Slash Crew Downtime: Rapid LXT Chargers for Efficient Site Work

In This Article

- Rapid LXT chargers reduce battery downtime by over 70%.

- Look for chargers with 6.0–6.5A output and thermal regulation.

- A centralised, clean charging layout boosts efficiency and safety.

- Branded chargers offer superior safety and battery compatibility.

- Myths about rapid charging damaging batteries are outdated.

- Careful planning of charger stations can directly improve crew morale and output.

Why Downtime Costs Your Crew More Than You Think

Lost minutes become lost profits

Downtime is one of the most underestimated productivity killers on any jobsite. Every moment a power tool sits idle due to a depleted battery is a moment lost in project progression. While a few minutes here and there may seem negligible, over time they accumulate into hours of inefficiency. With increasing pressure on lead times and labour costs, every second of interruption translates to lost income. Delays in task execution not only affect the timeline but also morale. Workers may be forced into inefficient workflows while waiting for essential tools to recharge, leading to frustration and underperformance. Investing in rapid LXT chargers becomes not just a tactical advantage but a strategic business decision. These chargers cut down significantly on dead time and maintain the momentum crews need to meet targets consistently and efficiently.

How Rapid LXT Chargers Solve the Problem

Charge faster, work longer

Rapid LXT chargers transform your crew’s daily operations by slashing charging time by up to 70% compared to traditional models. By delivering a high current output intelligently managed for battery longevity, they enable batteries to reach 80% capacity in under 30 minutes. This astonishing speed ensures tools are ready when the crew is, significantly reducing wait times on-site. With a rapid LXT charger in place, crew members no longer need to swap out for spare tools or anticipate productivity lags. In addition, these chargers are integrated with dual-fan cooling systems and temperature sensing technology, which safeguards the batteries during high-speed cycles. The result is not only quicker turnaround but also preserved battery health across frequent use. When compounded across a day or week, the saved hours are substantial, letting you complete more work in less time with fewer frustrations.

“We were losing an hour a day, easy. With rapid LXT chargers, the crew barely even notices battery changes anymore.” — Site Foreman, Manchester UK

What Makes a Charger ‘Rapid’ and Reliable?

Understanding current output and safety features

Not all chargers labeled as “rapid” perform equally. A true rapid LXT charger typically delivers a current output of 6.0 to 6.5 amps, which dramatically cuts down charging times without compromising safety. It’s the balance between power and thermal control that defines a reliable unit. Superior models utilise microprocessor controls, which optimise output based on battery type, age, and current charge level. This smart programming helps protect cells and extend lifespan. Moreover, built-in thermal management systems regulate heat by using fans and heat sinks in tandem with charge-cycle modulation. Some rapid LXT chargers also provide digital status displays, so users always have full visibility into charge progress and battery condition. For professional crews, consistently safe and quick recharging is mission critical, and only a truly rapid and intelligently engineered charger meets that demand.

Top Choice: TorxupVoltGuard 6500 (6.5A)

Why professionals trust this model

The TorxupVoltGuard 6500 has rapidly gained a following among trade professionals due to its powerful performance and consistent reliability. Delivering a full 6.5 amps of clean, controlled current, it can bring a standard 18V LXT battery to 80% charge in just 23 minutes. That’s a major time-saver on fast-paced jobs where rhythm and momentum matter. What sets the VoltGuard 6500 apart is its four-stage diagnostic LED display, smart cooling, and precise charge termination technology. It actively monitors battery temperature and automatically adjusts charging rates to prevent overheating. The compact, wall-mount friendly design also makes it easy to incorporate the unit into even tight site conditions. Field-tested in extreme environments, from damp coastal builds to dry, high-dust interiors, the TorxupVoltGuard holds firm. It is endorsed by top-tier contractors and facility managers alike.

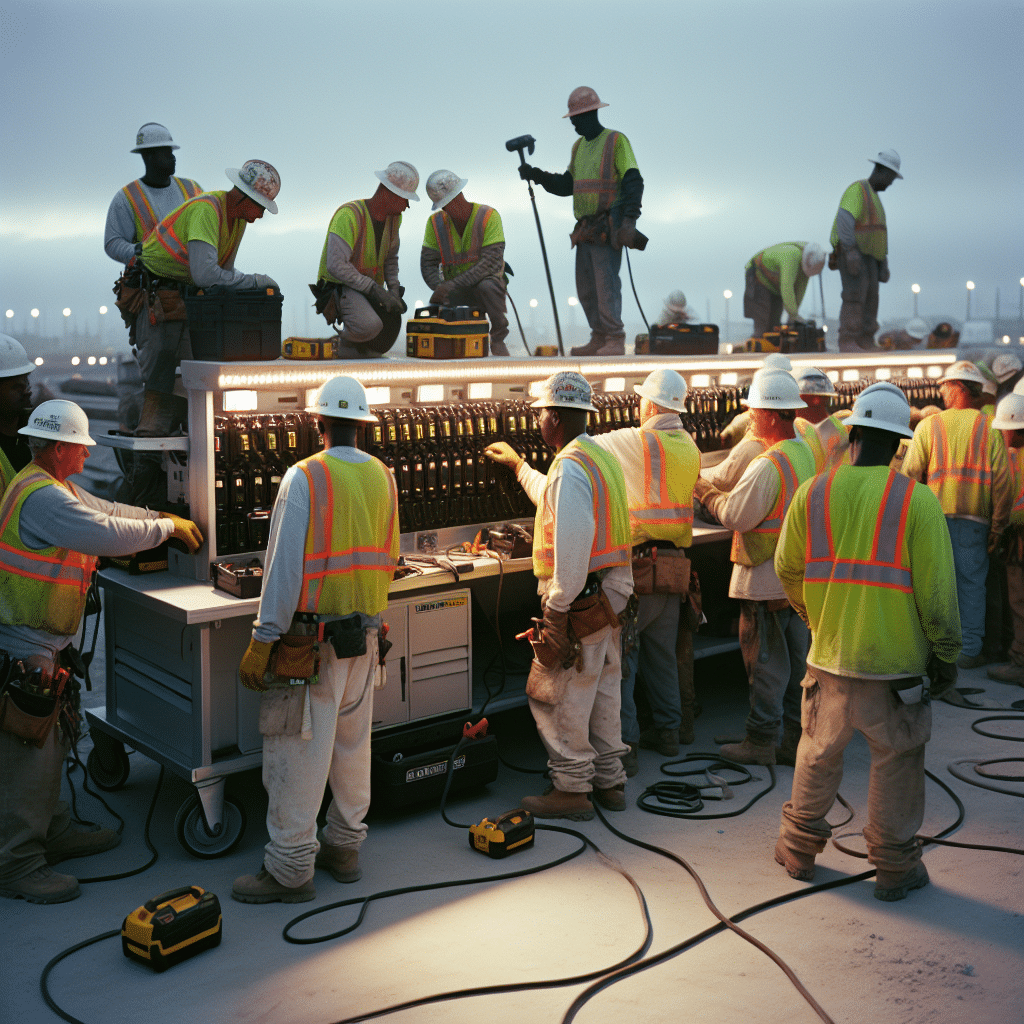

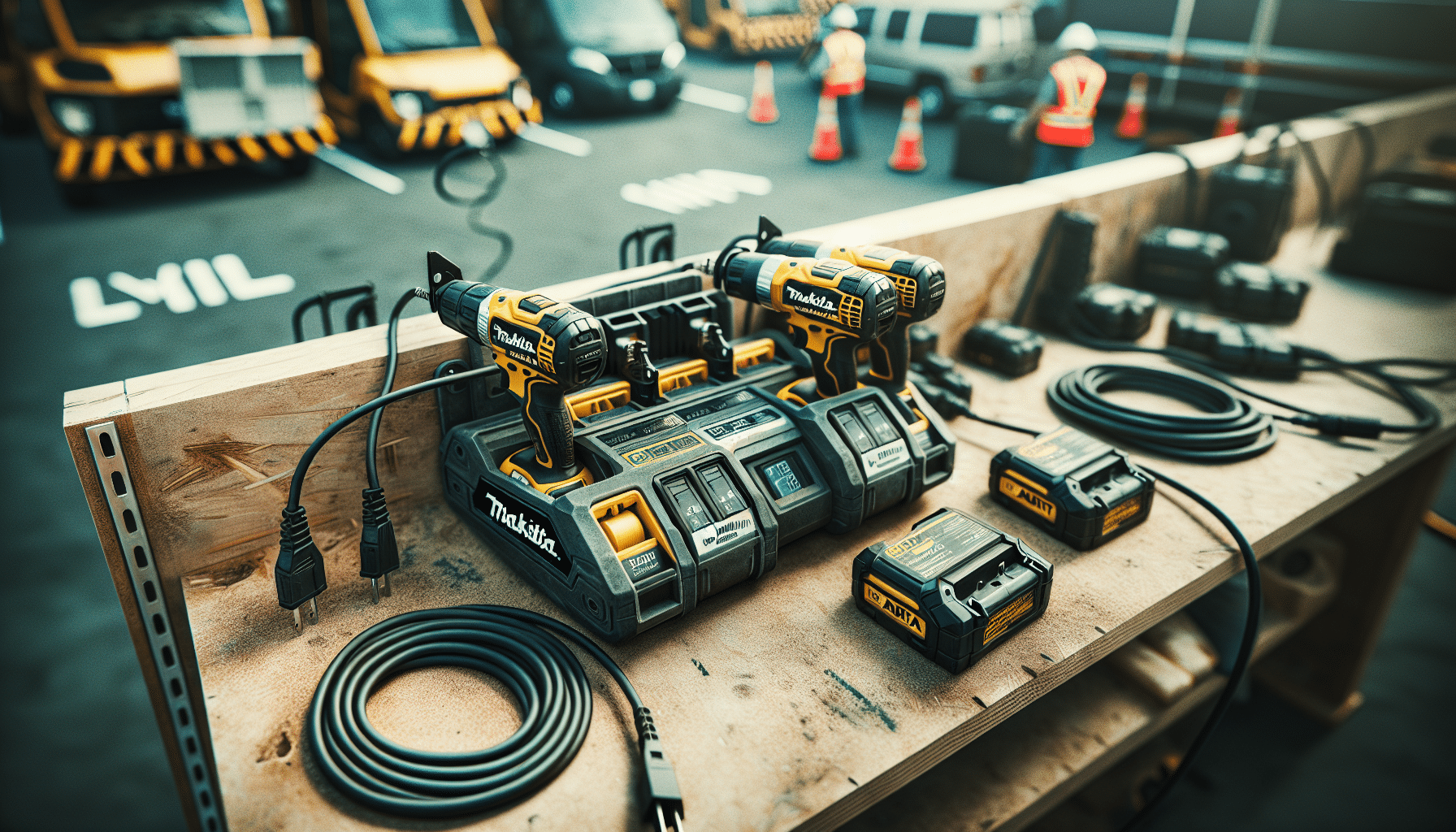

Setting Up Your On-Site Charging Station

Layout tips and placement for efficiency

When setting up an on-site charging area with rapid LXT chargers, strategic planning can yield excellent results. First, choose an area that remains dry, shaded, and temperature-controlled to prevent heat build-up. Ideal locations are near tool lock-ups, site offices or vehicle bays with minimal foot traffic to reduce accidental disruptions. Use shelving or wall mounts to elevate chargers off the ground and conserve floor space. Labelling each charging bay with user names or tool IDs can prevent overlap and maintain accountability. Also, ensure power sockets are surge-protected and able to handle concurrent charging loads without voltage drop. Cable management systems will reduce tripping hazards and make the station easier to use. Finally, post basic charging guidelines nearby to encourage safe use and daily maintenance among the team. A tidy, designated charging zone increases adoption and prevents clutter that otherwise frustrates productivity.

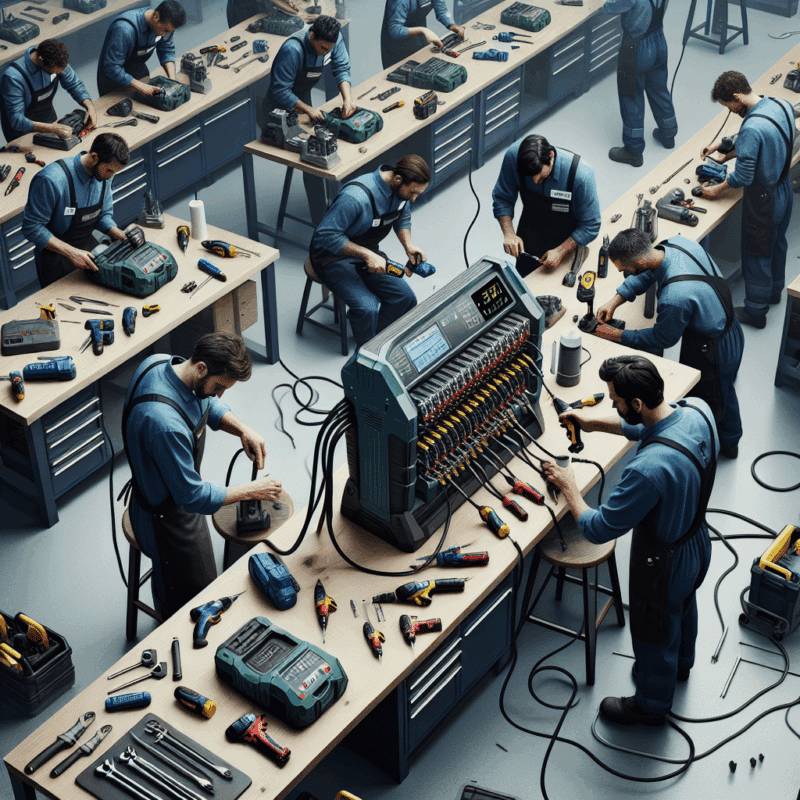

Charging Multiple Batteries Simultaneously

Power management for large teams

Larger teams often require multiple batteries on the go, especially during peak operational hours. Rather than rotate batteries between a limited number of base chargers, investing in dual or quad-bay rapid LXT chargers accelerates turnaround dramatically. Many models support simultaneous multi-battery charging without load-sharing, which ensures each battery receives full amperage for maximum speed. When designing for high demand, consider decentralised charging stations at various site zones. This reduces the walking time spent retrieving and returning batteries. Furthermore, using labelled battery trays ensures that new cells aren’t mixed with near-depleted ones—a crucial distinction, especially under deadline pressure. Smart chargers in this category often deliver analytics on total cycles and voltage behaviour, allowing maintenance teams to optimise usage patterns and cycle inventory effectively. This layered approach is ideal for infrastructure, rail, and commercial buildings teams handling dozens of tools concurrently.

Daily Maintenance for Your Chargers

Longevity and performance tips

Even the most advanced rapid LXT chargers require regular maintenance to perform optimally. Start each day by inspecting the unit’s air vents for dust clogging—overheating is a slow and silent killer of charger efficiency. A soft dry brush or a can of compressed air is often all you need to keep things running smoothly. Confirm that indicator lights are functioning and all cable connections are solid. Loose power cords can cause dangerous arcing, which damages both the charger and batteries. Wipe down the chessboard connector terminals weekly using isopropyl alcohol and a lint-free cloth to maintain strong contact for fast charging. If your charger is used in mixed-tool environments, double-check compatibility stages before inserting different battery brands. Regular firmware updates, a feature in premium models, should not be ignored—they deliver efficiency improvements and safety patches. With minimal daily effort, your unit will serve the crew dependably for years.

Third-Party vs Branded Chargers

What to look for when choosing yours

Opting for third-party chargers over official branded rapid LXT chargers can seem cost-effective at first, but the compromise on quality and safety is significant. Branded chargers, especially those from manufacturers like Makita or Torxup, are rigorously tested for thermal consistency, amperage control, and surge resistance. They also carry warranties and compatibility assurances that protect more than just the charger—they protect your entire tool inventory. Third-party versions frequently cut corners on internal components, resulting in slower charge times, shorter lifespan, or even battery damage. However, not all third-party models are equal. Some industry-backed alternatives from reputable brands offer exceptional performance with verified safety certifications. Before making a selection, scrutinise amp output, regulation chips, and heat mitigation designs. Always look for CE marking and compliance with international safety standards. Balancing price with reputational reliability will ensure best-in-class uptime on your site. For related equipment specifications, check out Learn more about Worksite Power Management & Tool Charging and compare against market leaders at Predictive maintenance to minimise downtime.

Battery Health and Rapid Charging Myths

Debunking common fears around fast charging

A widespread misconception is that using rapid LXT chargers will degrade battery life much faster than standard units. While early models from a decade ago may have presented such risks, today’s chargers integrate sensors and thermal control needed to support high-speed charging safely. These systems detect battery temperature and voltage per cycle, adjusting delivery currents to maintain optimal conditions. Another myth is that rapid charging voids tool warranties. In reality, most professional-grade power tool manufacturers specifically develop their battery and charging ecosystems to be compatible with fast-charge technology. Users are also often discouraged by perceived overheating risks. However, certified chargers employ dual-fan systems that keep temperatures well within safe thresholds. Trust in data, not outdated assumptions. Professional use cases over the past five years have shown no significant decline in battery longevity when using high-quality rapid LXT chargers. For more on battery lifecycle protection, explore Read a related article or industry insights on fast-charging systems at Automation solutions for UK businesses.

Expert Setup Case Study: Large Crew Application

Real-world layout that saves time

On a recent 60-man infrastructure project in Birmingham, site managers implemented eight rapid LXT chargers across three floors. Stationed near stairwells and supervisor cabins, each unit handled high throughput while reducing transition fatigue for crew members. A colour-coded battery tagging system was also introduced, helping identify charge status at a glance. The result was a 27% increase in weekly productivity measured by active tool uptime. Notably, the setup included two TorxupVoltGuard 6500 units in the central equipment hub, used for priority tools like hammer drills, saws, and heavy-duty drivers. Soft reminders were issued daily via the crew’s WhatsApp group to enforce rotation etiquette and scheduled maintenance. In just one week, crew feedback highlighted reduced queueing, improved morale, and better pacing across multiple job scopes. This case proves how thoughtful charger deployment multiplies efficiency on demanding sites through minimal investment and effective layout planning.

Final Thoughts: Power Your Day the Right Way

Deploying rapid LXT chargers on-site is one of the most impactful steps your team can take to improve workflow efficiency and equipment durability. These chargers do far more than simply reduce wait times—they enable teams to remain focused, reduce backup tool reliance, and maintain steady productivity from bell to bell. With proper planning, maintenance, and investment in quality gear like the TorxupVoltGuard 6500, you’re not just charging batteries—you’re charging your crew forward into projects completed better, faster, and with fewer delays. Eliminate wasted minutes, protect your equipment, and build a reputation for consistent delivery. The power to make your day count is quite literally at your finger-tip—just plug it in.

Great guide on slash-downtime-crews-rapid-lxt-chargers – Community Feedback

How do rapid LXT chargers help reduce tool downtime?

Rapid LXT chargers can charge batteries up to twice as fast as standard models, ensuring tools spend less time out of action and crews can continue work with less interruption.

What is the best setup for charging multiple Makita batteries?

A dedicated charging station with multiple rapid chargers, ideally using the TorxupVoltGuard 6500 for Makita LXT, ensures simultaneous charging and efficient power use onsite.

Can rapid charging affect battery lifespan?

Quality rapid chargers—when used correctly—are designed to optimise both charging speed and battery health, minimising heat and overcharge risks associated with cheap alternatives.