ripple effects across team performance and safety compliance. Replicating this system-wide brings your rapid charging setup to professional standards. Read a related article

Managing Wires and Safety Hazards

Smart Cable Routing Tips

Cable clutter is more than an eyesore—it’s a hazard. Tripping over tangled cords or damaging charging leads can result in costly downtime. For a safe rapid charging setup, implement a structured cable management system. Use under-desk cable trays to route power cords securely. Velcro ties and spiral wraps can group multiple cables into one controlled run. For each charger, install adhesive cable clips to direct the wire path towards power outlets neatly. Labelling each cable by corresponding battery voltage not only supports log tracing but also prevents accidental unplugging. Moreover, invest in heat-resistant cable sleeves if your bench is exposed to high ambient temperatures. Regular audits of your wiring conditions underline a disciplined and hazard-free workspace. In-depth EV rapid charging basics

Choosing the Best Rapid Chargers

Why CE-Certified Tools Matter

All equipment used in a rapid charging setup must meet rigorous safety certification standards. CE-certification ensures compliance with European safety and EMC (Electromagnetic Compatibility) requirements. Cheap, uncertified chargers may save upfront money but often lack built-in thermal sensors, voltage regulation, and surge protection. These omissions significantly increase the risk of faults, fires, or equipment degradation. When evaluating chargers, prioritise units with intelligent diagnostic indicators—these can warn you of battery health issues or incorrect battery placement. Consider dual-port rapid chargers which support simultaneous charging of different battery types. Always refer to your tool manufacturer’s guidance to ensure pairing compatibility. Reputable manufacturers offer helpful online tools to match batteries correctly, enabling a consistent and efficient rapid charging setup. Streamline technical setup with automation

Routine Safety Checks and Maintenance

Essential Workshop Practices

Like any electrical installation, your rapid charging setup requires periodical inspections and upkeep. Begin each week by checking all cords for fraying or heat warping. Plug units into socket testers to verify grounding and polarity. At the end of each day, clean the contact points on both chargers and batteries to reduce resistance spikes. Use compressed air to clear out dust from vent fans. Create a maintenance log that tracks issues found and fixes implemented. Engage all team members in scheduled briefings, covering proper shutdown and reset procedures during overloads. A proactive approach to care elevates your bench’s throughput and ensures long-term reliability for daily operations.

Workflow Tips for Teams Sharing a Charging Bench

Rotation Systems and Access Zones

In team-based environments, even the most advanced rapid charging setup can falter if shared access isn’t managed correctly. Avoid bottlenecks by establishing mail-slot-style access zones—each with defined ownership of a charger and battery batch. Introduce timed rotation cycles, where users switch stations every hour or upon completion of a task, whichever comes first. Provide a centrally located whiteboard to flag battery status updates or mark out-of-order units. Train staff on FIFO (first in, first out) battery organisation. For advanced setups, integrate RFID labelling on batteries and assign digital booking slots through a shared calendar. These team workflow techniques convert a simple bench into an enterprise-level charging platform.

“A rapid charging setup transforms tool downtime into high-output work time. It’s an investment in speed, safety, and sustainability.”

Conclusion: Your Charging Bench, Optimised

A well-executed rapid charging setup acts as a productivity engine for any workshop. By carefully selecting your workbench, managing airflow, segregating battery types, and choosing effective chargers, you establish a system built not just for charging—but for performance. Don’t underestimate ongoing maintenance and team coordination; these tie your setup together. Structured planning transforms a reactive process into a proactive workflow. Implement the steps we’ve walked through to elevate your safety, speed, and tool lifecycle. Ultimately, a methodical rapid charging setup saves time, reduces hazards, and helps you consistently hit project targets.

Great guide on step-by-step-rapid-charging-bench-setup – Community Feedback

How do I set up a rapid charging bench for my tools?

Choose a suitable workbench, ensure safe electrical access, use high-quality rapid chargers, and arrange chargers for air flow and easy battery swapping.

What is the best way to arrange chargers for efficiency?

Space chargers for ventilation, place frequently used batteries within easy reach, and group chargers by battery type to streamline workflow.

Which safety precautions are essential for a charging bench?

Always use CE-certified chargers, avoid overloading outlets, maintain adequate ventilation, and regularly inspect cables and connections for damage.