How Advanced Charger Safety Features Cut Workshop Risks

In This Article

- Advanced charger safety protects both equipment and personnel from thermal, electrical, and physical hazards.

- CE certification is essential for compliance and assures rigorous safety standards.

- Smart charging systems enhance equipment lifespan and operational efficiency.

- Investing in premium chargers yields greater reliability and long-term cost savings.

- Training and SOP adoption are key to maximising the benefits of advanced safety features.

- Integrated safety features reduce downtime and support predictive maintenance workflows.

- Makita-compatible systems offer enhanced interoperability alongside robust safety measures.

- Real-time fault response and overload protection prevent catastrophic incidents.

Why Charger Safety Matters in Modern Workshops

Understanding the Risks of Unsafe Charging

Advanced charger safety is no longer a luxury—it is a workshop necessity. In today’s increasingly electrified workspaces, reliance on cordless tools and battery-powered equipment is widespread. However, many still underestimate the significant hazards linked to inadequate charging protocols. Overheating, electrical shorts, and unregulated energy surges pose real risks not just to equipment but also to personnel. A single failure in a poorly designed charger can lead to catastrophic outcomes ranging from degraded battery life to workplace fires. In contrast, investing in advanced charger safety prevents these threats and ensures compliance with the UK’s rigorous electrical standards. Maintaining workshop safety must start with the power sources that keep operations moving.

Core Features of Advanced Charging Safety

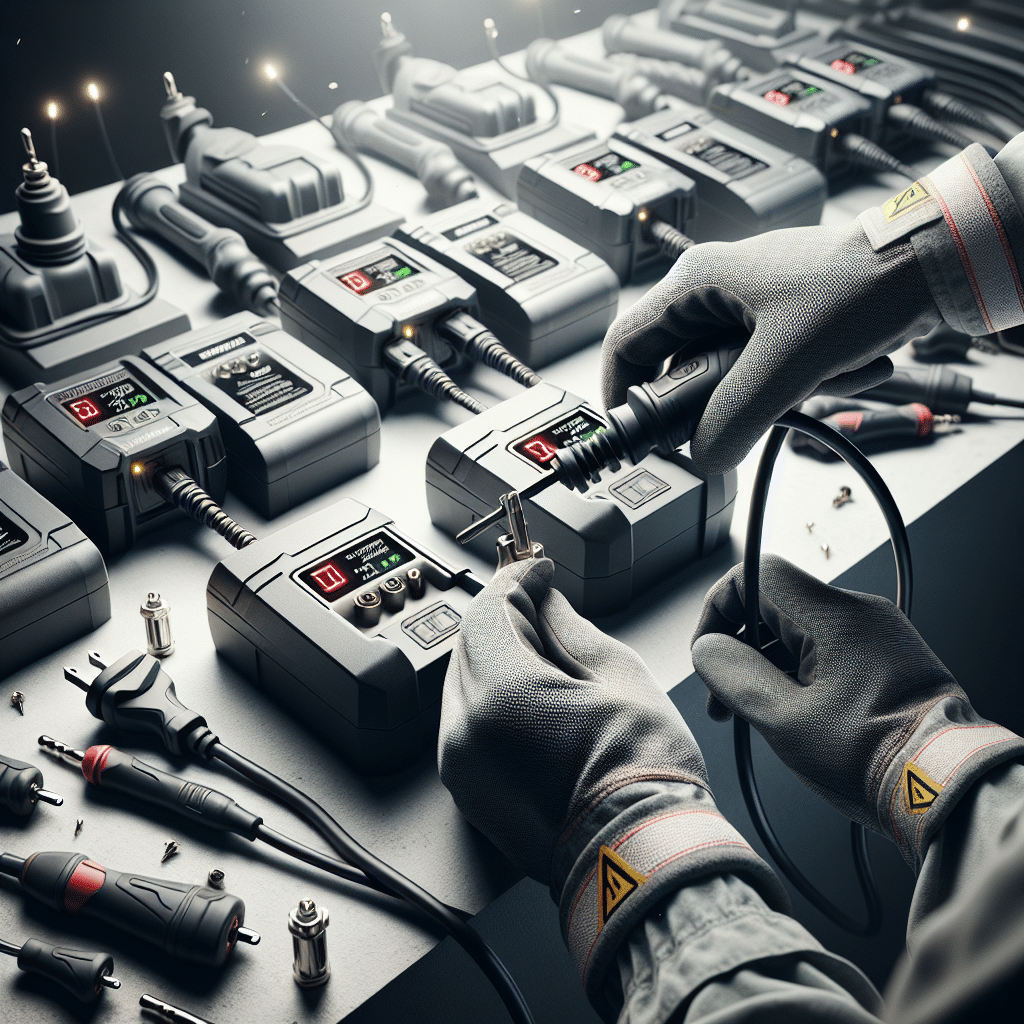

Real-Time Fault Detection and Smart Response

One of the foundational pillars of advanced charger safety is real-time fault detection. Premium charging systems now incorporate sophisticated circuit boards equipped with microprocessors that detect irregular voltage levels, polarity issues, and short-circuit anomalies. Upon detection, the charger automatically interrupts the charging cycle before any damage can occur. This immediate response dramatically reduces both fire hazards and equipment downtime. Moreover, these smart responses are often logged and displayed on LCD panels, aiding in diagnostics and training efforts. Learn more about Safe Power and Charging Practices for Workshops provides further insight into integrating diagnostics into your maintenance regime. No longer must technicians rely on visible defects; advanced features analyse performance continuously and intervene when needed.

“Embedded AI-powered sensors make modern chargers not just smarter, but proactively safer than ever before.”

Impact on Equipment Longevity and Reliability

Employing advanced charger safety systems directly affects the longevity of battery-powered tools. Overcharging and thermal stress are the two primary causes of premature battery degradation. When batteries are charged beyond their temperature thresholds or current capacity, their chemical composition degrades at an accelerated rate, leading to reduced lifespan and loss in performance. Chargers equipped with safety features such as dynamic voltage regulation, load balancing, and auto shutoff mechanisms arrest these issues before harm is done. Your investment in equipment pays greatest dividends when it lasts longer, and the best way to ensure that is to charge it intelligently. In addition, manufacturers like Makita have begun to include firmware updates for smart chargers, enabling compatibility with newer battery chemistries and preventing obsolescence over time. By embracing these advanced features, workshops enjoy longer tool life and fewer replacements.

What CE Certification Means for UK Workspaces

CE certification is not merely a box-ticking exercise; it is a legal requirement for electrical equipment in the UK market. The “CE” mark signifies that a product complies with relevant EU health, safety, and environmental protection legislation, which UK regulations continue to honour post-Brexit through UKCA marking equivalence. Advanced charger safety today goes hand-in-hand with CE compliance. It ensures that all critical features—from insulation resistance to EMC shielding—meet stringent performance and safety standards. A CE-certified advanced charger is tested against real-world operating conditions and designed for reliability under duress. Therefore, purchasing only CE-certified chargers is not just a compliance measure but a proactive safety policy. Do modern safety features cut accident risk elaborates on CE and UKCA regulatory equivalencies affecting electrical workshop equipment.

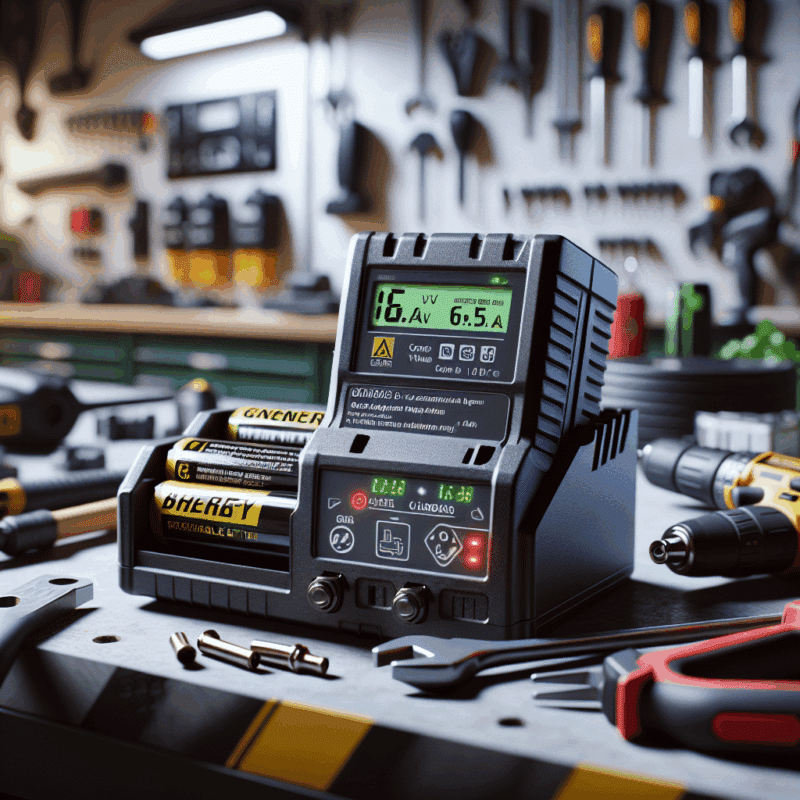

Thermal Control and Overload Protection Explained

Thermal control systems are fundamental in any setup prioritising advanced charger safety. These components utilise temperature sensors embedded within the charger to monitor both internal electronics and the battery pack. Should heat levels exceed safe operating thresholds—typically around 45°C—the charger automatically throttles current flow or halts charging altogether. This prevents thermal runaway, one of the top causes of battery explosions. In parallel, overload protection acts through circuit isolation, preventing an excess flow of current that could ignite sparks or cause chargers to malfunction. Together, they form a dual-layer defence shield. These safety checks operate independently and in conjunction, offering exceptional resilience to unexpected faults. Ultimately, these protections turn charging from a risky process into a controlled, optimised operation.

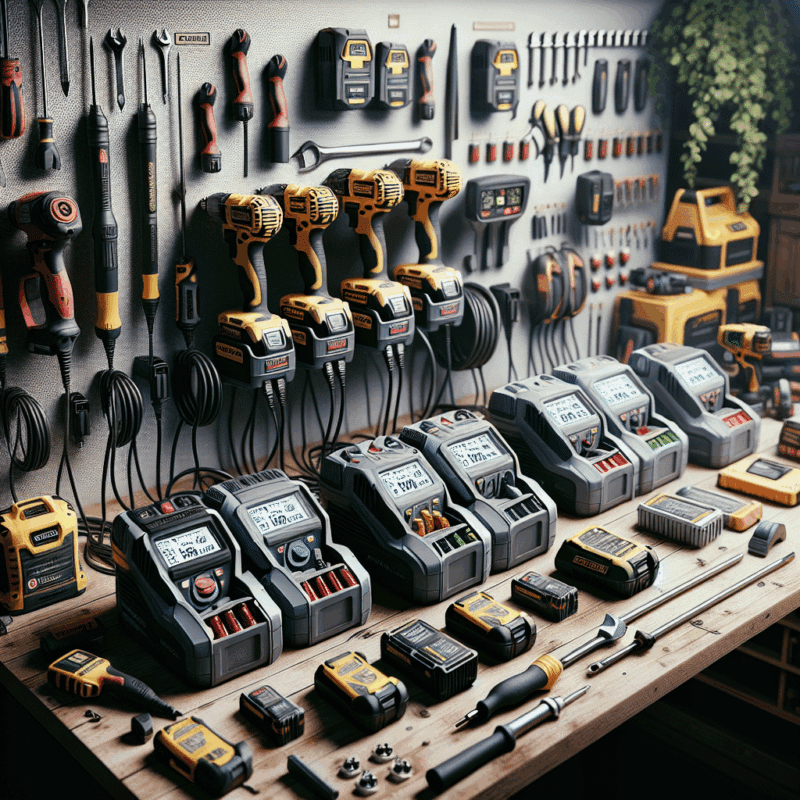

Safe Charger Integration with Makita Tool Systems

Makita tool systems have long dominated the UK contractor and workshop landscape. Their ecosystem thrives due to interoperability, durability, and now—superior safety. Advanced charger safety features are deeply embedded in Makita’s latest dual-port fast chargers and intelligent battery modules. Chargers recognise not just the battery type but also detect usage cycles, temperature, and residual charge to regulate input dynamically. Integration doesn’t stop there. It extends into Makita’s cloud-connected tracking platforms, allowing workshop managers to view charging logs, plan maintenance, and track tool usage. Combining these technologies with robust charger safety architecture ensures optimal performance and full lifecycle management. Read a related article provides a detailed overview of compatible Makita systems and safety modules ideal for high-output environments.

Training Teams on Safe Charging Protocols

Even the most advanced systems falter if improperly used. Thus, training is a critical aspect of successful adoption. Staff must understand how to properly connect battery units, monitor diagnostics, and recognise fault indicators on smart charger interfaces. Equally, teams should be briefed on emergency responses—what to do when a charger indicates thermal fault or overload. Sites employing advanced charger safety should host routine safety drills and refreshers, paired with laminated quick-start guides posted near charging stations. Visual indicators such as status LEDs, fault buzzers, and coloured tag systems make this training more intuitive and effective.

Furthermore, investing in ongoing certification through partnerships with charger manufacturers ensures your staff remains current with evolving safety features. As manufacturers roll out firmware updates and newer editions, previously omitted hazards may gain prevention protocols. Empowered teams operate safer, more productive workshops—and that assurance pays financial and moral dividends alike.

Profitable Productivity Gains from Safer Charging

Though safety is often viewed as a cost, intelligent investment in advanced charger safety translates into real profit. Downtime caused by faulty tools or fire incidents costs far more in repairs, medical leave, and lost work hours. By significantly reducing these disruptions, businesses can reallocate time to billing projects and building client trust. Chargers with cooling systems and energy efficiency certifications reduce utility costs. When integrated into a lean maintenance system, smart chargers provide usage analytics that inform purchasing decisions: how many batteries are actually needed, and when? This level of insight allows for leaner inventory and reduced capital expenditure. Essential updates on product safety regulations underscores how smart tools and chargers can increase margins for medium-sized workshops through predictive diagnostics.

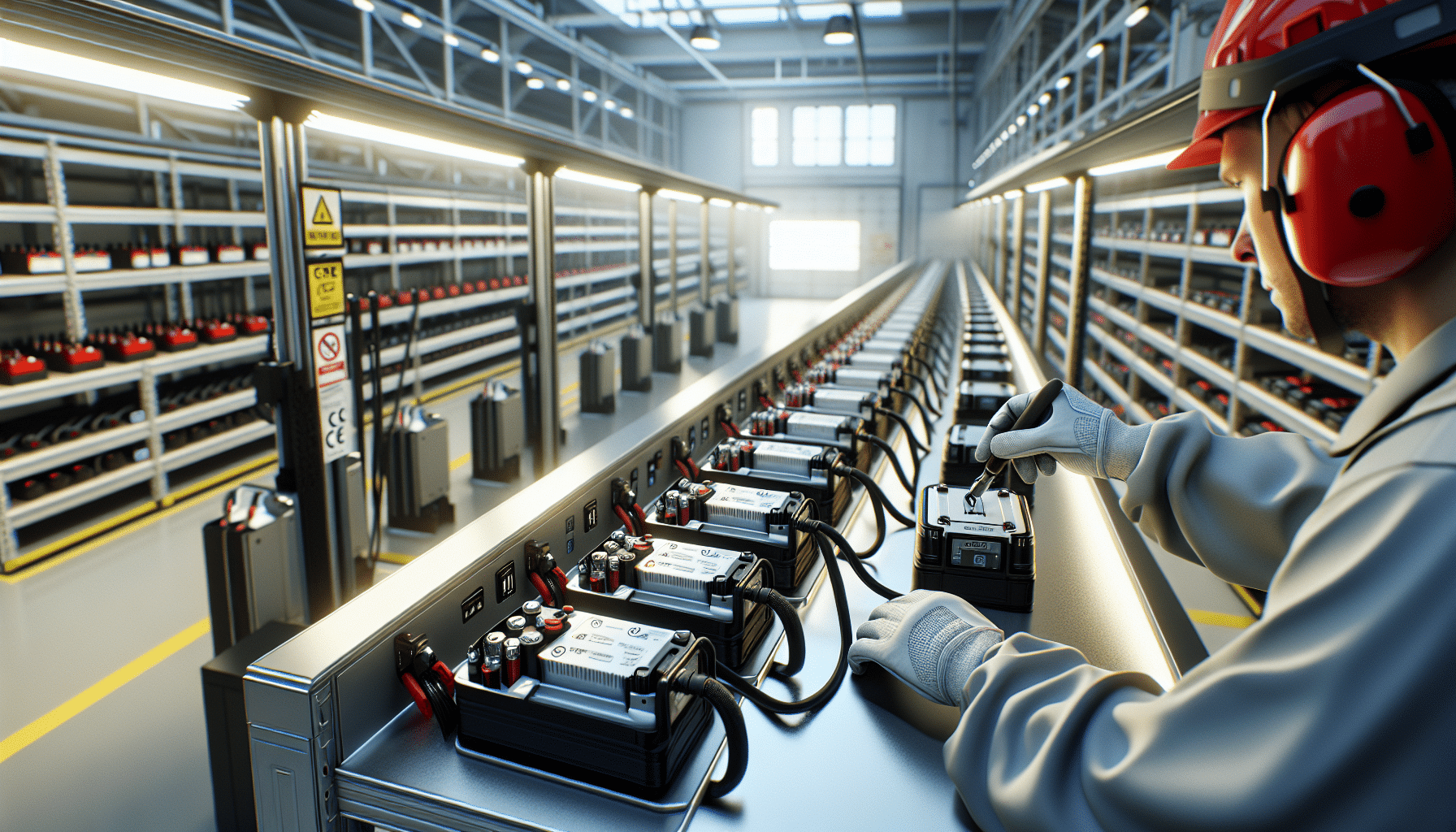

Comparing Premium Chargers vs. Generic Brands

Generic chargers may boast attractive prices, but they seldom meet the safety or performance benchmarks of premium units. Often lacking CE certification, these chargers typically omit vital components such as thermal cut-offs, GFCI (Ground Fault Circuit Interrupter), or reverse polarity sensors. Contrastingly, premium chargers offer well-documented safety engineering, backed by years of research and regulatory scrutiny. Brand-name chargers integrate with firmware updates and often include warranties recognised by insurers. Should an incident occur, using a non-certified charger could void your warranty—or worse, lead to legal liabilities. The upfront cost difference becomes trivial when considering potential losses due to damage. Every pound spent on a quality, CE-compliant charger reinforces your safety infrastructure and operational uptime.

Your Smart Next Step: Investing in Safer Charging

Advanced charger safety represents not just a trend, but a paradigm shift in how workshops prioritise power management. From protection circuitry to environmental compliance, it impacts every level of operations: safety, efficiency, productivity, and profitability. Investing in certified, smart charging systems is a step toward future-ready infrastructure. In a fast-paced industrial setting, there is no margin for error when energy is mismanaged. By equipping your workspace with intelligent chargers, you shield your team, tools, and time from unnecessary risk. Take action today by evaluating your current charging setup, educating your team, and partnering with suppliers who prioritise quality as much as output. In doing so, you don’t just adopt advanced charger safety—you redefine operational excellence.

Great guide on advanced-charger-safety-features-reduce-workshop-risk – Community Feedback

How do advanced charger safety features reduce workshop accidents?

They automatically detect faults, prevent overcharging, and control temperature, significantly lowering risks of fires, damage, or electrical incidents in a workshop.

What specific safety features should I look for in a charger?

Key safety features include thermal protection, short circuit prevention, automatic shutoff, charge status indicators, and certification like CE or equivalent for UK workshops.

Are premium workshop chargers worth the investment for safety?

Yes, premium chargers with advanced safety features provide greater protection for both staff and equipment, reducing downtime and costly incidents from charger failures.