Leveraging Real-Time Battery Data for Smart Tool Rotation

In This Article

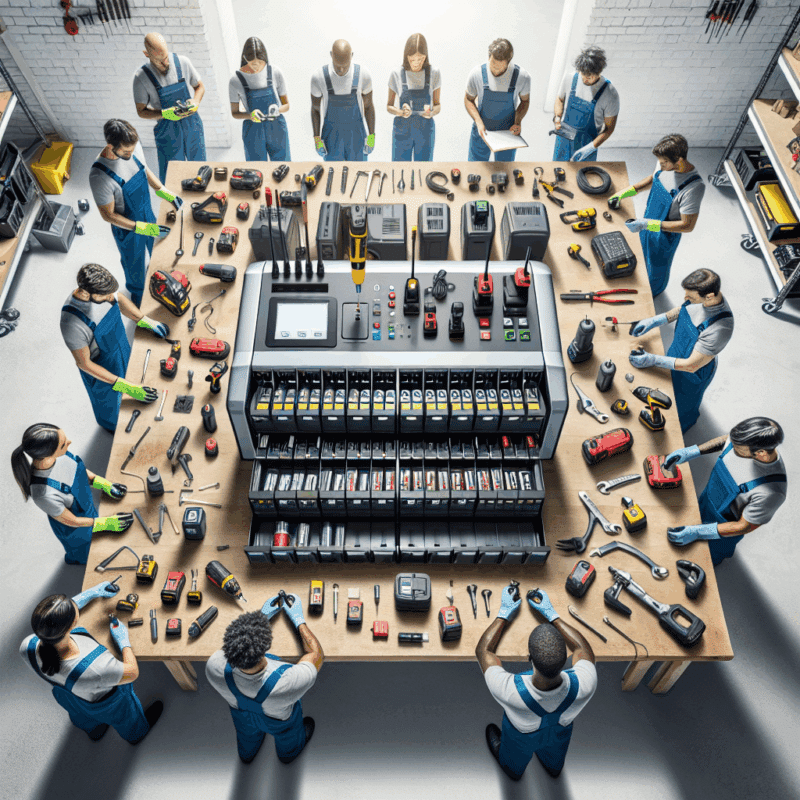

- Real-time battery monitoring prevents downtime and keeps team productivity high.

- Smart chargers with LCDs provide live data for effective rotation planning.

- Automated scheduling based on battery data enhances workflow precision.

- Proper layout of charging stations sharpens access and boosts compliance.

- Using systems like VoltGuard 6500 helps unlock real, metric-backed efficiency.

- Staggered, data-informed battery rotations preserve cell health and cost less over time.

Why Real-Time Battery Monitoring Matters

The Impact on Tool Rotations

Real-time battery monitoring is revolutionising how professionals manage cordless power tools on-site. By providing up-to-the-second insights into battery levels, temperature, charge cycles, and load profiles, this technology enables a level of oversight previously impossible in traditional setups. Construction managers and workers are empowered to make precise decisions about when to swap out, recharge, or reroute tools based on reliable battery metrics. As battery analytics become a central part of equipment management, wasted time locating charged batteries is being phased out.

Maximizing Efficiency: Using Real-Time Battery Data for Tool Rotations

This precision not only enhances productivity—it also reduces frustration. Imagine running a rotary hammer just to have it stop mid-hole from an unexpected power drop. With real-time battery monitoring, this is avoidable. Current power statuses are visible remotely or directly on-site, offering confidence in tool usage. Predictability becomes the norm, not the exception. Moreover, scheduling rotations based on real-time metrics drastically cuts unnecessary idling, a hidden yet costly drain on larger operations. Learn more about Battery Management and Smart Charging for Power Tools

The Role of Smart Chargers on Site

LCD Screens and Live Status Updates

Smart chargers have reshaped how we refuel batteries on-site. Thanks to integrated LCD screens, team members gain immediate visual access to real-time data about charge status, battery health, cycle history, and estimated completion times. Unlike older models with a single LED or generic icon, modern smart chargers deliver a rich data feed in plain sight.

Optimizing Workflow: The Best Strategies for Scheduling Battery Swaps On Site

These devices communicate clearly, helping tradespeople see whether a pack is charging, nearing full, or in need of replacement. In systems like the VoltGuard 6500, multiple batteries can be slotted into configurable ports. The device prioritises charging based on battery condition and urgency. This data-centric approach keeps the job moving forward, not stalled in delay.

Real-time battery monitoring through chargers reduces guesswork. Instead of stockpiling extras “just in case”, crews rotate fewer batteries more efficiently. This reduces waste and extends battery lifespan by avoiding overcharging or deep-cycle stress. Combined real-time battery monitoring methods

“We switched to smart chargers with live updates and gained back over five hours per week in tool availability.” – James R., Site Manager

Scheduling Tool Swaps to Boost Jobsite Flow

Minimising Delays Through Predictive Swapping

Skilled site supervisors now integrate battery data into their planning to anticipate tool availability. With real-time battery monitoring, one can forecast when a battery is likely to run out and proactively have a charged unit ready nearby. This predictive swapping strategy minimises tool downtime and stops production bottlenecks before they begin.

Real-Time Monitoring: Insights on Makita Chargers in the UK

Instead of reacting to dead batteries, workers are now responding to patterns: batteries with a certain load usage typically drop below 20% after two and a half hours, for instance. Armed with this knowledge, forepersons schedule hand-offs of pre-charged batteries just before a tool goes offline. The result is steady work rhythm, improved morale, and tighter control of jobsite momentum.

Better yet, these processes can be aligned with existing shift and task rotations. A floor installer doesn’t lose time walking back to the charging station every 90 minutes if a freshly charged tool is delivered during scheduled breaks. Real-time battery monitoring makes this choreography possible. Read a related article

Rotational Planning to Extend Battery Lifespan

Avoiding Overuse and Power Drain

Batteries degrade from two major causes: excessive heat and consistently deep discharges. Most damage occurs unnoticed when users allow batteries to drain to zero multiple times per week, which accelerates cell decay. Rotational planning, guided by real-time battery monitoring, resolves this by cycling batteries based on live health readings rather than gut feeling or routine.

Boosting Jobsite Efficiency: The Benefits of Battery Rotation

The goal is not merely to rotate batteries for availability, but to rotate them intelligently to preserve performance. For instance, batteries nearing their maximum charge cycles can be phased to lighter tasks to reduce strain, prolonging their viable lifespan. Data from chargers and in-tool sensors contribute to smart decision-making.

Moreover, by ensuring that no single pack is disproportionately relied upon, the battery fleet remains evenly used. This uniform degradation simplifies maintenance forecasting and budget planning. It’s no longer a guessing game—it’s science-backed rotation yielding long-term economic returns.

Insights from the Field: Tradespeople’s Tips

Real Jobsite Experiences

Tradespeople across the UK share a common sentiment: those using real-time battery monitoring wouldn’t return to the “old way”. Electricians, scaffolders, and carpenters alike report noticeable gains in job efficiency and stress reduction. One tip from a Yorkshire-based joiner: colour-code battery docks to identify which packs are fresh, nearing empty, or midway through charging.

Essential Tool Rotation Strategies: Tips for Professionals

Another practice gaining traction involves assigning unique QR codes to each battery. When scanned, these link to a shared app updated in real-time, showing status, maintenance history, and even last known location. While initially sounding tech-heavy, these systems quickly prove invaluable in high-demand zones like commercial builds or rail work.

Many tradespeople also laud the pairing of on-tool sensors with Bluetooth monitoring apps. Real-world insights reveal how tools are used under load and in high-heat conditions. Armed with such data, task allocation becomes safer and more efficient. It’s not about babysitting batteries; it’s about equipping workers with knowledge for seamless tradecraft. Enhancing jobsite routines with automation

Integrating Rotation with Automation

Smarter Workflow Management

Automation isn’t just for factories. On modern construction sites, digital integration is helping crews rotate batteries in synchronised harmony. Software platforms that integrate with real-time battery monitoring tools allow site managers to build automated schedules that notify team members when tools require swaps or breaks for optimal performance.

Harnessing Real-Time Data: The Future of Battery Monitoring

With cloud-based notifications and interlinked devices, jobsite workflow now mirrors a well-oiled assembly line. When a battery hits 35% charge, a message can trigger alerting the nearest staffer. Kitting in fresh units becomes part of the automated supply rhythm. It’s not a gimmick—this orchestration delivers premium efficiency on repetitive task sites like infrastructure projects.

Additionally, collected data becomes a feedback loop. Algorithms learn your site’s rhythms over time and refine workflows—automating what was once guesswork. The era of deeply manual battery management is giving way to a digitised, precise system that saves energy, time, and money.

Comparing Chargers and Their Monitoring Abilities

Why Displays Matter

Not all chargers are created equal. Quality monitoring capabilities vary drastically across brands and models. The crucial differentiators include screen size, data granularity, update frequency, and integration options. Units with real-time feedback ensure workers receive precise charge states, alerts, and maintenance flags without needing to guess or inspect physically.

Seamless Scheduling: Tools for Battery and Tool Swaps

Some advanced systems allow multiple ports to be remotely accessed via a mobile interface, sending updates straight to phones or tablets. This is especially valuable for large teams where logistical communication is key. Chargers without such feedback mechanisms ultimately cost more in downtime and confusion.

When investing in a charger fleet, stakeholders must assess not just wattage output, but clarity of information. Transparent uptime visibility ensures smooth operational flow. A charger that speaks clearly is worth three silent bricks that simply blink a light. Real-time battery monitoring excels only when supported by equally communicative hardware.

How the VoltGuard 6500 Enhances Efficiency

Built for Makita Users

The VoltGuard 6500 is designed to integrate seamlessly with Makita’s 18V LXT battery platform. Known for its intelligent four-channel charging ports, this unit stands out by offering a comprehensive real-time battery monitoring dashboard directly on its OLED screen. Each port displays active charging curves, temperature thresholds, and time-to-completion estimates.

Enhancing Workshop Productivity: A Guide for Makita Users

With built-in scheduling AI, the VoltGuard system adjusts allocations dynamically. If one battery is slated for imminent high-drain usage, it gets priority. This predictive balancing reduces inefficiencies and ensures that your team always has a pack at peak performance.

For Makita-heavy sites, this synergy is a game-changer. No more second-guessing if that battery is really charged. With the VoltGuard 6500, you don’t wonder—you know. Its inclusion in your workflow brings measurable gains in time savings and tool uptime.

Jobsite Layouts for Maximum Charging Access

Smart Placement Tactics

Positioning chargers for optimal jobsite access is as important as owning smart devices. A well-thought-out layout ensures that battery stations are never more than 60 seconds from primary work zones. Construction managers should evaluate shift calendars, task stations, and worker density patterns to locate charging points strategically.

For instance, on vertical builds, charger bays placed near lift cores enable centralised recharging spaces shared across floors. Horizontal sites, like warehouses or railways, benefit from wheeled mobile stations that track tasks across wide areas. Pairing each station with real-time battery monitoring modules turns every dock into a live maintenance hub.

Visibility is key—chargers on open frames or wall brackets with active screens keep everyone informed. Improved access also encourages consistent battery etiquette, reducing abandonment or hoarding of packs. Strategic layout plus live monitoring equals peak project tempo.

Conclusion: Optimise Today, Save Tomorrow

Real-time battery monitoring has emerged as a vital pillar in modern tool management. No longer a future luxury, it is now an essential part of jobsite planning and execution. It allows project managers and tradespeople to stay proactive, prevent power interruptions, and extend the longevity of expensive equipment through informed rotations.

By embracing data insight and integrating advanced technologies like smart chargers and scheduling software, companies position themselves at the forefront of jobsite productivity. In a sector where every second and penny matter, intelligent rotations driven by real-time monitoring are indispensable. Tomorrow’s savings are secured by today’s optimisations. Adapt now, and lead with performance and precision.

Great guide on leveraging-real-time-battery-data-schedule-rotations – Community Feedback

How does real-time battery data improve tool rotation?

Real-time battery data enables you to track charge levels and usage, so teams can rotate tools just before batteries run low, minimising downtime and increasing site productivity.

What are the biggest benefits of scheduled battery rotation?

Scheduled battery rotation ensures consistent power delivery, maximises battery lifespan, and prevents job interruptions by keeping charged tools in steady use throughout the day.

Which charger is best for monitoring Makita batteries?

Chargers with LCD screens, such as the Torxup VoltGuard 6500, display live charge data and health stats, helping trades manage tool rotations precisely and efficiently.