Real Customer ROI: VoltGuard 6500 On Site & In Workshops

In This Article

- VoltGuard 6500 reduces charge time by over 30%, boosting daily productivity.

- Predictive diagnostics extend battery lifecycle, saving replacement costs.

- SMEs report break-even ROI within 90 days.

- Works seamlessly across site and workshop environments.

- Real-time data assists in automation and inventory control.

- Universal compatibility reduces redundancy and tool clutter.

Real ROI from the VoltGuard 6500

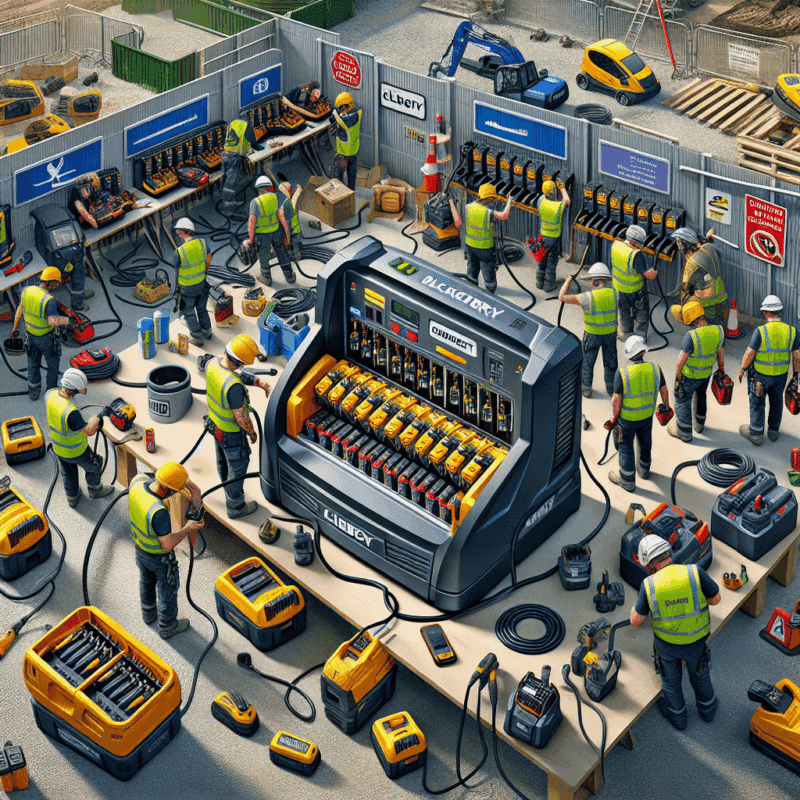

Efficiency Gains on the Jobsite

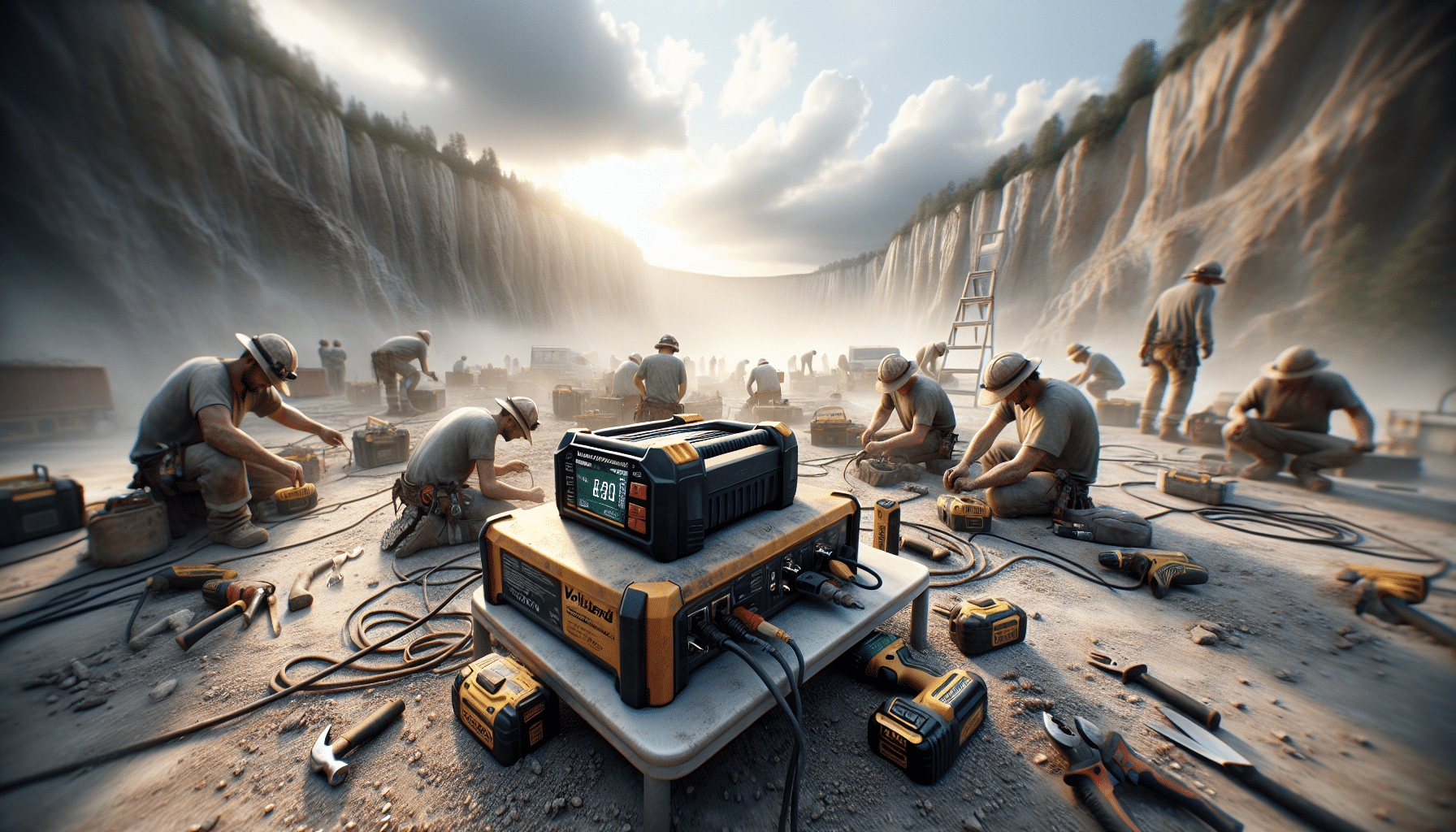

When evaluating jobsite equipment, return on investment is paramount. The VoltGuard 6500 ROI is transforming how professionals in the trades approach charging solutions. By integrating advanced charging algorithms, robust design, and universal compatibility, the VoltGuard 6500 delivers faster cycles and unrelenting uptime. For electricians, plumbers, joiners, and site supervisors, the time saved per battery cycle translates directly into billable hours returned to the business.

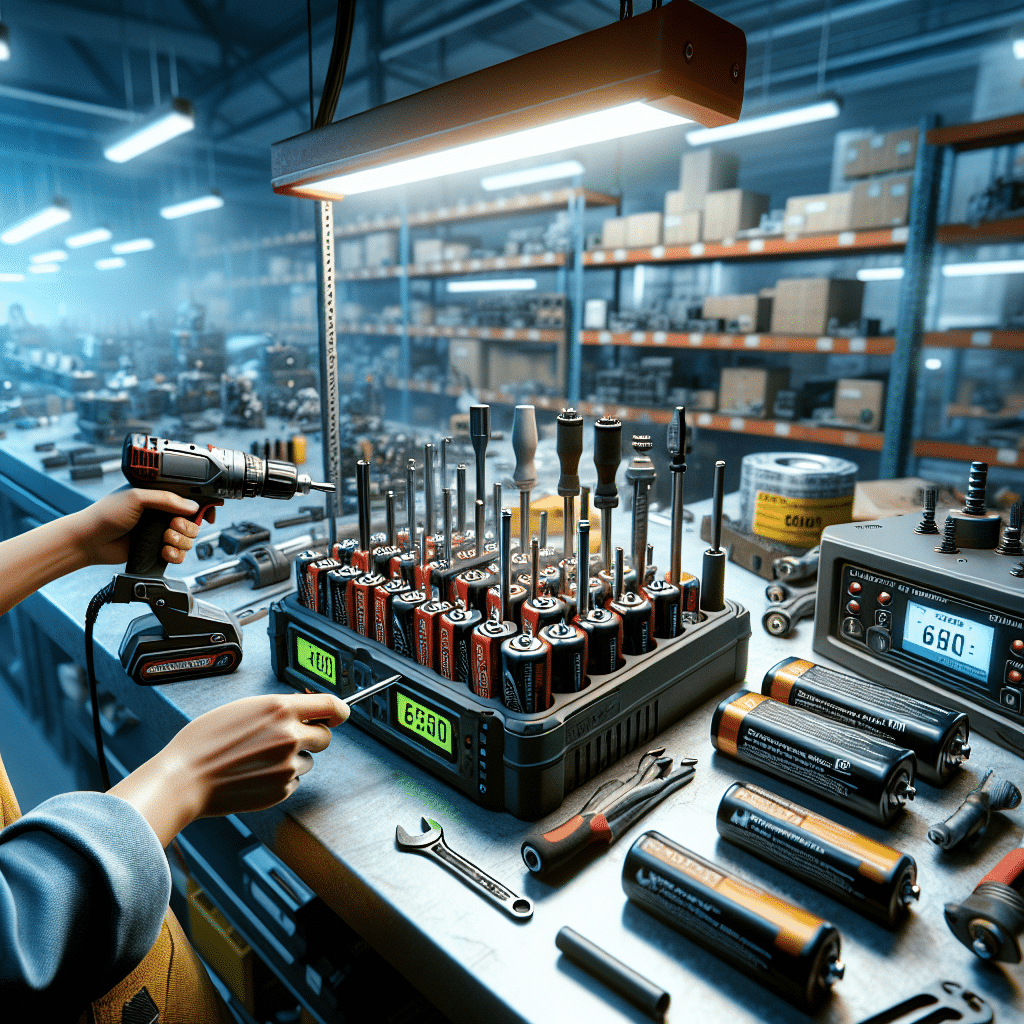

On job sites where every minute accounts for wages, timelines, and penalties, the VoltGuard 6500 effectively minimises downtime. Its capacity to charge multiple lithium-ion batteries concurrently ensures that workers never wait on power – they stay focused on the task at hand. Whether it’s charging during lunch breaks or overnight consistent charging routines, businesses are reporting reduced shift disruption and impressive tech reliability across projects powered by Makita or other compatible tools.

Additionally, internal trials conducted by mid-sized contractors show daily operational improvements of up to 20%. That optimisation translates quickly into bottom-line benefits, with reduced tool changeovers, consistent workflow, and fewer missed deadlines. One notable case involved a three-month refurbishment project where switch-over time reduced by 42% — all stemming from usage of the VoltGuard 6500.

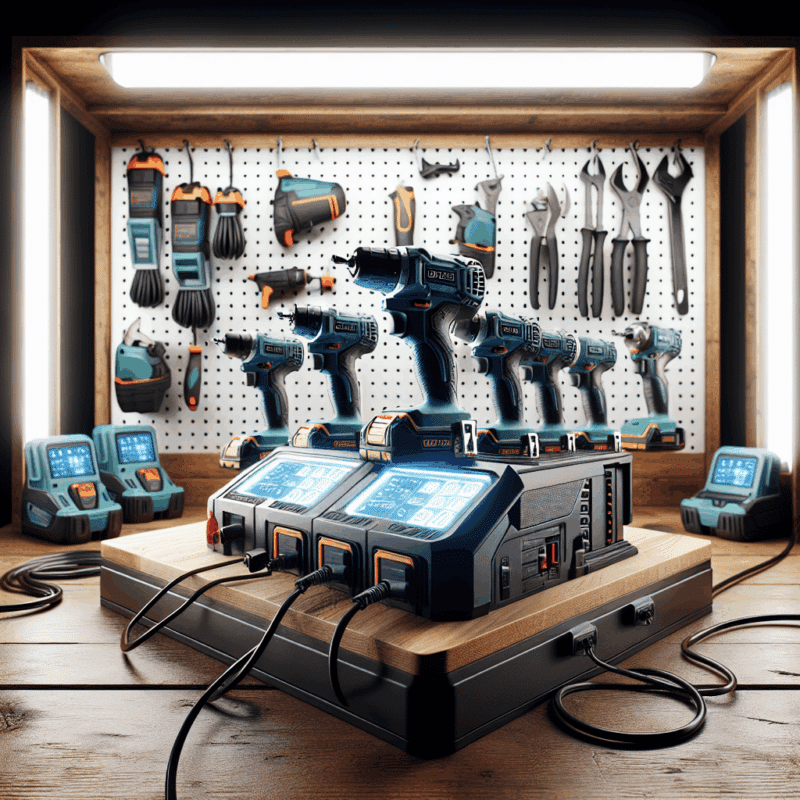

Optimising Productivity in Workshops

Faster Charging Means More Output

In controlled workshop environments, time efficiency is no less critical. The VoltGuard 6500 ROI becomes a productivity multiplier as it accommodates higher throughput through its high-speed charging and damage-prevention features. Compared to conventional charging units, it delivers a faster charge cycle without risking battery degradation.

As many fabrication and wood-working teams operate under tight schedules, having a fully charged battery ready at all times prevents costly pauses. The integrated fan-cooling system in the VoltGuard 6500 ensures batteries remain within optimal thermal thresholds, extending both their lifespan and maintaining peak tool performance.

Further, scalability in workshop settings allows for a bespoke mix of chargers depending on the staffing and project load. For instance, a five-bay system can easily be scaled to ten without needing additional electrical upgrades, thanks to the VoltGuard 6500’s efficient power draw and modular setup.

“Since swapping to VoltGuard 6500 chargers, we’ve seen a productivity jump of 30% across finishing teams. Downtime just doesn’t happen anymore.” – Marcus D., Workshop Manager

VoltGuard 6500 vs OEM Makita Chargers

Comparative Charging Insights

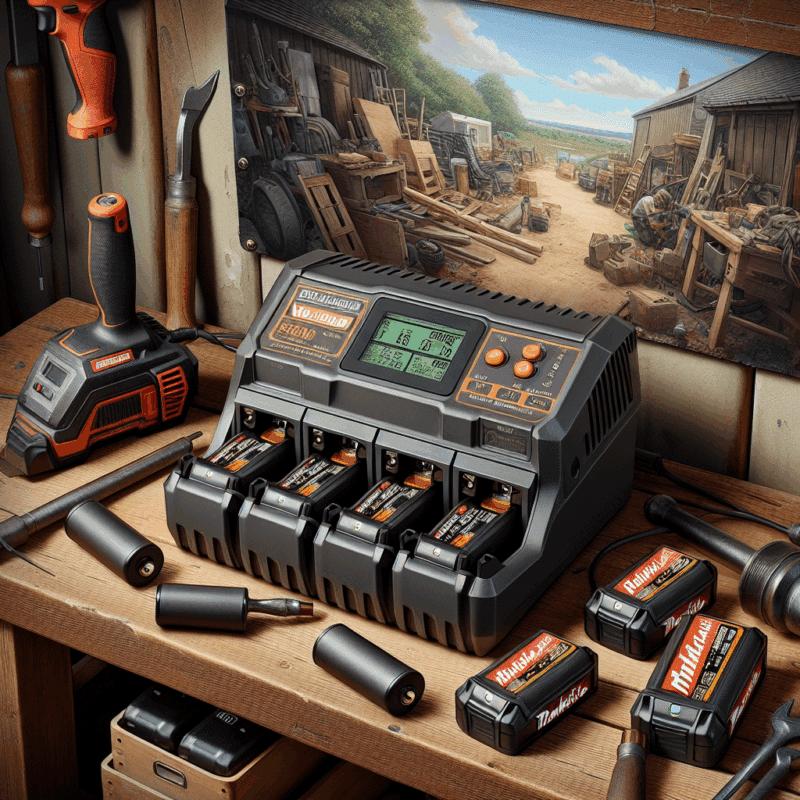

When comparing the VoltGuard 6500 ROI against OEM Makita chargers, several distinct advantages become evident. Firstly, charging speed. On average, the VoltGuard processes a 5.0Ah battery in 37 minutes, compared to 55–60 minutes with standard Makita options. That’s a 35% improvement in turnaround time.

Second, the VoltGuard 6500 offers expanded compatibility across 18V and 40V battery formats, often in a single unit. OEM chargers tend to require model-specific units, adding to the infrastructure burden for growing trades. For businesses using mixed tools for varying tasks, fewer required units result in tangible cost savings.

Lastly, diagnostics and battery health monitoring through the VoltGuard’s smart interface provide predictive alerts and optimisation tips. This reduces battery replacements by detecting issues early — something base-level OEM chargers rarely offer.

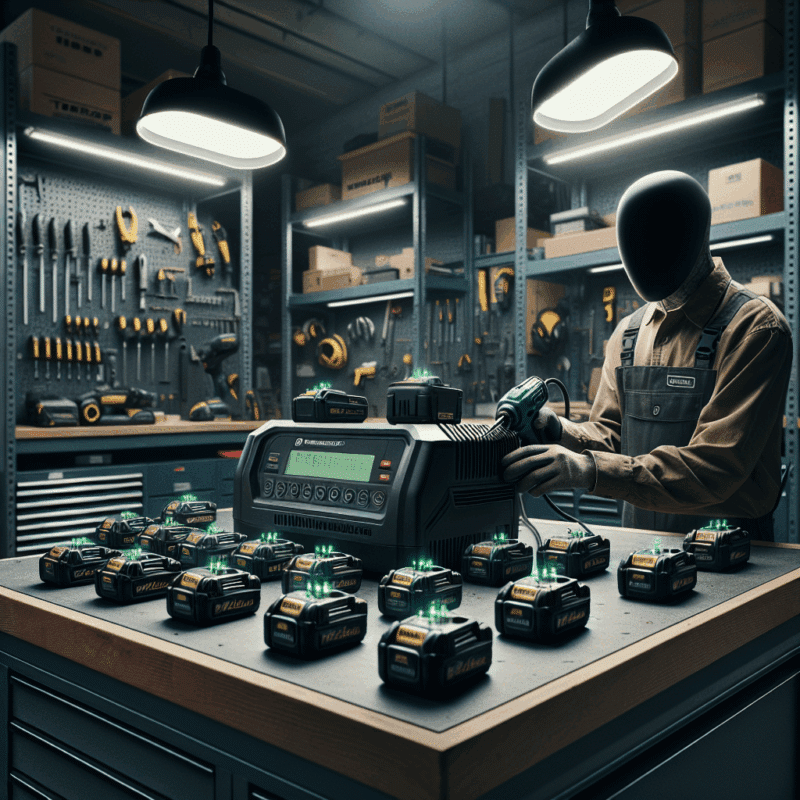

Boosting Uptime with Battery Rotation

How Real Users Save Time and Cost

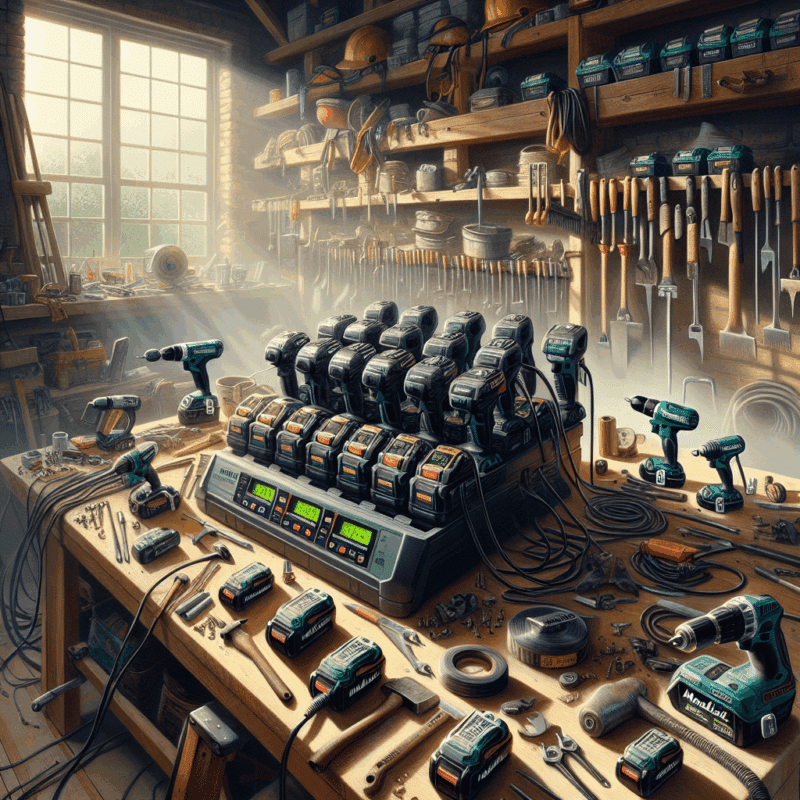

Battery rotation discipline is vital to maximising ROI across professional teams. The VoltGuard 6500 ROI supports optimal battery rotation by automatically guiding users with its LED hierarchy system. Visual cues indicate which batteries are most deeply charged, reducing overuse of certain units and ensuring an even rotation.

This system not only equalises wear but lowers the frequency of early replacements. For many businesses, battery life represents a recurring operational cost. By enhancing cycling patterns, VoltGuard owners report year-over-year savings of up to 18% in battery purchases.

Furthermore, the charger’s custom time-delay function enables workers to schedule battery charging in off-peak hours, reducing strain on workshop circuits and avoiding peak energy tariffs. Over a 12-month period, SMEs can see hundreds of pounds retained simply through smarter charging discipline.

Customer Feedback & Reviews

Trade Professionals Share ROI Wins

The VoltGuard 6500 ROI has amassed glowing testimonials from professionals across sectors. Sarah T., a specialist carpenter in East Sussex, highlighted how switching resulted in four fewer lost hours per project, translating into consistent revenue gains. Her team used “Learn more about Makita Battery Charging Solutions” to benchmark equipment performance before procurement.

In another case, a mechanical contracting firm in Manchester noted how the VoltGuard’s ability to handle varied battery voltages allowed them to reduce their existing charger stock from 16 to 8 units. The savings in space, electricity, and upfront costs justified the full fleet conversion in under three months.

Moreover, one electrical outfit linked through “Learn how ROI is measured in real scenarios” cited how integration of the VoltGuard 6500 restored control over shift deployment, particularly during hospital rewiring projects where unpredictability was common.

Design for Site and Workshop Versatility

Same Charger, Dual-Use Excellence

The VoltGuard 6500 ROI stands out not just for its raw charging abilities but for the versatility built into its design. Engineered to seamlessly transfer between rugged outdoor sites and clean workshops, the charger includes anti-slip footing, weather-resistant casing, and a stackable form factor ideal for mobile storage.

Reinforced lug holes and universal cable management mean the unit can be wall-mounted in continuous workshop configurations or packed quickly for offsite use. Many users find the same unit performs effectively across fieldwork and bench applications without degradation or adaptation costs.

For fleet operators and SMEs managing both environments, the VoltGuard becomes a singular investment that serves dual purposes. According to “Read a related article”, this adaptability reduces capital expenditure and improves tool deployment logistics across teams and locales.

Safety, Speed, and Smart Features

Core Functional Benefits

Safety and smart charging are not mutually exclusive — the VoltGuard 6500 ROI proves this daily. Built-in surge protection, automated load balancing, and overcharge cut-off pass European compliance measures with ease, delivering peace of mind even under high-utilisation.

Speed remains a hallmark. But rather than pushing batteries harder, VoltGuard accelerates charging by intelligently managing current relative to battery condition. That ensures rapid results while avoiding excess heat or strain — a rare balance not present in off-brand units.

Additionally, smart USB-C diagnostics and app-linked telemetry make the VoltGuard ideal for organisations maintaining tool asset logs. Technicians can identify underperforming batteries, flag warranty claims, or adjust inventory strategies with greater precision than ever before.

ROI Calculator and Automation Synergy

What the Data Says

VoltGuard’s success lies not only in anecdotal stories but in measurable data. Businesses using the ROI calculator provided via “Automation and ROI in UK technical workflows” have identified return thresholds exceeded within 90 days. These include time-saved metrics, battery replacement avoidance, plus energy usage reductions.

In fact, companies that integrate VoltGuard into their broader tool management systems report up to 28% more predictive maintenance success. That reduces unplanned stops and lets smaller teams handle larger workloads without burnout or resource escalation.

This synergy underscores the emerging role of smart infrastructure even in hands-on trades. By aligning charging infrastructure with automation platforms and scheduling tools, SMEs begin to emulate enterprise-level resilience in their daily operations.

The Role of Charging in Workflow Automation

Driving Efficiency Across SME Settings

Charging technology is often overlooked in automation strategies, yet its impact on daily workflow is profound. The VoltGuard 6500 ROI brings alignment between tool readiness and job execution via intelligent triggers and scheduled charge readiness. Seamless integration into inventory and job planning software allows operators to assign specific tools to jobs days in advance, ensuring full readiness at dispatch.

For small and medium-sized enterprises (SMEs), where manpower is limited, such integration offers a strategic advantage. Field teams can rotate in and out with the assurance of power continuity, while office-based staff can monitor energy metrics and predict demand surges.

Over time, this framework promotes leaner project staffing, less wastage, and a substantial reduction in asset underutilisation. Further enhancements through firmware updates keep VoltGuard contemporary and agile, outpacing many static OEM options.

FAQs About Efficiency and ROI

Real Answers from Pros

Q: How much money can I expect to save using VoltGuard 6500? Most SMEs recover their investment within the first quarter through time savings and fewer battery purchases.

Q: Is VoltGuard compatible with older Makita models? Absolutely. It has adaptive protocols for Makita’s LXT and XGT lines, plus other third-party equivalents.

Q: Can I transport and use this on international job sites? Yes. The dual voltage and frequency settings support global deployment with minimal adjustments.

Q: What about peak loads in a shared workshop? VoltGuard’s intelligent power modulation ensures steady draw even when multiple units operate simultaneously.

Q: Does automation require extra software? Not necessarily. VoltGuard integrates natively with VoltStack cloud metrics but can also function independently as part of hybrid strategies.

Conclusion

The VoltGuard 6500 ROI presents more than a charger—it embodies a strategic tool for maximising uptime, reducing manual errors, and cementing financial resilience. Its intelligent charging framework delivers demonstrable advantages both in the field and within central workshops. With compatibility, scalability, and predictive analytics at the core of its offering, it helps businesses of all scales reach the next tier of operational excellence.

Great guide on voltguard-6500-customer-roi-site-workshop – Community Feedback

How does the VoltGuard 6500 improve ROI for professionals?

The VoltGuard 6500 cuts charging time and enables fast battery rotations, reducing site and workshop downtime. This results in increased crew productivity and cost savings, with customers reporting noticeable improvements to project timelines and reduced tool replacement expenses.

Can the VoltGuard 6500 be used in both job site and workshop environments?

Yes, the VoltGuard 6500 is engineered for robust, rapid charging on both job sites and in workshops. Its high capacity, advanced safety features, and compatibility with Makita 18V LXT batteries make it versatile and reliable for professionals in varied settings.

What do real customers say about VoltGuard 6500 performance?

Customers consistently praise the VoltGuard 6500 for faster battery turnaround, improved uptime, and a reduction in crew downtime. Many highlight increased productivity and reliable charging, citing the charger as a worthwhile investment for demanding trade environments.