Smart Battery Rotation for High-Capacity, Nonstop Tool Operation

In This Article

- Adopt battery rotation tactics like FIFO to extend battery life and reduce downtime.

- Use multi-bay chargers arranged strategically to improve accessibility and efficiency.

- Track battery health and usage with digital logs and consistent labelling systems.

- Aim for 3–5 batteries per tool depending on power draw and worksite needs.

- Train teams to identify overuse patterns and correct them early with standardised procedures.

- Invest in smart, high-capacity charging units for scalable operations.

- Use case study insights to model workplace improvements and empower team contributions.

Understanding the Importance of Battery Rotation

Why Battery Rotation Impacts Efficiency

Effective battery rotation tactics are at the heart of any operation that relies heavily on cordless power tools. Using a consistent and methodical approach to managing your battery inventory not only boosts equipment availability but also prolongs battery lifespan. Rather than randomly using whichever battery appears most charged, structured rotation ensures that all batteries receive equal usage and downtime for charging and cooling.

Without a proper system, batteries tend to get unevenly used—some are overcycled prematurely, while others remain idle and degrade due to inactivity. Over time, this imbalance results in frequent failures and increased costs. Proper battery rotation helps mitigate these problems by systematically alternating usage, preventing over-discharge, and optimising charge cycles. For any professional workshop or site aiming for seamless daylong tool operation, this routine becomes indispensable.

How to Implement Smart Battery Workflow

First-In, First-Out (FIFO) Strategy

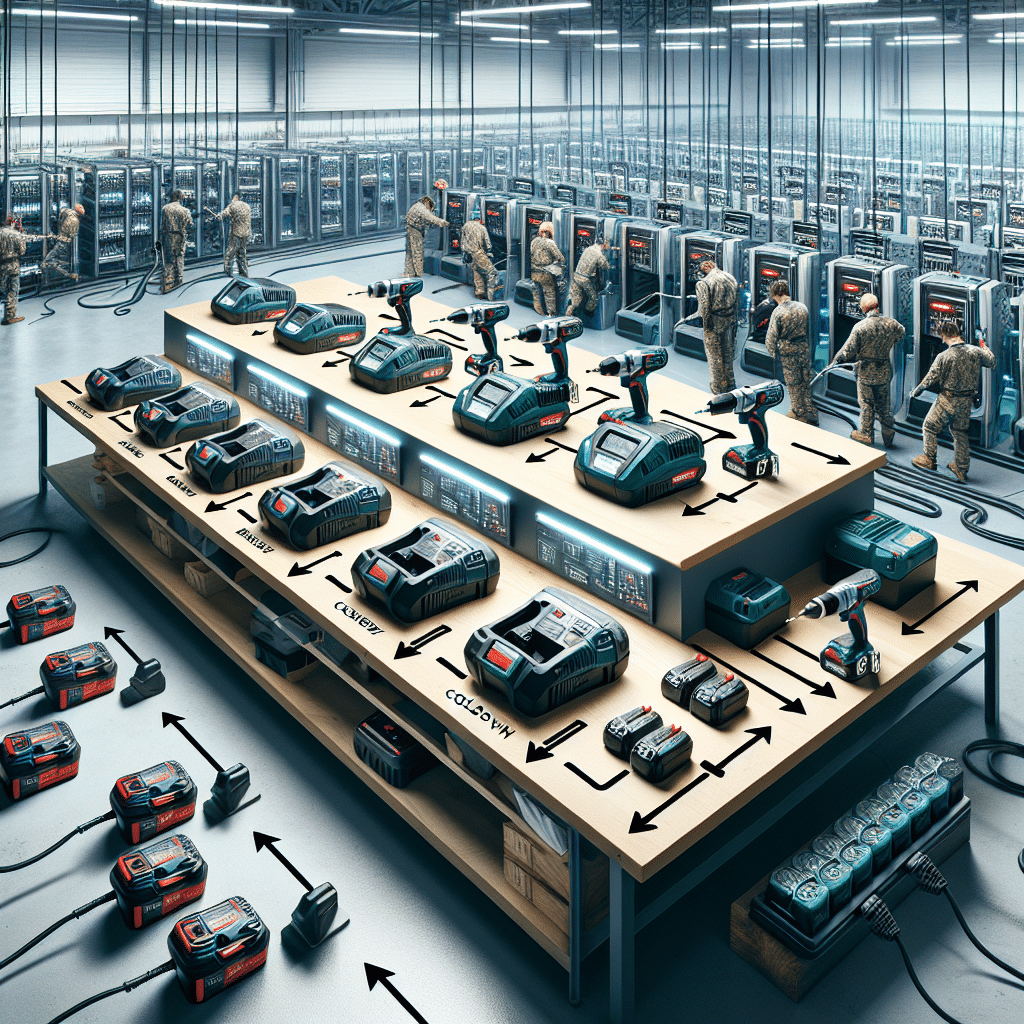

The cornerstone of structured battery rotation tactics lies in the First-In, First-Out (FIFO) methodology. This strategy dictates that the first battery to be charged should also be the first one used. Adopting FIFO minimises the risk of repeated use of the same battery while other packs remain idle, thereby distributing wear evenly across your collection.

To implement FIFO effectively, stations should be marked and batteries placed in a sequential order. Labelling helps, but so does user discipline: train staff to always pick the least recently charged battery. This longevity-enhancing practice is even more crucial for lithium-ion batteries, whose chemistry benefits significantly from rotational use and who can deteriorate when left unused for extended periods.

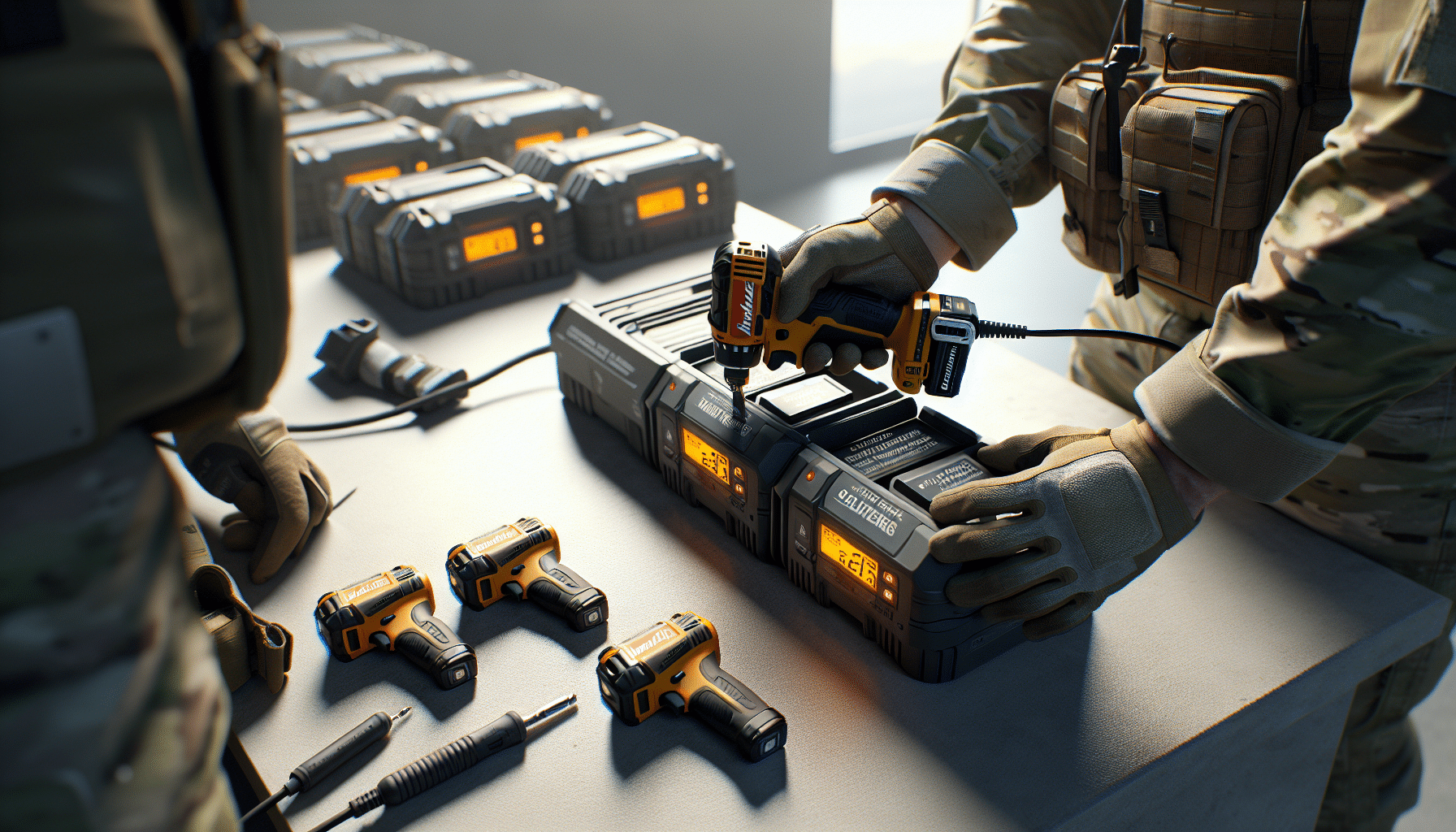

Multi-Bay Charging: The Backbone of Nonstop Power

Preparation and Charging Station Layout Tips

Multi-bay charging stations form the operational backbone for high-demand battery fleets. Whether in workshops or remote field sites, having the capacity to recharge a high number of batteries simultaneously is central to ensuring uninterrupted tool use. More importantly, the physical layout of these charging zones significantly influences the flow and accessibility of charged batteries.

Well-structured stations avoid clutter and confusion, which are enemies of accurate battery rotation. Arrange bays in logical FIFO order, label each charger, and maintain a dedicated ‘charged’ and ‘used’ section. Also, consider airflow and heat dispersion. Chargers should be positioned with spacing guidelines that assist cooling, especially if used intensively over long periods. Tag each bay with identifiers and use visual signals—like LED indicators or colour codes—to highlight battery status.

Balancing Battery Lifespan and Performance

Safe Charging Practices for Li-ion Packs

Successful battery rotation tactics go beyond usage—they start at the charging stage. Lithium-ion batteries, while more stable than older chemistries, still demand precise care to ensure they perform optimally. Always use manufacturer-recommended chargers and avoid exposure to high temperatures, especially while charging. Temperatures above 45°C can result in irreversible damage and reduced cycle count.

Avoid overcharging by disabling any outdated charging equipment lacking auto-shutoff features. Additionally, refrain from deep discharges. Tools should be swapped to fully charged batteries before the pack is entirely drained. This process preserves internal chemistry, sustaining capacity across hundreds of cycles. Temperature-controlled charging cabinets may also be considered in high-capacity environments. These help stabilise operational conditions under varying weather or industrial heat fluctuations.

Recommended Battery Quantities per Tool

Optimising for Continuous Use

A key piece of any battery rotation blueprint is planning how many battery packs each tool requires for smooth, continuous deployment. As a rule of thumb, three batteries per tool forms a basic standard: one in use, one cooling or idle, and one charging. However, densities should be adapted based on workflow pressures, tool power requirements, and charge times.

For example, high-drain tools like rotary hammers or saws may require four to five batteries in rotation to balance output and recharge timelines adequately. It’s also helpful to monitor mean usage times and charging durations. With that data to hand, teams can avoid under-capacity scenarios that lead to downtime. Adjust rotas regularly depending on seasonal needs or per-project intensity scales.

Labelling and Tracking for Rotation Success

Using Tags, Logs, and Colour Systems

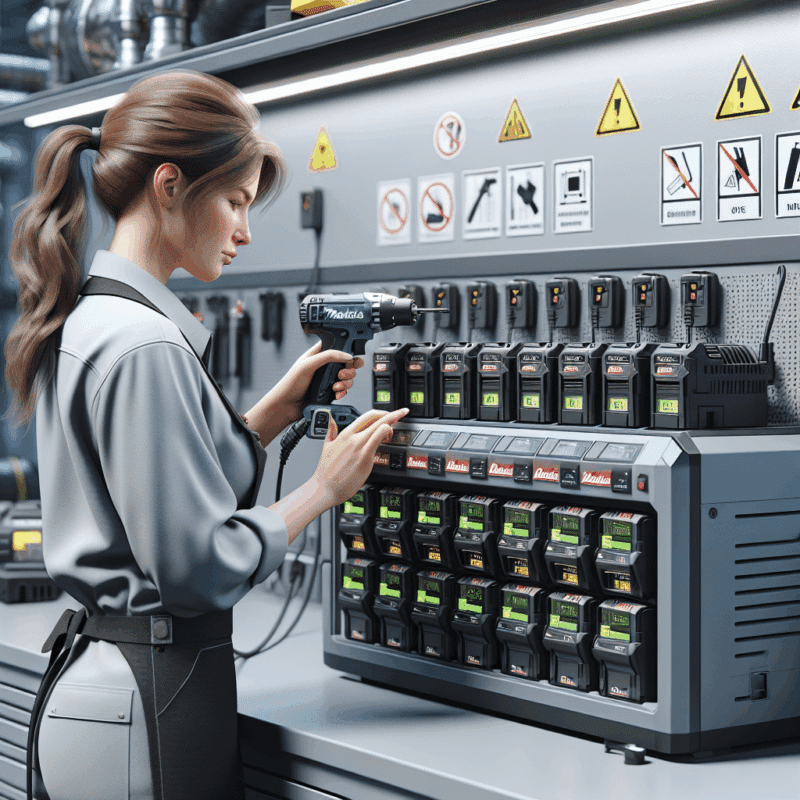

Failing to track battery usage effectively undermines even the best rotation tactics. Each battery should be clearly labelled with an ID number, purchase date, and entry into rotation. Colour coding is a powerful visual aid: use coloured heat-shrink wraps or adhesive dots to signify battery age or group assignment.

Digital tracking also plays a crucial role. Apps and spreadsheets can log every cycle for each battery, alerting teams when one approaches end-of-life or deviates from expected performance. Such systems also support warranty tracking and help maintain replacement schedules. Handwritten logbooks, barcode systems, or RFID tags provide increased accountability depending on scale. The key is consistency—whichever system you choose, apply it across the fleet.

Common Pitfalls to Avoid When Rotating Batteries

Overuse, Deep Discharge, and Mismatched Charging

Despite good intentions, many operations fall prey to common errors with their battery rotation tactics. Chief among them is the overuse of specific batteries while others remain effectively dormant. This leads to accelerated degradation of a subset of the inventory and convolutes forecasting efforts. Implementing FIFO and proper tracking eliminates this quickly.

Another issue is permitting batteries to fully discharge during active use before swapping them out. Deep discharge not only cuts cycle counts dramatically but also risks triggering protective shutdowns from which some packs never recover. Charging mismatches—such as using third-party or incompatible chargers—also invite trouble. These can result in incomplete charges or worse, unsafe charging behaviour. Avoid all of these by instituting strict rotation protocols and standardized charging ecosystems.

How Teams Benefit from Strategic Rotation

Less Downtime, Better Battery Health

When battery rotation is managed well, the benefits ripple throughout team operations. Tool uptime increases measurably because batteries are always available—and at the right charge level. Workers don’t waste time searching for usable packs or waiting for a charge cycle to finish.

Moreover, battery life is extended through balanced usage, which reduces expenditure on replacements. Maintenance managers can forecast pack replacement schedules more predictively, ensuring proper budget planning. Morale also improves: workers become confident that their tools won’t let them down mid-task. On large worksites or time-critical projects, this advantage equates to real financial and reputational gains. Learn more about Power Tool Battery Management & Optimisation

Choosing the Right Chargers for High-Volume Use

Rapid Multi-Port Charging Options Reviewed

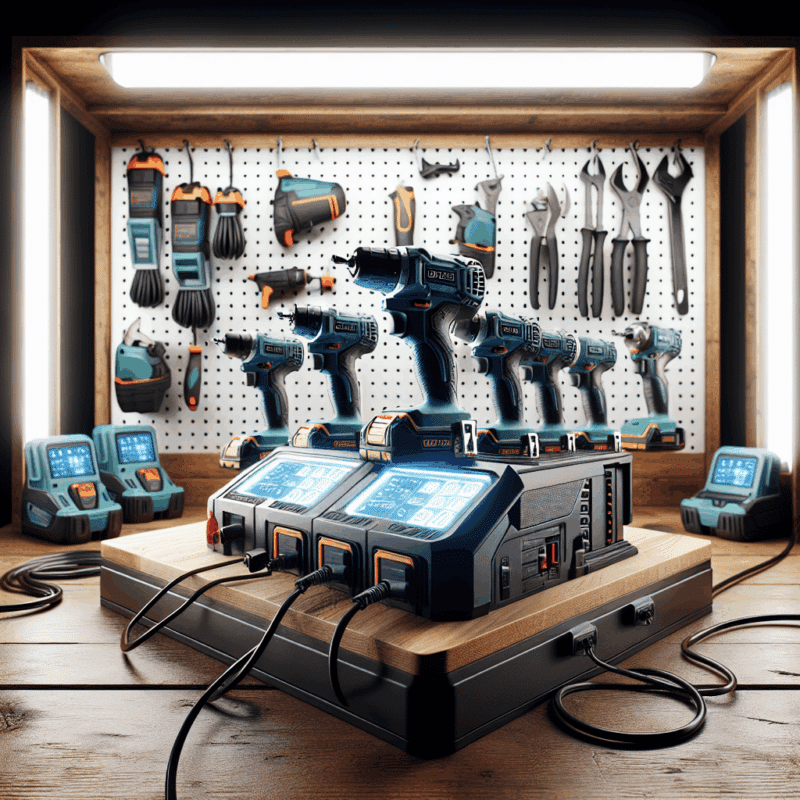

Not all chargers are created equally—especially when it comes to managing battery rotation tactics at scale. High-volume workflows benefit from multi-port chargers that allow 4, 6, or even 8 batteries to cycle at once. Integrated smart chips are ideal because they balance individual charge delivery based on battery condition and state of charge.

Leading manufacturers now offer stackable or wall-mounted modular systems that conserve space while scaling efficiently. Some even feature LCD interfaces showing charge progress, temperature alerts, and estimated completion times. Portable charging carts with built-in safety cutoffs are also worth exploring for mobile teams. Before purchasing, evaluate the charge rate (typically expressed in amps), compatible voltages, and whether the charger supports pass-through cooling or charge scheduling. battery safety protocols for high-capacity systems

Case Study: Battery Rotation on a Busy Worksite

Lessons from Professional Usage

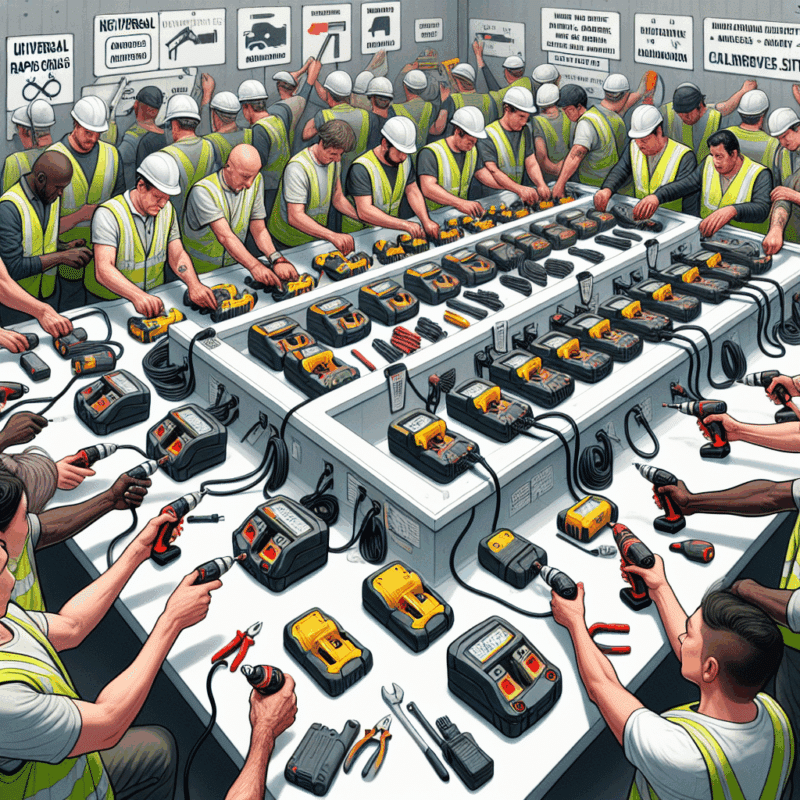

Consider a large-scale commercial refurbishment project in Manchester where over 30 cordless tools were in use across multiple floors. The site initially struggled with downtime due to irregular battery availability. Teams hoarded packs in toolboxes, and chargers were scattered and misaligned with power access points.

After initiating structured battery rotation tactics with FIFO storage racks, multi-bay charging units, and a teamwide labelling scheme, reliability and productivity surged. Downtime linked to battery failures dropped by 60% in the first three months. Additionally, the lifespan of batteries increased by roughly 25% compared to previous cycles. The team noted marked improvements in workflow scheduling and lower stress among site supervisors. Read a related article optimising digital power tool workflows

“Implementing a battery rotation system halved our tool replacement costs in one year. Worth every ounce of effort.” — Site Manager, Large-Scale Infrastructure Project

Conclusion: Build a Seamless Power Workflow

In high-demand professional environments, robust battery rotation tactics are non-negotiable. They form the backbone of productivity, safety, and cost efficiency. By committing to structured systems such as First-In, First-Out strategies, multi-bay charging setups, and proactive labelling protocols, teams can ensure a consistently available supply of reliable power.

Begin by assessing your current workflow and identifying gaps in battery rotation. Implement changes with the entire team onboard and support the shift with proper training, tracked accountability, and the right charging infrastructure. With these steps in place, your tools will work as hard and as uninterrupted as your team does.

Great guide on high-capacity-battery-rotation-nonstop-tool-flow – Community Feedback

What is the most effective way to rotate high-capacity tool batteries?

Adopt a first-in, first-out system: use each battery in sequence, charging the depleted ones as you swap. This avoids leaving any batteries idle for too long, reduces wear, and ensures balanced usage across your battery fleet.

How many batteries are needed for nonstop tool operation?

For continuous tool flow, at least three batteries per tool are ideal: one in use, one charging, and one cooling down. Larger teams or high-demand sites may require more to ensure there’s always a fresh battery ready.

Does frequent charging affect the lifespan of high-capacity Li-ion batteries?

Regular cycling within 20-80% charge helps maintain battery health. Avoid deep discharge or charging to 100% every time, as this reduces wear and extends the overall battery life.