How LCD Voltage & Amp Displays Boost Workshop Productivity

In This Article

- LCD voltage displays transform battery charging into a data-driven workflow.

- Real-time insights reduce tool downtime and enhance readiness.

- Voltage readouts assist in identifying battery health issues early.

- Standardising on LCD chargers simplifies workshop training and safety.

- Technician feedback supports the move towards smarter, precise practices with measurable ROI.

Why Voltage & Amp Displays Matter

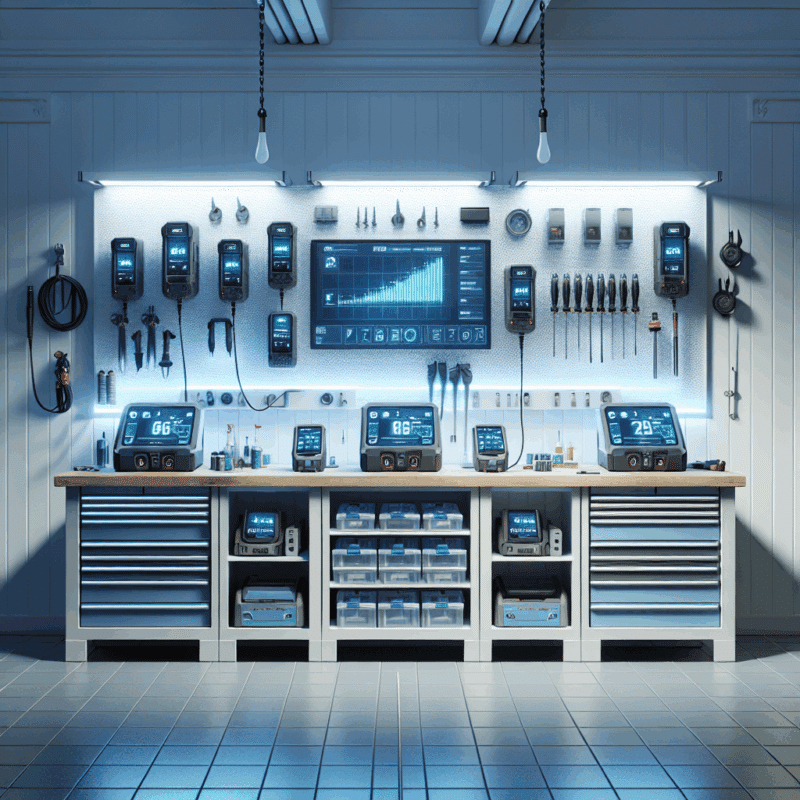

Transforming Battery Visibility into Workflow Efficiency

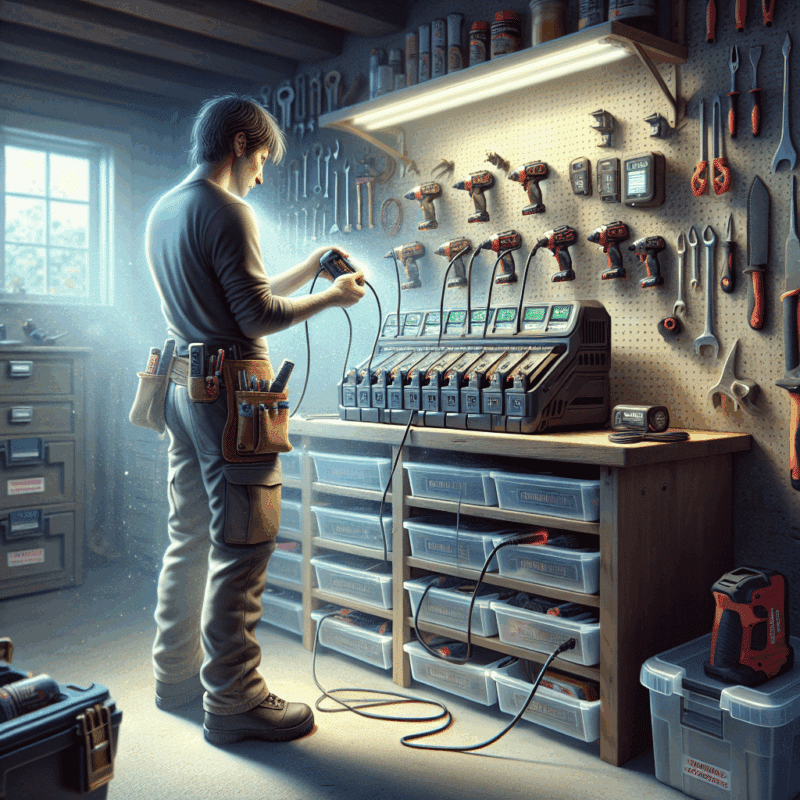

In high-paced workshop environments, accuracy and timing are crucial. The inclusion of a voltage display on battery chargers represents a critical enhancement to battery management protocols. It offers an up-to-the-second readout of the voltage and current flowing into a battery—a transformation from relying on vague LED indicators to precise, quantifiable data.

The voltage display provides real-time information about a battery’s charging status. Whether working with lithium-ion or NiMH batteries, this readout enables technicians to monitor the voltage level and verify if the battery is charging correctly or if an anomaly is present. Prior to the widespread introduction of LCD displays, power tool users had minimal insight into their battery’s actual state. Today, knowing an exact number reduces guesswork and improves operational transparency.

Moreover, employing a charger with a voltage display helps improve planning across a technician’s work cycle. If a tool isn’t ready when expected, it disrupts the workflow. With clear feedback, workers can coordinate tool readiness more effectively and reduce periods of idle time. Ultimately, this leads to fewer interruptions and increased productivity.

The Data Behind LCD Chargers

Real-Time Charging Metrics vs. Traditional Guesswork

For decades, charging stations relied on LED status lights to convey rudimentary battery information—green for good, red for charging, and flashing lights for errors. However, these indicators are often ambiguous. LCD chargers, by contrast, provide a tangible, numerical output through their voltage display, which fundamentally changes how users interpret performance.

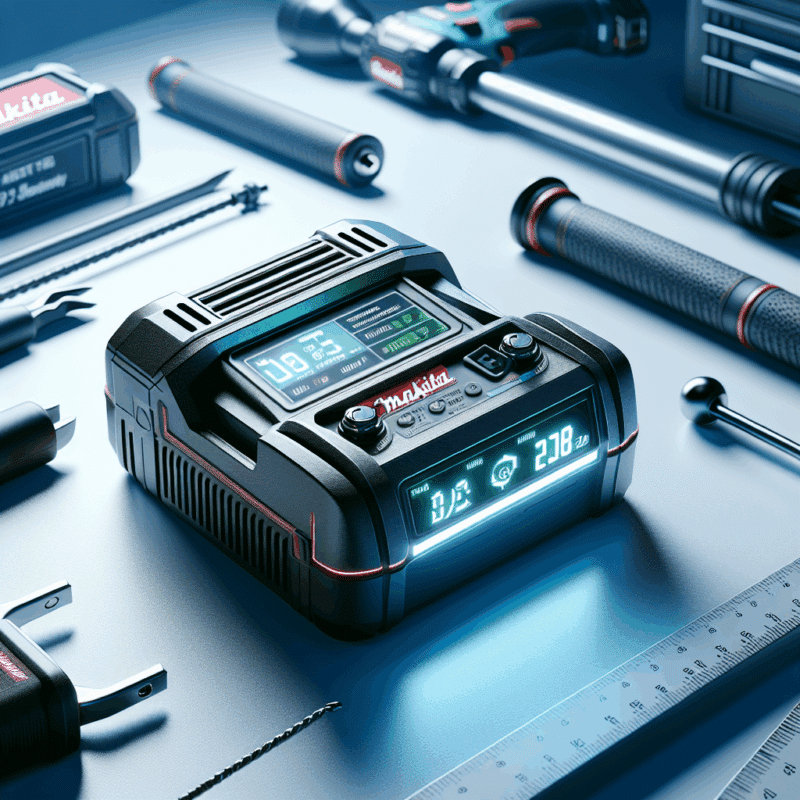

The quantifiable nature of voltage and current readings removes uncertainty. For instance, a reading of 18.0V on an LCD display instantly tells a technician that a battery for a Makita 18V tool is nearly charged. Conversely, if the voltage stalls or drops unexpectedly, it may signal issues like over-discharge or internal cell imbalance. This early warning can prevent battery degradation over time.

Manufacturers have begun integrating charging metrics that include not only voltage and amps but also temperature and full-charge estimation. These upgrades empower users to act proactively instead of reactively. Real-time readings reduce unnecessary checks and eliminate downtime related to battery availability. Having this data upfront leads to smarter maintenance and scheduling across tool-intensive shifts.

“Since integrating voltage display chargers, we’ve reduced tool-related delays by over 30% per quarter.” – Workshop Supervisor, Leeds

Improving Tool Readiness in Every Shift

How Reduced Downtime Impacts Project Flow

Maintaining project momentum hinges on ensuring every tool is charged and available when needed. In automotive, construction, and joinery workshops, assigning a battery to a job only to realise it’s dead can lead to frustrating time losses. The voltage display bridges this information gap by giving a visual indicator of charge status prior to deployment.

Workflow inefficiencies often stem from batteries being rotated in and out without clear status indicators. LCD chargers offer a strategic response to resource bottlenecks, allowing technicians to quickly assess which batteries are closest to full charge. This evidence-based decision-making mitigates queue times and enhances scheduling accuracy.

Some facilities have reported up to 40% improvement in shift tool readiness by standardising on chargers with voltage and amp displays. The data gathered aids not only in readiness but also in audits, allowing supervisors to pinpoint recurring issues such as charging inefficiencies or battery misuse. It lays the groundwork for predictive maintenance, ultimately ensuring operational continuity.

Using LCD Feedback to Detect Charging Issues

Preventing Overcharging and Underutilisation

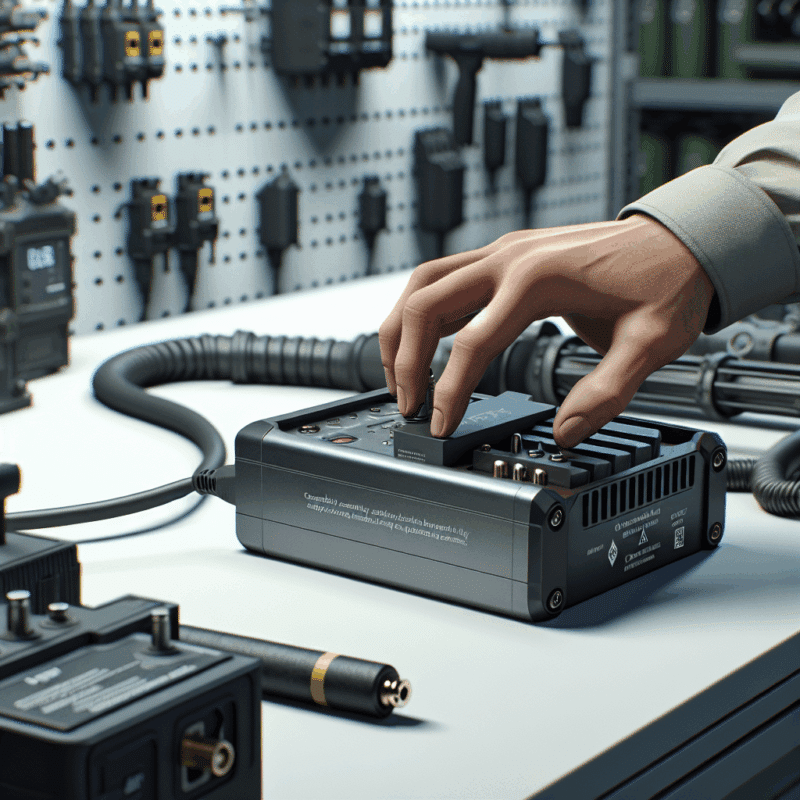

Voltage displays are not just for monitoring—they act as an early warning system. Anomalies such as batteries that plateau at below-average voltages or that charge unusually quickly may indicate deeper issues like ageing cells or circuitry faults. With a traditional LED-only charger, these issues often go undetected until performance noticeably deteriorates.

LCD feedback brings such subtleties to light. If a Makita 5Ah battery, which should rest near 20V fully charged, levels out consistently under 18V, this could indicate cell imbalance or degradation. Overcharging scenarios, where the voltage exceeds expected parameters, also become visible. These instances demand immediate action to prevent long-term battery wear or even safety hazards.

Rather than reacting to tool failures mid-shift, technicians and supervisors using voltage display technology can set up inspection routines and remove compromised batteries from the rotation. Over time, this extends battery lifespan and promotes a consistently high level of performance across the tool pool.

Charger Compatibility and Workshop Standardisation

Finding the Right LCD Model for Makita Tools

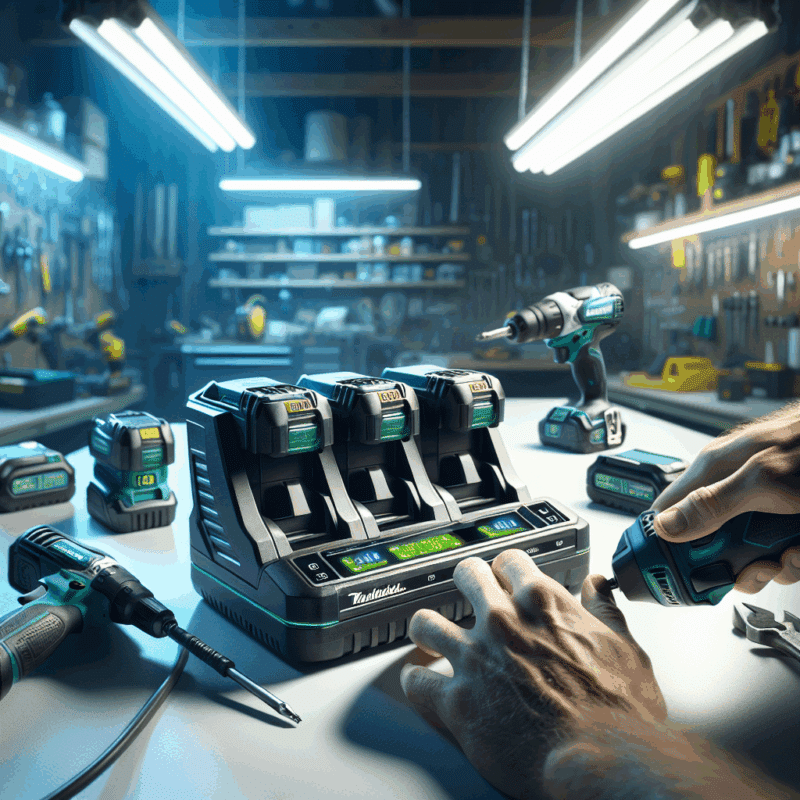

Not all voltage display chargers are built equally, especially when it comes to compatibility with specific tool brands like Makita. When seeking to upgrade, it’s crucial to consider both voltage range and physical docking interface. Some LCD chargers on the market support a universal socket approach, while others are custom-built to ensure snug fits and safe contact points for particular battery lines.

For Makita users, selecting a charger that supports 14.4V to 18V lithium-ion batteries with an in-screen diagnostics suite is ideal. Advanced models also offer temperature readouts, turbo charging capabilities, and built-in safety cut-offs. In multi-station environments, having several uniform models simplifies training and ensures consistent user experiences. This shift towards standardisation streamlines operations and minimises errors due to incompatible pairing.

Workshops that deploy mains-powered as well as portable LCD chargers can also improve tool accessibility across sites, including off-grid or mobile units. To deepen your understanding of charger compatibility and workshop setup, be sure to review our comprehensive compatibility guide – Learn more about Power Tool Battery Charging & Optimisation.

Design Features that Signal Quality

What to Look for in Your Next Upgrade

Voltage display chargers vary significantly in build and interface clarity. To identify a high-quality model, look for features like high-visibility LCD panels with backlighting, ruggedised housing for industrial environments, and sealed buttons to prevent dust ingress. A display that can report voltage accurately to two decimal places usually indicates more reliable sensor calibration.

Other indicators of superior quality include integrated error code readouts, real-time amperage tracking, and cooling fans for thermal regulation. Safety certifications such as CE, RoHS, and short-circuit mitigation circuitry show that the product meets international electrical regulations. Additionally, chargers with replaceable fuses extend hardware life and reduce downtime when minor issues occur.

Strong design isn’t just about durability—it’s about providing clear, actionable data. A poorly-lit screen or blinky interface is almost as limiting as a non-LCD charger. Visual clarity promotes confidence in the tool management process. To compare leading models based on usability, see our head-to-head product chart – Understanding breakdown voltage in electronics.

Safety Through Visual Indicators

When Real-Time Alerts Prevent Downtime Disasters

Safety is paramount when dealing with high-capacity lithium batteries. Batteries that overheat or become unstable can cause not only equipment damage but also severe personal harm. Fortunately, advanced LCD voltage display chargers often include alerts for rare but dangerous charging conditions.

Voltage inconsistencies and amperage spikes are usually precursors to battery faults. An LCD warning—such as an icon display or flashing voltage readout—can prompt technicians to interrupt a charge and inspect conditions more closely. By setting boundaries for acceptable voltage ranges, businesses gain another layer of protection against fire risks and overcurrent scenarios.

In regulated industries, meeting safety reporting requirements is also easier when detailed logs or screen captures from LCD interfaces are available. This approach contributes to meeting ISO protocols and local safety audits. For deeper insight into battery safety thresholds and printer-specific risks, refer to AI automation strategies for UK businesses.

Case Study: The Torxup VoltGuard in Action

Measurable Impacts from LCD Diagnostic Feedback

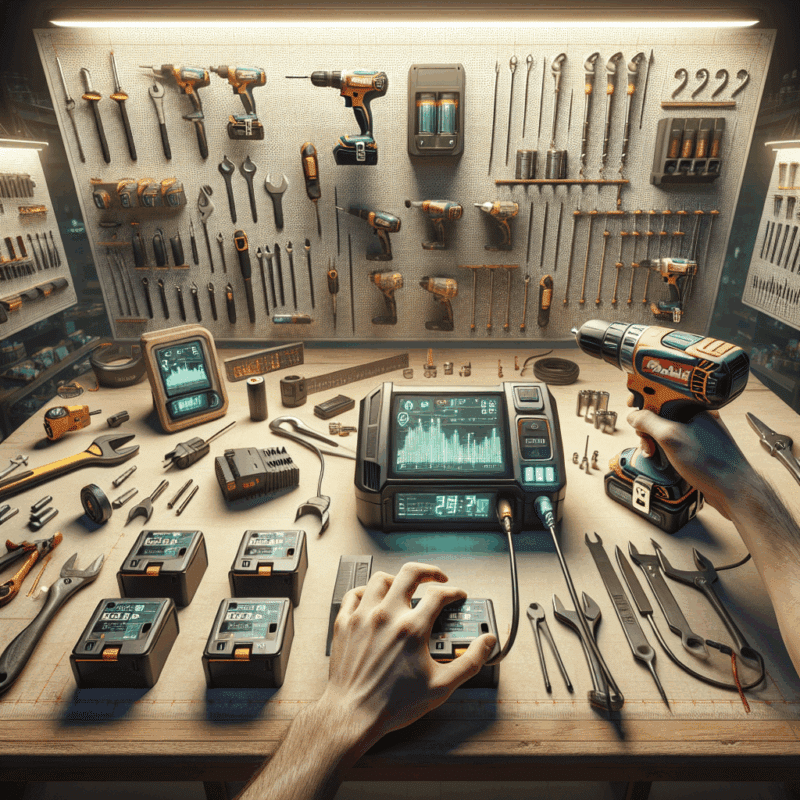

When the Torxup VoltGuard was introduced at a Midlands automotive supplier, managers recorded improved battery rotation times within the first month. Prior to implementation, workshop staff often misjudged battery health, leading to job delays and power tool inefficiency. The addition of precise voltage display chargers offered clear visibility into charge progression and real-time anomalies.

After a two-month benchmarking phase, battery-related interruptions dropped by 41%. Staff attributed this to being able to match batteries with job length more accurately, avoiding the need for mid-task swaps. Additionally, the visible data helped train junior staff more effectively, speeding up integration periods by up to two weeks.

This case study underscores a broader takeaway: LCD-enabled voltage display systems are not a luxury—they are integral to running a reactive and efficient workshop. For internal insights and more real-case implementations, visit our feedback dashboard – Read a related article.

Employee Feedback: What Technicians Say

Hands-On Takes from the Workshop Floor

Technicians working day-to-day in high-demand workshops consistently express appreciation for the clarity that a voltage display provides. “I used to just plug things in and hope for the best,” says Sarah Fulton, a senior mechanic at a machinery workshop in Sheffield. “Now I know exactly what point the charge is at—I can make decisions based on numbers, not blinking lights.”

Users also note the benefits shared between newer and vintage tool models. Even if a battery is older, its charging patterns can be tracked accurately using the voltage display, helping determine its future viability. Some have gone as far as repurposing lower-performing batteries for light-duty tasks based on display diagnostics alone.

In crew-based environments, the displays encourage dialogue and skill-sharing. Apprentices quickly learn the ropes by interpreting readouts instead of relying only on supervisor input. This democratization of data levels up the whole team.

Conclusion: Charging Smarter in Modern Workflows

The transition from traditional chargers to those equipped with a voltage display marks a pivotal evolution in workshop technology. By offering actionable data, these tools enhance readiness, reduce downtime, and elevate safety standards across the board. From lone electricians to expansive industrial teams, the shift to smarter charging is already proving its worth.

More than just a screen, the LCD interface delivers insight, accountability, and precision. Whether you’re upgrading your current setup or outfitting a new workshop, adopting a charger with a voltage display is not only a wise investment—it’s a competitive necessity in today’s demanding landscape.

Great guide on lcd-voltage-amp-display-workshop-productivity-explained – Community Feedback

How does an LCD display for voltage and amps increase productivity?

An LCD display provides instant feedback on voltage and current, allowing users to monitor battery status in real time. This minimises downtime, identifies charging issues quickly, and ensures tools are always ready, ultimately boosting productivity in workshops or on sites.

Why is monitoring voltage and amps important for battery longevity?

Monitoring voltage and amps ensures batteries are charged within safe parameters, preventing overcharging or overheating. This helps extend battery life, reduces replacement costs, and maintains consistent tool performance in professional settings.

What features should I look for in a charger LCD screen?

Look for clear real-time voltage and amp readouts, warning indicators for errors, compatibility with your battery type, and robust build quality to withstand workshop environments. These features provide actionable insights and enhance overall safety and efficiency.