How to Implement Multi-Bay Charging in High-Volume Environments

In This Article

- Multi-bay charging increases productivity by supporting multiple tool batteries at once

- Choose compatible, high-performance systems with smart features for optimal value

- Prepare a clean, ventilated, and power-supportive environment for safe installation

- Incorporate power monitoring tools to track battery health and charging cycles

- Use structured labelling and tracking to ensure even battery usage

- Follow maintenance protocols to prevent electrical faults and extend charger life

- Safety and compliance must drive layout and user-training strategies

- Smart accessories enhance functionality and ensure reliable operations

Why Multi-Bay Charging Matters

Understanding the Operational Advantage

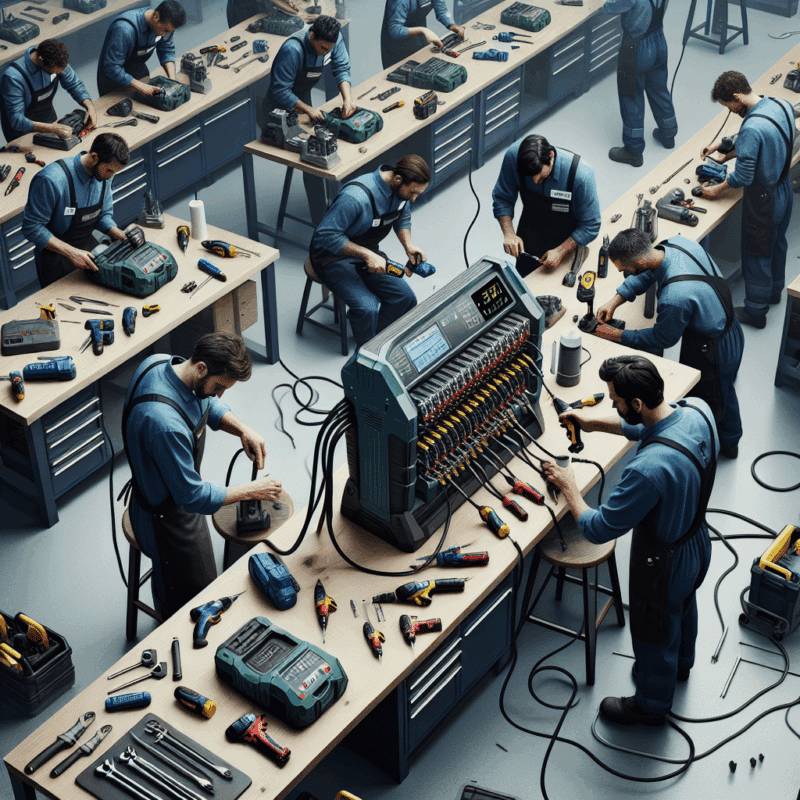

In high-volume environments—such as automotive workshops, warehouse operations, and manufacturing facilities—the demand for powered tools and equipment is relentless. Multi-bay charging offers an efficient solution to meet this demand. Unlike single-charger setups that restrict throughput, multi-bay charging accommodates multiple battery units simultaneously, eliminating bottlenecks and keeping workstreams uninterrupted.

Multi-bay charging systems are designed for organisations that need continuous access to fully charged batteries throughout the working day. The ability to charge up to 8 or more batteries concurrently allows workers to swap power sources seamlessly. This ensures that critical tools remain operable and maximises machine uptime in environments where delays can result in significant financial losses or breaches in service level agreements.

Moreover, using multi-bay charging stations reduces wear on individual batteries by encouraging organised rotation and proper maintenance. Integration of smart-charging algorithms further helps extend battery lifespans, saving money in the long term. When every minute matters, multi-bay charging isn’t just helpful—it’s essential.

Preparing Your Environment for Installation

Selecting the Right Location and Infrastructure

Before investing in a multi-bay charging station, you must first assess the physical and electrical environment in which the system will be installed. Optimal placement of multi-bay chargers depends on tool usage patterns, foot traffic, and the proximity to workbenches or storage units.

Ideally, the charging area should be free from dust, chemicals, and direct exposure to heat or sunlight. These environmental factors can degrade battery performance over time. Ensure your facility can support stable electrical supply to the designated area, particularly since multi-bay units draw more current than individual chargers.

It’s also crucial to assess airflow and ventilation in the charging zone. Some batteries release heat during charge cycles, which can impact safety and efficiency if poorly ventilated. Clearly marked wall sockets, dedicated breaker systems, and surge-protective circuits should all be part of the environmental preparation plan.

Choosing Your Multi-Bay Charger

Compatibility, Performance, and Safety

One of the most important factors in a successful multi-bay charging setup is selecting the correct charger model. Different brands and tool manufacturers provide proprietary battery systems—making compatibility a primary concern. Whether you’re using Makita, DeWalt, or Bosch batteries, ensure the charger chosen supports the voltage and form factor of those systems.

Beyond compatibility, look for performance-oriented features. Fast-charging capacity, thermal monitoring, and overcharge protection are technical criteria that should not be overlooked. Safety certifications such as CE, UKCA, and RoHS compliance offer additional assurance that the device meets operational safety standards.

Modern multi-bay chargers also include smart management features like battery health indicators, thermal dashboards, and programmable cycles. These can provide actionable data to maintenance teams, making adjustments before unexpected failures occur. Investing in capabilities now is a safeguard for high-volume service delivery.

Power Management and Electrical Considerations

Protecting Tools and Extending Battery Lifespan

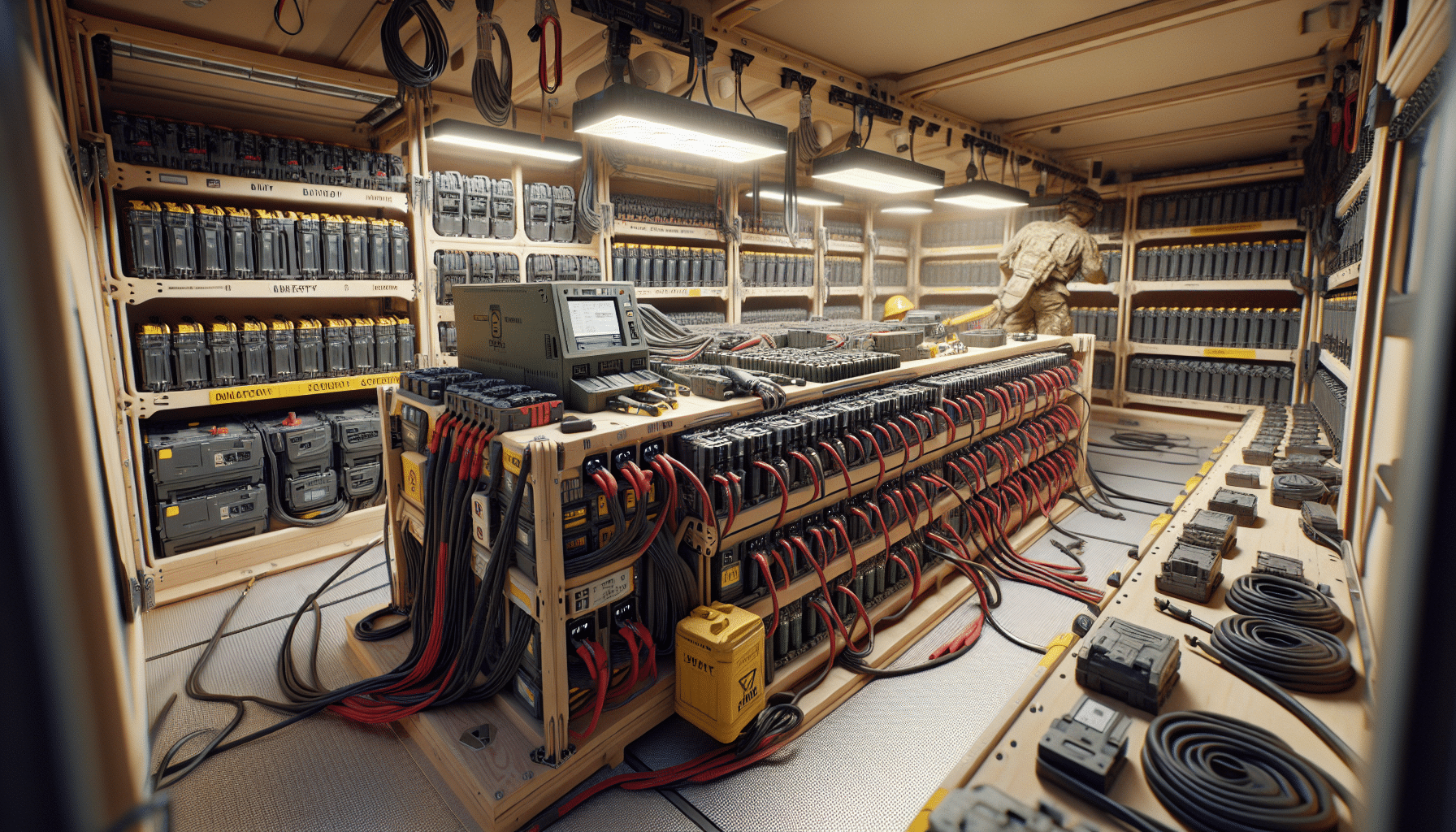

Reliable electrical infrastructure is foundational to any sustainable multi-bay charging solution. Begin by ensuring that your breakers and circuits can safely handle not only the rated amperage but any potential power surges. Overdrawing leads to system trips or—worse—equipment failure.

Voltage regulation is equally critical. Spikes or fluctuations can quietly degrade expensive lithium-ion or NiMH batteries even if chargers remain operational. Using an industrial-grade power conditioning unit or line-interactive UPS can mitigate these risks. Surge protectors paired with residual-current devices (RCDs) offer an extra layer of protection to users and devices alike.

Additionally, balancing the timing of charge cycles reduces peak load on your electrical grid. Smart systems may offer scheduled-charging features to optimise energy usage during off-peak hours, contributing to reduced utility costs and carbon footprint alike.

Workflow Optimization Through Smart Charging

Reducing Downtime and Battery Swapping

Integrating multi-bay charging with your workflow analysis leads to powerful gains in logistics efficiency. For example, by aligning battery rotation protocols with tool check-in/check-out schedules, you eliminate idle time spent waiting for replacements. This improvement alone can increase daily output by a measurable margin.

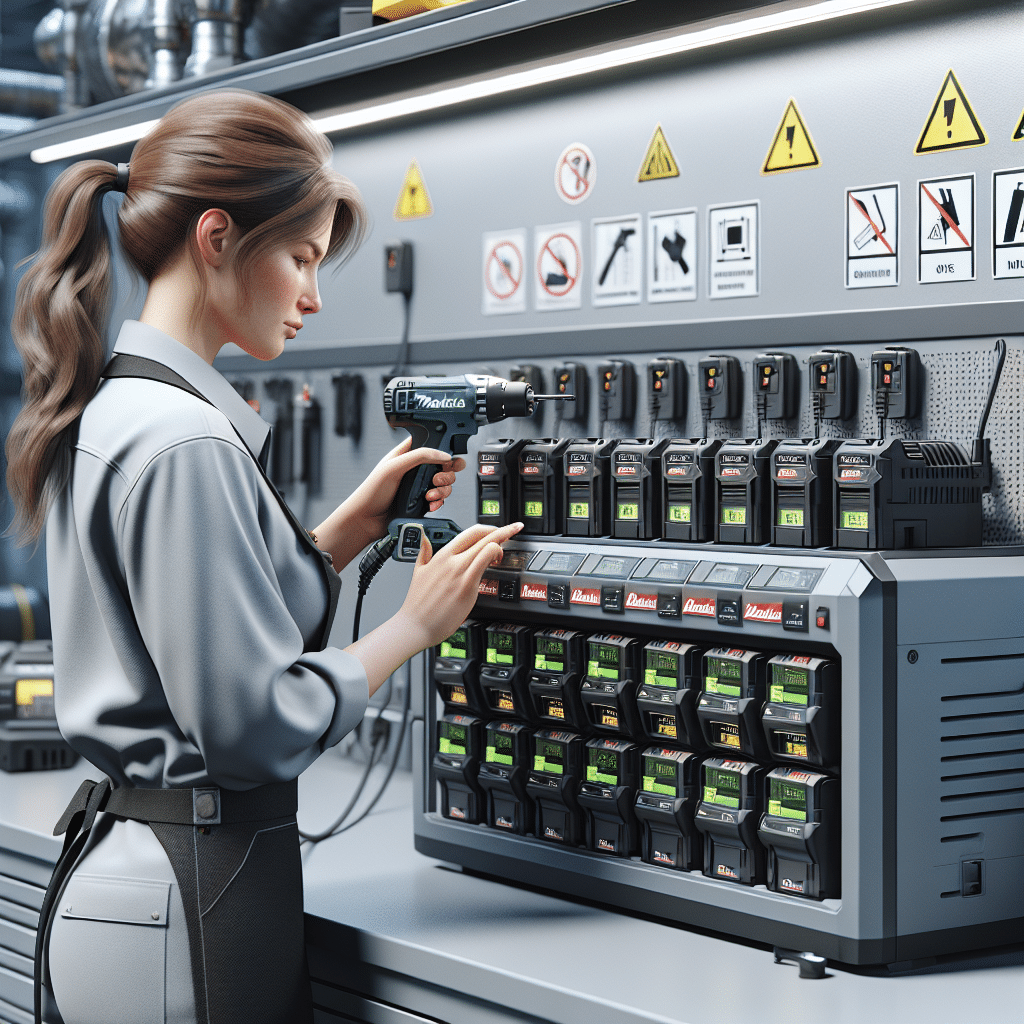

Smart multi-bay systems include features like individual battery monitoring, LED status indicators, and remote alerts. These features allow staff to see in real-time what batteries are ready or nearing end-of-life, encouraging better rotation. Incorporating these insights into shift-change protocols enhances accessibility without increasing workload.

Best-in-class workshops take this a step further by linking their charging systems with inventory management platforms. Such integrations allow analytics teams to identify usage trends, prioritise rotating weaker batteries, and plan stock replenishments accurately. Learn more about Power Tool Charging Solutions

Setting Up for Safety and Compliance

Meeting Regulations and Best Practices

Health and Safety Executive (HSE) regulations in the UK highlight the importance of using electrical equipment in safe and approved conditions. Deploying a multi-bay charging station must therefore adhere to general workshop safety standards, including sufficient fire suppression access, visible hazard signage, and insulation safeguards.

Battery chemistry must also be considered. For instance, lithium-ion batteries require specific handling guidance. Guidelines such as proper spacing between units and avoiding stacking are not merely suggestions but vital practices to reduce risk. Many leading systems include enclosure features or rack-mounted arrangements to aid in this regard.

Conducting a pre-installation risk assessment becomes even more important when first deploying multi-bay charging setups. Document these inspections, train staff on response procedures, and install emergency shutoffs where relevant. Safety-first initiatives assure regulatory compliance and foster a more informed workforce. Efficient simultaneous charging with multi-bay units

Maintaining Your Charging Ecosystem

Routine Maintenance and Checklist Essentials

While multi-bay charging solutions are built for reliability, proper maintenance keeps them running at peak performance. Each manufacturer supplies maintenance guidance, but every facility should develop a unique checklist suitable for its volume and operating conditions.

Regular checks should include cleaning of ports, inspecting for frayed cables, and ensuring firmware is up-to-date—especially on smart units. Verifying temperature sensors and checking indicator lights prevents small issues from escalating. Weekly visual inspections and monthly electrical tests create a proactive regimen that extends longevity.

Moreover, assigning responsibilities to specific team members or maintenance roles helps ensure accountability. Don’t allow routine maintenance to fall through the cracks—it only takes one failed bay to delay entire production lines. Read a related article

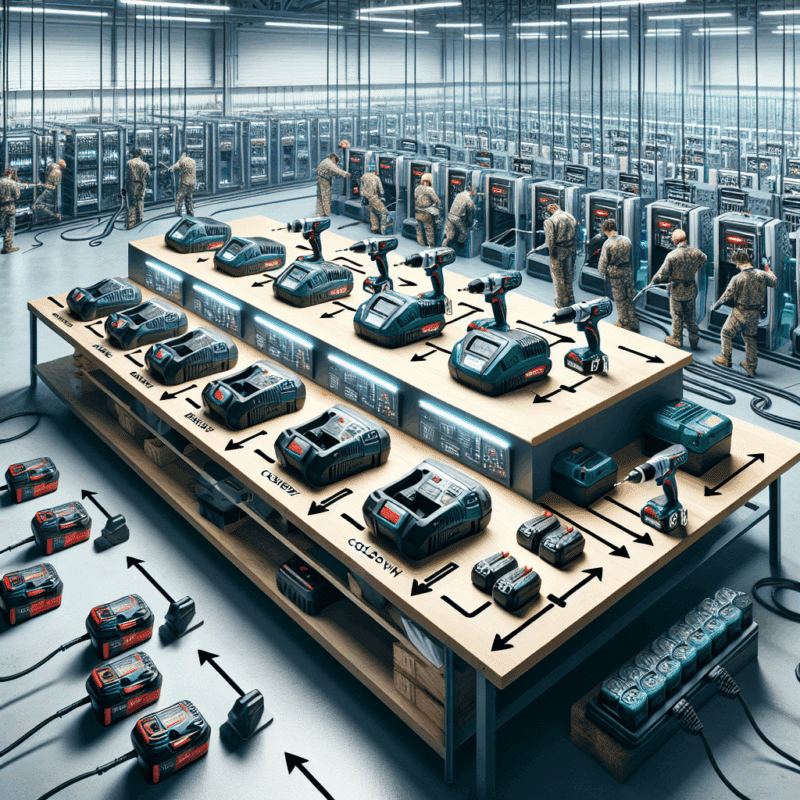

Labelling, Tracking, and Battery Rotation

Keeping Chargers and Batteries Organised

Without an organised labelling and tracking system, even the best multi-bay charging setup will fail to deliver optimal results. Start by clearly marking each battery with unique identifiers, usage logs, and installation dates. Consistent tracking can reveal ageing batteries before performance degrades significantly.

Implementing a ‘first-in, first-out’ (FIFO) policy for batteries ensures fair wear and avoids overuse of newer units. Multi-bay chargers should be labeled by bay number, creating a predictable structure staff can follow. Colour-coding by battery chemistry or department can offer further refinements in complex operations.

Some modern solutions integrate QR codes or RFID tags on batteries. When scanned via a mobile app, these provide access to service records or charge histories. This facilitates rotation and accountability metrics—an ideal protocol for ISO-certified facilities.

Case Example: Workshop Setup Using Torxup VoltGuard

Real-World Layout with Makita-Compatible Solutions

Consider a mid-sized automotive workshop operating 50+ Makita tools daily. Before adopting the Torxup VoltGuard multi-bay solution, they faced a 10% loss of productivity due to battery downtime. Workers frequently waited for a charge or used partially charged units, compromising output.

After installing two 8-bay VoltGuard systems, the team created defined charging zones using mounted wall racks, ESD mats, and lockable cabinets. Each bay was labelled and integrated with a basic battery tracking system using Google Sheets tied to QR codes. Battery rotation compliance rose to 95% within three weeks.

Furthermore, the integration of smart monitoring reduced unexpected battery failures by 68%. The multi-bay charging solution streamlined worker flow, allowing administration to repurpose one floor manager from ad hoc battery management duties to quality control—a net productivity gain. Smart tools for streamlining workflows

Tools That Help: Monitoring Systems and Accessories

Smart Displays, Surge Protectors, and Storage

Strong support tools transform a good charging station into a truly optimised ecosystem. Smart monitoring hubs, like the PowerSync series, offer dashboard displays showing battery health, charge cycles, and load statistics. These are particularly valuable in high-traffic environments.

Industrial-grade surge protectors and voltage regulators provide further assurance when operating across multiple circuits or during high seasonal demand. Look for accessories that feature audible alerts or automated shutoffs when irregularities are detected. This proactive reporting protects costly tools from fried batteries or dropped output.

Storage should not be forgotten. Modular shelving, lockable compartments, and fire-retardant organisers keep the entire charging zone clean, ergonomic and safe. Know that well-designed spaces reinforce safe and efficient practices throughout the team.

“Since implementing a multi-bay charging system, we’ve cut our downtime in half and rotated through over 200 batteries without issue. It’s been transformative.” – Facilities Manager, Midlands Assembly Co.

Conclusion: Charge Smarter, Not Harder

In high-volume environments where every tool, battery and workflow counts, dependable multi-bay charging creates a tactical advantage. From reducing downtime and boosting output to extending battery life and enhancing compliance, these systems are engineered for serious performance gains.

However, successful integration hinges on thoughtful planning. Facility managers must evaluate environmental safety, compatibility, and long-term power needs before installation. Training teams in proper rotation procedures and scheduling regular maintenance ensures the solution continues to deliver measurable ROI well beyond initial deployment.

Ultimately, adopting multi-bay charging isn’t just about keeping devices ready—it’s about empowering people to keep executing without compromise.

Great guide on multi-bay-charging-high-volume-environments – Community Feedback

What is a multi-bay charger and how does it benefit high-volume operations?

A multi-bay charger allows simultaneous charging of multiple batteries, ensuring a continuous power supply, minimising downtime, and streamlining workflows for demanding, high-volume environments.

How do I set up a safe and efficient multi-bay charging station?

Choose a ventilated area, use high-quality chargers, ensure proper spacing, install surge protection, and regularly inspect cables to safely and efficiently charge numerous batteries at once.

Which features should I prioritise when selecting a multi-bay charging solution?

Key features include rapid charging speeds, intelligent cooling, compatibility with your batteries, built-in safety mechanisms, and robust build quality for site or workshop reliability.