Precision Charging: Why LCD Data Matters for Battery Output

In This Article

- Precision charging relies on LCD feedback for actionable performance improvements.

- Real-time data reduces overcharging risks and extends battery life.

- Professional workflows benefit from efficient, strategic charging schedules.

- Makita-compatible chargers require voltage and amp compatibility specifics.

- Smart chargers are indispensable in multi-unit workshops or shared team environments.

The Importance of Real-Time Charge Data

How LCD Screens Provide Live Feedback

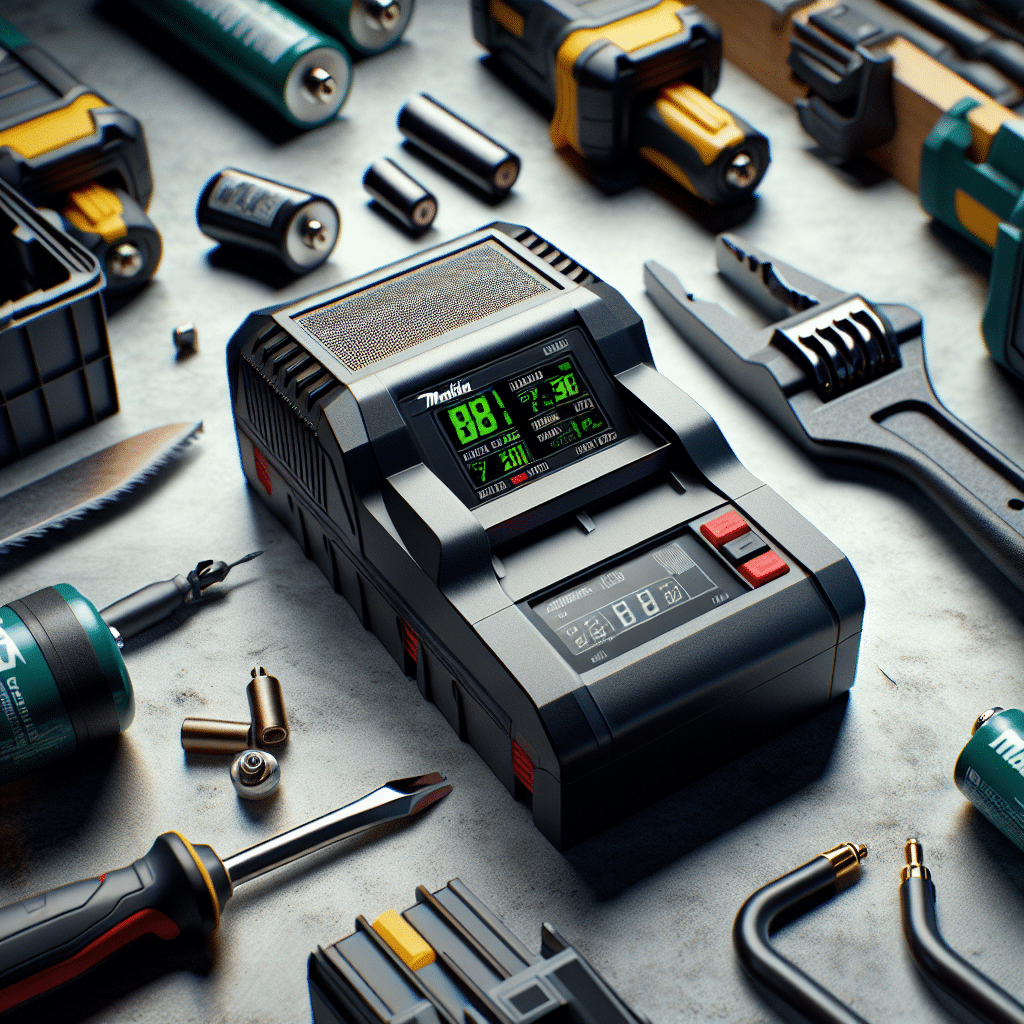

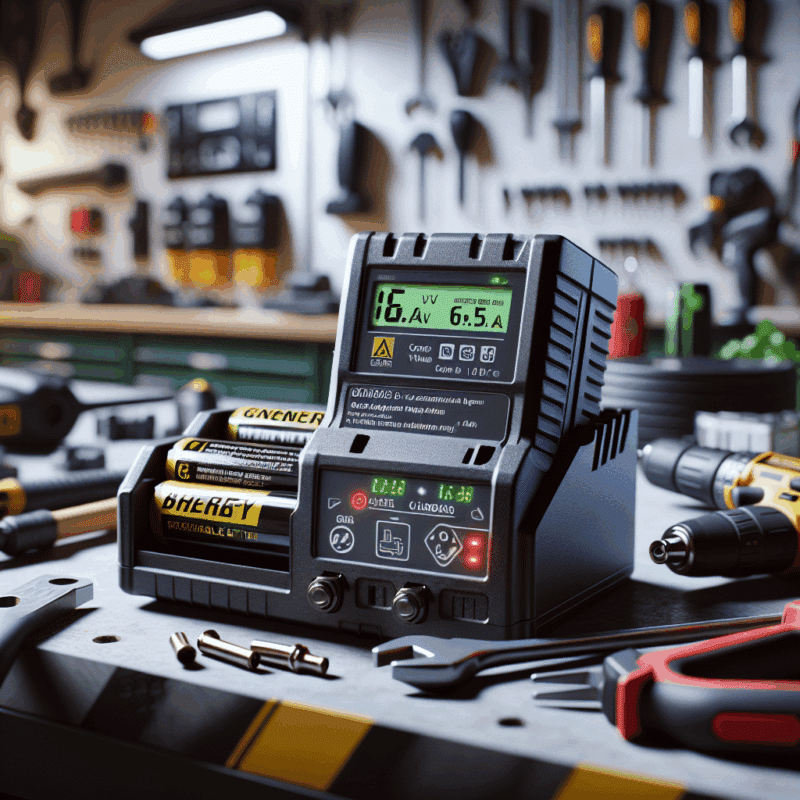

Precision charging begins with knowing exactly what your battery is doing in real time. LCD screens fitted into modern chargers enable a dynamic flow of data that includes exact voltage levels, current draw measured in amps, charge percentages, estimated time remaining, and temperature readings. Rather than relying on vague LED indicators, users now gain tangible insight into each element powering their toolkits. This real-time visualisation is essential not just for convenience but also for strategic energy management on-site.

For professionals using Makita-compatible LXT batteries, precision charging brings an entirely new dimension of control. Once a battery is docked, the LCD monitor immediately displays status feedback within seconds. The user can determine if the battery is trickle charging, fast charging or experiencing thermal throttling. These insights allow for better job planning since teams can predict exactly when batteries will be ready for service again. Without this visibility, the risk of idle time and operational disruption grows significantly.

Improving Battery Health Through Monitoring

Using Voltage and Amp Displays Effectively

One of the chief advantages of precision charging is the role it plays in maintaining battery longevity. Li-ion batteries—such as those used in Makita tools—degrade if repeatedly subjected to overcharging, overheating or rapid charge rates. LCD chargers solve this by offering continuous tracking of both voltage (V) and current (A). When voltage rises too high toward the battery’s maximum threshold, users know it is time to end the charge cycle or switch to balanced charging mode.

Amp readings also provide essential intelligence. A battery drawing excessive amperage during charging could indicate internal resistance issues, thereby informing preemptive replacement or servicing. Conversely, understanding amp draw patterns lets users segment batteries for different workloads—charging high-amp batteries slower, for example. Ultimately, the ability to monitor power flow at this level drastically improves safety and extends useful battery life, saving money and reducing waste.

“Monitoring charge data via LCD is no longer optional—it’s the professional standard for reducing battery mortalities and improving predictive maintenance.” — Battery Engineer, UK Construction Alliance

Boosting Jobsite Output with Smart Charging

Why Performance Relies on Accurate Charging

Efficient charging isn’t about speed alone. It’s about accuracy, adaptability, and performance synchronisation. In a live jobsite environment where cordless tools are mission-critical, the introduction of precision charging through intelligent LCD-equipped units marks a revolution in productivity. Knowing the exact state of each battery allows workers to prevent downtimes and schedule workflows methodically. For example, when multiple teams rely on shared batteries, real-time data allows for equitable rotation and uninterrupted usage.

Workers can quickly identify which battery is closest to full charge, switch tools mid-use and avoid thermal saturation that compromises long-term performance. Particularly in colder climates or high-humidity environments, precision charging also helps dictate when batteries require acclimatisation. This ensures jobsite performance remains optimal regardless of environmental challenges. Strategically empowering charging routines can uplift daily project output by up to 25%.

Avoiding Overcharging & Preventing Faults

Data Alerts That Warn Before Damage Occurs

Traditional chargers stop charging once a preset time elapses or when voltage hits a basic threshold. While functional, this ‘safe mode’ doesn’t always account for performance anomalies. LCD units take a smarter approach with precision charging alerts. Indicators include threshold breach notifications, unusual amp draw patterns, or overheating risks. These alerts enable early response before damage sets in, preserving both charger and battery integrity.

For example, if a battery starts cycling erratically between voltage levels during a recharge, that data is flagged visibly. Some models even incorporate beep alerts or Bluetooth connectivity for mobile notifications. For tradespeople managing high-value equipment portfolios, such proactive fault detection is invaluable. It helps them intervene and prevent cascade failures—like a faulty battery damaging a charger, which in turn compromises the entire charging station.

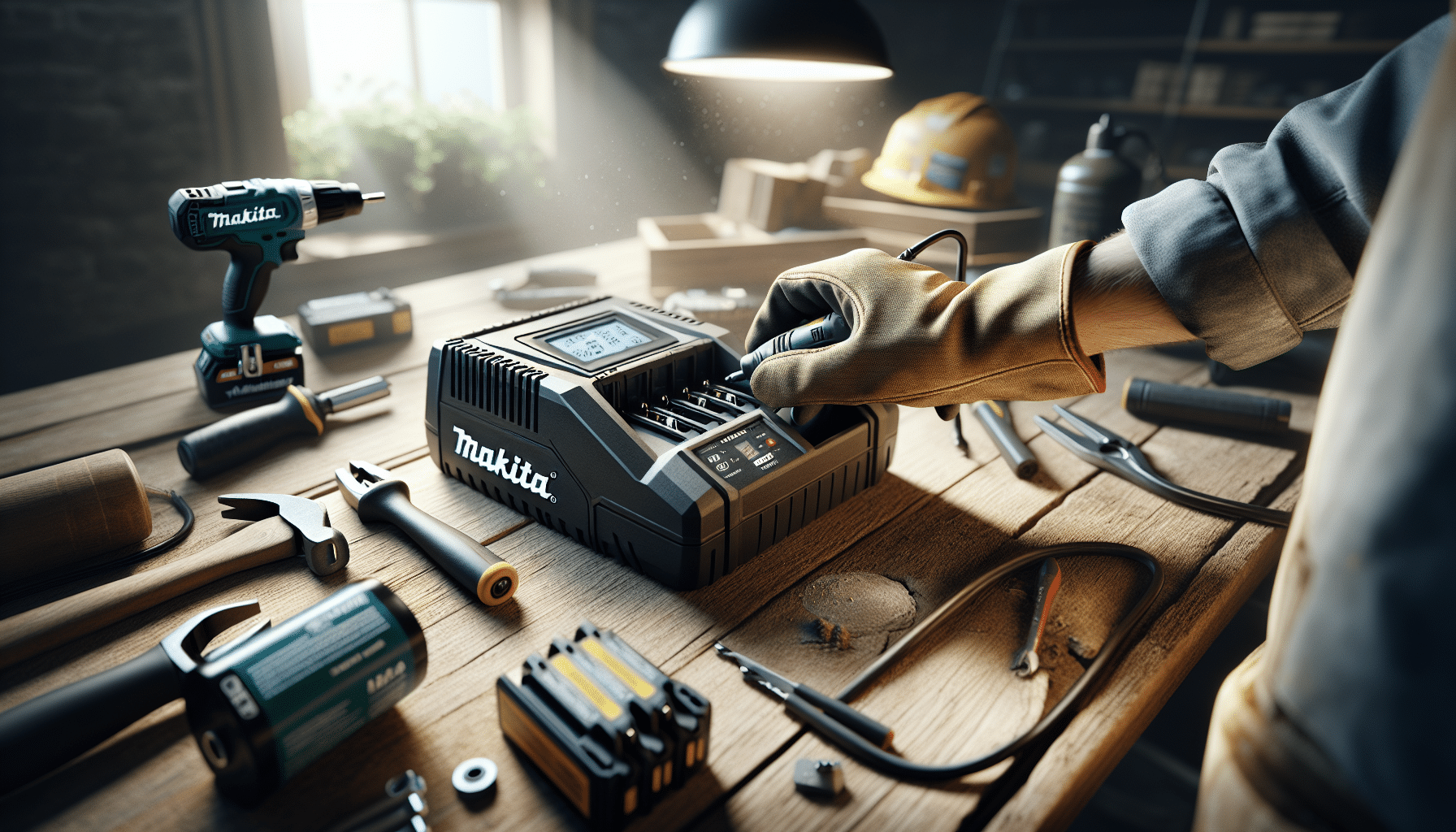

Best Practices with Makita-Compatible Chargers

Your Guide to Using LCD Screens Correctly

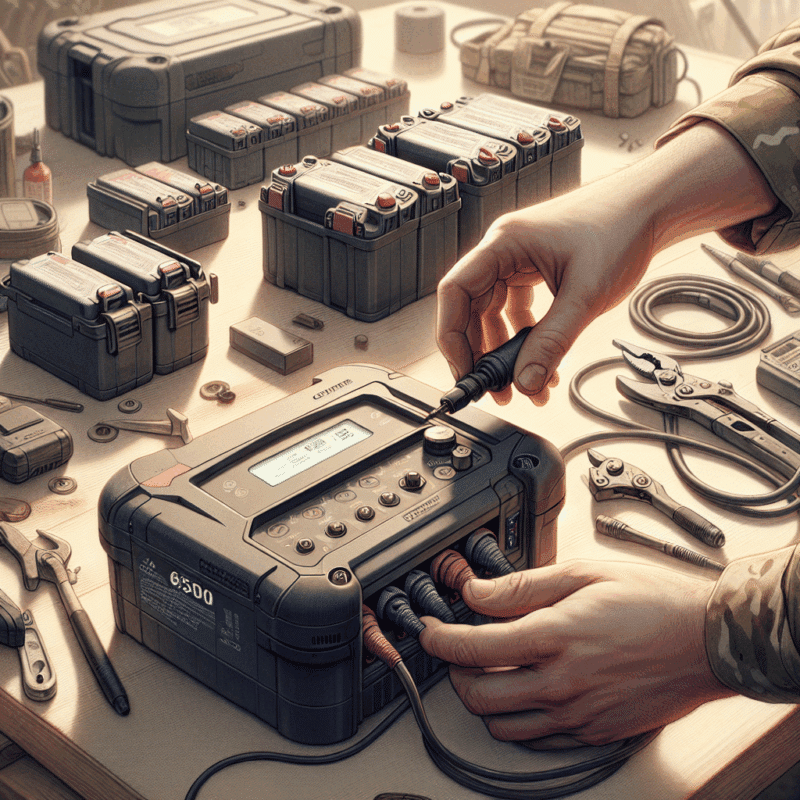

Makita’s LXT system is one of the most prevalent battery ecosystems in professional use. When paired with LCD-based chargers, the importance of correct setup and interpretation cannot be overstated. First, always place batteries on flat, ventilated surfaces to avoid heat retention. Next, interpret the initial LCD data upon insertion: a steady, low current indicates stabilised trickle charge, while higher currents signal rapid charging that should be monitored closely.

Users should regularly catch anomalies in voltage plateaus or temperature jumps, which could hint at problems like cell imbalance or incomplete energy absorption. Furthermore, integrating calibration cycles—charging and discharging batteries fully once every ten cycles—helps optimise LCD algorithmic accuracy for long-term precision charging. Extensive training is often unnecessary; reading the display just a few times builds familiarity and proficiency quickly.

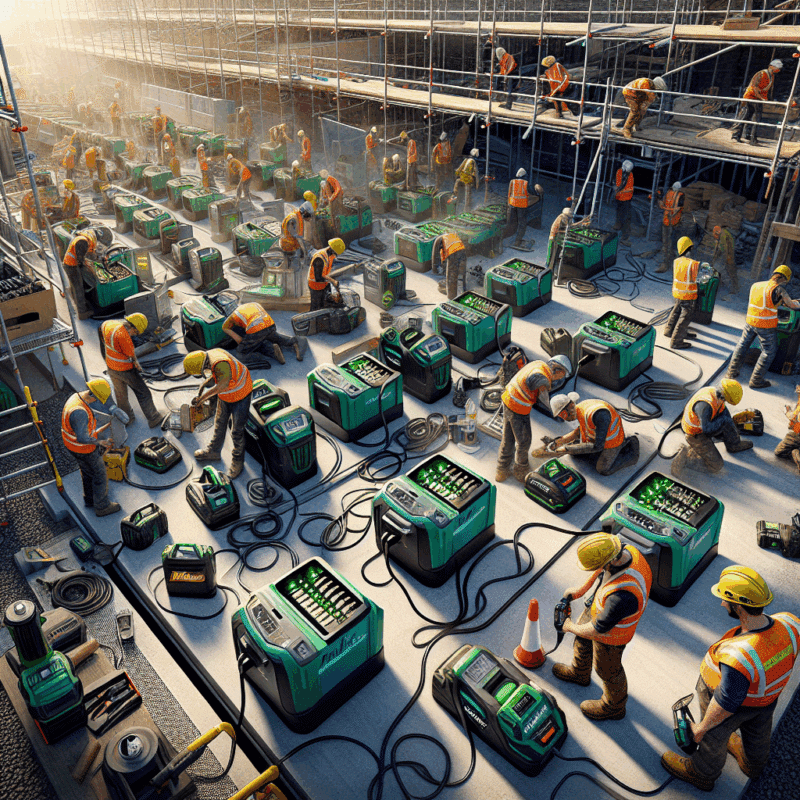

Managing Multiple Batteries in a Workshop

Creating a Charging Station Strategy

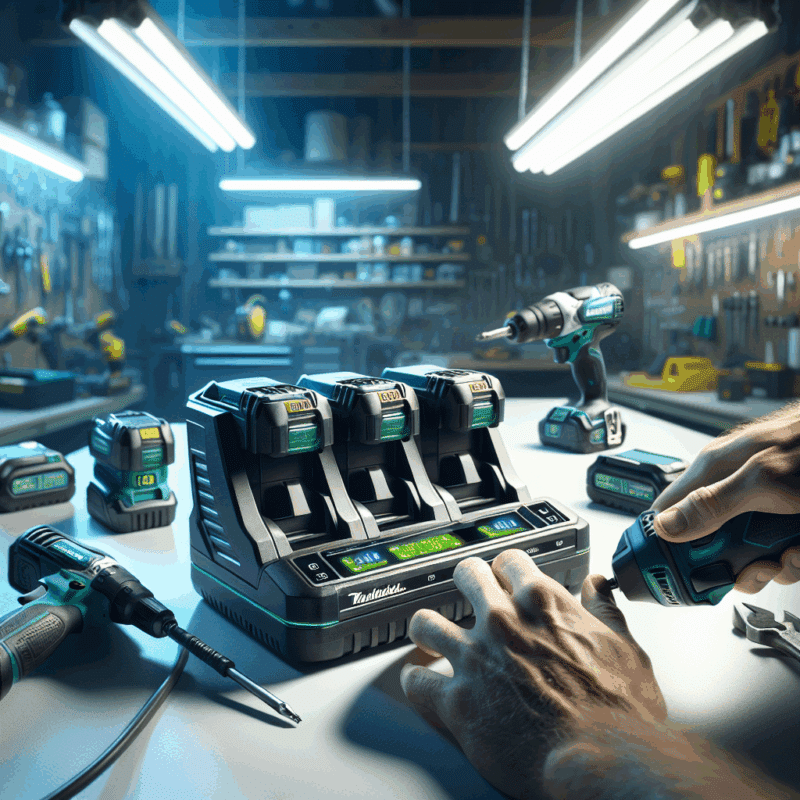

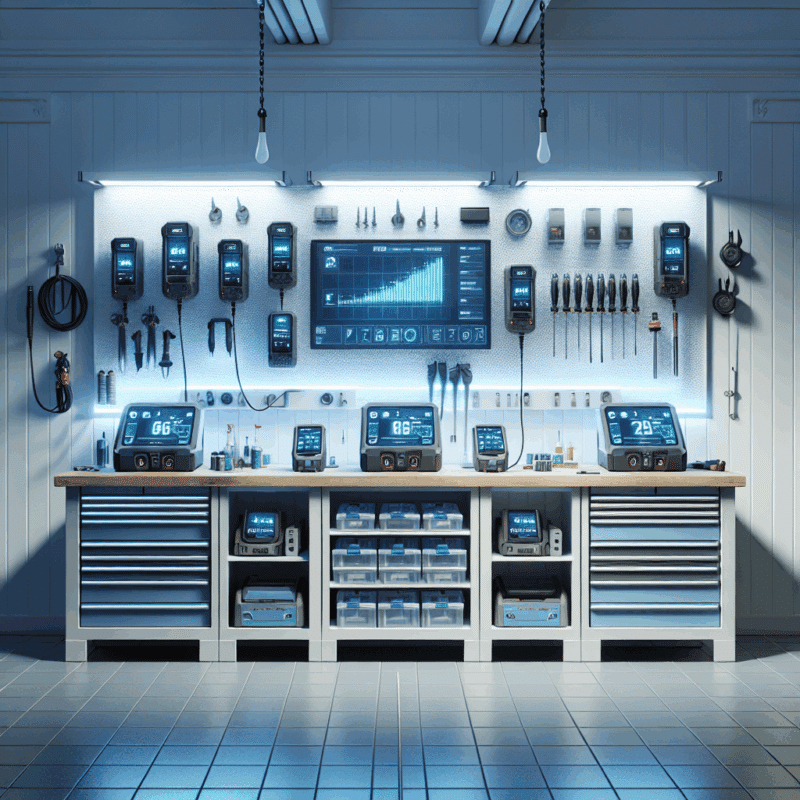

Workshops often feature more than ten batteries cycling through charges across shifts. In such environments, precision charging becomes not just useful but indispensable. Establishing a labelled charging station with charts for voltage norms, charge timings and battery IDs ensures efficient rotation. Users who leverage LCD chargers can identify underperforming batteries and remove or recycle them before they compromise output.

For example, grouping batteries by their average recharge time allows a clean tier system: quick-returns, mid-speed and slow chargers. This eliminates guesswork among team members and reduces charging bottlenecks. For even better results, assign one staff member per shift to inspect LCD anomalies daily. This proactivity removes unexpected failures from the equation. Precision charging in this context becomes a key cog in the workshop’s productivity engine.

Choosing the Right LCD Charger

Key Specs for Makita LXT Compatibility

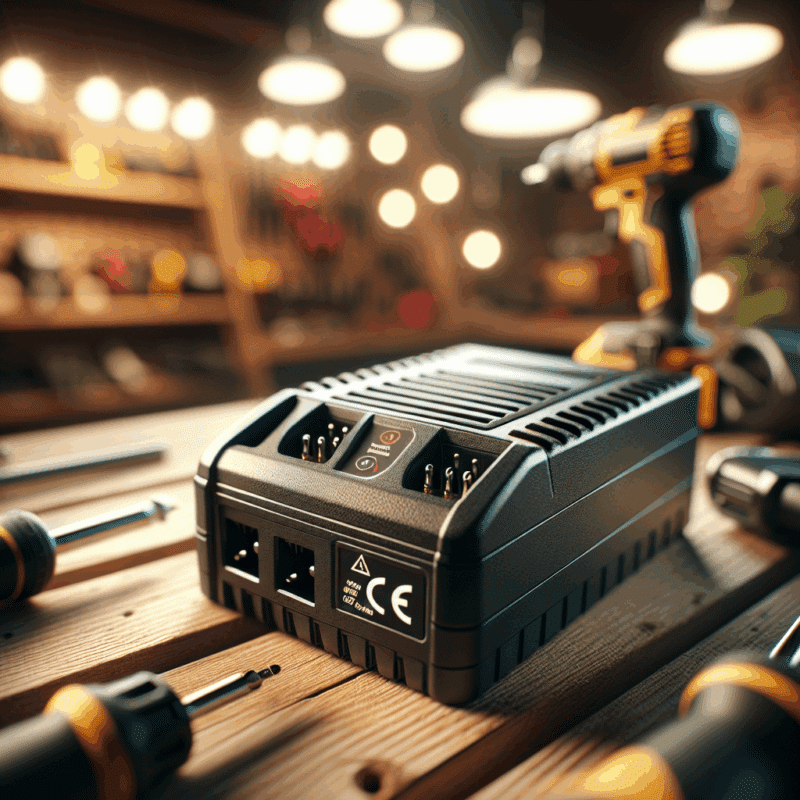

While many chargers boast LCD interfaces, not all qualify for true precision charging. For Makita compatibility, prioritise chargers that explicitly mention support for 10.8V to 18V LXT Li-ion models. Recharge current should range between 1.5 to 3A, adjustable or auto-sensed, while voltage readings should calibrate in 0.1V increments for accuracy. Dual-socket charging options offer better multitasking, while intelligent fans help manage thermal equilibrium.

Look for LCD units with real-time temperature readings, charge cycle count logs, and diagnostic features. A USB output or mobile sync function is also advantageous for remote monitoring. Be wary of overly generic chargers; if it doesn’t state compliance with Makita’s battery ID system, compatibility can suffer. Ideally, consider devices that are compliant with both CE and RoHS standards—offering the best in ecological and electronic safety. Browse available models from approved vendors via Learn more about Charging Technology & Power Management.

User Insights & Real-World Examples

What Tradespeople Say About Precision Charging

Feedback from real-world users overwhelmingly supports the shift towards data-driven charging. James O’Leary, a site foreman from Manchester, comments, “Since implementing LCD chargers on-site, we’ve seen virtually no battery failures, and daily tool readiness has been near-perfect.” Similarly, Sophie Black, a maintenance contractor in London, notes how she “schedules her day based on charge timings, using the real-time data to plan site moves efficiently.”

Forums like UKToolTalk and trade associations across Britain echo these experiences, with users praising how precision charging has helped them extend battery life by over 30%. The collective verdict is clear: charging without data is now considered outdated and inefficient. For more community insights and charger reviews, see Read a related article and subscribe to updates via Advanced algorithms for fast battery charging.

Charge Cycle Tracking and Efficiency Metrics

How to Interpret Data Logs

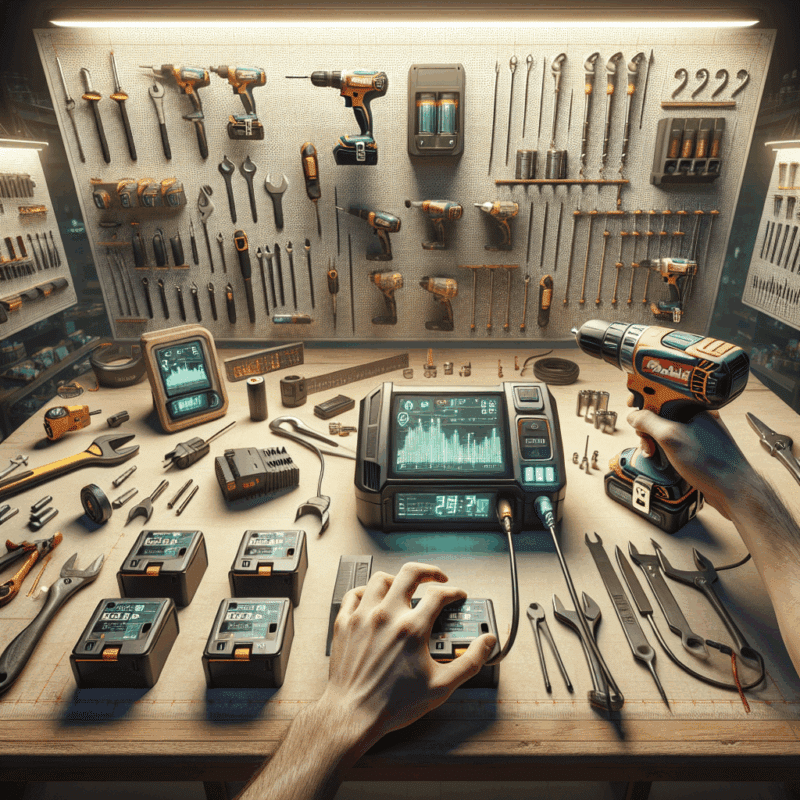

Modern LCD chargers don’t just visualise current power flow—they track long-term performance through log files. Typically, these logs will show the number of full charge-discharge cycles completed, peak voltage reached, and frequency of fast charges. Parsing this data helps technical leads and workshop managers understand which batteries to prioritise for replacement and which can handle high-demand usage.

For instance, if one battery shows a cycle count of 700 with gradual peak voltage decline, it indicates approaching end-of-life, even if it still appears functional. Flagging such metrics ensures replacements can be procured in advanced cycles, never during peak projects. Stats like average recharge time and recorded temperature symmetry also help improve deployment strategies. You can find tools to automate data log imports via Automated data workflows for business efficiency.

Future-Proofing Your Power Management

Integrating Smart Tools with Smart Charging

The final evolution of precision charging lies in its integration with the growing ecosystem of smart tools. Makita’s expanding Bluetooth-enabled products can now pair with precision chargers to provide synchronised charging, usage tracking and even cloud-backed diagnostics. This simplifies asset management and dramatically improves remote operability for dispersed teams. Through APIs or proprietary apps, users can consolidate charge station status and battery reports in one place.

As AI and IoT technologies advance, expect predictive algorithms to soon adjust charge rates based on calendar bookings or performance history. A battery used heavily on Monday, for example, could auto-adjust on Tuesday’s recharges to protect longevity. Businesses adopting these innovations now will enjoy compounding ROI through efficiency, longevity and consistent power independence.

Conclusion: Smarter Charging Starts with Data

Precision charging represents the shift from reactive to proactive battery management. By embracing LCD-enabled data feedback, both solo contractors and large-scale operations can dramatically reduce faults, improve uptime and maximise every volt of battery power. With Makita-compatible units rising in feature-rich variants, there has never been a better time to upgrade your power ecosystem. Make charging intelligent, actionable and accurate—align your tools with the future.

Great guide on precision-charging-lcd-data-battery-output-guide – Community Feedback

How does LCD charging data impact daily battery output?

LCD charging data gives real-time insights into voltage and current, letting users spot issues early, manage charging cycles accurately, and prevent overcharging. This boosts battery health, output, and safety for daily use.

What metrics should I watch on an LCD charger?

Key metrics include voltage, current (in amps), and charge status. Monitoring these helps ensure batteries are charged optimally, prevents overheating, and allows you to track real battery performance over time.

Can using LCD displays prolong battery life?

Yes, by monitoring real-time charge data, users can avoid overcharging, spot battery faults, and charge at the optimal rate. This careful management can extend overall battery service life substantially.