Overcoming Common Power Issues on Large-Scale Work Sites

In This Article

- Always assess total site load before deploying equipment.

- Use CE-certified, segmented chargers with surge protection for safety and uptime.

- Prevent voltage drop with interim panels and thicker-gauge cabling.

- Implement team-specific charging zones and RFID tracking.

- Train staff thoroughly and log all equipment changes or maintenance actions.

Why Large-Scale Work Sites Face Power Challenges

Common strain points in demanding environments

Large-scale site power demands have risen sharply, particularly with the widespread use of high-consumption tools, electric vehicles (EVs), and modular cabins requiring round-the-clock power. On busy construction sites or remote infrastructure projects, maintaining stable electricity distribution is increasingly complex. A lack of foresight in planning circuits, underestimating load requirements, or deploying outdated infrastructure all commonly lead to costly outages, tool failures, or even safety violations.

Unlike residential or small office settings, large-scale environments routinely see sudden power spikes when equipment such as compressors, hoists, or electric diggers activate simultaneously. These abrupt demands can cause voltage drops, risking damage to sensitive electronics and delaying critical operations. Moreover, harsh weather conditions, site relocations, and overall temporal setups compound the risk profiles, making dependable large-scale site power not just desirable but essential to avoid prolonged downtime.

Assessing Site Load and Circuit Layout Safely

Understanding core power distribution problems

Before deploying any large-scale site power solution, a thorough assessment of existing load requirements must be conducted. While this might seem like a basic step, many sites skip it during accelerated project timelines. Start by listing all tools, chargers, lighting systems, heating units, and any temporary buildings tied into the grid. For accuracy and safety, always calculate the maximum simultaneous power draw. Underestimating site load is one of the top causes of blown fuses and breaker trips.

It’s equally important to map existing circuit layouts. Overloaded circuits can behave erratically, leading to intermittent faults that are often misdiagnosed. Where possible, each zone should be allocated its own power circuit. Implementing load-balancing strategies — such as splitting high-draw equipment across separate phases — can also mitigate voltage instability at key junctions. Use CE-compliant distribution boards with isolators, and clearly label all components to support safe adjustments and inspections.

“Safe, balanced electrical layouts are fundamental to preventing outages on expansive work sites. Every kilowatt must be accounted for.” — Facilities Engineer, E.U. Infrastructure Program

Choosing the Right Charging Infrastructure

From outlets to multi-bay solutions

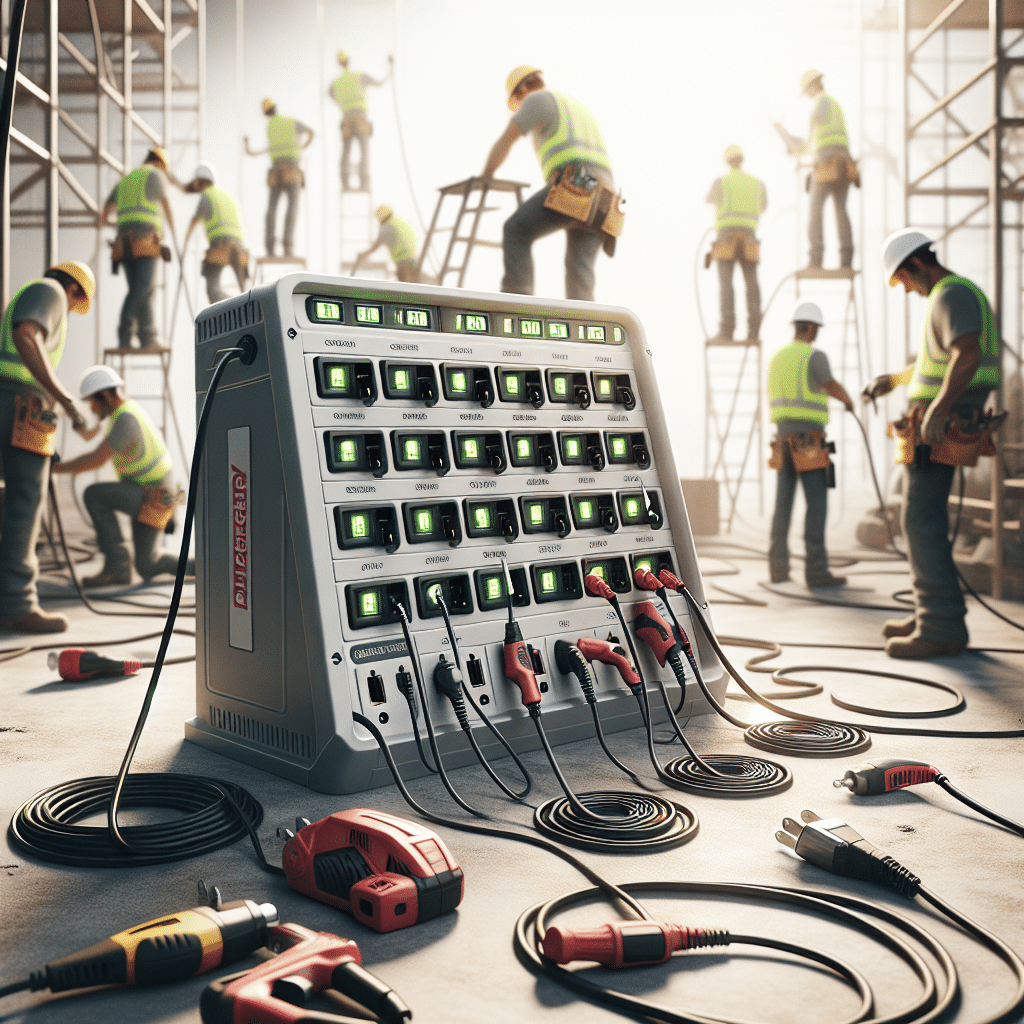

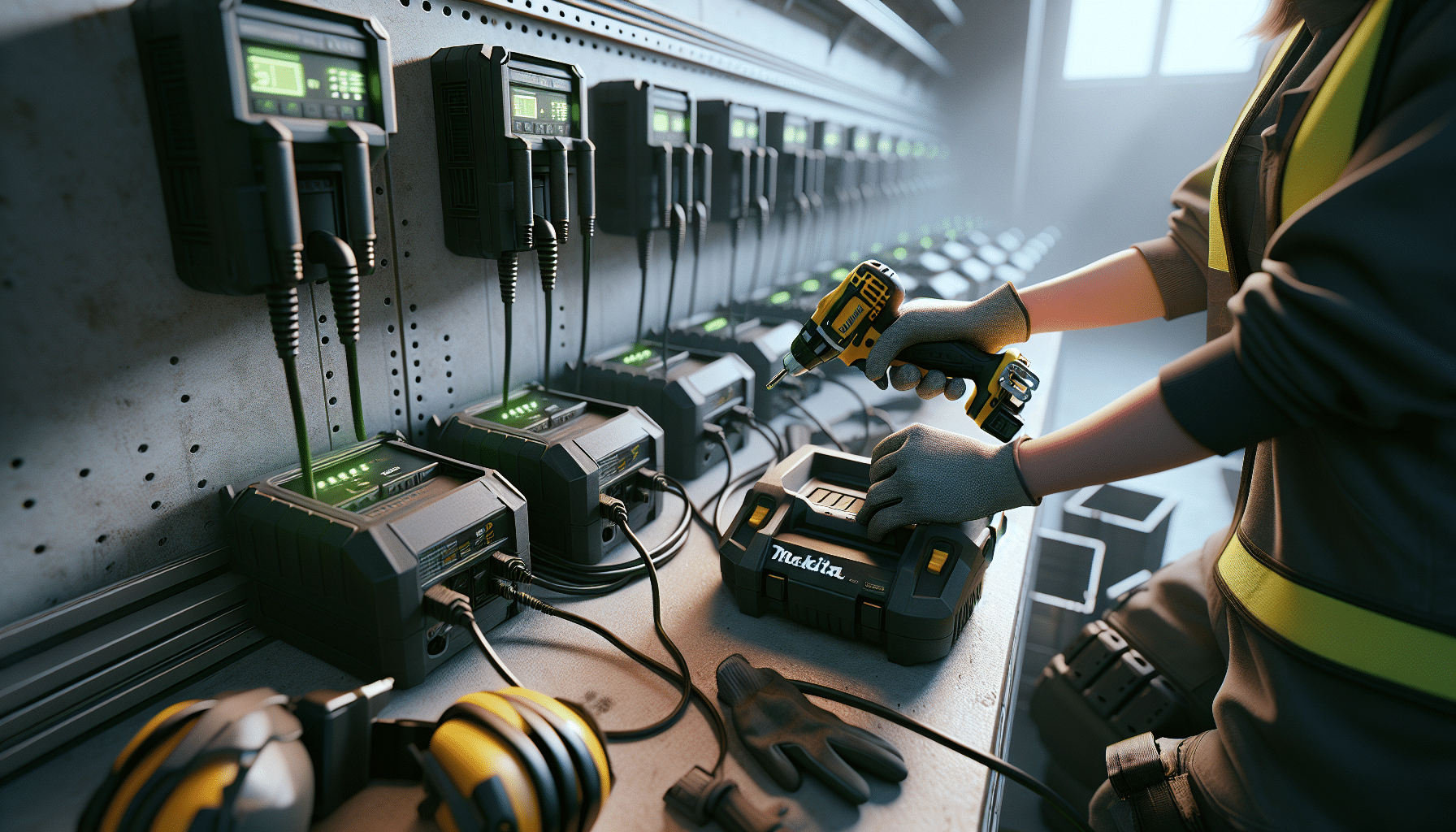

A critical aspect of sustaining uninterrupted large-scale site power is the deployment of appropriate charging infrastructure. You must go beyond basic plug-and-play concepts. Think instead in terms of centralised versus decentralised charging. Centralised solutions — such as secure power tents or multi-bay stations — provide a safer operating environment, particularly when equipped with climate-resistant sockets, surge protection, and lockable panels to deter power theft.

Decentralised charging also has its merits, especially where tool demands vary by team. However, these setups must be matched to the electrical capabilities of nearby circuits. Avoid running high-wattage chargers from extension leads; instead, use dedicated connection points that are IP-rated for outdoor use. For Makita and DeWalt-compatible systems, invest in rugged mounts and mounting brackets that align with CE certifications. Learn more about Power Solutions for Industrial and Construction Sites

Preventing Voltage Drops and Overloads

Stabilise unpredictable current with easy upgrades

Voltage drop is a persistent issue across sprawling worksite environments. Long cable runs in particular are prone to power degradation, which can erode equipment lifespans and cause efficiency losses. The most effective approach is to reduce distance wherever practical by installing interim power nodes — intermediate panels that bridge long connections while refreshing voltage delivery locally.

Additionally, upsize cable diameters to reduce impedance, and choose low-loss connectors. Monitoring tools like clamp meters and power quality analysers help track real-time current flow, flagging potential overloads before failure occurs. For highly active sites, pair these with smart load balancers that continually adjust output based on demand levels. This technology avoids the extremes — from overvoltage that damages circuitry, to brownouts that compromise safety-critical operations.

Surge Protection and Safety First Installations

Safeguard crew and equipment with compliance-ready gear

Surge events — whether caused by grid fluctuations or onsite switching surges — pose strong risks to both workers and equipment. A high-quality surge protection system is no longer optional; it should be hardwired into all major distribution points across the site. Look for SPD (Surge Protective Device) units that comply with BS EN 61643 standards, with clear test and reset features for fast diagnostics.

Safety begins at installation, and proper earth bonding is a must. Improperly earthed enclosures can cause harmful discharge currents, especially when heavy machines like tower cranes power on. Install RCDs (Residual Current Devices) and RCBOs (Residual Current Breakers with Overcurrent protection), which trip circuits when dangerous anomalies occur. Always source components from reputable vendors — suppliers should provide CE markings and conformity declarations. Solving typical site power challenges

Managing Charging for Multiple Teams

Smart scheduling and power zone planning

On a fully operational site, various teams rely on a rotating stockpile of tools that must remain charged. Without structured allocation, this often results in competing power demands across overlapping shift patterns. Introduce sector-specific charging zones based on tasks or teams — for instance, designate one area for lifting tools and another for cutting equipment. This segmentation ensures more even load distribution and shortens cable logistics.

Smart scheduling platforms allow team leaders to pre-book charging slots — a practice already popular on busy EV forecourts. Apply the same logic to work sites. When paired with RFID authentication or QR tagging systems, it becomes possible to audit which team accessed which charger, providing data transparency and enabling fault-tracing in the event of equipment failure. Such discipline enhances site efficiency and supports environmental targets by avoiding unnecessary idling or overcharging.

Maximising Uptime with CE-Certified Rapid Chargers

Why high-speed charging doesn’t have to mean risk

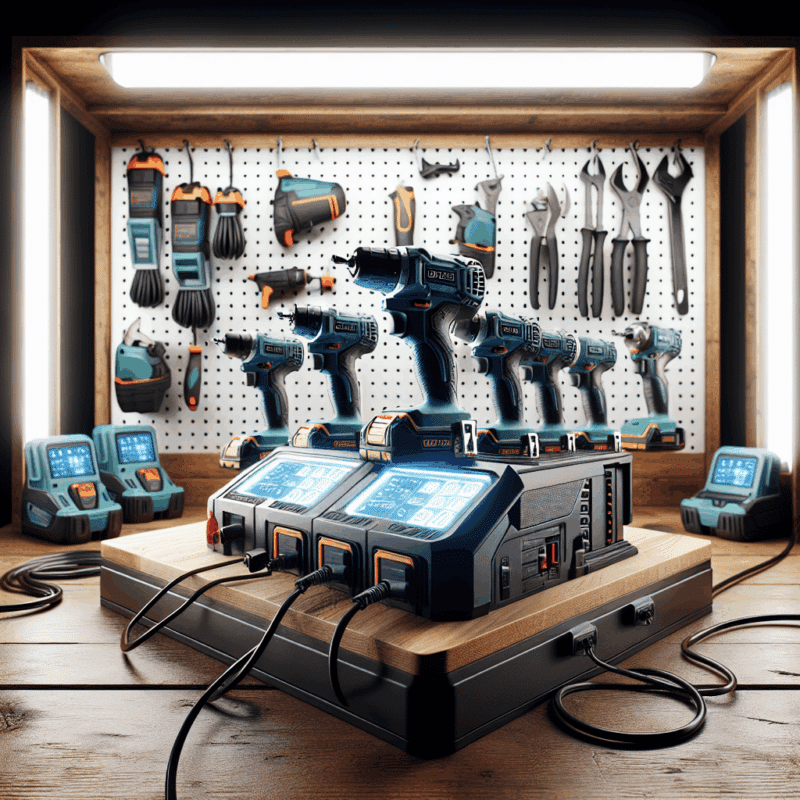

With project deadlines under constant pressure, many teams turn to high-speed, rapid chargers to keep tools functional through double shifts. CE-certified models bring agility without compromising safety, but require cautious deployment. First, verify compatibility — not all battery platforms support fast charging without degrading lifespan. Makita 40V, for example, accepts rapid input, but requires staged current ramping.

To truly maximise uptime, adopt temperature-compensated chargers with inbuilt telemetry. These devices communicate charging status back to central control, enabling proactive intervention before runtime bottlenecks occur. Pair units with protective casing to shield against debris and moisture. Finally, never daisy chain rapid chargers — always use dedicated outlets. Read a related article

Case Study: Makita-Compatible Fast Charging Setup

Boosting performance with VoltGuard 6500

During a six-month infrastructure upgrade in Manchester, contractors deployed the VoltGuard 6500 charging unit across four sub-sites. Each unit delivered 6kW of stabilised current to a multi-bay locker system linked to Makita LXT-compatible batteries. This helped power rotary hammers and impact drivers over 18+ hour cycles.

The VoltGuard 6500 features thermal monitoring, surge protection aligned to IEC standards, and individual locking bays that prevent unauthorised battery access. Operators reported a 42% drop in tool failure rates and a 27% gain in productive uptime. Thanks to integrated LED signals and diagnostic indicators, the team reduced charger-related defects even during extreme rain exposure. Upcoming European compliance for equipment

Practical Maintenance Tips for On-Site Charging

Stay efficient and safe long-term

Routine maintenance is the cornerstone of long-term reliability in large-scale site power applications. Begin with visual inspections of cable runs. Look for signs of abrasion near high-traffic zones and replace any frayed connections immediately. Use lockout kits on suspected damaged units to ensure they’re not used until repaired.

Clean terminals regularly, especially on high-connectivity chargers. Dust and mud are frequent problems on construction sites, and without cleaning, they’re a silent enemy degrading electro-conductivity. Run monthly tests on RCD/RCBO breakers and update marker labels if altered. Create an inspection logbook that traces all alterations or faults per station — this aids audit-readiness and supports compliance with HSE electrical safety guidelines.

Staff Training & Safe Charging Protocols

Empowering teams to troubleshoot and act safely

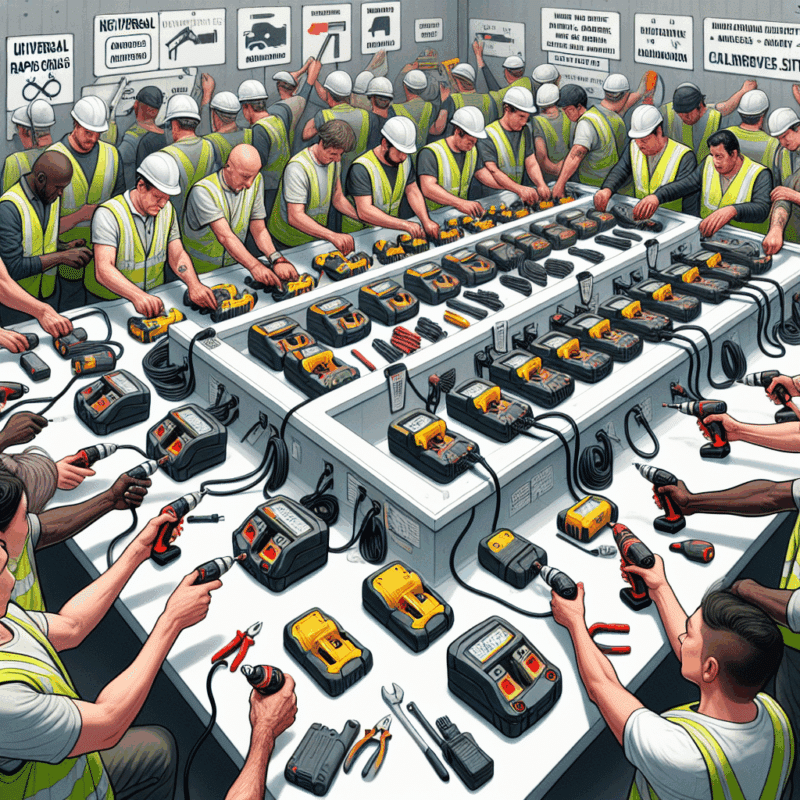

No matter how advanced your equipment, safety outcomes always hinge on user behaviour. Conduct induction training for all new hires that includes practical handling of charging equipment. Include demonstrations on identifying early signs of overheating, cable damage, and circuit overloading. A strong familiarity with RCD trip procedures enables faster recovery when minor faults arise.

Standardise charging protocols with laminated conduct guides placed near stations, clearly showing wattage tolerances and do/don’t actions. Encourage a culture of reporting — if a socket appears loose or a cable runs unusually warm, it should be logged without delay. Deploy supervisors to carry out safety drills simulating charging faults, ensuring that response times are swift and methodical.

Final Thoughts: Keep Your Tools and Team Powered

Planning a high-functioning large-scale site power ecosystem requires intentionality, precision, and a safety-first mindset. With the right blend of design strategy, compliant equipment, and robust scheduling, even the busiest work environments can run smoothly. Voltage drops, charger failures, and rogue surges should not be accepted as inevitable — rather, they are preventable with data-led assessments and user-oriented planning. As you grow operations or prepare for upcoming tenders, take time to reinforce your power management systems.

Great guide on overcome-common-power-issues-large-sites – Community Feedback

What are common power problems on large job sites?

Frequent issues include voltage drops, overloaded circuits, unreliable outlets, and equipment malfunctions from unstable power supply.

How can I improve power stability on site?

Use certified multi-bay chargers, dedicated circuits, surge protection, and regularly review site wiring and load distribution.

Are fast chargers safe in demanding environments?

Yes, when you use CE-certified, quality-tested rapid chargers designed for trade environments, they offer both safety and reliability.