Powering Peak Performance: Essential Charger Upgrades for Trade Pros

In This Article

- Trade charger upgrades are vital to maintaining productivity on tool-heavy job sites.

- Multi-bay, fast-charging systems eliminate energy bottlenecks and reduce downtime.

- OEM chargers offer superior safety features over many alternatives.

- Effective cable management and charger station setup improve safety and efficiency.

- Fleet-wide battery rotation with reliable tracking extends lifespan and performance.

- Real tradespeople report measurable time savings and smoother operations post-upgrade.

The Critical Need for Charger Upgrades in the Trade Sector

Tool fleets are growing—your charging must keep up

In today’s trade environments, battery-operated tools dominate the modern construction site. From cordless drills to impact drivers and saws, these machines offer freedom of movement and operational safety. However, with increased reliance on cordless equipment comes the critical need for upgraded charging infrastructure. Trade charger upgrades are no longer optional—they are essential for ensuring continuous operations and managing larger fleets of tools effectively.

Tool-heavy trades such as plumbing, electrical, HVAC, and construction often run multiple battery cycles daily. As tool inventories expand, outdated chargers create bottlenecks that restrict productivity. Workers waiting for batteries to charge leads to project delays, missed deadlines, and decreased client satisfaction. Therefore, implementing robust, fast-charging systems prevents workflow interruption and supports scaling operations seamlessly.

Additionally, outdated chargers may lack the safety mechanisms modern devices incorporate. Overheating, improper current regulation, and limited adaptability to varying voltages can lead to premature battery wear or even device failure. Investing in trade charger upgrades allows professionals to benefit from enhanced safety, automation, and consistent power delivery across job sites. Learn more about Optimising power and charging solutions for demanding trade environments

Identifying the Right Charger for Your Jobsite

Fast, rugged, scalable—essentials for worksite performance

Choosing the right charger for the jobsite depends on several key factors, including the number of workers, types of tools used, available power sources, and the environmental conditions present. Trade charger upgrades should not only deliver fast charging speeds but also stand up to rugged jobsite demands. Shock resistance, weatherproof casings, and secure locking mechanisms become important design criteria when equipment is used in dusty, wet, or inconsistent weather zones.

Professional worksites also benefit from scalable charging options. A single-bay charger may suit light-duty, individual tasks, but they cannot support teams of ten or more. In these scenarios, trade charger upgrades must scale to multi-port systems that allow dozens of batteries to charge simultaneously, preserving workflow efficiency.

Compatibility is another consideration. If you use multiple tool brands across your fleet, consider chargers that support mixed-brand platforms or universal battery interfaces. Such flexibility future-proofs your investment and accommodates tool evolution without repetitive equipment replacement costs. Many of the newer intelligent chargers also offer diagnostics and battery health monitoring, providing insights into performance issues before they escalate.

Why Multi-Bay Chargers Are Game Changers

Charge more, wait less

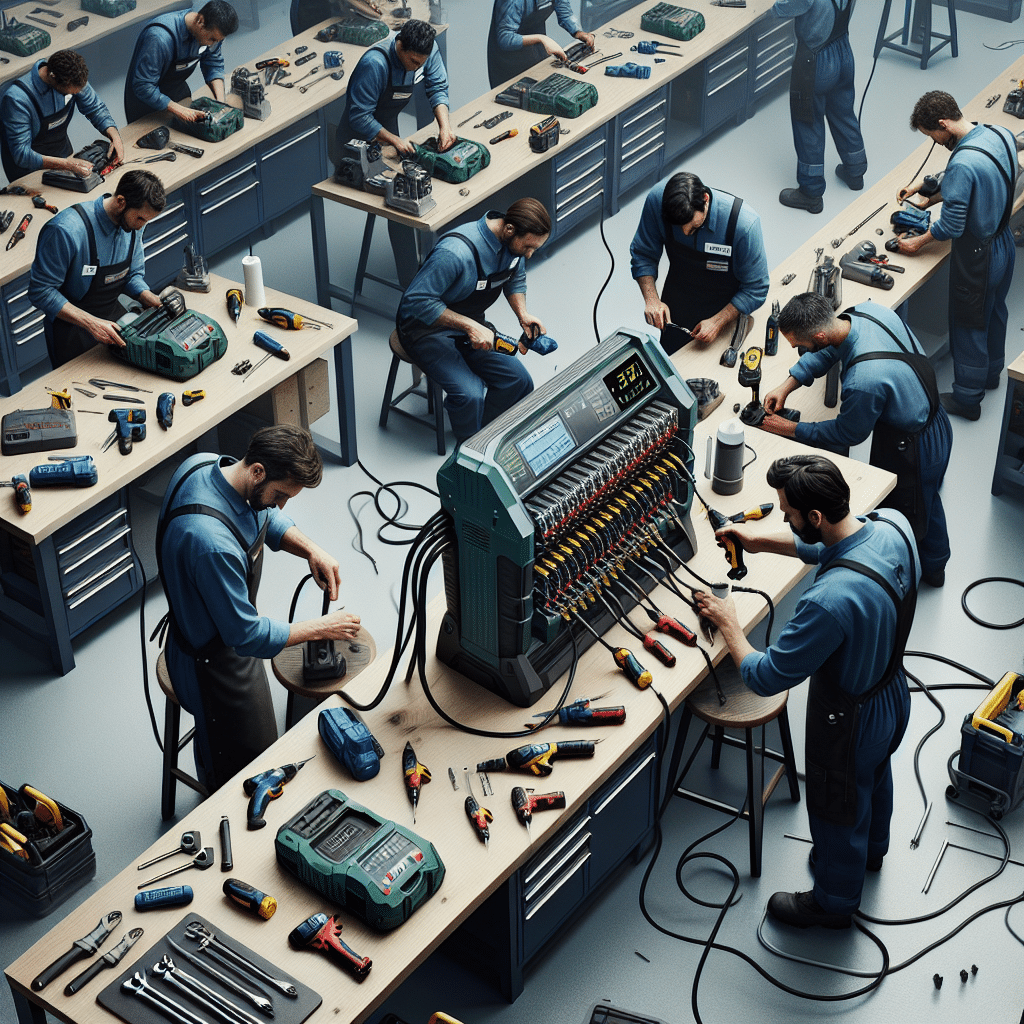

For many trade professionals, time truly is money—and that philosophy fuels the growing adoption of multi-bay chargers. These systems are the cornerstone of strategic trade charger upgrades, enabling crews to hot-swap batteries and maintain an uninterrupted workflow. Rather than waiting sequentially for each battery to finish charging, workers simply grab a charged unit from a designated bay and keep working.

Multi-bay systems often support concurrent charging, not just queued charging. This means each battery receives power independently, significantly reducing the turnaround time from depleted to ready-for-use. Additional features such as LED indicators, smart queue sequencing, and temperature control enable smarter, safer operations.

Some models now include wall-mount and stackable designs, optimising space in tight jobsite trailers or workshop benches. Investing in well-designed, high-output multi-bay chargers empowers your workforce with the confidence that energy availability will not restrict their productivity. In-depth review of peak-performance chargers

Makita-Compatible Chargers: OEM vs Alternatives

Safety, certifications, and real-world use cases

Makita remains one of the most dominant brands used across UK trade sectors, and its 18V LXT platform is nearly ubiquitous. When considering trade charger upgrades, professionals often weigh OEM (original equipment manufacturer) models against aftermarket alternatives. Although alternatives can present upfront cost savings, they may not always offer the operational safety or efficiency of purpose-built OEM designs.

Authentic Makita chargers come with built-in protections such as overcurrent shutoffs, cell voltage equalisation, and Intelligent Charging Mode—helping extend battery life and prevent system failures. They are also extensively tested under EU and UK safety regulations, ensuring compliance on regulated job sites.

Conversely, third-party chargers may lack the stringent quality control of their OEM counterparts. While some do perform well in controlled conditions, real-world feedback often highlights overheating risks, failure when faced with inconsistent voltages, and substandard enclosure durability. When scaling up a charger fleet for your team, trade charger upgrades should always prioritise reliability and long-term value over short-term savings. Managing compliance for imported charging tools

Scaling Charging Infrastructure for Teams

From mobile crew vans to full-site deployment

Larger teams require coordinated charging infrastructure to avoid tool downtime. As companies take on bigger contracts or expand into multiple crews, it becomes essential to rethink how chargers are deployed and maintained. Trade charger upgrades play a pivotal role in ensuring consistent performance both in transportation vehicles and on static job sites.

Mobile units such as crew vans benefit from specialised 12V DC-to-AC conversion units that power chargers while on the road. These setups allow workers to recharge batteries during transit, maximising on-the-move productivity. Inside service vans, secure charger mounts and vibration-dampened shelves elongate charger life while keeping the setup neat and accessible.

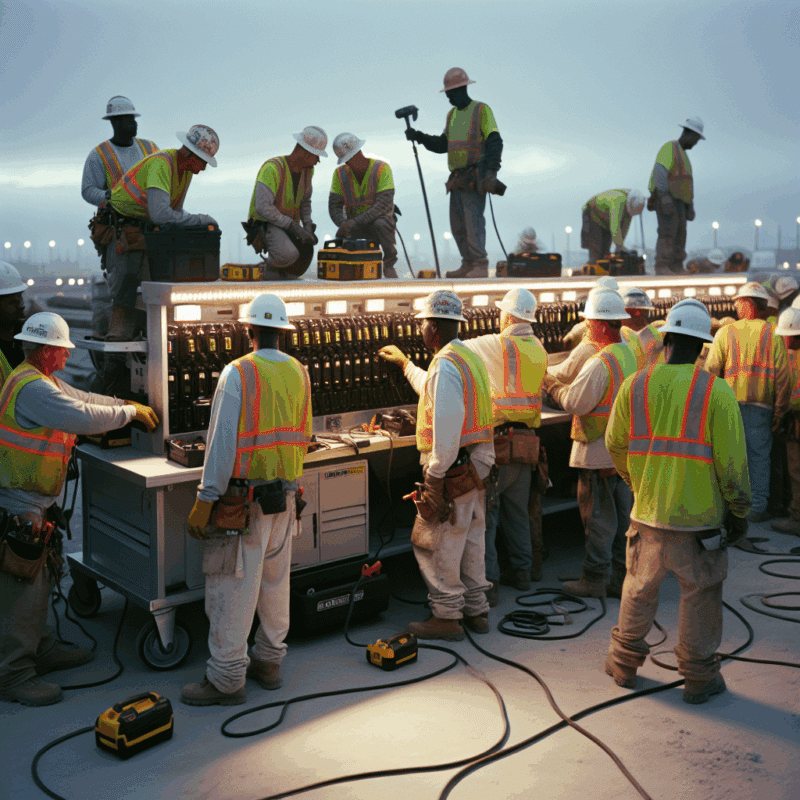

On large construction sites, central charging stations become necessary. These zones need structured power delivery (potentially via industrial extension reels), dedicated ventilation, and moisture shielding. More advanced upgrades may integrate IoT-enabled charger lockers, allowing staff to reserve or unlock charged batteries securely and track usage trends. Read a related article

Reducing Downtime with Rapid Charging

Less waiting, more doing

Rapid charging is not simply a luxury—it is core to effective time utilisation. Trade charger upgrades focused on speed can recharge batteries to 80% in as little as 15–20 minutes, especially with lithium-ion packs. This dramatically reduces tool stagnancy and helps keep projects running on schedule.

However, speed should not come at the cost of safety or battery longevity. High-output chargers that improperly regulate heat can cause internal battery damage, leading to shortened service life or catastrophic failure. Reputable rapid chargers now use integrated fans, phase-balancing circuitry, and programmable charge cycles that match battery chemistry.

For top-tier performance, professionals are encouraged to invest in compatible rapid chargers approved by the tool manufacturer, or those that have been extensively third-party tested. It’s the balance between speed, safety, and serviceability that determines a charger’s real value.

Setup Tips: Cable Management and Station Layout

Safe and clutter-free workshop charging

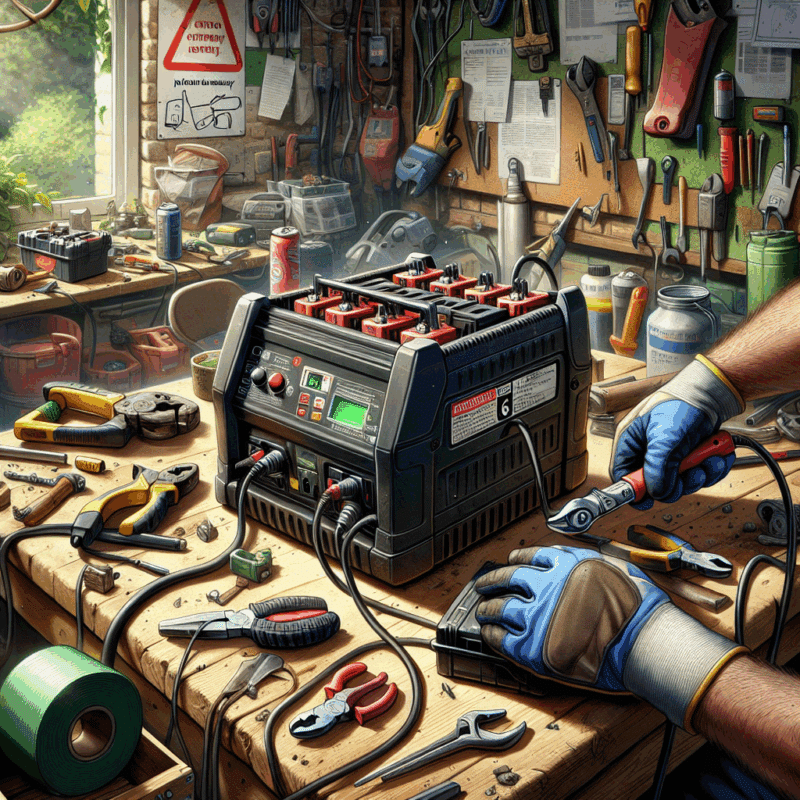

Proper charger deployment extends beyond simply plugging the unit into a socket. Strategic layout and cable management dramatically improve safety, efficiency, and aesthetics. Trade charger upgrades should involve assessing the physical setup alongside the equipment selection.

Start with mounting chargers at bench height and grouping them by battery type or voltage range. Doing so reduces confusion amid the bustle of a busy workspace. Use labelled cable clamps and velcro ties to route charger cords securely to wall sockets—avoiding trailing wires on walking paths that can cause tripping hazards.

Where possible, integrate storage for spare batteries and tools near the charger station. A well-organised area allows for faster swaps and helps workers maintain focus instead of hunting for equipment. If your space permits, consider modular shelving with adjustable hooks and lighting to improve the overall usability of the station.

Proven Products: The Torxup VoltGuard 6500

Why this 6.5A charger stands out

Among trending charger models in 2024, the Torxup VoltGuard 6500 has earned praise from trade professionals for offering performance, efficiency, and rugged durability. Designed specifically for high-volume tool users, the VoltGuard 6500 boasts simultaneous dual-bay charging, six-point safety sensors, and overcurrent protection—making it ideal for everyday jobsite rigours.

The charger delivers precise 6.5A output across both bays, accelerating charge times without risking overheat. Its intuitive interface shows real-time voltage feedback, battery health insights, and charge percentage estimates. Additionally, its cast aluminium shell resists impact, while internal foam lining protects sensitive charging pins.

Real-world reviews have reported that the VoltGuard significantly reduces total battery wait time, saving crews an estimated 22% of their tool downtime compared to prior setups. With ergonomic cable-routing channels and wall-mount hardware included, installation is equally efficient. This model is fast becoming the benchmark when it comes to forward-thinking trade charger upgrades.

Fleet Readiness: Keeping Batteries in Rotation

Best practices for efficiency and lifespan

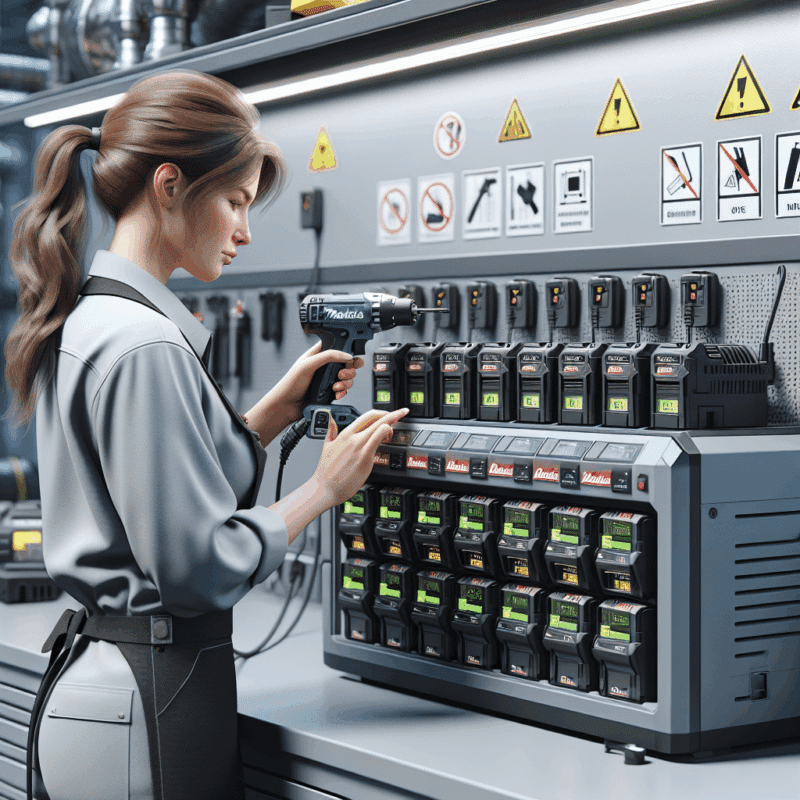

Efficient battery rotation is key to smooth jobsite functioning. Neglecting rotation leads to unbalanced wear, unexpected rundown, and inconsistent performance—especially on large teams. Trade charger upgrades must support processes that maintain battery health across the board.

Tag each battery with a number or colour code and implement a first-in, first-out routine. Ensure staff always pick the oldest charged battery first. Use maintenance logs (digital or physical) to track cycles, allowing appropriate retirement or service of failing units. Some modern charger platforms now sync with cloud software, automating this process.

Avoid stockpiling too many batteries on passive cycle, where they remain unused for days. Idle batteries lose charge and degrade faster. Keeping them in active rotation ensures optimal performance and gets full value from your tools and charger investment alike. Combined with regular voltage checks and storage at proper ambient temperatures, these practices ensure the longevity and availability of your battery fleet.

Real User Tips from Tradespeople

Insights from workshops across the UK

Real-world feedback offers valuable insight into charger configurations that genuinely improve productivity. UK-based joiner Iain Frith shared how his four-person team saved up to 90 minutes daily by implementing a 6-bay smart charger and developing a strict battery rotation policy.

Meanwhile, an electrical contractor in Leeds praised the integration of solar-powered battery chargers on their remote installs: “In areas where mains power was sporadic, we still kept going—those trade charger upgrades paid for themselves within months.” Others mentioned wall-mounted units in crowded vans with motion-secured brackets preventing damage during transit.

The consensus is clear: thoughtful charger investment, combined with operational discipline, delivers measurable gains in output and morale.

The Future of Charging for the Professional Trade

Looking ahead, innovations in trade charger upgrades will continue to enhance speed, portability, and intelligence. Wireless charging surfaces for batteries, solar-integrated stations, and AI-optimised power distribution are on the horizon. Meanwhile, diagnostics-rich platforms will give teams predictive insights into battery failures before they occur, reducing costly surprises mid-project.

As the professional trade evolves, success will increasingly hinge on the interplay between battery technology and charging infrastructure. From rapid throughput workshops to mobile jobsite setups, those who invest in scalable trade charger upgrades today will stay ahead of the curve, deliver greater client value, and maintain a happier, better-equipped workforce long term.

“Since upgrading our charging stations and organising our battery fleet, our project timelines have tightened up by over 12%. We may not think of chargers as productivity tools—but they absolutely are.” – Dale M., Site Supervisor

Great guide on powering-peak-performance-charger-upgrades-tool-heavy-trades – Community Feedback

What makes a charger upgrade essential for tool-heavy trades?

A charger upgrade increases charge speed, reliability, and reduces downtime for professional teams. It ensures consistent power supply for multiple tools, supporting continuous productivity and preventing bottlenecks on busy worksites.

Are third-party Makita-compatible fast chargers safe for trade use?

Quality third-party Makita-compatible chargers that are CE-certified can be just as safe and reliable as OEM models, provided they offer necessary protection features and robust build standards.

How can multi-bay and rapid charging solutions improve workshop productivity?

Multi-bay and rapid charging allow simultaneous charging of several batteries, keeping tool fleets ready without waiting. This maximises efficiency for teams needing constant power throughout demanding shifts.