How to Choose the Best Charger Setup for Site & Workshop

In This Article

- Assess power loads and ensure wiring matches charging demands.

- Use a mix of rapid, dual, and standard chargers for flexibility.

- Prioritise charger compatibility within a unified tool ecosystem.

- Implement dedicated charging layouts with proper labelling.

- Verify safety certifications and maintain a clean charging environment.

- Scale smartly with charging hubs and inventory management tools.

- Explore real-world solutions adapted by industry professionals.

- Invest in quality for long-term ROI and reduced downtime.

Why Your Charger Setup Matters

Impact on Jobsite Productivity

When considering a site charger setup, few realise how dramatically it can impact the rhythm and reliability of day-to-day operations. The right configuration not only guarantees drones of electric tools stay energised throughout the shift, but also ensures minimal downtime, reduced bottlenecks, and safe power management. A poorly planned charger arrangement can cost hours of delay weekly. Productivity on-site rises significantly when tradespeople don’t have to share or queue for charged batteries. This setup becomes the literal and figurative powerhouse of the site.

Assessing Power Needs for Site and Workshop

Calculating Amperage and Load Capacity

Before selecting a site charger setup, it’s essential to evaluate your total power requirement. Start by listing all power-hungry devices you plan to charge simultaneously. Look at their amperage rating—often displayed on the device itself. Multiply voltage by amps to get wattage, then tally the total for your daily load. Pay close attention to circuit breaker ratings and ensure the combined charger use won’t trip systems. Many workshops are not wired for large-scale simultaneous charging and may need an electrical upgrade. Investing in a load calculator tool or consulting a certified electrician helps prevent future outages.

“Understanding your total electrical load is not optional—it’s essential safety and performance insurance for any serious workshop.”

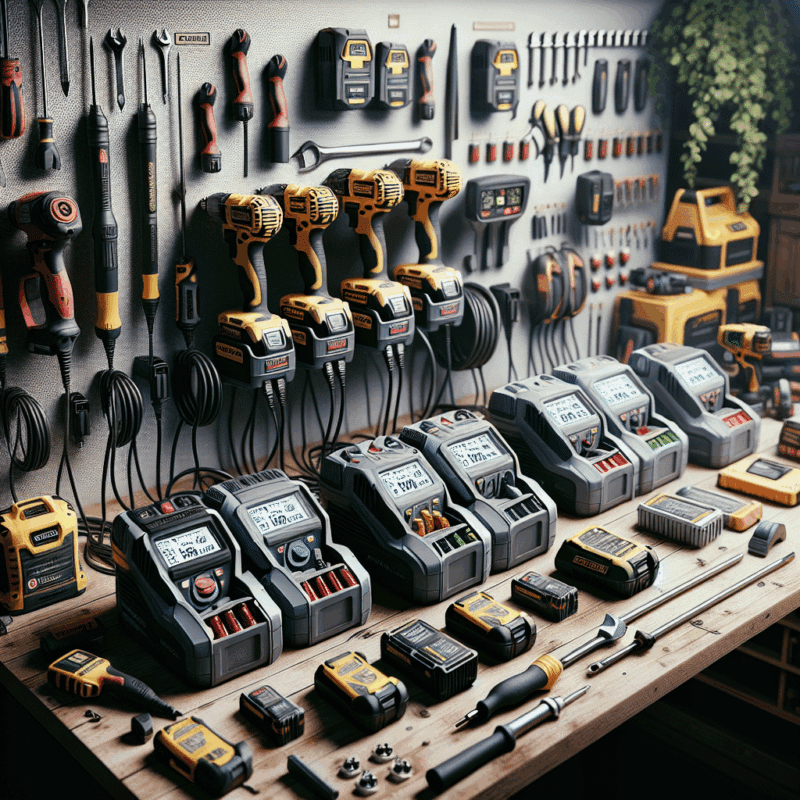

Types of Chargers for Power Tools

Standard, Dual, and Rapid Chargers

Chargers come in various types, each designed for different requirements. A standard single charging dock suffices for light usage but presents a bottleneck when multiple users share the site. Dual chargers allow two batteries simultaneously, while rapid chargers significantly reduce charge times—perfect for high-demand environments. For any site charger setup, integrating a mix of charger types based on crew size and battery depletion rate yields optimal results. Ensure each unit is compatible with your primary battery architecture, especially if fielding tools from multiple generations.

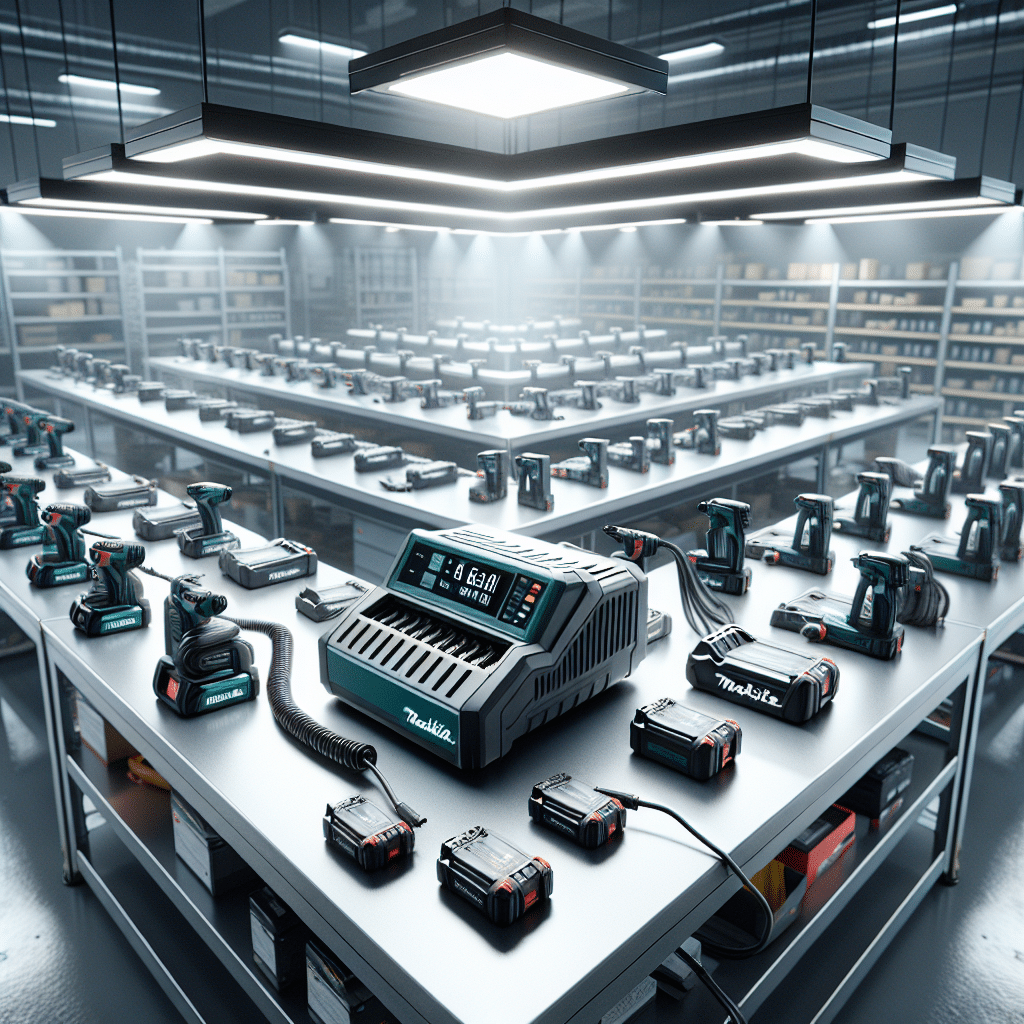

Compatibility with Makita and Other Tool Brands

Voltage, Connector Types, and Battery Fit

Tool-brand compatibility can make or break an efficient site charger setup. Brands such as Makita, DeWalt, and Milwaukee use proprietary battery shapes and voltages (e.g., 18V LXT vs. 20V Max) to lock users into ecosystems. Mixing battery types without planning can flood your workspace with incompatible chargers. Ensure voltage and amp ratings align across your fleet. Adapter kits exist but often introduce unreliability. It’s safer to stick with a unified brand or collection series for simplicity. Additionally, verify connector prongs match and that battery packs seat firmly within chosen charging slots.

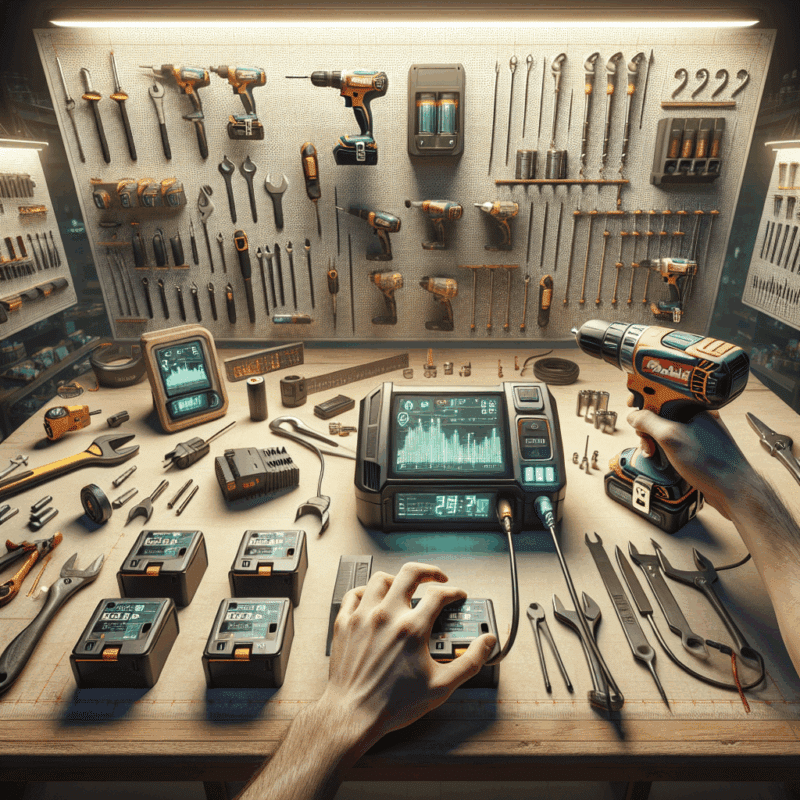

Choosing Rapid Chargers: Pros and Cautions

Battery Health Considerations

Rapid chargers provide undeniable convenience by drastically reducing downtime. However, they utilise higher internal temperatures to accomplish this speed. Over time, frequent fast charging can degrade battery lifespan if used improperly or excessively. A smart site charger setup includes a mix of rapid and standard chargers, designating rapid models for high-turnover tasks while using standard units for overnight charging. Always check that your batteries are rapid-charge compatible to prevent long-term harm. Equally important, invest in chargers with intelligent cooling fans and thermal shut-off to protect your inventory.

Layout Optimisation for Workshop Charging Stations

Safe Cable Management and Labelling

A chaotic charger corner becomes a safety hazard and slows down every crew when locating the right charger or battery. Good layout practices ensure your site charger setup supports a lean work environment. Mount charging units vertically along walls or inside dedicated tool cabinets to save space. Annotate each charger with laminated labels denoting tool compatibility, user, or priority level. Implement colour-coded cables and tie-down straps to control clutter. Power strips should be mounted, not loose, to minimise tripping risks. Finally, keep charging stations away from flammable materials or dusty, unventilated spots.

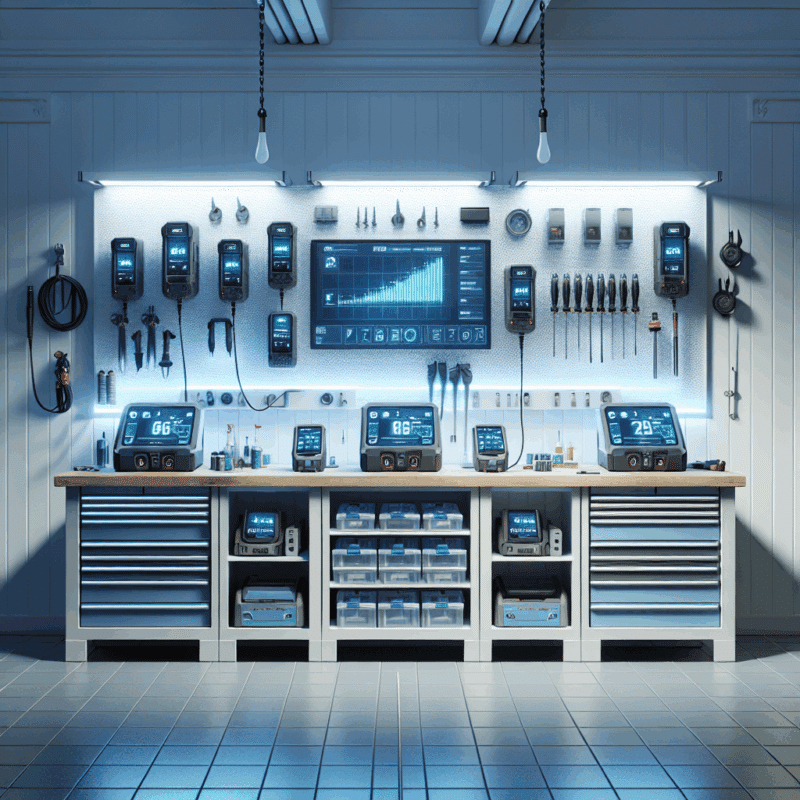

Safety Certifications and Charging Environment

What to Look for in Certified Equipment

For any site charger setup, safety should never be an afterthought. Chargers should carry certification marks such as CE (Conformité Européenne), UKCA, or UL. These verify that the equipment has been tested against overheating, short circuiting, and general operational safety. Additionally, ensure your workshop environment adheres to the requirements laid out in charger manuals—most notably ambient temperature and humidity levels. Ventilation is paramount. In commercial-scale setups, install smoke detectors near charging banks and enforce a switch-off protocol at day’s end. Site selection checklist for charging stations provides an up-to-date list of trusted safety-certified charger models.

Managing Batteries at Scale

Charging Multiple Units Simultaneously

When managing a dozen or more batteries each day, you quickly realise that an ad hoc charger or two won’t suffice. Scale requires strategy. Begin with a central inventory system—ideally digital—to track which batteries are in use, charging, or need disposal. Next, your site charger setup should feature tiered charging stations: high-demand at waist level, low-demand at the bottom shelf. Consider smart chargers that indicate total charge cycles and offer network connectivity via apps. These allow facilities managers to foresee battery health issues before failure. For larger companies, docking stations that charge four or more batteries concurrently are available.

Real-world Setups from Pros

Tradespeople Share Site Charging Tips

Veteran tradespeople advise investing in modular charging boards that can travel with mobile toolboxes. One recommended site charger setup involves using stackable tool trolleys fitted with charging caddies and internal power strips. This keeps chargers protected during transit and ensures functionality on arrival. Another tip is integrating USB outlets into power hubs for phone or tablet use—often a forgotten but invaluable convenience onsite. Learn more about Power tool charging solutions for professionals offers a photo gallery of real-world workshop charging setups submitted by builders across the country. Learn how professionals have improved workflow just by redesigning their charging stations.

Cost vs Value in Upgrading Chargers

When It Pays to Invest in Speed

Cost is always a factor in any major workshop decision. While it might be tempting to opt for cheaper, slower charging units, this often results in delayed projects, frustrated workers, and frequent replacements. Analytical models show that investing in high-efficiency chargers can pay for themselves over three months via increased workflow alone. Equally, cheaper units are less likely to provide warranty support or battery analytics. Your site charger setup becomes an asset when properly selected. Visit Read a related article to use our charger ROI calculator and explore real-cost comparisons between economy models and rapid-charging solutions.

Final Recommendations

Setting up a charger arrangement is more than plugging in a set of devices. It requires strategic planning, brand alignment, safety oversight, and ongoing management—all tailored to your specific project scale and tool ecosystem. A well-configured site charger setup enhances efficiency, prolongs battery life, and reduces risk. Prioritise safety-certified chargers, integrate smart management tools, and regularly evaluate whether your layout is meeting evolving demands. For in-depth product tests and up-to-date compatibility charts, visit EU product compliance and insights.

Great guide on choosing-best-charger-setup-site-workshop – Community Feedback

What factors matter when choosing a site charger setup?

Consider charger compatibility, required amperage, safety certifications, site power capacity, charging speed, and how many batteries you need to charge simultaneously.

Is a rapid charger safe for regular workshop use?

A rapid charger with proper safety certifications is safe for frequent use, provided it matches your batteries and is operated under recommended conditions.

How do I maximise battery life with my charger setup?

Use a charger matched to your battery’s voltage, avoid full discharges, store batteries at moderate temperatures, and follow manufacturer maintenance advice.