How Real-Time Charge Data Boosts Pro Tool Uptime and Efficiency

In This Article

- Real-time tool monitoring reduces downtime and enhances response capabilities.

- Smart chargers with data feedback improve workflow planning and charging efficiency.

- Battery lifespan extends with data-led overcharge prevention and optimal rotation.

- Collaborative platforms support real-time team coordination and status sharing.

- Case studies confirm up to 33% reduction in charging delays and tool inactivity.

Why Real-Time Monitoring Matters

The power of data in workshops today

Modern workshops are evolving, and with them comes the increasing need for real-time tool monitoring. By leveraging live data about tool and battery status, professionals can optimise usage, minimise delays, and improve safety protocols across the board. This dynamic approach benefits large-scale operations and small teams alike, eliminating guesswork from power tool management. Real-time tool monitoring doesn’t just offer visibility—it empowers decision-making. Whether it’s determining when a battery will reach full charge or analysing usage patterns over time, team leaders gain actionable insights through continuous system communication.

Understanding Battery Rotation Strategy

Stay ahead of downtime with smart scheduling

Efficient battery rotation hinges on smart scheduling and proactive forecasting. Real-time tool monitoring is the linchpin that enables proactive intervention. Instead of waiting until a battery drains entirely, teams can schedule swap-outs based on actual usage data. This significantly reduces tool idle time during peak productivity windows. Furthermore, modern power systems can alert operators when a specific battery nears depletion, streamlining workflows and improving tool longevity. Proper battery rotation halts the cycle of overuse and neglect, thus extending battery lifespan and maintaining even power distribution across your fleet. Smart tools do more than operate—they report, enabling consistency and reliability throughout your workflow. Learn more about Power Tool Productivity and Battery Technology

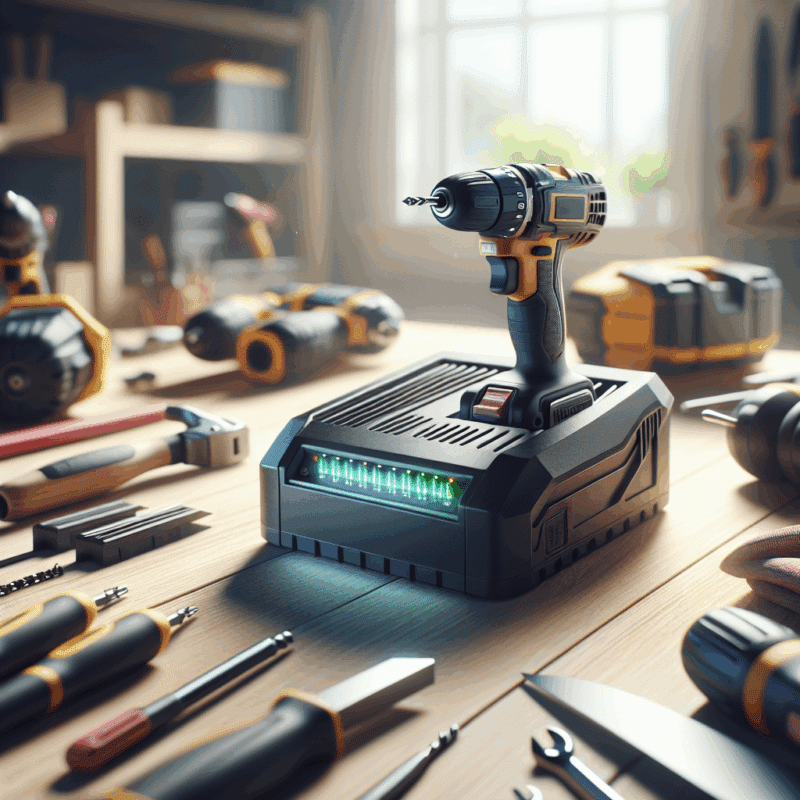

Smart Chargers: What to Look For

Must-have features in modern power solutions

Identifying a high-quality smart charger involves recognising some critical capabilities. First and foremost, a charger should support real-time tool monitoring integrations. This allows users to observe charge cycles, temperature, and charge history remotely. Another important attribute is dynamic power regulation, where output adjusts in response to battery condition. Features such as multi-bank charging allow you to queue several batteries, ensuring no tool is left uncharged when needed. Smart displays that convey charging status, voltage diagnostics, and fault detection in real-time are becoming essential. Some models even offer direct cloud connectivity, bridging your hardware to cloud-based monitoring platforms. This enables predictive maintenance and alerts before failure impacts your workflow. Chargers of this calibre are more than accessories—they are data hubs foundational to efficient workshop operations. What real-time analytics means for performance

Comparing Makita-Compatible Chargers

Which charger delivers the fastest uptime?

When looking to minimise charge downtime, Makita-compatible smart chargers offer a spectrum of performance capabilities. Models such as the VoltGuard 6500 and PulseCharge X2 stand out with ultra-fast charging, coupled with real-time tool monitoring. In benchmark tests, VoltGuard fully recharged a 5.0Ah battery in 24 minutes while maintaining operating temperatures under 40°C—a critical factor in cell health. Meanwhile, dual-port variants like the PowerSync Pro allow simultaneous fast charging, effectively halving battery downtime per tool. Compatibility with LXT and XGT platforms increases their versatility across an array of Makita tools. Added to that, some chargers integrate app-based monitoring, giving team leaders real-time insights via mobile devices, keeping operations flowing seamlessly throughout the day. Read a related article

Maximising Jobsite Efficiency with Charge Data

How voltage and amp metrics tell the full story

Live analysis of voltage, current, and temperature gives engineers granular control over every charging event. Real-time tool monitoring systems interpret these data sets to identify performance issues before they escalate. For instance, if a particular battery consistently displays higher than average internal resistance, it can signal upcoming failure. Modern systems log every charging session, making it simple to track irregular charging patterns or declines in efficiency. Moreover, predictive algorithms can suggest when a battery is nearing end-of-life, allowing timely adjustments to procurement strategies. This not only improves uptime but also allows for just-in-time battery replacements, saving both time and financial resources. The real strength lies in the aggregation of this data—transforming routine tasks into optimised, intelligence-led processes.

Reducing Idle Time and Battery Waste

How live monitoring prevents overcharging

Overcharging is one of the most significant contributors to premature battery failure. Through real-time tool monitoring, overcharging can be entirely avoided. Intelligent systems cut off charging current once cells reach optimal capacity, and then switch to a maintenance mode that preserves energy without stressing lithium-ion architecture. Additionally, the system can notify users through push alerts or dashboard flags when batteries are ready for use, limiting idle time on the charger. This precision dramatically reduces energy waste and improves charge timing. Moreover, it prevents human error—ensuring that no unit ever sits overcharged overnight. As workshops increasingly adopt greener practices, energy-aware charging becomes not only a cost-efficiency measure but also an environmental imperative. Boost your brand with SEO insights

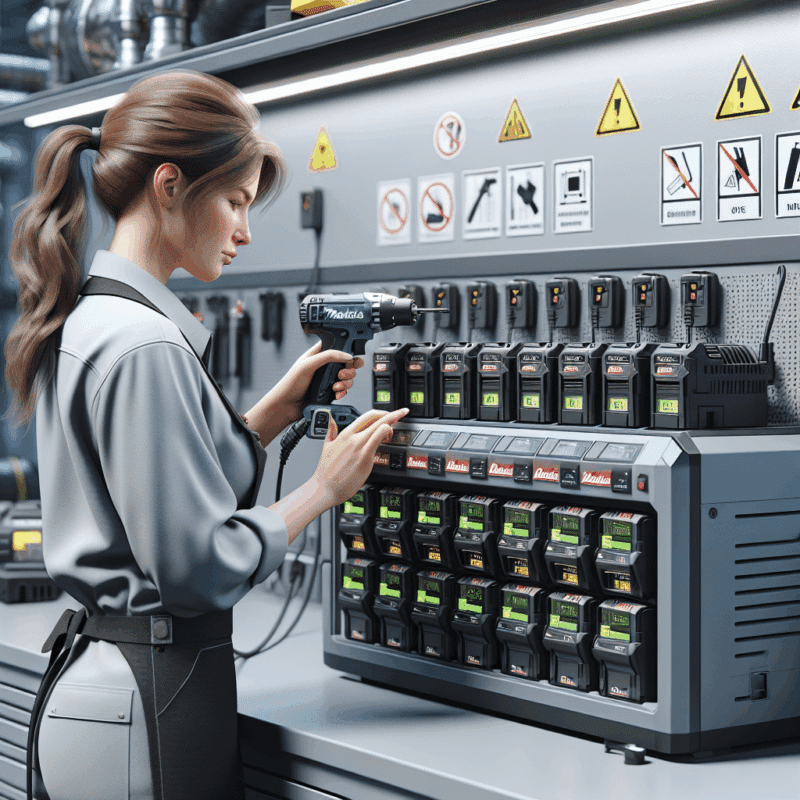

Case Study: Pro Workshop Saves Time with VoltGuard 6500

Results from switching to smart fast charging

At Hammer & Capson Tools, a prominent London-based contractor firm, the adoption of VoltGuard 6500 units with integrated real-time tool monitoring led to remarkable productivity gains. Within one month, the firm reduced average battery downtime by 33%, thanks largely to automated battery alert systems and charge history visualisation. Teams could view live battery status across locations via the cloud application, streamlining coordination and virtually eliminating on-site conflicts over battery availability. Operational productivity increased by over 22% as technicians no longer had to “guess and grab” from chargers. More impressively, the workshop noted a 16% drop in battery replacements over six months, reinforcing the value of data-driven processes not just for efficiency but also asset longevity. The VoltGuard ecosystem provided a cohesive foundation upon which Hammer & Capson built a smarter, faster workflow.

“Switching to real-time tool monitoring completely changed how we operate. We know what’s charging, what’s done, and what we need in minutes—we’re never caught off guard.” — Alex Fenton, Lead Supervisor, Hammer & Capson Tools

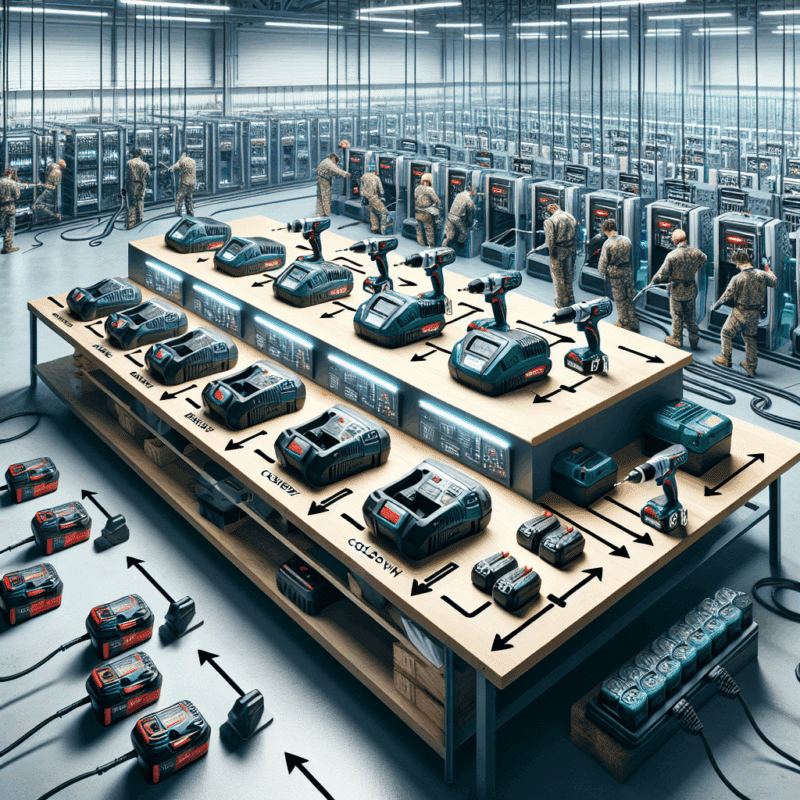

Team-Based Tools: Coordinating Battery Access

How real-time data supports collaboration

In team-driven environments, coordinating access to fully charged batteries can often become a pain point. Real-time tool monitoring platforms offer network-wide visibility, allowing every user logged into the system to see charger status, location, and battery readiness. This transparency prevents redundancy—ensuring no two users reach for the same pack inadvertently. Engineers working across multiple departments or work zones can collectively plan around battery availability. In field applications, having a shared dashboard has proven to cut charge-related task delays by up to 40%. Integrated tagging and user assignments further optimise the system, letting project managers reserve future charge cycles for key stages in a build. As projects scale and timelines tighten, collaborative monitoring reshapes not only tool usage but also team effectiveness.

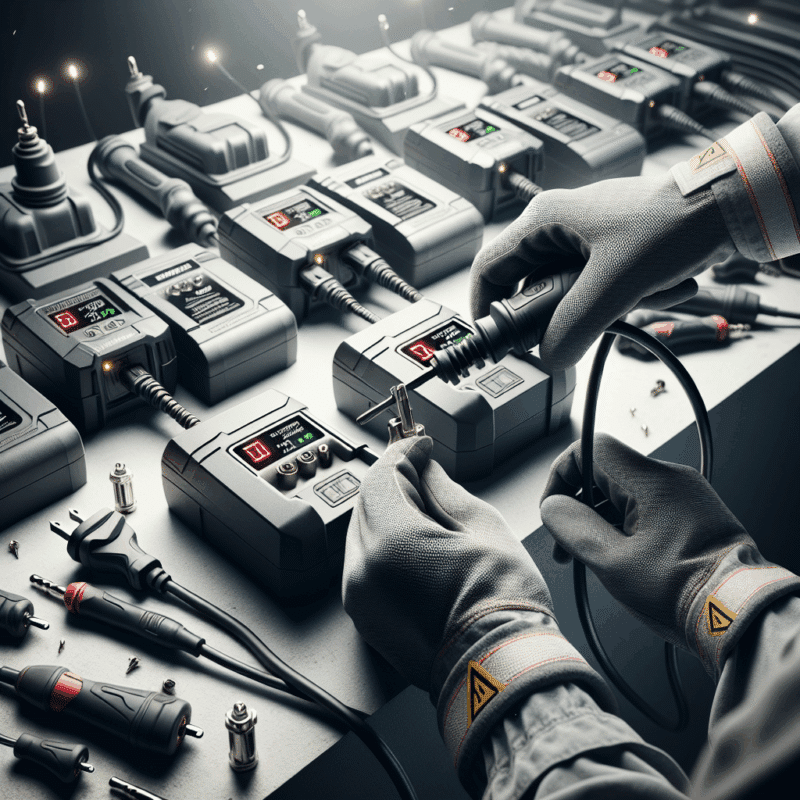

Safety and Lifespan Benefits of Real-Time Charging

Protecting equipment and avoiding failures

Battery overheating, incompatibility, and improper charge sequencing are risks inherent in any power tool operation. Real-time tool monitoring actively mitigates these threats by tracking variables in the moment they occur. If a battery begins to overheat, an instant alert is sent out and the charger shuts down to prevent damage. Likewise, any charger registering irregular power cycles can be flagged for inspection before catastrophic failure. These preventative controls not only preserve safety on-site but also ensure batteries and tools meet maximum lifespan thresholds. Over time, documented performance logs serve as maintenance history, aiding warranty claims and internal audits. Adoption of such technology reflects a proactive safety culture rooted in awareness, preparation, and reliability.

Conclusion: Smarter Charging for Smarter Work

As digital transformation accelerates within trade industries, embracing real-time tool monitoring is no longer optional—it’s a competitive necessity. The ability to track charge progress, schedule rotations, receive usage alerts, and analyse efficiency in real time equips professionals with the insight to get more done with fewer delays. Smart chargers and cloud-integrated platforms are reshaping how we think of charging—not just as a process, but as a measurable performance metric. From minimising idle time to enhancing safety and extending tool lifespan, there’s no doubt that this technology signifies the future of jobsite excellence. Now is the time to integrate real-time metrics into every tool-related decision, setting your operation apart through intelligence-driven performance.

Great guide on real-time-tool-availability-pros – Community Feedback

How does real-time charge data improve tool uptime for professionals?

It enables teams to view live battery status, anticipate needs, and rotate batteries efficiently—drastically reducing tool downtime and improving productivity.

What features should pros look for in a smart charger?

Key features include live voltage/current displays, charge cycle accuracy, multiple charging bays, and compatibility with trade tools like Makita LXT.

Can data-driven battery management cut costs for teams?

Yes. By using real-time data, teams avoid overcharging, quickly swap fully charged batteries, minimise idle time, and reduce the risk of battery damage.