Reduce Tool Spend: Prolong Tool Life with Advanced Charger Tech

In This Article

- Advanced chargers significantly contribute to power tool life extension through custom energy regulation.

- Battery health monitoring helps detect and prevent wear before it becomes damaging.

- Long-term tool spend is lowered through predictive maintenance and smarter charging.

- Premium features in smart chargers provide superior ROI in professional settings.

- Data-rich ecosystems improve decision-making and enhance operational efficiency.

Understanding Advanced Charging Tech

How Smart Chargers Protect Your Tools

At the heart of your power tool performance lies the unnoticed hero: the battery charger. In the pursuit of tool life extension, the adoption of smart, advanced charging systems represents a game-changing innovation. Unlike conventional chargers, smart chargers integrate microprocessors capable of tailoring the charge cycle based on the specific chemistry, temperature, and health state of the battery pack.

This customisation prevents undercharging or overcharging—two of the most common culprits that degrade batteries and shorten tool lifespan. Smart chargers continually monitor voltage levels and environmental data to deliver the optimal current and shut off once full charge is achieved. This prevents unnecessary stress on battery cells, directly resulting in longer-lasting tools.

Moreover, features like ‘eco-mode’, ‘cell-balancing’, and thermal regulation ensure that even under daily use, your tool’s battery remains in prime condition for as long as possible. Leveraging these capabilities enables professionals to optimise performance while minimising the frequency of expensive replacements—an essential step in true tool life extension.

Why Battery Health Matters

Signs of Wear and Preventable Damage

Battery health serves as the linchpin of power tool longevity. Deterioration often begins subtly, with diminished runtime and slower response speeds. These symptoms, if unchecked, will develop into more serious issues such as tool misfires, overheating, and ultimately complete failure. However, most battery-related failures are preventable with the integration of monitoring-oriented charging technologies.

Understanding the health indicators—like voltage retention, charge acceptance rate, and cell resistance—allows technicians to take targeted action early. Premium chargers provide diagnostics that alert users when batteries are operating outside optimal parameters. Addressing these issues proactively not only extends individual battery life but reduces overall wear and tear on the tool itself.

In industrial environments, battery stress is amplified due to repetitive cycles and environmental pressures. Smart chargers combat this by delivering adaptive energy flows based on real-time cell diagnostics. These safeguards compound over time, ensuring significantly greater tool life extension than traditional charging methods.

Cost of Replacing vs Protecting Tools

Long-Term Value Strategies

When evaluating the true cost of tool ownership, many overlook the cumulative expenses tied to frequent replacements. While the upfront price of an advanced charger may exceed that of a standard model, the cost-to-value ratio shifts dramatically when tool life extension is brought into the equation. Maintaining a tool for five to seven years rather than replacing it every two substantially reduces capital expenditure across departments.

To illustrate, consider a mid-tier hammer drill used daily on a construction site. If the battery is poorly maintained and replaced every 12 months at £100 per cell, that alone compounds to £500 over a five-year period. Add labour cost from downtime, disposal cost, and the environmental impact, and the figure climbs even higher. In contrast, using a data-integrated smart charger extends battery life by 50–100%, halving total expenditure over time, not to mention eliminating unanticipated failures.

The investment in premium charging technologies is not just about convenience. It’s a strategic financial decision designed to extend lifespan, reduce spend, and increase budgeting predictability across all tool-heavy operational sectors.

Best Practices for Workshop Efficiency

Tips That Make a Big Difference

Tool life extension is not achieved solely through better technology—but through implementing strategic daily practices. Start by organising your charging stations to ensure airflow around batteries, keeping them cool during charging cycles. Excessive heat is a primary factor in reduced battery lifespan.

Next, use batch logging or digital tracking sheets to monitor charge cycles. Many advanced chargers come equipped with memory modules or Bluetooth capability to pair with apps for easier logging. This data helps identify patterns that might otherwise go unnoticed, such as overuse of a single battery pack, or declining efficiency in an entire batch.

Also, adopt a regular inspection routine. Look for physical signs of wear like cracks, bulges, or fluid leakage. Train your staff to identify these red flags early. Combining digital monitoring with manual inspections provides holistic protection across all your power tools, leading to significant tool life extension.

Chargers That Do More Than Charge

Enhanced Features Explained

Modern smart chargers have evolved into multifunctional diagnostic hubs. At the simplest level, they regulate charge cycles. At the most advanced, they offer thermal imaging, voltage curve tracking, and fleet-based battery auditing. These features enable predictive battery maintenance, a critical advance in tool longevity strategies.

Temperature sensors prevent overheated charging sessions. This is particularly relevant in warmer climates or poorly ventilated sites. Also, smart chargers that perform individual cell balancing maintain consistent performance across the entire battery pack, ensuring that degradation does not begin prematurely in any weak cells.

USB ports and app connectivity allow users to store diagnostics and generate reports. This is immensely valuable for industrial environments where equipment maintenance compliance is legally mandated. These innovations increasingly support tool life extension by offering more ways to analyse, adjust, and protect daily tool use effectively.

Power Tool Spend Reduction Examples

Real Workshop Savings Stories

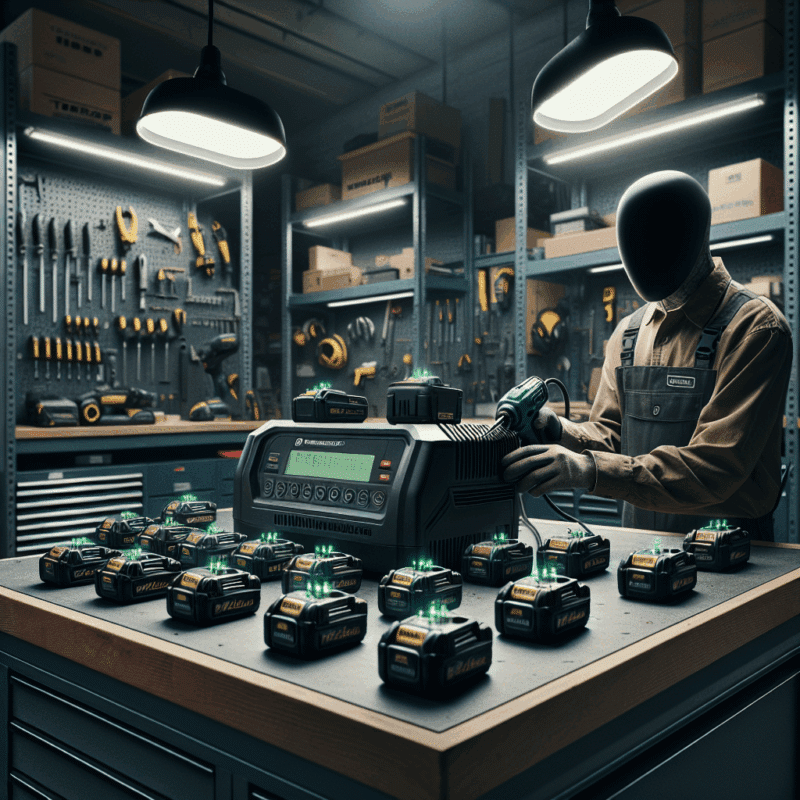

Over the years, countless workshops have pivoted to smart charging solutions with compelling financial outcomes. For example, a UK-based fabrication company recorded an annual 35% drop in tool-related capital spend simply by shifting to smart chargers across their fleet. Their tools previously lasted an average of two years, but post-upgrade, the lifespan extended to three-and-a-half years, reducing urgency around purchasing new equipment.

Similarly, on a housing development site in Manchester, foremen reported a 60% reduction in battery failures after equipping their teams with smart temperature-regulated chargers. They also found that workers altered behaviour to align with best practices once they had access to battery health feedback in real-time.

Adopting such smart systems is not just about technology—it changes workshop culture. By empowering staff with data and confidence in their tools, they become stakeholders in your tool life extension strategy—amplifying the cost savings across projects.

Comparing Charger Technology Tiers

Is Premium Worth It?

Tiered pricing in chargers reflects more than just brand premiums—it signifies the feature depth, build quality, and diagnostic power of the unit. Entry-level chargers are sufficient for hobbyists or occasional users, but they often lack intelligent circuit monitoring and temperature regulation critical for professional applications.

Mid-tier models introduce time-based cycling, short-circuit protection, and compatibility with multiple battery types. However, it’s in the premium category where tool life extension truly takes shape. These systems feature real-time analytics, app-based monitoring, and smart reconditioning modes that actively seek to restore lost battery performance.

In essence, the cost of premium technology is offset by the avoidance of battery failure, improved work continuity, and long-term equipment preservation. When accounting for the cost of idle labour due to tool delays, the financial argument for premium technology quickly becomes compelling. Expert strategies for longer tool life

Shop Smarter: Tools and Accessories

Matching Compatible Products

Another core aspect of tool life extension lies in compatibility. Mismatching chargers with batteries may seem negligible but can lead to chronic inefficiencies, voltage mismatches, and overheating. It is paramount to ensure that all accessories, connectors, and associated battery packs are manufacturer-approved or tested thoroughly for interoperability.

In addition, many advanced batteries and chargers offer ecosystem integration—meaning they share data, optimise performance, and even allow firmware updates. Investing in a closed-loop tool system ensures that components communicate seamlessly, reducing wear and optimising output.

By working within a trusted ecosystem, users are assured of superior quality control and extended lifespan thanks to unified operating standards. Learn more about Power Tool Maintenance & Efficiency

Maintenance Tips to Prolong Life

Checklist for Pro Users

Consistent maintenance serves as the foundation of any effective tool life extension strategy. To maximise performance, implement the following checklist in your workshop:

- Wipe tools and battery contact points after every use to prevent build-up of conductive debris.

- Store batteries at room temperature—avoid extreme cold or heat.

- Use intelligent chargers with built-in diagnostics and temperature regulators.

- Avoid running batteries to full depletion before recharging. Aim for 20–80% cycles.

- Labelling and rotating battery usage prevents overburdening singular packs.

- Update charger firmware if functionality is software-driven.

- Inspect charging ports weekly for signs of corrosion, dust or misalignment.

Following these routines rigorously will not only extend tool life but ensure safer, more reliable tool usage across all operational settings. Read a related article

Stay Ahead with Charging Data

How Monitoring Helps Efficiency

Today’s chargers are capable of producing logged output data, helping you make informed decisions. Data like charge time trends, temperature spikes, and usage frequency per cell can be used to write custom maintenance schedules or flag underperforming tools.

For fleet managers or operations supervisors, this data translates into visible ROI. Teams can analyse which batteries need proactive replacement and schedule maintenance downtime strategically—reducing surprise costs and increasing productivity. Furthermore, automated reports ensure accountability among users and transparent tracking of tool abuse.

Monitoring leads directly to more efficient processes and extended tool life. As data becomes the new benchmark, those adapting early will stay ahead operationally and financially. Streamline systems with AI-powered automation

“After integrating advanced smart chargers across our entire tool inventory, we saved over £4,000 in replacement costs in a single fiscal year.” — Operations Director, UK Civil Engineering Firm

Conclusion: Investing in Longevity

Tool life extension offers a multifaceted benefit schema: reduced capital expenditure, operational efficiency, environmental responsibility, and optimised performance. As demonstrated, advanced charging systems serve as a crucial enabler of these outcomes. From diagnostic capabilities to thermal monitoring and data tracking, the modern charger transcends its traditional role—evolving into a strategic resource of preventative maintenance.

When paired with compatible accessories, smart maintenance routines, and a commitment to data-driven operations, the result is not just prolonged equipment use—but an entirely transformed workflow. For professionals seeking predictability in budgeting, excellence in output, and sustainability in practice, the smart charger is indispensable.

Great guide on reduce-tool-spend-extending-life-advanced-charger-protection – Community Feedback

How does advanced charger protection reduce tool costs?

Advanced charger protection helps prevent battery damage, overheating, and overcharging, which reduces the frequency of tool repairs or replacements. This maximises battery lifespan and lowers the total spend on tools over time.

What strategies extend battery and tool life in workshops?

Use certified chargers with protection features, monitor charging data, keep batteries at optimal temperatures, and avoid over-discharging. Regular charger maintenance also supports longevity and reliable performance.

Are premium workshop chargers worth the investment?

Premium chargers typically offer superior safety features, faster charging, and better battery management, significantly extending your tool’s effective life and reducing overall maintenance costs.