Makita LXT Workshop Upgrades: Maximise Savings With Rapid Charging

In This Article

- Makita LXT workshop upgrades improve tool uptime and lower cost per project

- Rapid multi-bay chargers reduce downtime and enhance battery health

- Third-party chargers require CE certification and voltage control safeguards

- Strategic charger placement optimises workflow in high-demand environments

- Battery rotation protocols significantly lengthen lithium-ion lifespan

- Upgrades often reduce the number of spare batteries required by up to 40%

- Real-life case studies demonstrate measurable performance boosts post-upgrade

- Smart selection focuses on amperage, compatibility, and power safety

Why Makita LXT Charging Strategy Matters

The Impact of Inefficient Charging

The effectiveness of any power tool ecosystem hinges on one crucial factor: uninterrupted power. In the realm of Makita LXT workshop upgrades, charging strategy is not merely a convenience—it’s vital to productivity, safety, and bottom-line results. Workshops that rely on inconsistent or uncoordinated charging routines often face significant delays, reduced tool availability, and unnecessary battery purchases due to wear.

Many workshops operate under outdated assumptions that one or two single-bay chargers suffice. However, when projects scale and tool usage intensifies, this model quickly fails. Technicians commonly find themselves queuing tools for charge, interrupting workflows and causing minor delays that compound into hours of inefficiency over a week.

Modern upgrade strategies resolve these pain points. Incorporating scalable, rapid-charging stations into your Makita LXT setup transforms a reactive model into a proactive power approach. This prevents bottlenecks caused by overlapping charge cycles and ensures tools remain deployed for longer stretches without unplanned interruptions. A tightly managed LXT charging system ultimately becomes the lynchpin of workflow improvement.

Rapid Charging: Save Time and Tools

Benefits of High-Speed Multi-Bay Chargers

Speed is critical on a high-demand site. A Makita LXT workshop upgrade is only as strong as the efficiency of its charging infrastructure. Powerful multi-bay chargers, especially those designed for dual or quad battery support, can drastically reduce total downtime. Faster charge cycles of under 45 minutes for 5.0Ah batteries, for example, allow consistent tool rotation without operational slowdown.

Moreover, Makita-recommended rapid chargers typically feature active cooling systems. These regulate battery temperature during high-current charging, which not only preserves cell integrity but also boosts service life. In real terms, this capability saves money by reducing the frequency of battery replacement.

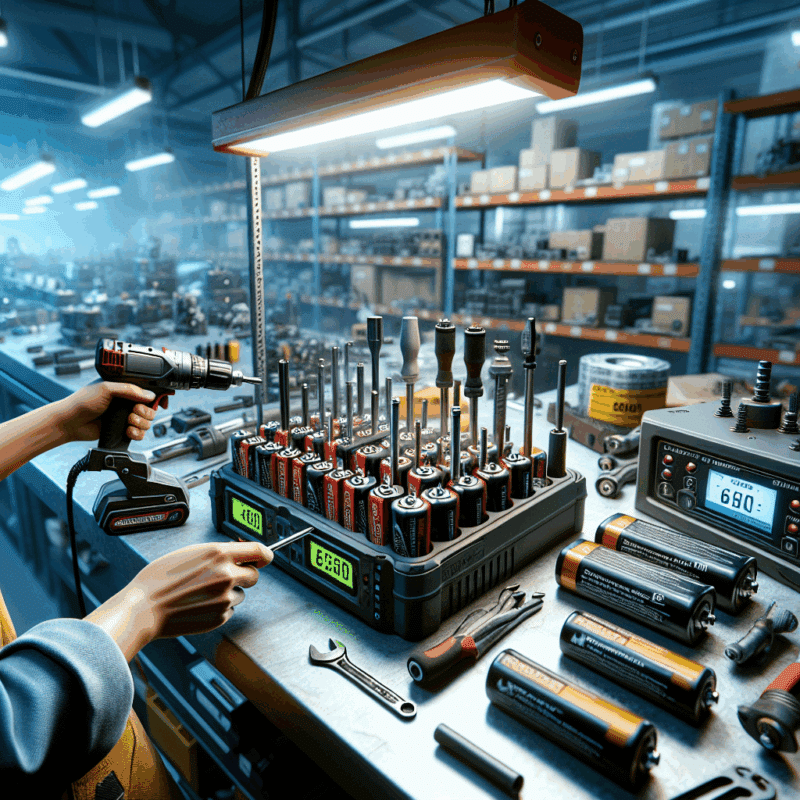

Diagnostics play an essential role, too. Premium LXT multi-bay chargers offer LED indicators, error detection, and automatic shut-off. These features safeguard both tools and workers by preventing overcurrent exposure and voltage fluctuations. Your workers spend less time guessing battery status, and more time delivering results on task.

“Since integrating high-speed dual chargers in our vehicle bay, repair cycle time has dropped by 31%”—Fleet Maintenance Manager, Bristol

Comparing Makita OEM vs Third-Party Chargers

What to Look For in a Compatible Charger

Among the most hotly debated choices in Makita LXT workshop upgrades is whether to stick with Makita OEM chargers or explore third-party alternatives. Both options come with their own advantages—and risks. Original Makita chargers are certified to work natively with LXT batteries, ensuring ideal amperage, voltage alignment, and battery preservation.

That said, several non-OEM chargers have entered the market offering faster rates, more charging slots, and unique features like wall-mount configurations or USB ports. While these can be tempting from a cost perspective, compatibility must always be verified. The wrong charger can devalue batteries through overheating or irregular charge profiles, voiding tools’ warranty terms as well.

Always look for chargers with CE marks and built-in diagnostics. Reviews from actual tradespeople on tools forums and third-party vendor platforms should also be consulted. A reputable third-party charger can be a smart investment, but diligence is essential.

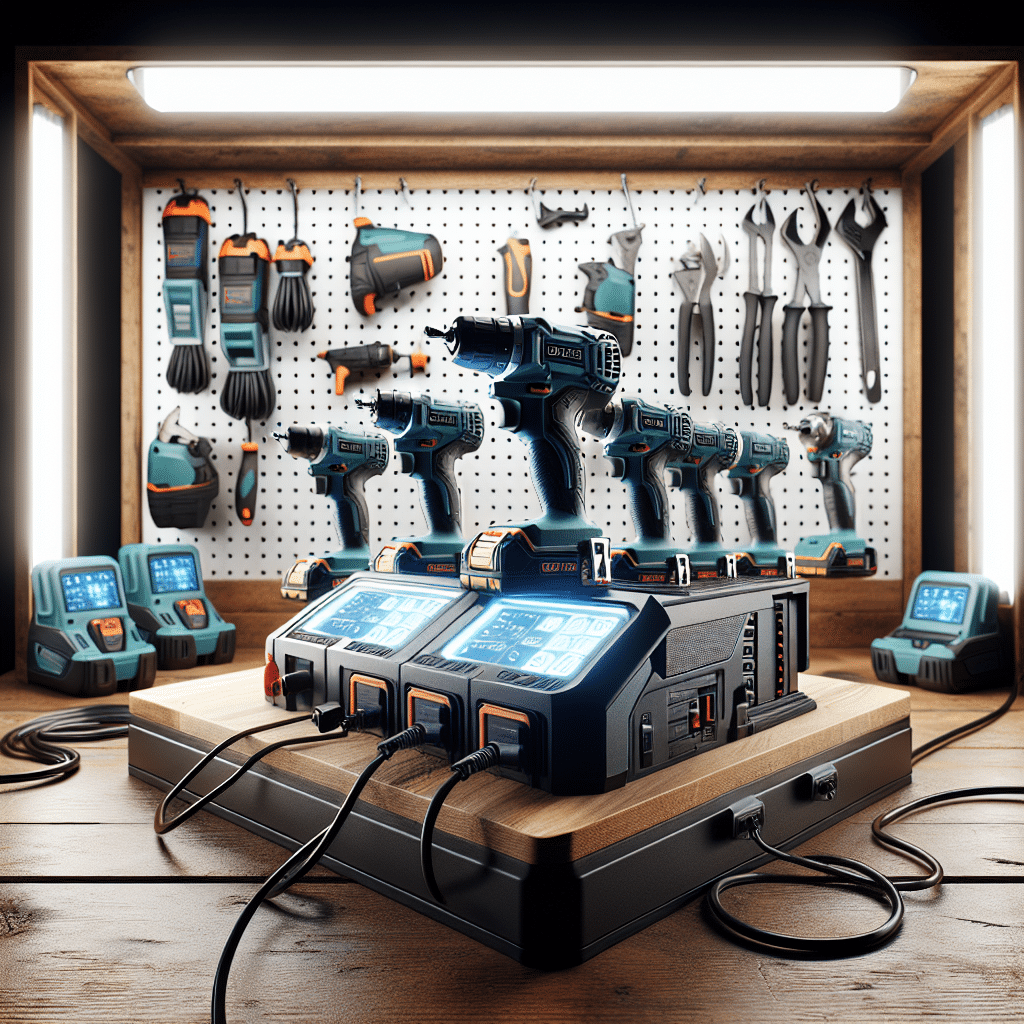

How to Position Your Charging Stations

Optimising Workshop Layout

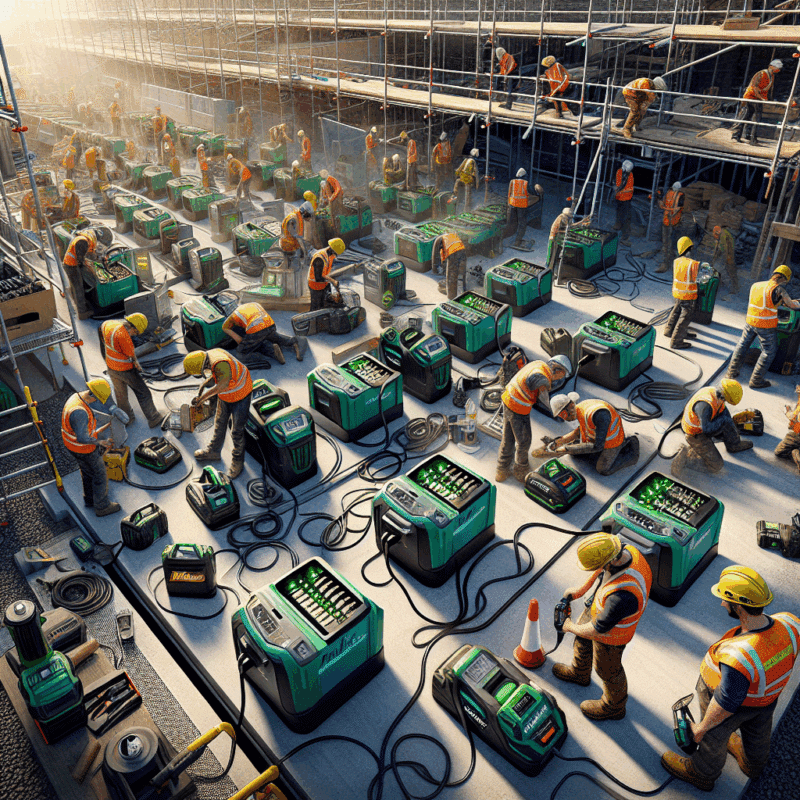

Once you’ve upgraded your charging fleet, your next concern must be placement. Strategic positioning transforms your Makita LXT workshop upgrades from useful to indispensable. Place stations near key work areas to minimise foot traffic and reduce wasted motion. In busy mechanical workshops, this might mean situating chargers by tool walls or under benches with appropriate ventilation.

Also consider dedicating charging zones for different tool sets. For instance, keep versions with higher amp requirements—such as SDS drills or planers—on chargers with stronger current throughput. Meanwhile, high-cycle tools like impact drivers benefit from quick slots near operator zones. Labelling shelves or battery docks ensures smoother rotation and less hoarding of fully charged packs.

Proper organisation also prevents power clutter. Where possible, integrate cable management systems to avoid trip hazards and overstretching wires. Channels and conduit can keep everything safely in its place, ensuring charger maintenance is easy and hazard-free.

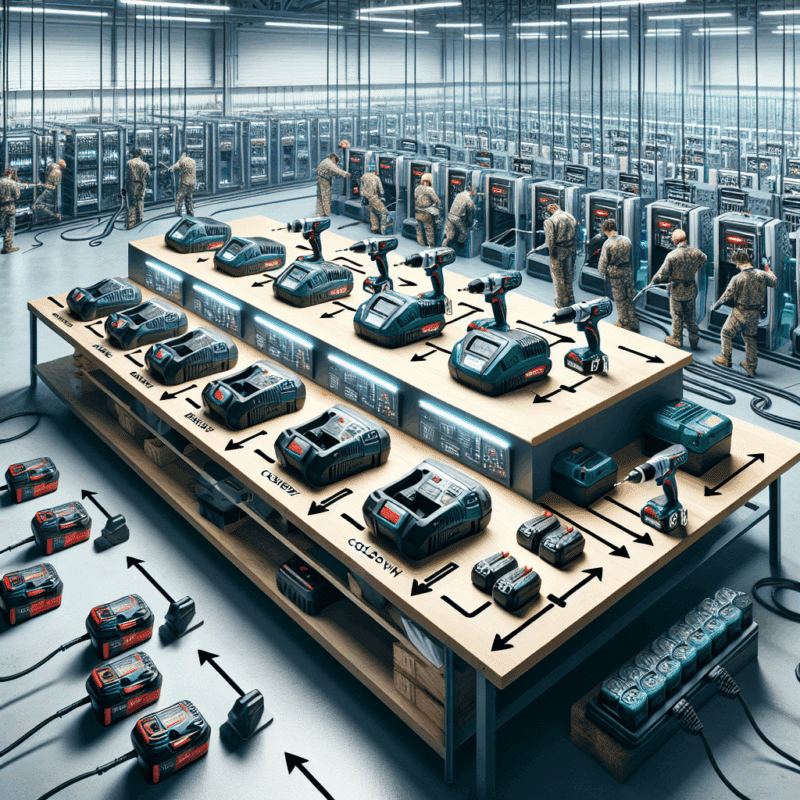

Battery Rotation & Maintenance Tips

Maximising Battery Life in Practice

Battery abuse is a silent killer in workshop economics. Too often, teams unknowingly run packs down to unsafe voltage levels or mix charge cycles randomly across battery types. A Makita LXT workshop upgrade plan must address this at the root through programmed rotation and regular inspection.

Set a labelling system using colour-coded rings or barcode tags to log battery use. Assign batteries on a rota, ensuring each pack is used and charged evenly across time. Periodic resting cycles—where batteries are allowed to cool for 30 minutes post-use before placement on a charger—can also extend lifespan significantly.

Cleaning contacts occasionally with a dry microfibre cloth eliminates transmission inefficiencies, while firmware updates for smart chargers optimise pairing even further. Do not underestimate these minor investments of time; they can salvage thousands of pounds yearly in avoided battery replacements.

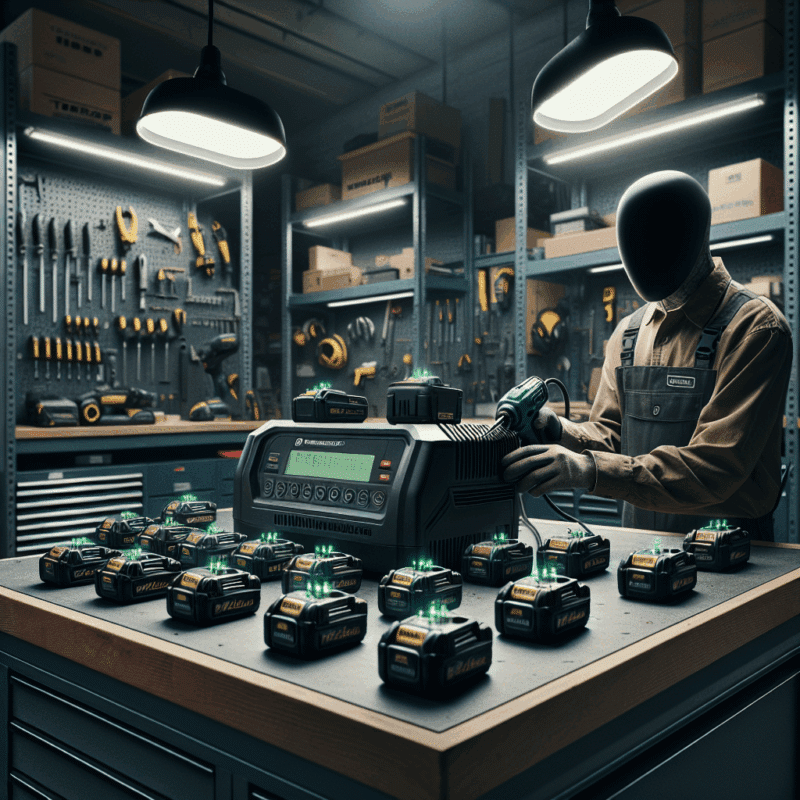

Cost-Saving: Reducing Spare Battery Needs

Calculate ROI Through Downtime Reduction

Purchasing backup batteries is one of the largest silent costs in power tool ownership. Yet many companies do this only to compensate for inefficient charging management. Upgrading to Makita LXT rapid charging configurations can lower the overall need for surplus inventory by ensuring constant availability of charged units.

The financial logic is simple. Fewer batteries mean lower capital investment and less environmental overhead. Consider this scenario: a shop using conventional charging might depend on 20 batteries across 10 tools. After upgrading to multi-bay, high-speed units with disciplined rotation, it may only require 12 batteries to meet the same performance standards.

That reduction represents almost 40% in upfront battery cost savings. Over three to five years, such savings grow through reduced replacement frequency, shorter charge cycles, and fewer project delays. Performing a cost-benefit breakdown can validate these outcomes clearly. Learn more about Cordless Tool Charging Solutions

Case Study: Upgrade Success in a UK Workshop

Before and After Charging Efficiency

To contextualise the value of Makita LXT workshop upgrades, consider Taylor Joinery Co., operating out of Sheffield. Prior to their system overhaul, they employed six single-unit chargers shared among 12 workers. Tools were routinely undercharged, leading to dozens of frustrating stoppages daily.

After introducing two Makita DC18RD dual bays and one DC18SF four-bay charger, paired with battery rotation schedules, they witnessed a 47% drop in downtime across six months. More importantly, workers no longer fought over equipment or resorted to underpowered replacements. Productivity rose steadily, and overtime hours dropped.

This case highlights how modest upgrades, when applied systematically, deliver exponential gains from the inside out. Read a related article

How to Select The Right Multi-Bay Charger

Amperage, Compatibility & Certification

Choosing the ideal charger stems from three vital considerations: amperage output, battery type compatibility, and regulatory certification. Amperage dictates charge speed while compatibility ensures the safe pairing between charger and your desired 18V battery type. Look for support for all Makita LXT packs: 3.0Ah, 4.0Ah, and 5.0Ah in particular.

Next, examine how many chargers can operate simultaneously without overloading your shop’s circuit breakers. Calculating total current draw avoids workshop outages exacerbated by high-speed charge demands. Modern Makita multi-bay chargers include smart load-balancing circuitry, but third-party models may not.

Finally, certification cannot be overlooked. Choose only chargers marked with standardised safety approvals such as CE or GS. For exported models, review whether local safety compliance is met to ensure insurance or landlord conditions aren’t breached. Understanding LXT in Makita battery technology

Safety Approval for 3rd Party Chargers

Understanding CE Marks and Voltage Control

Electrical safety should never be compromised for speed. Makita LXT workshop upgrades involving non-OEM chargers require additional due diligence. Any compliant charger marketed in the UK must display a CE mark, which signifies alignment with the EU mechanism for electronic device safety.

This relates closely to voltage control. High-speed chargers without intelligent regulation pose severe risks to both workers and battery packs. Overvolt surges degrade battery cells, while overheating can activate thermal shutdowns—or worse, fires. A reliable charger will actively moderate voltage delivery to preserve system integrity.

Electrical engineers recommend sourcing units that list specific current ratings, fail-safe protocols, and country-specific compliance measures, especially if imported. Look for independent test data posted by reviewers or on official documentation. Certifications are not merely a stamp—they’re a shield for your operations. Why multilingual product sites matter

Real-World Questions from the Workshop

Community Tested Advice

Users across the UK trades community frequently ask: “Is investing in rapid chargers really worth it?” The answer is overwhelmingly yes, provided your workshop uses more than four tools daily. Others ask if fast-charging damages battery life. The evidence points to no—if batteries are not hot when charged and charging units include built-in cooling fans.

Another common query revolves around simultaneous charging: “Can I safely charge four batteries at once overnight?” For certified models with voltage-regulated circuits, this poses no issue. Just ensure airflow is unobstructed and chargers are not exposed to flammable material nearby.

Lastly, those new to Makita LXT workshop upgrades often wonder about size, noise, and mounting options. Multi-bay units can be wall-mounted and often produce only low fan hums—perfectly acceptable even in home-based garages. With some planning, every workshop can benefit from scaling their infrastructure.

Wrap-Up: Optimal Charging Equals Savings

Makita LXT workshop upgrades deliver tangible returns when executed strategically. Proper charger selection, workshop layout, and battery maintenance ensure not only faster workflow but safer and more economical operations. When your batteries are always ready, your team stays productive—and projects run on schedule.

Invest in rapid chargers, assess performance regularly, and stay informed about tool safety and compatibility. A deliberate, well-documented approach to charging isn’t just a convenience. It’s a direct contributor to profits, efficiency, and peace of mind.

Great guide on makita-lxt-workshop-upgrades-rapid-charging-savings – Community Feedback

What upgrades make the biggest difference for a Makita LXT workshop?

Rapid multi-bay chargers and optimised charger placement significantly improve tool uptime and save on replacement batteries.

How can rapid charging save money in the workshop?

Rapid charging reduces tool downtime, extends battery life, and improves team productivity, lowering the need for spare batteries.

Are Makita LXT compatible chargers as safe as genuine Makita chargers?

Certified Makita-compatible chargers with proper CE safety and voltage regulation can safely match or even outperform standard OEM chargers.