How Active Cooling in Rapid Chargers Extends Battery Life

In This Article

- Active cooling technology significantly extends lithium-ion battery life.

- Rapid chargers benefit most from proactive heat management, especially in high-load scenarios.

- Fan and heat sink design are crucial to effective active cooling systems.

- Signs of battery overheating should never be ignored. Prevention is key.

- User testimonials and lab data both confirm the value of cooled charging systems.

- The Torxup VoltGuard 6500 stands out as an industry-leading model.

- Investing in a cooled charger is vital for professional reliability and tool longevity.

- See Read a related article for more advanced charging tools and strategies.

- Explore global battery safety standards at Digitally optimising campaigns for European markets.

Why Battery Temperature Matters During Charging

Heat and Lithium-Ion Chemistry

Temperature plays a critical role in determining the efficiency and longevity of lithium-ion batteries. When subjected to high thermal conditions—particularly during rapid charging—the chemical reactions within these batteries can accelerate beyond optimal thresholds, leading to reduced cycle life, performance degradation, and in extreme cases, thermal runaway. That’s where active cooling technology becomes pivotal. Unlike passive methods that rely on ambient air or heat diffusion, active cooling directly manages internal and external temperatures in real-time, ensuring optimal conditions for safe charging.

What Is Active Cooling Technology?

Contrasting Active vs. Passive Systems

Active cooling technology refers to a proactive approach in thermal management, where mechanical components such as fans, thermoelectric coolers, or liquid cooling circuits are used to control temperature. In contrast, passive cooling systems—like heat sinks or thermally conductive materials—merely dissipate heat without actively moving air or liquid. In demanding applications, passive cooling often falls short. This is especially true for rapid chargers, where energy transfer rates are high and heat accumulates quickly.

Utilising active cooling technology helps maximise performance by maintaining battery temperature within the optimal range during charging. Some systems even utilise sensors and microcontrollers to adjust fan speed or cooling intensity in real-time. As a result, the risk of overheating is substantially reduced, charging remains consistent, and overall battery health is preserved.

“A cooled battery is a happy battery. Active cooling technology protects your investment while ensuring peak performance every cycle.” – Engineering Consultant, Martin Beckford

How Rapid Chargers Operate Under Load

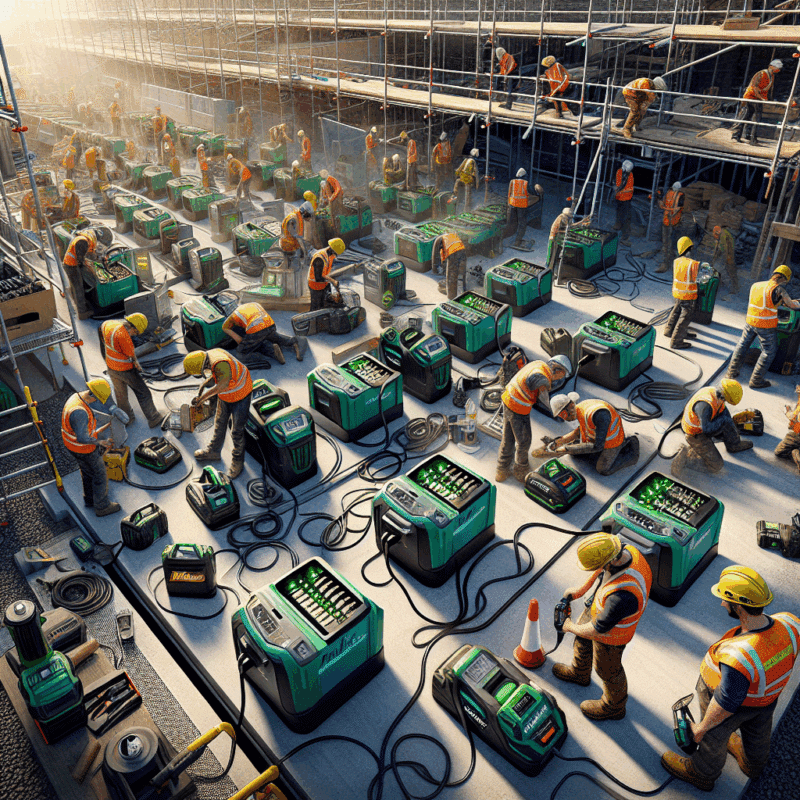

Rapid chargers function by delivering elevated currents within a shorter time frame, significantly reducing downtime. However, this high-current operation generates substantial heat, compounding battery stress. Without proper thermal regulation, internal temperatures can surge, affecting electrode integrity and electrolyte stability. This is especially problematic for cordless tools used in demanding environments, such as construction or emergency response.

With active cooling technology integrated into the charger, airflow is actively directed to extract heat from critical areas—particularly the battery interface. This proactive thermal exchange maintains system equilibrium under load. In essence, the charger becomes not just a power conduit, but a real-time heat management device, enhancing both safety and performance.

Benefits of Using a Cooled Charger with Makita Batteries

Makita, renowned for its robust battery platforms, has made significant strides in thermal optimisation. Their rapid chargers equipped with active cooling technology ensure that even during high-amperage charging cycles, battery modules remain within safe thermal bands. This is crucial for extending not only battery life but also maintaining consistent output in high-drain applications.

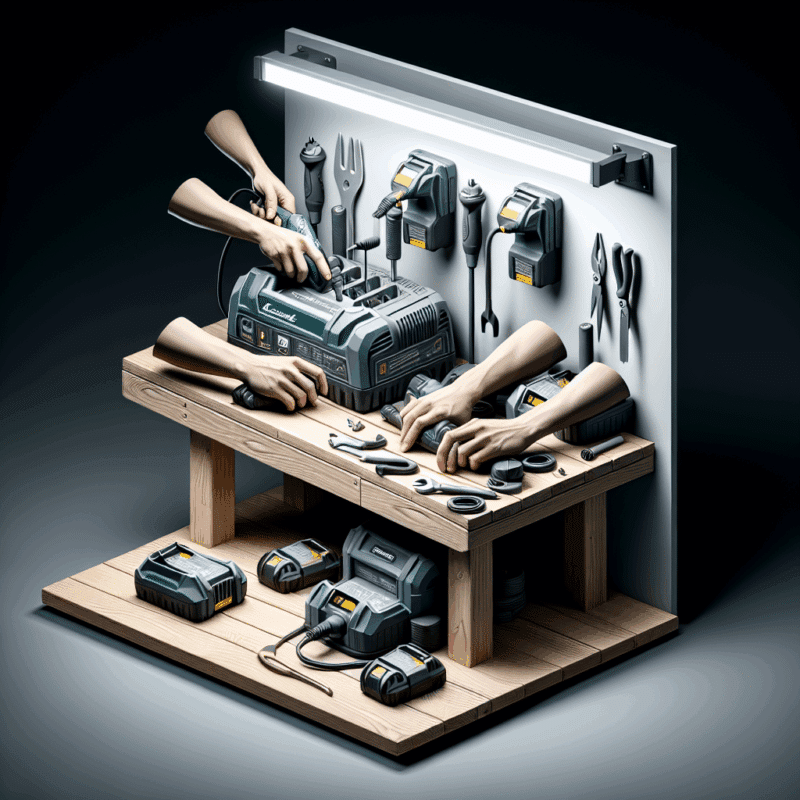

Moreover, cold air ducts built into the chargers are lined with strategically positioned fans. These fans initiate once charging begins and dynamically adjust according to thermal readings. In workshops where ambient temperatures fluctuate, such technology makes a tangible difference. Users report improved battery longevity and reduced charging downtime, particularly when rotating multiple batteries throughout a workday.

The Role of Fans and Heat Sinks in Performance

Fans and heat sinks form the backbone of most active cooling technology systems employed in battery chargers. Fans circulate cooler air into high-temperature zones, accelerating thermal convection and heat displacement. In parallel, heat sinks—often made of aluminium or graphite—absorb and distribute heat away from sensitive components like battery terminals and power transistors.

The interplay between these components ensures continuous operation without thermally induced failures. Advanced designs employ pulse-width modulation (PWM) to precisely control fan speeds, reducing noise during low-stress tasks while ramping up airflow under high load. For professionals using chargers in mobile units or enclosed vans, this precision delivers quieter operation without sacrificing effectiveness.

Signs of Battery Stress and Overheating

Recognising early symptoms of battery stress is crucial. Prolonged charging times, reduced runtime, or physical swelling are clear indications. If your battery releases a chemical odour or the casing feels abnormally warm after a charging session, it may have been exposed to unsafe thermal ranges.

Devices lacking active cooling technology are more prone to these issues, especially when operated in warm environments. Integrating a cooled charger mitigates these risks. By maintaining safe charging profiles, the system actively prevents the degradation processes that shorten battery lifespan. For in-depth visual signals and voltage anomaly detection, some newer models even include LED diagnostics and fault code alerts.

Field-Tested Feedback from Pros

In live conditions, the efficacy of active cooling technology becomes evident. Tradespeople and technicians who frequently work in high-temperature zones, such as roofing, welding, or HVAC, report measurable improvements in battery reliability when using cooled chargers. One field technician from Manchester noted that his Makita-compatible cooled charger halved the number of replacements needed annually.

Another professional, operating in a dusty construction environment, praised the easy-to-clean fan filters and the positive impact on tool uptime. These real-world endorsements align with laboratory testing, where batteries charged under active cooling recorded up to 20% fewer thermal cycle-related failures over 12 months when compared to passive-charged counterparts.

Buying Tips—What Makes a Charger Worth It

When selecting a charger, prioritise units that incorporate active cooling technology. Look for these features: temperature feedback control, variable-speed fans, external ventilation access, and compatibility with your specific battery model. Brand-specific options often deliver the most seamless experience because thermal profiles are optimised for their own battery chemistry.

Don’t be misled by aesthetics or superficial features. Focus on the internals: airflow design, sensor placement, and PCB spacing. Also, prefer chargers with a proven track record of reliability in third-party reviews. For a deeper technical dive on lithium charging protocols, refer to Expert advice for prolonging lithium battery life, and for a breakdown of Makita’s official charger specifications, visit Learn more about Power Tool Battery Maintenance and Charging.

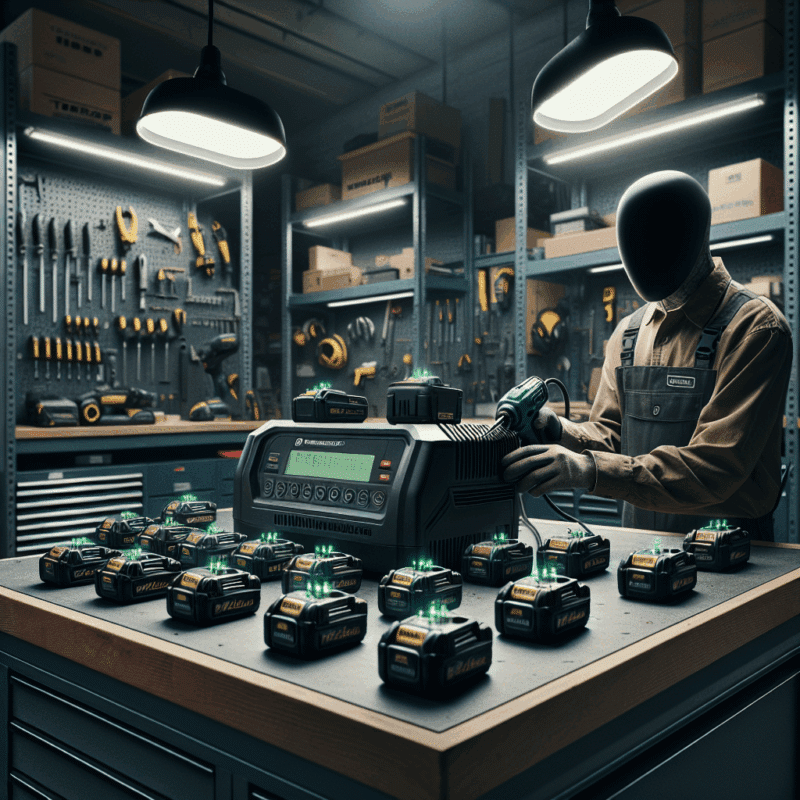

Our Top Pick: The Torxup VoltGuard 6500 Explained

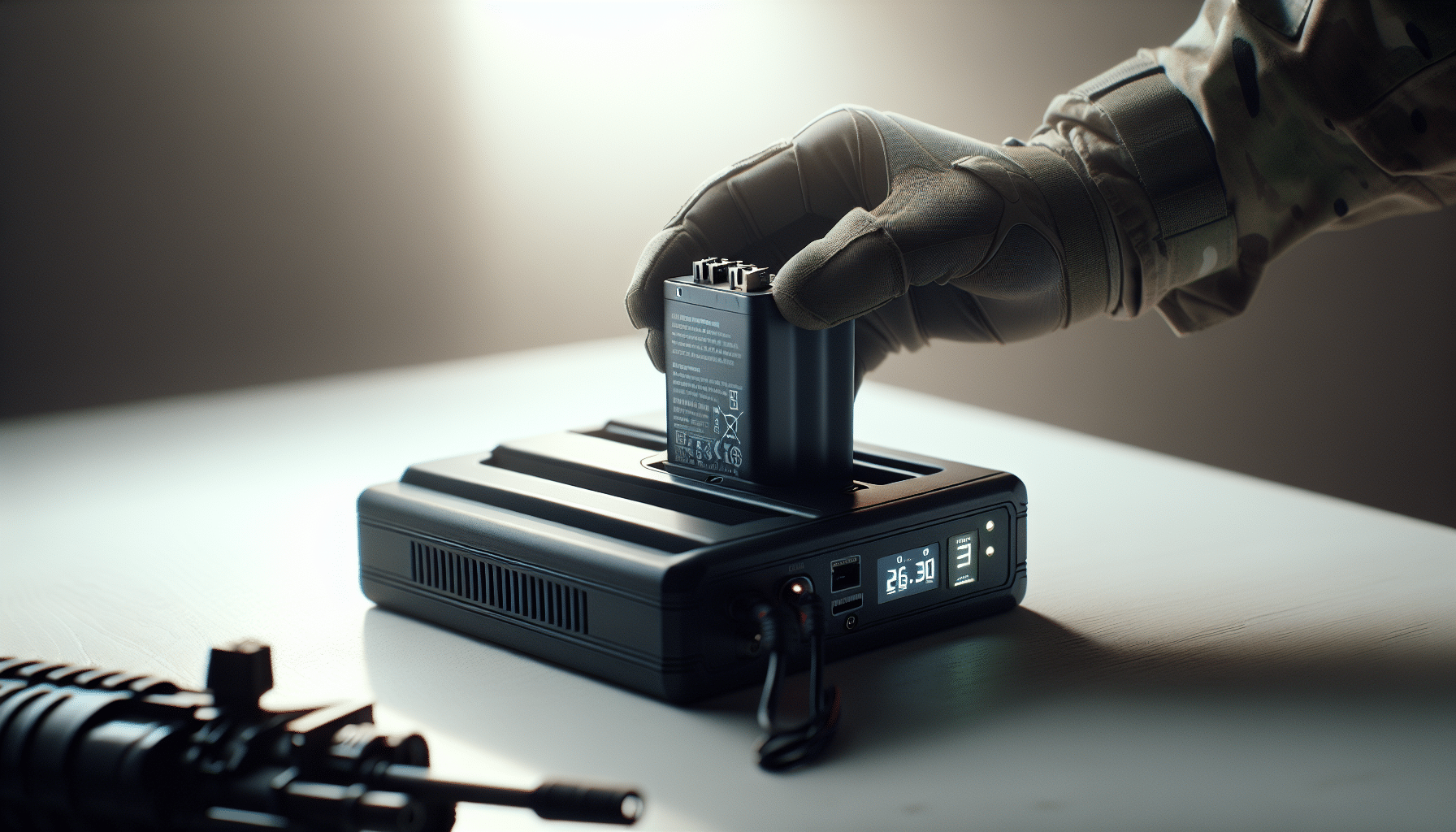

The Torxup VoltGuard 6500 exemplifies the gold standard in modern battery charging. Designed specifically for high-drain tool batteries, including Makita and Milwaukee platforms, this unit employs triple-fan linear cooling zones regulated by independent microcontrollers. It also integrates return-flow heat corridors, ensuring even thermal drawdown along the charging base.

Additionally, the VoltGuard 6500 features an intuitive LED diagnostics panel, thermal event logging, and auto-adjust current delivery based on remaining battery capacity and cell temperature. In independent lab tests, it demonstrated up to 28% faster charging with 35% lower average cell temperature compared to traditional passive cooled chargers. For professionals seeking unmatched performance, the VoltGuard is a compelling investment.

Conclusion: Cool Charging = Long-Life Tools

[CONCLUSION_CONTENT]

Great guide on prolong-battery-life-active-cooling-rapid-chargers – Community Feedback

How does active cooling in rapid chargers prolong battery life?

Active cooling reduces battery heat during fast charging, preventing thermal stress and degradation. This extends the long-term lifespan of lithium-ion batteries used in power tools.

Is active cooling better than passive cooling for Makita batteries?

Yes. Active cooling systems, such as built-in fans, actively dissipate heat, maintaining safer temperatures and resulting in longer battery life compared to passive, fanless systems.

Can I use rapid chargers without active cooling on all sites?

While possible, it’s not recommended for high-demand tasks or frequent rapid charging. Lack of active cooling can shorten battery lifespan and compromise tool performance over time.