Prevent Downtime: Integrate Fast Charging Policies in Your Workshop

In This Article

- Prevent unplanned downtime by adopting structured fast charging policies.

- Choose Makita-compatible chargers with thermal protection and cycle balancing.

- Organise dedicated, well-labelled charging zones for improved efficiency.

- Use voltage and charging data for predictive maintenance decisions.

- Train all staff on battery rotation and safety protocols regularly.

Why Unplanned Downtime Derails Productivity

Hidden Costs of Tool Inactivity

To prevent unplanned downtime, it’s critical to understand its hidden costs. Downtime interrupts project timelines and erodes efficiency, but many overlook the underlying expense of idle tools and workers. When a cordless power tool runs out of charge mid-task and no fully charged battery is available, immediate workflow disruptions occur. Multiply this by multiple teams on large sites and you’re facing both direct costs—such as overruns on project delivery—and indirect ones, like reduced employee morale and customer dissatisfaction.

Tool unavailability contributes to poor resource allocation and wasted labour hours. Teams either wait for charged batteries or are forced to reallocate jobs, derailing unit productivity. Of equal concern is the wear and tear improperly managed battery cycles can impose on tools. With each cycle, performance degradation becomes likely unless charge routines are optimised. Integrating smart charging solutions into daily workflows no longer remains optional—it is a required element of maintaining uptime and safeguarding market competitiveness.

What Is a Fast Charging Policy?

Core Concepts Powering Modern Workshops

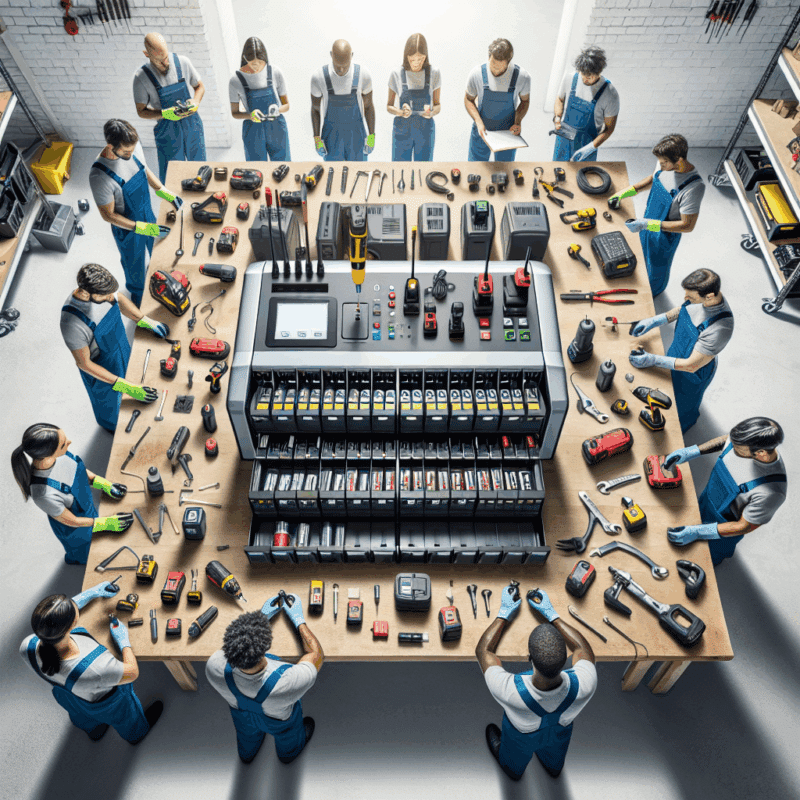

A fast charging policy is a structured strategy that governs how batteries are charged, swapped, and managed within a workshop or field operation. The concept aims to prevent unplanned downtime by ensuring that batteries are always available, reliable, and operating at peak capacity. At its core, this policy includes guidelines around charger placement, battery rotation, and charger selection—all tied to usage timing and team shift patterns. By prioritising charge speed and battery availability, workshops can service more clients, finish jobs promptly, and reduce idle periods significantly.

Fast charging policies are especially beneficial when integrated with tools such as rapid Makita-compatible chargers, which dramatically reduce charge times. More so, these chargers can offer safety features including voltage regulators and heat monitors. Combine that with digital tracking systems and you gain data on charge cycles, battery health, and tool readiness. This structured approach forms the backbone of a well-optimised operation capable of scaling without quality compromise.

Benefits of Integrating Charger Routines

Going Beyond Convenience to Cost Savings

Among the clearest benefits of an integrated charging routine is the ability to prevent unplanned downtime through streamlined availability. When chargers are positioned strategically and usage cycles are tracked, teams no longer need to double-check if batteries are charged or waste precious time mid-task. Instead, routine ensures that fully charged devices are always within reach, optimising uptime across the board.

Another significant advantage lies in cost reduction. Implementing fast charging disciplines accomplishes this by reducing battery replacements. Properly cycled and cooled charging leads to extended battery lifespans, lowering purchasing frequency. Moreover, efficient energy use through smart chargers also translates to reduced utility costs. On high-volume sites, even small savings per charge compound substantially over time.

Beyond this, a well-managed charging routine supports compliance with safety protocols. By standardising who handles battery changes, where charging occurs, and during what periods, the likelihood of overheating, overcharging, or short circuit faults is substantially diminished.

Choosing the Right Makita-Compatible Fast Charger

What to Look for in Specs, Speed, and Safety

When selecting a Makita-compatible fast charger, several key features should guide your decision. First is the charging time. Look for models that can bring a standard 18V Li-ion battery to full charge in under 30 minutes. This may vary slightly depending on amperage but remains a good benchmark. Many Makita chargers are built with optimal cooling systems and can rebalance cell voltages, preserving battery life and efficient cycles—essential in the effort to prevent unplanned downtime.

Safety certifications are crucial. Look for CE-compliance and integrated thermal protection systems to prevent overheating. Additionally, ensure the charger automatically shuts off once full charge is achieved; this feature minimises risk and unnecessary energy wastage. Compatibility across multiple Ah ratings—such as 1.5Ah to 6.0Ah—is also beneficial for teams operating with diverse battery capacities.

On workshops involving multiple users, charger visibility also matters. Status indicators—LED lights or digital displays—are helpful for tracking progress at a glance. For a deep dive into selecting gear that’s built to last, check out Learn more about Workshop Efficiency & Power Management.

Best Practices for Multi-Team Sites

Fast Charging at Scale

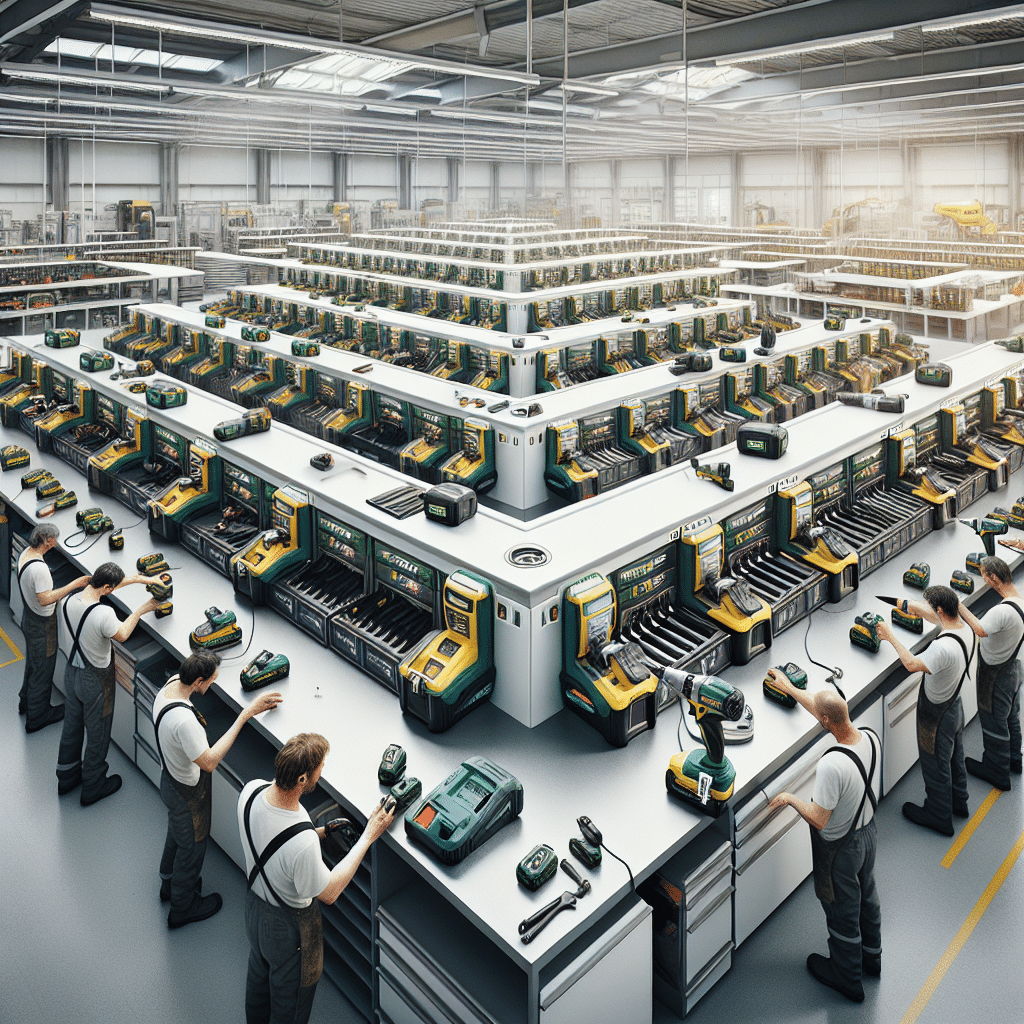

Scaling fast charging across a multi-team operation requires careful coordination. Each team should have allocated battery kits, with routines clearly aligned to shift timings. Implementing a group rotation system where discharged units are placed in a queue, and charged units are segregated, ensures symmetry across equipment availability. Without this structure, bottlenecks emerge—particularly during peak activity phases—leading inevitably to costly delays.

Assign a charge steward for each team responsible for overseeing their battery inventory and usage logs. This small procedural shift increases accountability and reduces instances of lost or undercharged batteries. Additionally, standardising charger models across all teams ensures interoperability, reducing confusion and improving efficiency.

Communication boards near charging zones can also inform users about unit availability and any charger faults reported. Consider linking your internal device readiness data directly to your site’s project scheduling software via digital sync. Doing this creates real-time visibility into resource readiness. For even better integration, refer to Read a related article.

Organising Dedicated Charging Zones

Practical Layout Tips for Efficiency

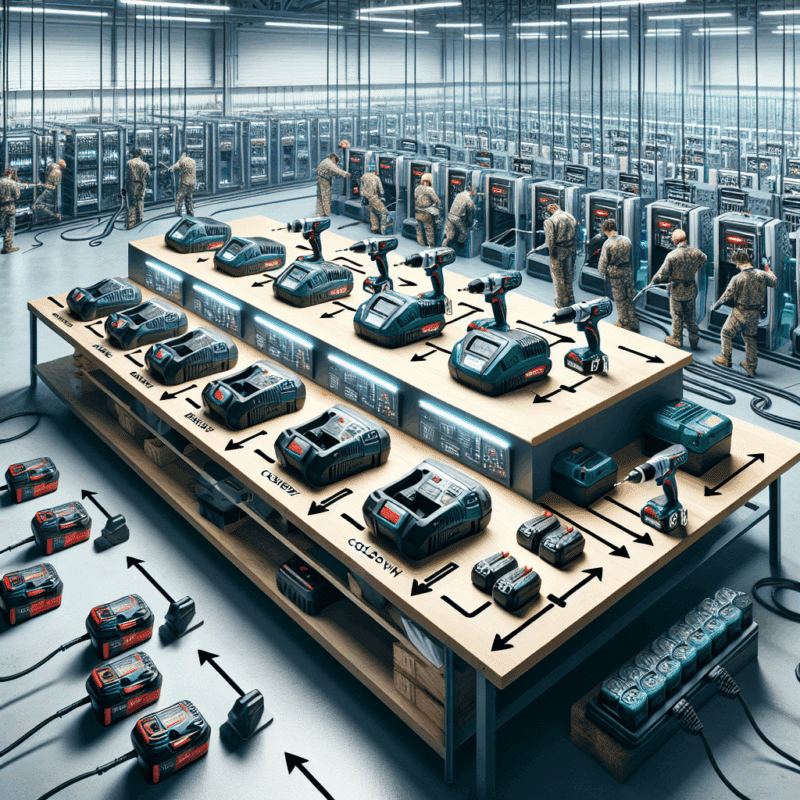

Designating an area strictly for charging makes a substantial impact on battery policy success. Centralised charging bays located near high-traffic tool returns make for quick and effective deployments. Ensure each station is well-ventilated, away from flammable materials, and has ample wall access for cable organisation. Labelling each bay clearly reduces confusion during peak use windows.

Where floor space is limited, vertical racking systems can support several charger mounts securely. Power sockets should support simultaneous load without risk of tripping breakers. For safety, conduct an energy load test to ensure the site grid can handle multiple fast chargers operating at once.

Colour-coded bins or hooks—indicating ‘Charged’, ‘Charging’, and ‘Needs Charging’—help visualise battery status. This tactile system complements more advanced digital dashboards, particularly on high-movement field sites where digital monitoring isn’t always accessible.

Data Monitoring for Downtime Prevention

Using Voltage & Amp Info to Plan Ahead

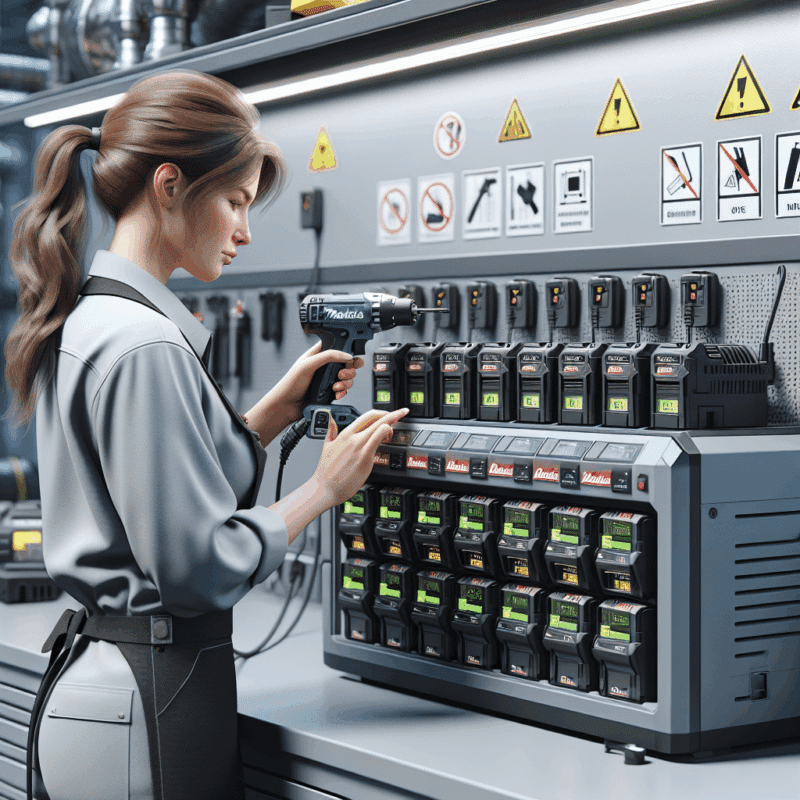

To consistently prevent unplanned downtime, it’s essential to harness battery charge data effectively. Modern Makita-compatible chargers often offer output tracking through digital interfaces. Measuring real-time voltage and amperage provides insights into charge efficiency, battery health, and potential degradation. Logging and comparing charge cycles allow predictive decisions around when a battery may need repair or replacement, avoiding sudden failures impacting tool usability.

AI tools that analyse this usage data can send alerts for malfunctioning units or when charge irregularities occur. Maintenance teams can then address minor faults before they escalate into major project interruptions. Over time, this data builds historical reliability scores for each battery pack, allowing sites to schedule replacements and upgrades before a slow decline affects operations. Learn how other companies are applying this technology via case examples at Reduce unplanned downtime in production environments.

Top Charging Policy Mistakes to Avoid

Don’t Let Fast Become Faulty

Many operations aim to prevent unplanned downtime but fall into common traps when implementing fast charging systems. A major misstep is overloading single power circuits with multiple chargers, leading to tripped breakers and charge interruptions. Another is failing to rotate batteries in and out of use regularly. Letting batteries sit for extended periods—fully charged or completely depleted—drastically shortens their lifespan.

Charging in unventilated areas or in direct sunlight can lead to dangerous thermal spikes. Furthermore, not documenting cycle usage often leads to over-reliance on aged batteries that degrade unexpectedly. To maintain safety and performance, avoid mixing third-party, incompatible chargers with Makita batteries. While devices may connect physically, mismatched voltage ratings risk both charger and battery damage. For additional technical advice, examine the manufacturer guidelines outlined at Boost team performance with real-time tracking.

“Integrating high-efficiency chargers and a proper policy reduced our tool-related downtimes by 40% within three months.”

Installation Tips for Rapid Charge Stations

Power Access, Safety, and Cable Management

Installing a rapid charge station should begin with power planning. Ensure supply lines can handle continuous high-voltage operation without fluctuation, especially in older buildings with dated wiring. Shield circuits with dedicated fuses to isolate charger load from general operations. Wall-mounted or benchtop installation should use flame-retardant materials, bolted reinforcement brackets, and waterproof rated sockets if exposed to damp conditions.

Cable organisation is paramount. Use trunking or secure cable wraps to eliminate trip hazards. Ground wires must comply with local electrical regulations, and all installation should be documented in compliance logs. Consider surge protection as a part of your setup—it not only protects the chargers but also safeguards every attached battery. Periodic inspections should be scheduled monthly to ensure ongoing safety and to reduce risk of fire or malfunction.

How to Train Teams on Charging Protocols

Culture of Preparedness

A charging policy is only as strong as the people following it. Train new and existing employees on identifying optimal charge timings, battery rotation procedures, and fault reporting protocols. Avoid assuming familiarity—schedule re-certification sessions every quarter and document all training records.

Hands-on workshops combined with visual signage near stations improve retention. Use example scenarios showing the consequences of incorrect charging or overuse. Create team incentives that reward uptime improvement metrics or fewer charge-related incidents. Most importantly, make charging responsibility part of each worker’s role accountability, not a secondary task left to chance.

Key Takeaways for Workshop Uptime

Integrating a robust fast charging policy is no longer a luxury—it is a mission-critical protocol to prevent unplanned downtime and support consistent productivity. By focusing on the right charger selection, training, installation, and data integration, workshops can maintain tool availability, improve safety, and save on costs across the project lifecycle. Don’t wait for the next job to stall due to a flat battery—empower your site team with the right preparation today.

Great guide on prevent-unplanned-downtime-integrate-fast-charging – Community Feedback

How do fast charging policies help prevent unplanned downtime?

Fast charging policies minimise tool idle time by ensuring batteries are ready when needed. They reduce workflow disruptions, supporting scheduled tasks and maintaining overall workshop efficiency.

What are best practices for implementing charging policies in multi-team environments?

Designate clear charging zones, schedule regular battery swaps, adopt multi-bay fast chargers, and communicate charging routines to all team members for seamless operations.

How can battery data help reduce downtime in workshops?

Monitoring voltage and amp metrics alerts users to battery health or charging issues early, allowing proactive maintenance and ensuring batteries are always ready for use.