Practical Guide to Charger Placement for Team Efficiency

In This Article

- Strategic charger placement reduces downtime and improves workflow efficiency.

- Centralised and visible locations encourage better battery habits.

- Different layouts suit varying environments—plan accordingly.

- Integrated cable management is essential for safety and clarity.

- Use IoT tools for optimised, data-driven charger management.

- Always ensure adequate airflow and adhere to electrical safety standards.

Why Charger Placement Matters

Reduce Downtime and Increase Efficiency

Efficient charger placement plays a vital role in ensuring streamlined operations across teams that rely on cordless power tools, mobile equipment or electronic devices. When chargers are appropriately positioned, downtime is reduced significantly, as staff members can quickly access charged units and continue working without unnecessary delays. Charger placement must be driven by an understanding of operational flow, team density and movement patterns to allow quick swap-outs and recharges in minimally disruptive ways. In shared workspaces or fast-paced environments, inadequate planning results in chargers becoming either inaccessible or forming traffic bottlenecks, thereby negating their utility.

Central locating of chargers, especially those compatible with high-demand tools such as Makita, DeWalt or Milwaukee, ensures batteries are always where the team needs them most. Strategic charger placement reduces physical strain, encourages regular charging behaviours and maximises tool availability throughout the working day. For engineering workshops, construction floors, and manufacturing zones, optimised charger zones become productivity catalysts, not just convenience corners.

Ideal Locations for Charger Stations

Centralised Power Access

One of the most effective approaches to charger placement is to locate stations centrally in high-traffic work areas. This centralisation reduces the total walking distance for team members needing to recharge or swap out batteries throughout the day. Whether you’re working in an open-plan warehouse or a segmented field operation, placing chargers near the core of activity zones ensures quicker access and minimal disruption.

Additionally, central locations enhance visibility of battery levels, helping supervisors and team leads monitor uptime indirectly. In open environments, team members are more likely to take advantage of convenient charger placements, developing habits that ensure constant battery rotation. For example, placing charging docks adjacent to entry/exit staging zones allows for easy swapping as users enter or exit an area during task transitions.

“After years of troubleshooting tool readiness issues, strategically placing our 18V chargers near central access points reduced our average downtime by 23%.” – Operations Manager, Midlands Manufacturing Co.

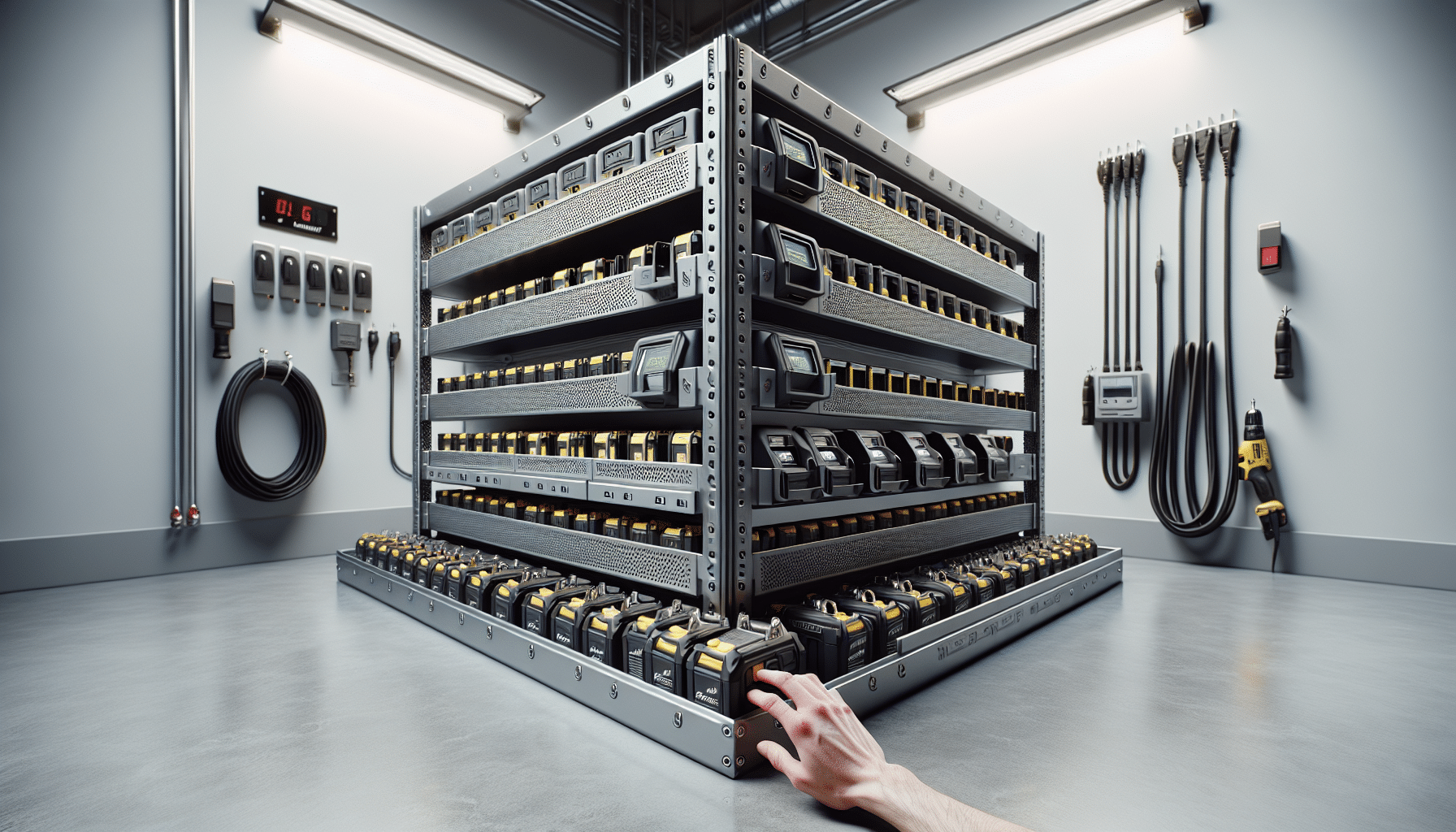

Types of Charging Layouts to Consider

There are several charging layouts that organisations can implement based on the physical space, team size, and nature of operations. Selecting the right layout is essential to optimise charger placement for maximum throughput.

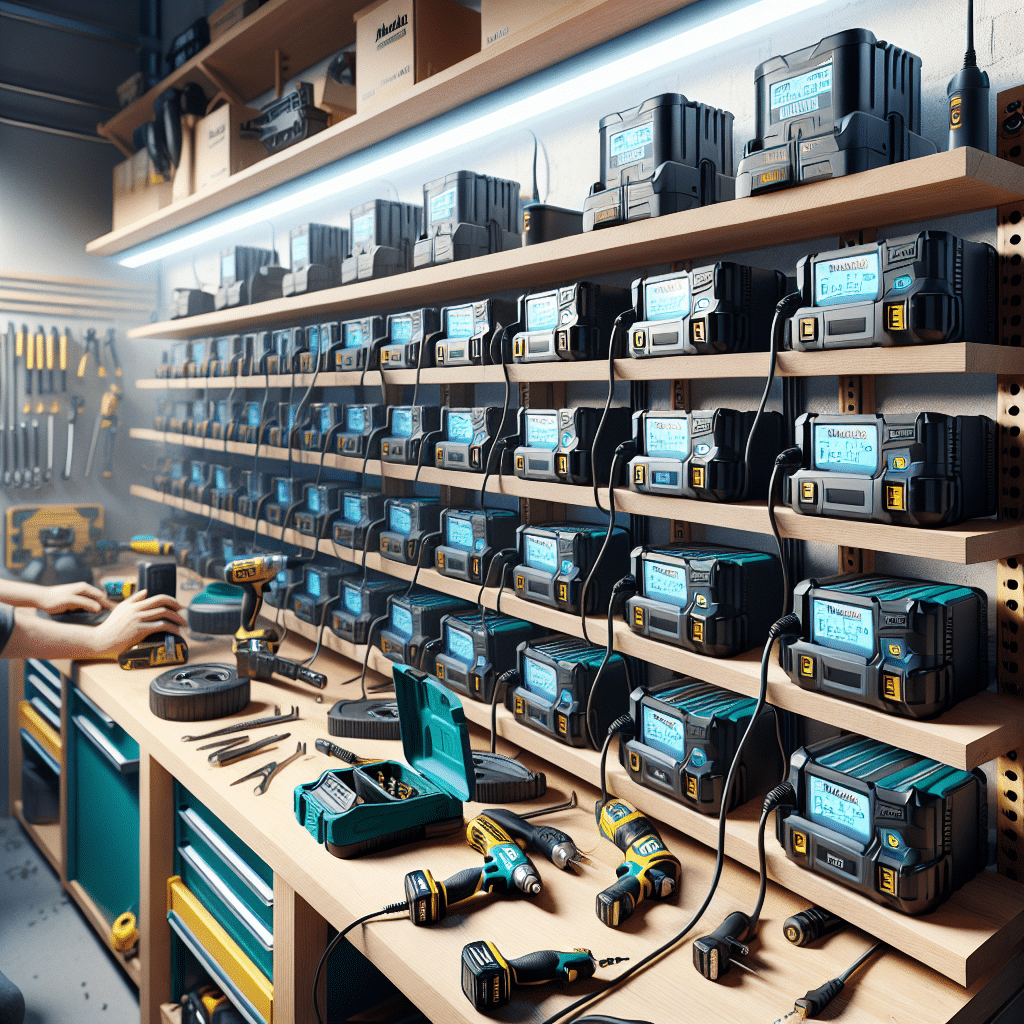

Linear Charging Rows

Ideal for long corridors or tool stores, linear rows allow chargers to be systematically arranged along walls or benches. This layout is space-efficient and allows for standardised cable management solutions.

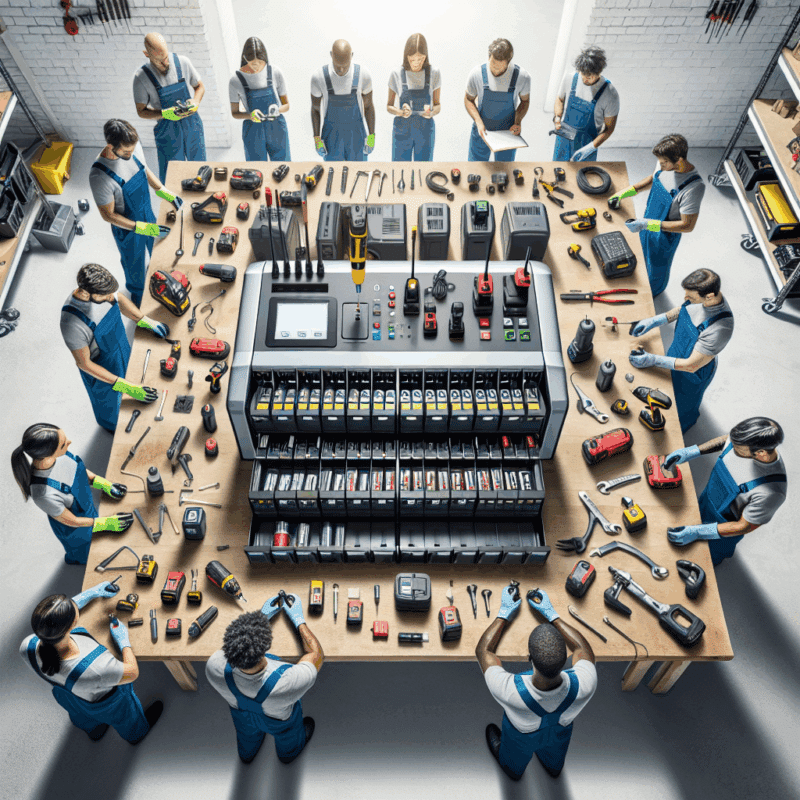

Clustered Pods

For larger teams or tools with diverse voltage needs, clustered pods—small groupings of chargers dedicated by task or tool type—allow for efficient compartmentalisation. It enhances battery organisation while maintaining access.

Mobile Charging Carts

Mobile solutions are growing in popularity, offering versatility in dynamic work environments. Charging trolleys bring charged batteries closer to active zones, supporting temporary or field operations.

Common Mistakes in Charger Placement

Despite good intentions, many organisations overlook some critical aspects when planning charger locations. One of the most frequent errors is placing chargers too far from action zones. While this may seem tidier, it forces users to break workflow momentum.

Another common issue involves failing to install sufficient outlets, resulting in chargers being daisy-chained or unplugged frequently. This is both unsafe and inefficient. Charger placement must also consider future scalability—whether you plan to double your team or add new tool categories, the infrastructure must adapt easily.

Finally, not adhering to manufacturer airflow requirements during placement can lead to poor charging performance or even early charger failure. Placement must respect space, power and cooling variables.

Integrating Charging Zones Into Workflow Paths

Successful charger placement lies in embedding stations seamlessly into daily task paths. For instance, placing chargers along the route from warehouse storage to the main assembly line encourages natural use. Integration in workflow paths minimises idle switching times.

Teams benefit when chargers align with physical movement flows. Interactive floorspace mapping tools can be employed to identify traffic-heavy zones perfect for charger integration. With this approach, charger placement becomes part of operational fluidity rather than an afterthought.

Moreover, when charging zones are visually demarcated and well-lit, they act as subconscious prompts. Add signage with battery status icons to further encourage top-ups during transitional moments.

Cable Management Strategies for Charger Zones

No discussion of effective charger placement is complete without thoughtful cable management. Cords strewn across floors not only cause clutter but introduce potential tripping hazards—compromising both data efficiency and worker safety.

Employing under-desk cable guides, wall-mounted conduit systems, or flush-mounted cable trays allows for clean, organised setups. Colour-coding electrical leads based on voltage or tool type can aid rapid identification, reducing human error during swaps.

Businesses should perform routine inspections on cable wear and box integrity. Chargers should also be placed at ergonomic heights to minimise bending or awkward positioning.

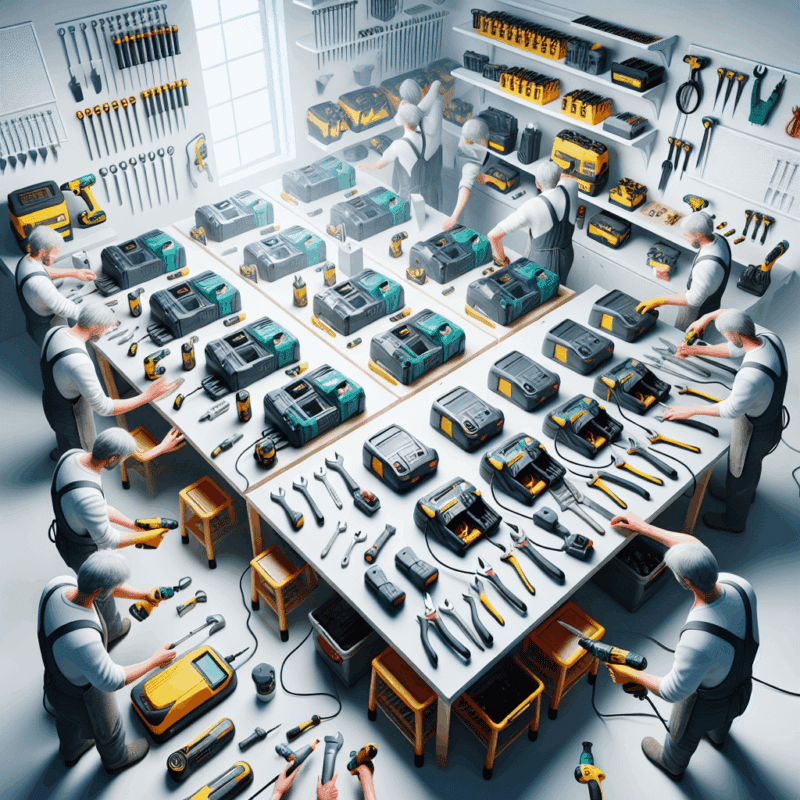

Case Study: Makita-Compatible Fast Charging in Action

A Midlands-based equipment hire firm recently upgraded its battery charging process for Makita-powered tools. The facilities team chose a zonal approach based on interactive blueprint analysis. Using feedback from supervisors, three distinct charger stations were created within core transit routes.

Within two months, the results were measurable. Downtime caused by low battery alerts fell by 40%, team battery rotation increased by 55%, and service calls relating to dead tools decreased by 70%. Charger placement directly impacted tool availability and operator productivity, with zero increase in energy usage.

By implementing a live dashboard that mapped charger activity (via QR tags and smart plugs), the company has since introduced predictive maintenance scheduling and real-time energy tracking.

Safety and Airflow Considerations

Safety is another cornerstone of effective charger placement. Power tools generate heat during usage and recharging. It’s essential that charger units be kept away from enclosed spaces without adequate ventilation.

All charger stations should be installed away from flammable materials and escape routes. Vent spacing around units must comply with OEM recommendations, which typically suggest a 5–15 cm clearance for passive airflow.

Moreover, power outlets should be fitted with surge protection, and sockets should match charger amperage to prevent burnout. Routine thermal imaging can help identify rising temperatures or faulty equipment before breakdowns occur.

Checklist for Setting Up a Smart Charging Workflow

Before finalising charger placement in any workspace, use this checklist to ensure both functionality and scalability:

- ✅ Is charger placement located within arm’s reach of the team’s active zones?

- ✅ Are cables tidy, secure, and organised with modular trays or clips?

- ✅ Are there clearly marked visual cues and tooltype-specific zones?

- ✅ Have power requirements and surge protections been addressed?

- ✅ Does the layout allow for future charger and tool expansions?

- ✅ Are staff trained to rotate batteries and identify faulty units?

- ✅ Are smart monitoring tools included to log usage data?

Use Learn more about Workshop Charging Optimisation to download our charger station readiness assessment toolkit.

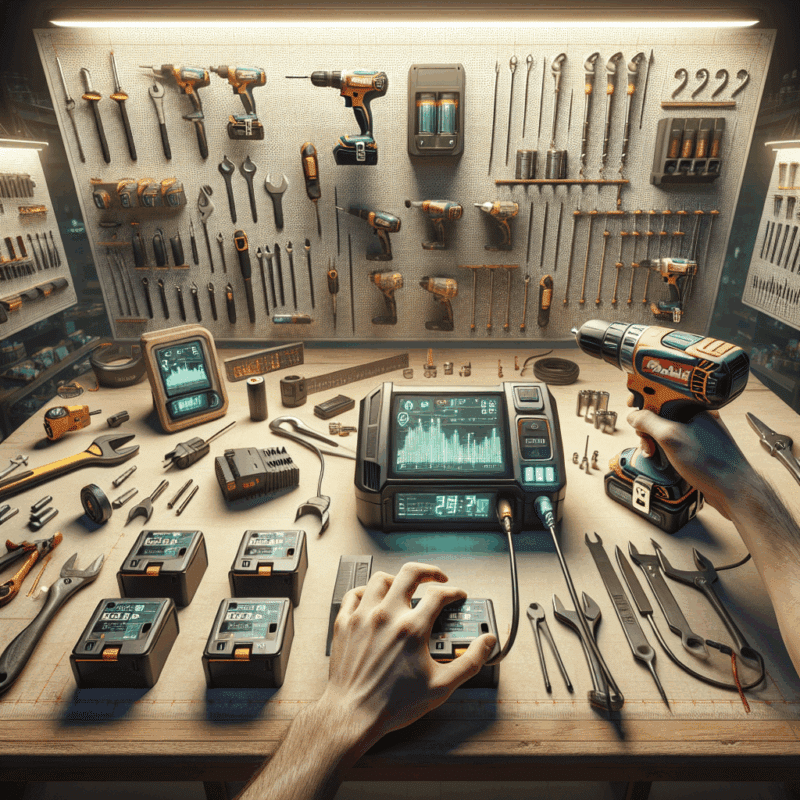

Technology Tools for Monitoring Charger Usage

Forward-thinking teams are investing in intelligent charger placement solutions enabled by IoT integrations. These smart systems allow real-time monitoring of battery throughput, charger load and depot idle times. Technologies such as Wi-Fi-enabled smart plugs or integrated charge monitors can link with workflow software.

Dashboards provide decision-makers with insights such as charger overuse alerts, battery age sequencing and even carbon footprint impact based on recharge cycles. These systems support lean management strategies and can notify facilities teams when chargers or batteries are underperforming.

Consider integrating solutions from vendors supporting open API platforms, allowing data to flow into existing project management tools or ERP systems. Implementations are available in cloud and edge variants depending on data sensitivities. Learn more at Optimal wireless charger placement solutions.

Conclusion: Placing Power with Purpose

The true value of considered charger placement transcends simple convenience. It defines a workspace’s rhythm, shaping the way teams interact with their tools and influencing the cadence of work itself. Wherever mobility and cordless tools are central to your operations, efficient charger placement holds the key to maximising output without increasing stress on personnel or systems.

By aligning charger zones to workflow paths, implementing smart layouts, and integrating real-time monitoring tools, organisations ensure uninterrupted productivity across all team layers. The future of productivity will be defined as much by where you house your power, as by the power tools you deploy.

For more resources on mapping workspace energy flows, visit Read a related article, or explore industry standards at Optimising team setups through efficient planning.

Great guide on practical-guide-charger-placement-maximum-team-throughput-interactive – Community Feedback

What is the best location for placing workshop chargers?

The optimal spot for workshop chargers is near high-traffic tool zones with clear access, sufficient ventilation, and close proximity to power outlets. Keep chargers off the floor and secured to avoid cable hazards and ensure team members can swap batteries quickly.

How does charger placement affect team productivity?

Good charger placement reduces walking time, prevents congestion during battery swaps, and minimises risk of accidents, leading to smoother workflows and increased jobsite productivity for teams.

What are common mistakes in charger placement?

Common mistakes include positioning chargers too far from work zones, overloading single outlets, stacking chargers unsafely, and not considering airflow which can cause overheating and early equipment failure.