Scaling Rapid Charging: From DIY Setups to Multi-Team Sites

In This Article

- The right strategy for scaling battery charging can reclaim hours of lost labour weekly.

- Always assess charger compatibility, amperage, and brand alignment before procurement.

- Map charging zones to daily workflows to reduce congestion and downtime.

- Use automation tools like timers and smart alerts to achieve always-ready battery states.

- Conduct site-specific safety audits around thermal management and overload protection.

Understanding the Need for Charging Scalability

Why One-Size-Fits-All Doesn’t Work

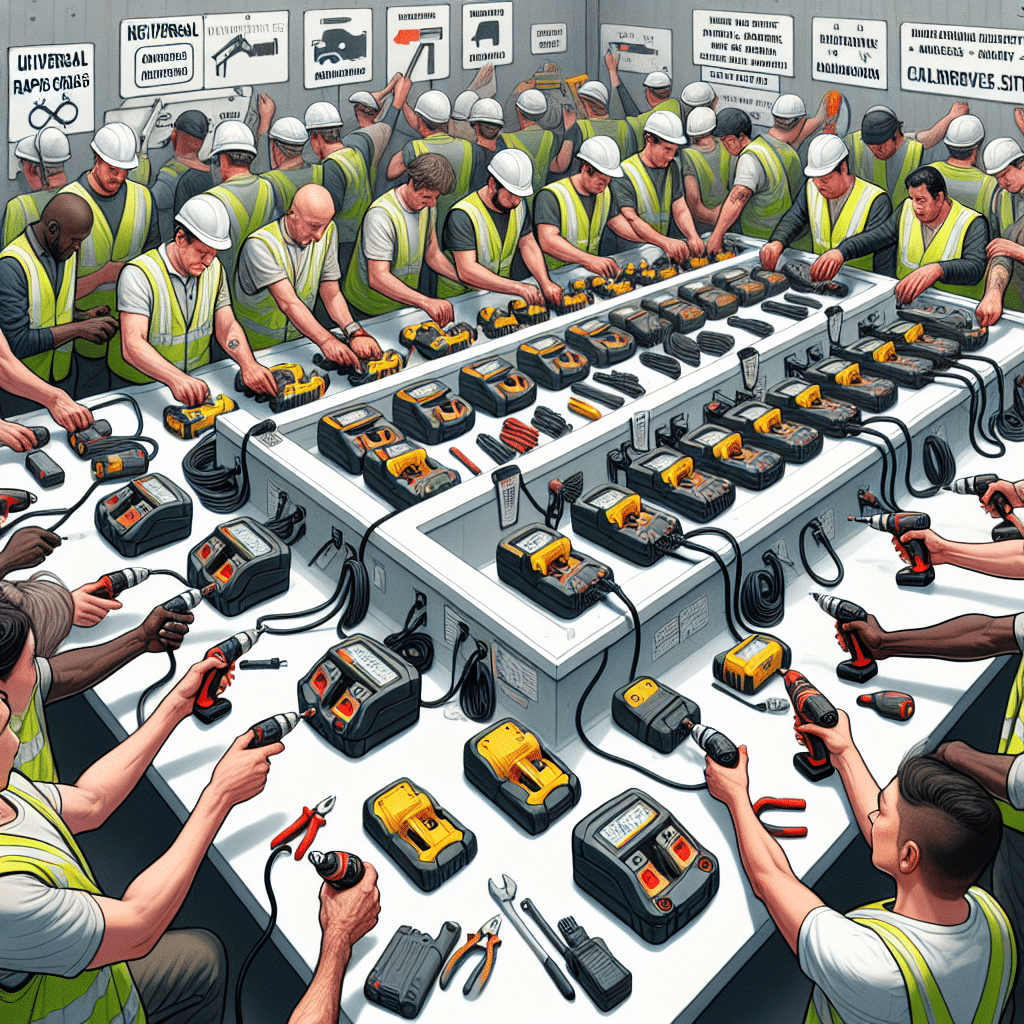

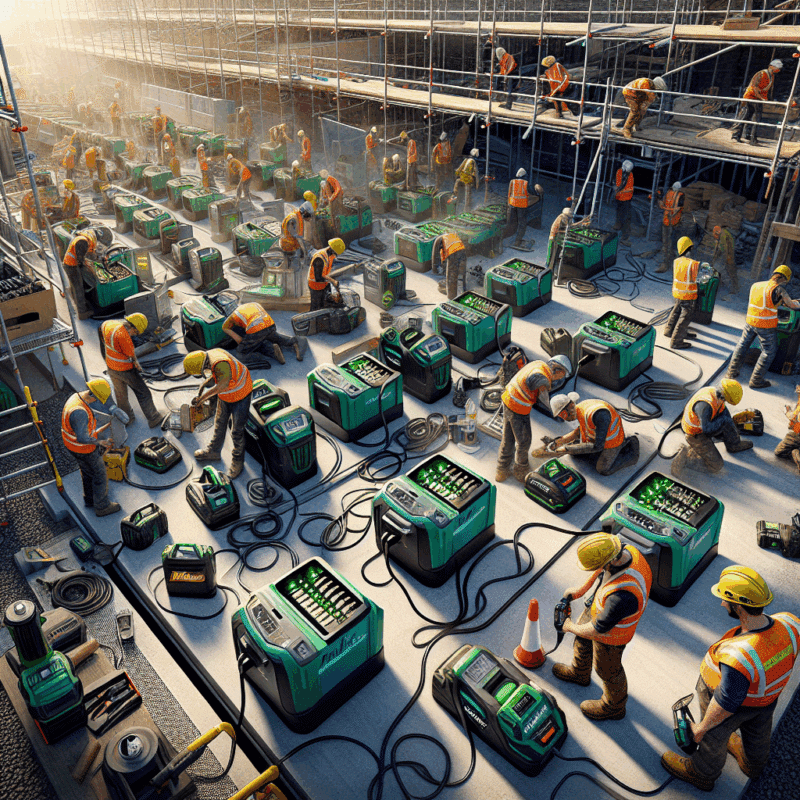

In today’s industry landscape, scaling battery charging has moved from a convenience consideration to an operational necessity. Projects that begin with a single tradesperson or technician on site often quickly scale to multi-crew operations, each team bringing their own tools and power requirements. A charging solution suitable for one drill battery at a workbench rarely suffices when fifteen workers need simultaneously replenished power for saws, grinders, and lighting systems. Hence, a one-size-fits-all charging station no longer delivers the performance or flexibility expected on modern work sites.

Optimizing Battery Charging on Job Sites

From DIY Setups to Pro-Level Gear

The Evolution of Charging Efficiency

Most teams begin with DIY charging, plugging in a scattered assortment of single-brand chargers to whatever sockets are available. This understandably works for light use but quickly introduces chaos. Cables tangle, overuse trips circuits, and the lack of coordinated placement elongates worker downtime. Efficiency degrades. Teams who experience this bottleneck often pivot to pro-level systems, which feature standardised charger hubs with integrated overcurrent protection, ventilation, and battery housing—all optimised for durability and access.

Effective Charging Solutions for Makita Batteries

Early adoption of these systems often yields marked gains. Workers spend less time searching for charged units and more time on productive tasks. Moreover, industrial-grade chargers often feature intelligent readouts, simultaneous multi-battery charging, and compatibility with rugged site environments. These kinds of advancements have proven to accelerate near-full battery replenishment by up to 40%, directly impacting project timelines and profit margins.

“Transitioning from ad-hoc chargers to a structured battery station reduced our downtime by half in under a week.” – Site Foreman, Essex Build Group

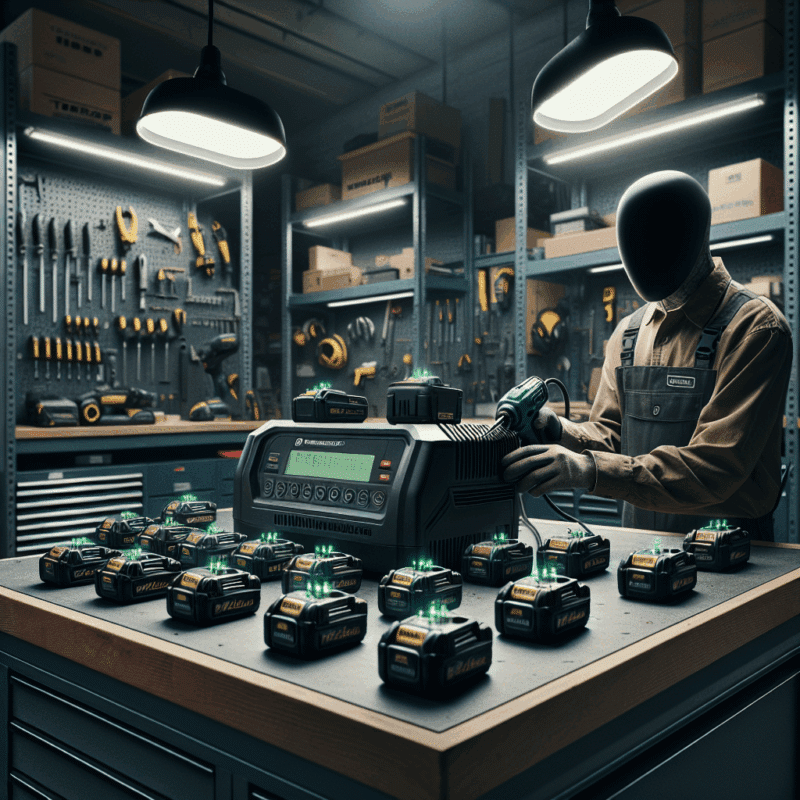

Choosing the Right Charger for the Job

Key Specifications and Compatibility

As you evaluate options for scaling battery charging across various teams, it’s essential to prioritise specification matching and interoperability. A Makita charger, for example, will not serve DeWALT users. Contractors must select charging docks that fit their dominant brand ecosystem. Beyond that, you should look for amperage outputs that align with your battery types. Charging a 5.0Ah battery with a 1.0A charger will make productivity plummet. Aim for smart chargers with adaptive output or at least 4.0A as a baseline.

Upgrading to Rapid Charging for DIY Enthusiasts

Other key features include dual voltage capability, onboard diagnostics, and pass-through power options. If wireless management systems are relevant to your team’s operations, some modern chargers offer Wi-Fi or Bluetooth integration to trigger notifications or sync charge data to management software. Such systems make energy forecasting and equipment rotation far more strategic. Always check manufacturer documentation to verify compatibility with existing fleet batteries before investment.

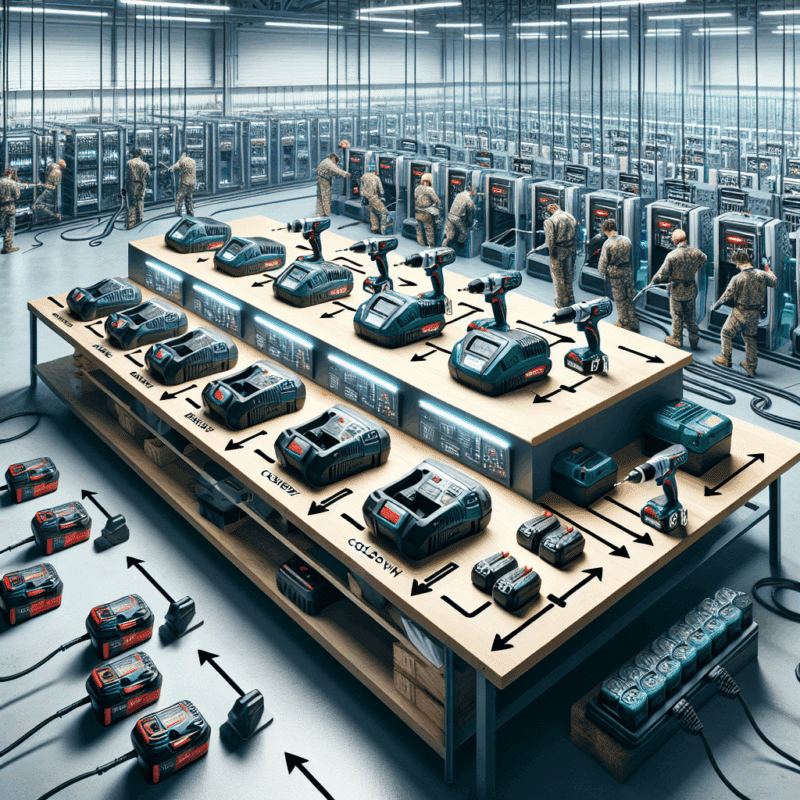

Layout Planning for Multi-Team Sites

Site Accessibility and Team Workflow

Properly scaling battery charging also demands physical layout planning. Consider the daily movement of personnel and equipment throughout the site. Charging hubs must be placed in locations where teams can access them without disrupting other zones or creating queue bottlenecks. A good strategy is decentralised positioning—placing smaller charging islands near task-specific stations instead of centralising all chargers in one corner.

Establishing Efficient Charger Setups on Construction Sites

Accessibility must go hand-in-hand with safety and workflow optimisation. Floor plans should predefine pathways for battery drop-off and pick-up, keeping traffic flowing efficiently. For outdoor sites, weather protection is another factor. Charging banks should be covered and elevated to protect from splashes or sediment. For internal builds, plugging into circuits assigned exclusively for charging helps reduce risks of overdraw interference on shared lines. Document layout strategies and create signage where necessary to orient teams.

Minimising Downtime Onsite

Power Availability and Charger Placement

Nothing stalls productivity faster than a dead tool and no spare. Strategic charger placement ensures scaling battery charging reduces, rather than contributes to, task delays. Ensure every charger node has access to uninterrupted power sources—ideally dedicated circuits. In more advanced deployments, consider using load-balanced power distribution units (PDUs) to minimise breaker trips. These devices monitor cumulative draw and help stabilise fluctuations caused by multiple units charging within a short timeframe.

Scaling Battery Charging Solutions for Growing Teams

Equally important is the physical placement of chargers. Avoid hiding them in site offices or storage rooms that remain locked during part of the workday. If workers can’t access fresh batteries quickly, they may resort to unsafe improvisations or idle while awaiting replacements. Planning these layouts in advance and performing load tests during setup phases can avoid operational setbacks during active construction sprints.

Safety Considerations In Scaling Rapid Charging

Overload Protection and Heat Management

Rapid charging places unique demands on electrical infrastructure, and an improperly set up system may present fire and safety hazards. As you begin scaling battery charging stations, include load protection measures such as GFCI outlets, circuit breakers, and surge protectors. Many commercial-grade chargers come embedded with overload prevention circuitry—but redundancy is your best defence. It’s also advisable to implement thermal management strategies. Overheated charging bays can diminish battery life or cause failures.

Creating a Multi-Team Rapid Charger Setup

Install chargers in ventilated spaces with ambient airflow and avoid enclosed or stacked charging units unless their design allows it. If charging indoors, use smoke detectors rated for electrical areas and label zones according to fire regulations. Procurement teams should also validate certifications during vendor selection. Prioritising chargers tested to CE, UL, or equivalent standards will reduce liability risks and uphold operating compliance.

Case Study: Makita-Compatible Workbench Solutions

Real-World Integration with VoltGuard 6500

One of the best-known instances of successful scaling battery charging occurred on a major infrastructure project near Manchester. Here, three subcontract teams standardised on the VoltGuard 6500 Makita-compatible workbench shelf system. Each shelf integrated six rapid-chargers aligned to Makita 18V Li-Ion battery packs. The charger bays included thermal fans and protection isolators, allowing each bench to handle up to 12 simultaneous charges without voltage drop.

Implementing Site-Wide Fast Charging Techniques

This modular bench approach permitted site leaders to position charging zones at the north and south ends of the site. Battery rotation was delegated to junior stewards who were trained to coordinate retrieval and exchange every two hours, eliminating the downcycle period completely. According to supervisor feedback, the VoltGuard system recovered up to 6 labour hours per day, across just 18 workers.

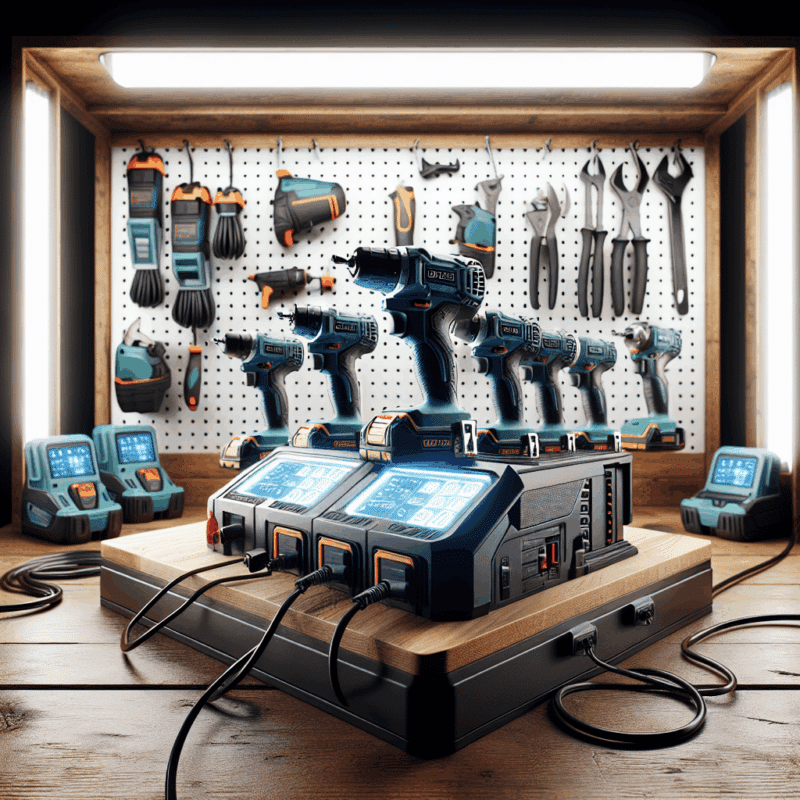

Smart Charging: Timers, Rotations and Notifications

Automation Meets Site Management

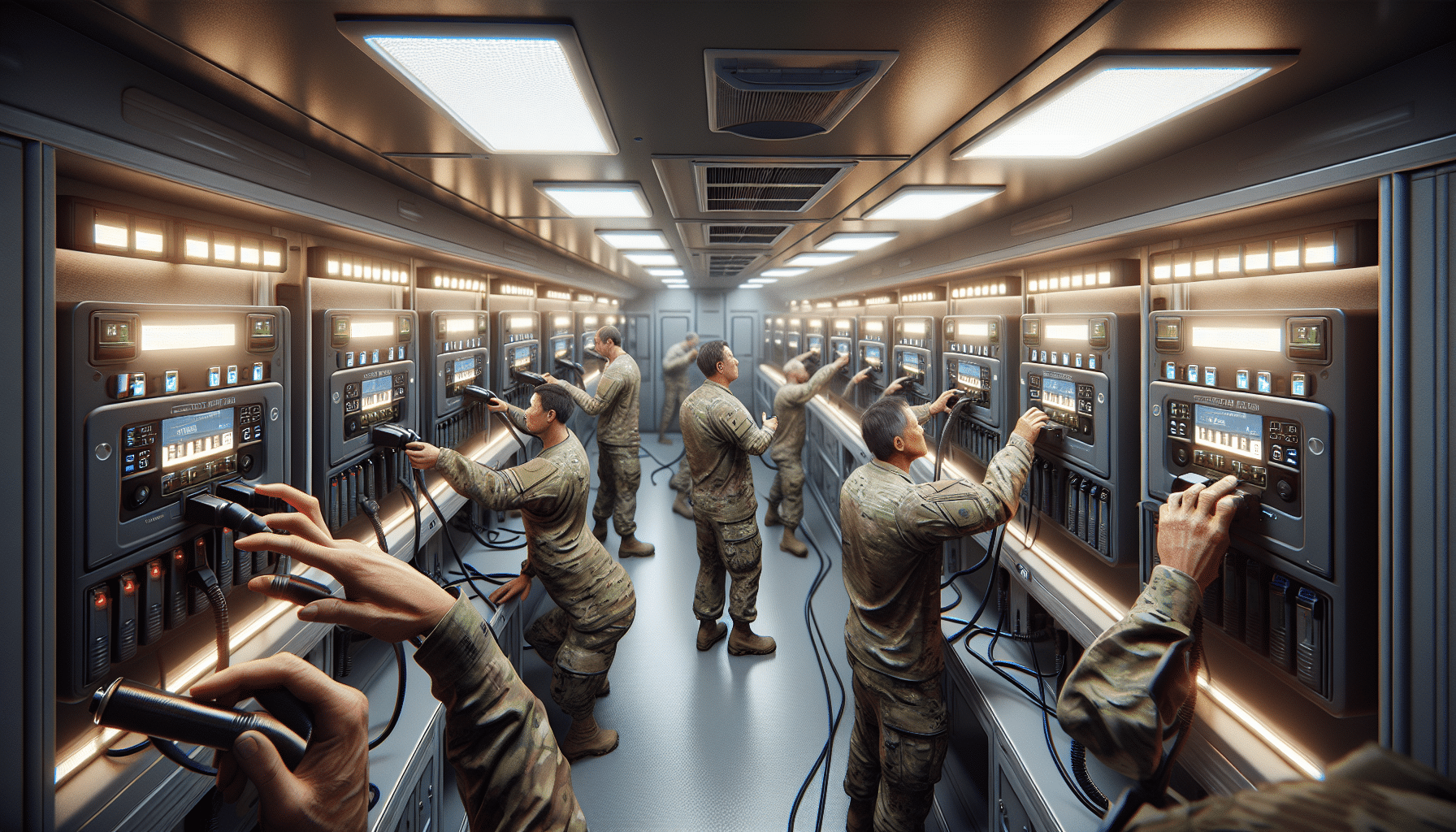

Scaling battery charging efficiently also means embracing automation. Smart chargers equipped with programmable timers can pre-condition batteries for peak usage hours. For example, by starting early-morning cycles automatically at 5:00 AM, fully charged tools await crews as they arrive. Charger rotation calendars—especially relevant on double-shift sites—ensure even wear across battery stock, extending lifespan and limiting maintenance downtime.

Professional Makita Battery Charging Strategies

Even more sophisticated systems integrate with IoT devices to send SMS or app-based alerts when batteries reach full charge, need inspection or have irregular temperatures. Such insights drastically improve your fleet’s performance and reduce resource waste due to overcharging or battery neglect. Implementing named-tag systems in combination with alerts has shortened average battery downtime by as much as 60% in field tests. Consider tying these to wider digital ecosystem platforms your operations already use. Learn more about Rapid Charging Solutions for Professionals

Common Pitfalls During Scaling

Underpowering, Overcrowding, and Inefficiency

Despite the benefits, common mistakes in scaling battery charging continue to disrupt workflows. One mistake is underpowering shared circuit lines. Contractors underestimate the power draw of six active chargers operating at peak load, often leading to tripped breakers or partial charge delivery. Another flaw is overcrowding chargers without corresponding increase in circulation or workflow mapping, leading to charger queues and tool shortages.

Inadequate labelling also remains a core culprit. Without a tagging system to indicate which battery belongs to which team, confusion multiplies and accountability erodes. To address such missteps, start with a micro-assessment of your current workflow, then incrementally adapt and test before full rollout. Leverage insights from related infrastructure scaling Read a related article or seek guidance from battery tech advisory councils Techniques for scaling website infrastructure.

Conclusion: Efficiency Powered by Planning

In evolving job sites, scaling battery charging must be regarded as a proactive strategic endeavour—not a reactive workaround. By understanding equipment compatibility, optimising charger layout, planning for safety, and leveraging smart technology, project leaders not only eliminate disruptions but build systems that sustain peak productivity. As demand for cordless operations increases, foresight in charging design becomes a competitive edge. Whether you are managing a three-person roofing crew or a forty-team civil project, success begins at the battery station. For deeper insights on adjacent tool system upgrades, visit: Automating strategies for multi-site scalability

Great guide on scaling-rapid-charging-from-diy-to-multi-team-sites – Community Feedback

How can rapid charging be scaled for large teams?

Scaling rapid charging for multiple teams requires choosing high-capacity chargers, such as multi-bay fast chargers, and positioning them in accessible site locations to ensure minimal downtime.

What’s the difference between DIY and professional charger setups?

DIY charger setups typically support low volume and fewer batteries, while professional setups prioritise speed, safety, and support higher tool turnover for team efficiency.

Are rapid chargers safe for continuous workplace use?

Modern rapid chargers with features like cooling fans and advanced protection circuits are safe for frequent use, supporting continuous site operations without damaging batteries.