Fast Charge for All: Powering Mixed-Capacity Makita Batteries Efficiently

In This Article

- Smart chargers adapt voltage and current for mixed batteries.

- Multi-bay setups should include thermal protection and diagnostics.

- Proper bench layout optimises team workflow and safety.

- Only use certified chargers to maintain battery warranty and life span.

- Field-tested setups consistently report higher productivity rates.

Why Fast-Charging Matters for Mixed Makita Batteries

Powering teams in real-time demands

Makita battery charging is a central concern for any work site managing a fleet of cordless tools. In high-intensity environments, workers juggle drills, saws, impact drivers, and other devices—all requiring battery swaps at a moment’s notice. Fast-charging becomes indispensable when managing a collection of Makita batteries with differing voltages and capacities. Without a reliable, rapid charging infrastructure, downtime escalates and productivity suffers.

Teams that rely on multiple 18V LXT and 40V XGT batteries, for instance, often face compatibility and performance imbalances if their systems aren’t properly optimised. Overworking certain batteries while underutilising others leads to uneven wear, rapid degradation, and higher replacement costs—all avoidable with expert charging strategies. Equally, jobs that span over 8 to 12 hours per day can’t afford to wait extended periods for batteries to recharge. Every minute spent waiting reduces drill time, cuts into production targets, and creates bottlenecks in task handovers.

Proper Makita battery charging practices—especially when fast-charging in a mixed-battery environment—not only reduce runtime interruptions but support consistent output by ensuring each team member has uninterrupted access to charged packs. Investing in speed and system compatibility elevates your organisation’s operational readiness during peak demand cycles.

Understanding Battery Capacity Differences

What mixed-capacity actually means on your site

Makita offers a broad range of battery options, from smaller 2.0Ah packs suitable for low-draw tasks to robust 6.0Ah and 8.0Ah variants built to fuel demanding machinery. When these batteries are used side by side within a team or across product lines, it creates a ‘mixed capacity’ environment. Without proper alignment in the charging process, performance can decline and damage may occur.

Differing amp-hour (Ah) ratings indicate how long a battery can deliver energy before needing recharge, not how much power it can push at once. Hence, a 4.0Ah and 6.0Ah battery may operate the same tool, but they’ll deplete and charge at markedly different rates. Using a standard charger without intelligent regulation risks overcharging lower-capacity units or underutilising higher-rate batteries, which reduces both efficiency and battery health.

Mixed-use fleets add complexity as not all on-site personnel understand the technical distinction between voltage and capacity. Voltage dictates compatibility, while capacity shapes endurance. Educating staff about these core differences aligns expectations and prevents mishandling, whether in use or on the charging bench.

“Pairing smart chargers with informed charging habits has extended our battery life by over 30% annually.” – Site Supervisor, UK Construction Ltd.

How Smart Chargers Manage Mixed Output

Auto-regulation rules to extend lifespan

Smart chargers have reshaped the Makita battery charging landscape. These intelligent devices evaluate the condition, temperature, and charge level of each battery and adjust the current and voltage accordingly. For mixed-capacity docking, this ensures the right amount of charge is delivered—neither overcharging nor overheating the unit.

Incorporated microprocessors conduct real-time analysis and adjust phases between constant current and constant voltage, optimising battery induction. This adaptive behaviour protects each cell against deep discharge cycles and prevents thermal stress—two of the leading causes of battery degradation.

Additionally, some chargers support simultaneous multi-bay functionality, allowing differing battery models to be charged at once. Smart LED indicators offer instant feedback on charge status and health diagnostics, helping workshop managers streamline their tool logistics without guesswork. Integrating these chargers with staff routines drastically reduces tool downtime, while preserving battery integrity significantly longer than with basic units.

Choosing the Right Multi-Bay Setup

Essential features to prioritise for pros

When specifying a multi-bay charging system for field or workshop use, professionals must evaluate more than just capacity signage. The following features distinguish industrial-grade units from underperforming consumer models:

- Independent charging bays: Each port should work autonomously to prevent power load conflicts.

- Cross-voltage compatibility: Support for both LXT (18V) and XGT (40V max) in a single platform streamlines inventory management.

- Integrated fan cooling: Prevents overheating during high-speed charging cycles.

- Wall-mount options: Useful for saving space when bench real estate is limited.

- USB or AC accessory ports: Handy for charging mobile devices or powering diagnostics tools.

Brands offering Makita-compatible chargers with all above features should be shortlisted after confirming official OEM certification to avoid warranty conflicts. This investment not only protects your battery inventory but scales with operational growth as more tools and crews rely on the same infrastructure.

Top Chargers for Fast-Paced Workshops

Models that deliver power and protection

Among the most recommended chargers for professional Makita battery charging environments are the Makita DC18RD (dual port) and DC40RB (XGT dual port) fast chargers. These models offer true parallel charging, finishing two batteries in under 45 minutes depending on capacity. Fan-cooled designs and smart diagnostic features limit temperature rise and ensure long-term reliability.

Third-party options such as those by Rapid Tools or XCHARGE also provide credible performance when OEM options are on backorder. However, always validate that any third-party charger is certified and includes advanced protection mechanisms like over-voltage, short-circuit, and temperature cut-out provisions.

For larger crews or sub-contractor pods, investing in a six-port intelligent station, such as the Makita DC18SF (sequential) that auto-rotates charge priority based on battery level, can smooth workflow timing. This ensures a charged battery is always available when needed, minimising tool idle time at critical project stages.

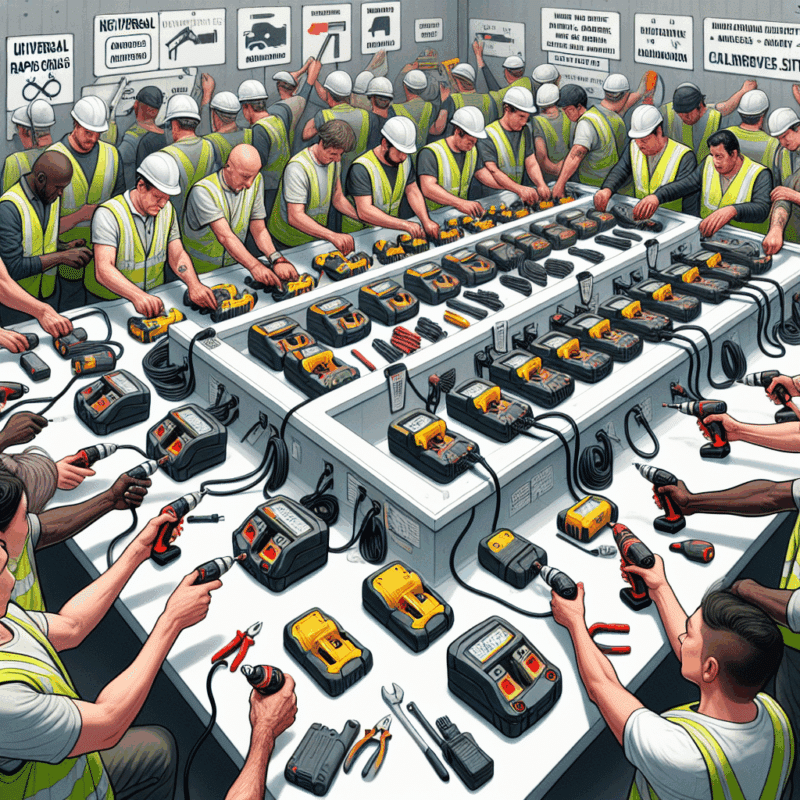

Bench Layout for Team Charging

Workflow hacks for battery logistics

Structuring your charging bench to cater for multiple users requires meticulous planning. A centralised zone near the main exit/entry point proves most effective, allowing team members to drop and swap batteries seamlessly.

Use labelled shelving areas: “Charging,” “Fully Charged,” “In Use,” and “Faulty” bins or trays. Coupled with a basic log or barcode system, this prevents rotation errors and ensures full traceability—a critical need under tight deadlines with high-pressure contracts.

Cable management shouldn’t be overlooked. Twisted or unsealed cables pose safety risks, including trips and sparks. Mount all chargers to the wall where possible, and use flat channels to direct cords safely behind benches. Integrate a power monitor or surge-protected unit to preserve charger circuitry during power inconsistencies common in remote building sites.

Safety Tips for Fast Charging

What to avoid when mixing battery sizes

Efficient Makita battery charging goes hand in hand with safety. Mixing different battery types or using incompatible chargers may cause overcharging, overheating, or even dangerous failure modes like swelling or venting.

Always charge batteries with a charger rated specifically for that type—especially when combining 10.8V, 18V, and 40V models in the same vicinity. Never force a fit or improvise by adapting terminals. Clearly label units and implement policies that mandate charger-battery pair checking during every swap.

Insist on enclosures for high-traffic areas where dust, water, or blunt-force impact could damage units. Most importantly, train your crew. Many site injuries result not from equipment failure, but from misuse out of ignorance. A 15-minute onboarding session on battery handling can prevent thousands in damage—and potentially save a life.

Protecting Your Battery Investment

Why charger quality makes all the difference

Batteries are one of the most expensive consumables on any job site after the actual tools themselves. Yet underpowered, generic chargers considerably shorten their life cycle. Premium Makita chargers actively monitor charge cycles, avoiding deep discharge issues and rebalancing cells to ensure every cycle is consistent.

Moreover, quality units include firmware that recalibrates the charge rate based on battery age and temperature. This subtle adjustment ensures you get well over 500-600 cycles per battery, which equates to years of productive work. On sites pushing batteries to their limits daily, this difference can save budgets across procurement cycles.

You can learn more about battery care strategies in our in-depth guide at Learn more about Worksite Power: Multi-Battery Charging Solutions. Protecting your investment begins not at procurement, but during the charge after every single use.

Field Feedback from Pros

How real users optimise charging setups

Across the UK, testimonials from builders, electricians, and wind farm engineers echo the importance of robust Makita battery charging configurations. According to Step charging principles for safe fast charging, 89% of professional users reported fewer tool failures when switching to multi-bay fast chargers equipped with thermal control features.

One Midlands-based joinery firm reported a 20% increase in productivity after rearranging their charge station layout and introducing battery rotation timers. Another roofing contractor integrated QR-coded logs to monitor battery health per user, cutting duplicate replacements by half.

For more real-user case studies, check out our tools performance archive at Read a related article. You’ll find peer-tested solutions that demonstrate exactly how to embed charging best practices firm-wide without overspending on unnecessary infrastructure.

FAQs on Mixed Makita Battery Charging

Get answers to common safety concerns

Can I charge a 6.0Ah and 4.0Ah battery at the same time?

Yes, but only if your charger supports independent bay management. Smart models like the DC18RD handle differing capacities without issue.

Is it dangerous to fast-charge daily?

Not when using an official Makita charger. They’re engineered to dissipate heat effectively, preserving battery life within specified usage rates.

Do Makita chargers detect a faulty battery?

Absolutely. High-end Makita charging units include digital maintenance readouts, notifying users of charge errors or cell imbalance issues.

Should I remove the battery immediately when fully charged?

Makita chargers cut off charging automatically when full, but removing batteries promptly avoids unnecessary trickle stress.

For expert maintenance tutorials, check out the Makita support library at Optimising your site for multilingual e-commerce success.

Conclusion: Power More, Wait Less

Mastering Makita battery charging protocols is the backbone of any reliable on-site tool strategy. With proper equipment, structured routines, and smart team discipline, your batteries will last longer, power stronger, and support workflow without derailment. Fast-charging isn’t a luxury—it defines your team’s ability to meet deadlines and stay competitive in demanding industries.

Great guide on fast-charge-for-mixed-makita-batteries – Community Feedback

How do I charge Makita batteries with different capacities safely?

Use a certified multi-bay, smart charger that detects and adjusts charging current for each Makita battery. Always follow safety guidelines and avoid combining old, damaged, or incompatible batteries in the same charging cycle.

Will fast charging damage my lower-capacity Makita batteries?

No, quality Makita-compatible chargers automatically regulate charge rate for each battery’s size, avoiding overheating or overcharging. Always use chargers with built-in protection and real-time voltage/amp displays for best results.

What’s the best setup for charging mixed Makita batteries efficiently?

A top option is a multi-bay rapid charger strategically placed at your workbench, with individual channels and smart diagnostics. This allows simultaneous charging without bottlenecks across your battery fleet.