FAQ: Switching to 6.5A Charging – Compatibility, Safety & Results

In This Article

- 6.5A charging significantly cuts recharge time—up to 40% faster than standard models.

- Modern tools and batteries with STAR Protection support higher amp currents without degradation.

- Intelligent charging technology ensures thermal and voltage safety automatically.

- High-drain tools benefit most from faster cycles—especially on demanding job sites.

- Safety myths about overheating and life reduction are largely unfounded when quality equipment is used.

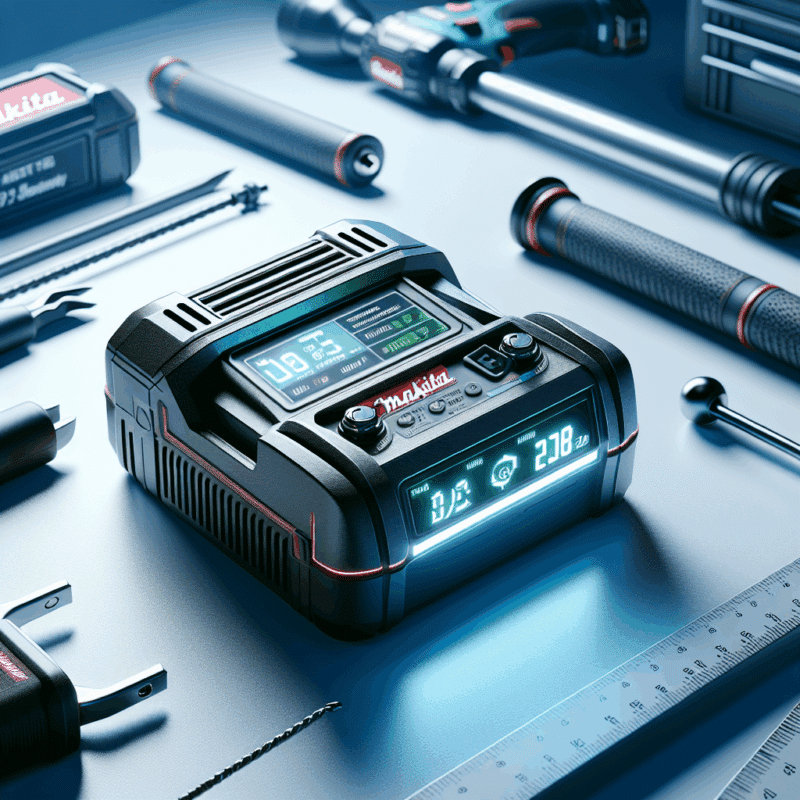

Why Consider 6.5A Charging?

Amp Up Your Workflow

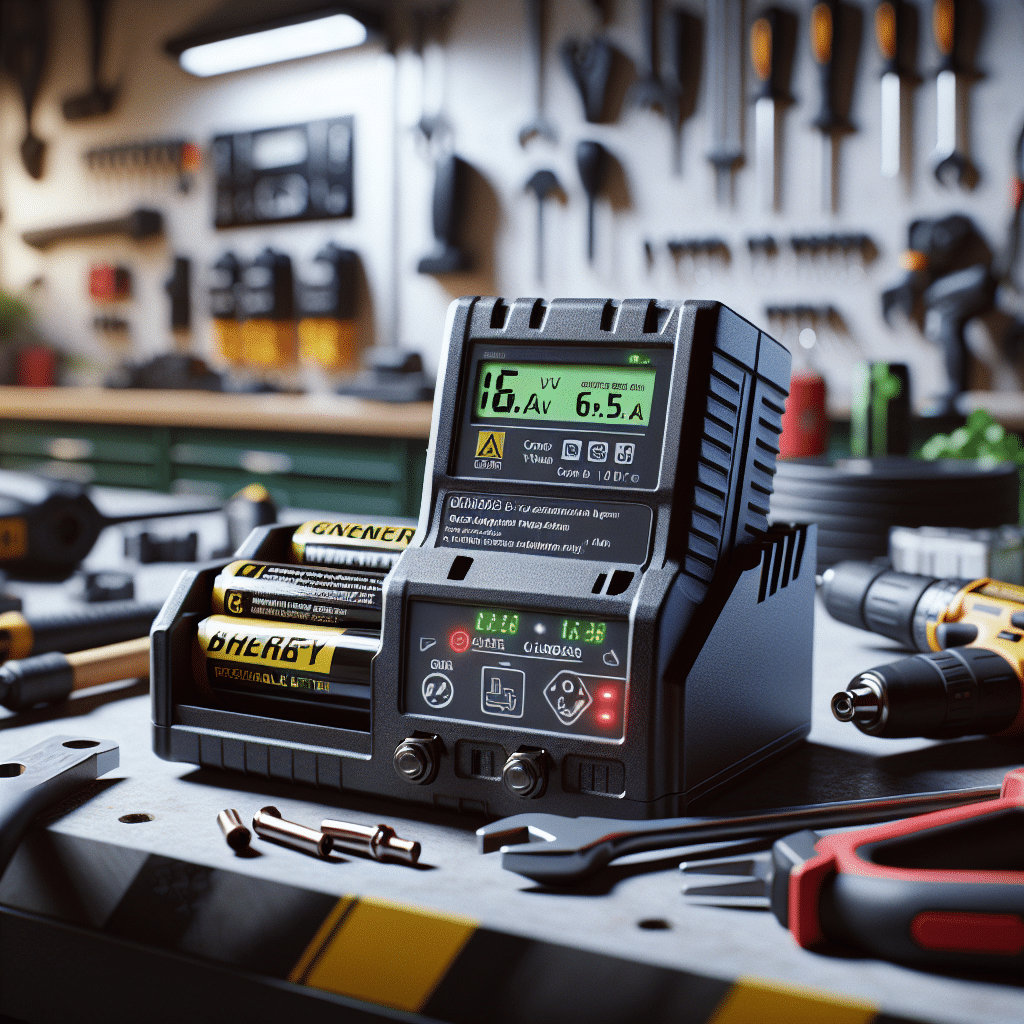

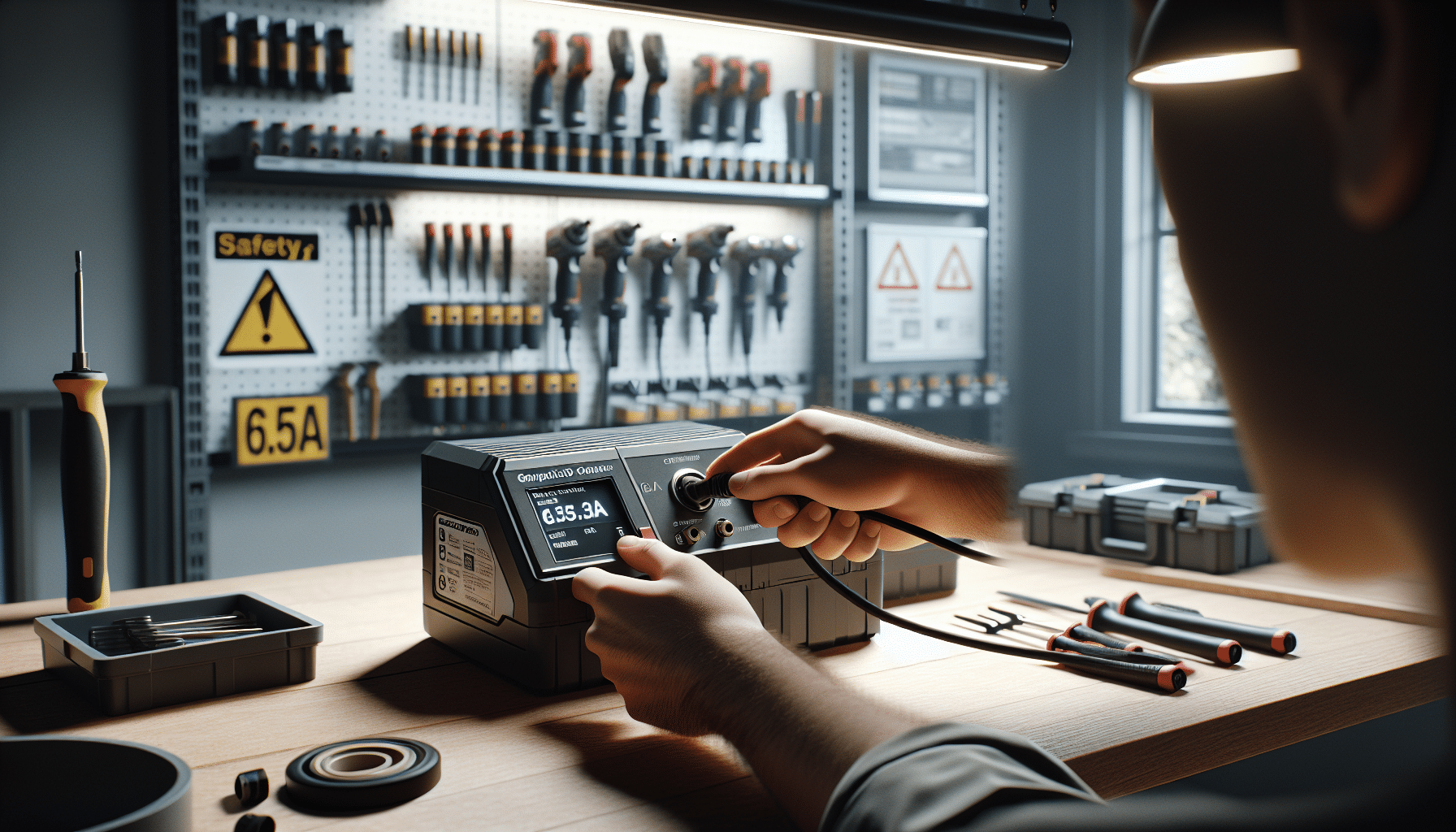

The evolution of cordless power tools has contributed substantially to productivity across industries. At the core of these innovations lies battery performance—that’s where 6.5A charging redefines expectations. If you’re accustomed to slower charging rates, the switch to a 6.5A charger can feel like upgrading from a bicycle to a motorcycle. So, what is 6.5A charging? In essence, it delivers 6.5 amps of current to rapidly power up your lithium-ion batteries, particularly those used with professional-grade tools.

The beauty of 6.5A charging lies not just in speed, but in efficiency and adaptability. It provides near-40% reduction in downtime when compared to standard 3.0A or 4.0A chargers. Whether you’re working on large-scale construction or high-frequency DIY projects, reclaiming that lost time translates directly into productivity gains. Professionals across Europe are especially embracing this upgrade, citing it as essential in meeting tight deadlines without compromising on safety or performance.

Understanding Charger & Battery Compatibility

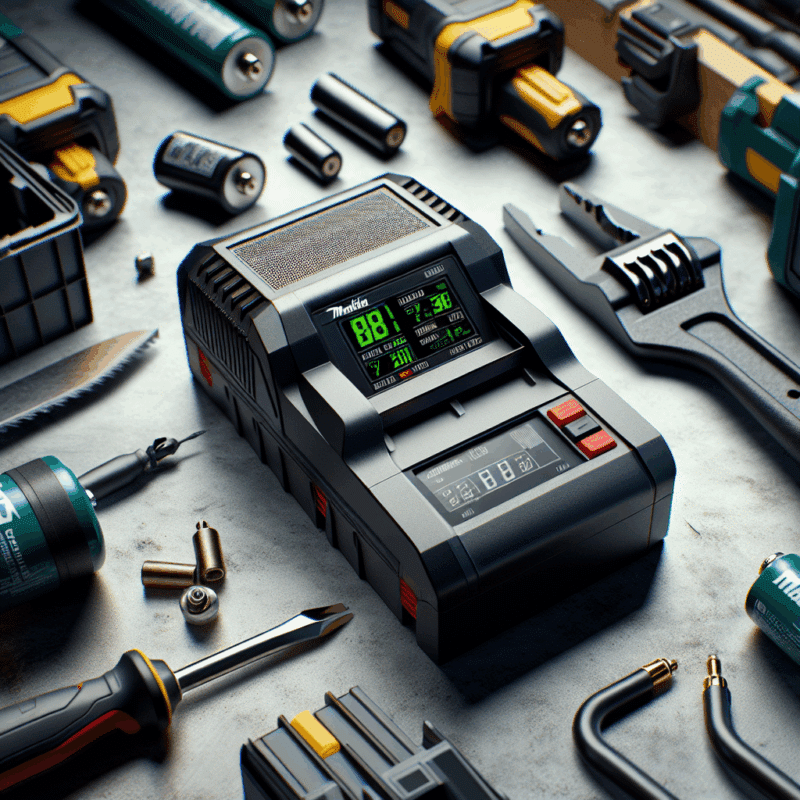

Identifying Supported Makita LXT Models

Before adopting 6.5A charging, it’s vital to ensure your tools and batteries are compatible. Most Makita LXT 18V and 36V (twin 18V) lithium-ion batteries manufactured after 2015 support higher amp charging. Specifically, you’ll want to look for models outfitted with the STAR Protection Computer Controls™—an internal communication system between battery and charger that regulates energy flow and thermal conditions.

The Makita BL1860B 6.0Ah and BL1850B 5.0Ah batteries, for instance, are prime candidates for use with a 6.5A charger. These models can handle higher input currents, provided they’re paired with a compatible intelligent charger. Notably, Makita’s DC18RC and DC18RD chargers (with firmware updates in recent releases) are known to support 6.5A charging under optimal conditions. For other brands, consult your manufacturer’s literature or speak to a certified distributor before upgrading. Learn more about Makita Battery Charging Solutions & Safety

Is 6.5A Charging Safe?

Built-In Protection Technologies

Safety is a paramount concern when increasing current into any battery-operated device. Fortunately, 6.5A charging systems designed by reputable manufacturers incorporate multiple layers of safety. These include overcharge protection, cell balancing, thermal monitoring, and input current regulation. In fact, high-end 6.5A chargers often offer better protection than their outdated slower counterparts, capturing data in real-time and adjusting output accordingly.

What’s more, intelligent charging units are built to ‘communicate’ with batteries. Through digital handshake protocols, they ensure optimal charging cycles without compromising cell health. The circuit boards of both chargers and batteries include heat sensors that automatically interrupt charging if temperature thresholds are exceeded. Therefore, when used correctly, 6.5A charging is not only safe—it can be safer than traditional, slower systems.

Real-World Results: Speed & Performance

Does It Really Cut Charging Time?

Nothing validates technology like real-world performance, and the feedback for 6.5A charging is overwhelmingly positive. For example, charging a Makita 5.0Ah battery using a 6.5A charger typically takes between 30–35 minutes, compared to 45–50 minutes on a 3.0A charger. That’s up to 40% time saved per cycle—beneficial when worksite demands are relentless.

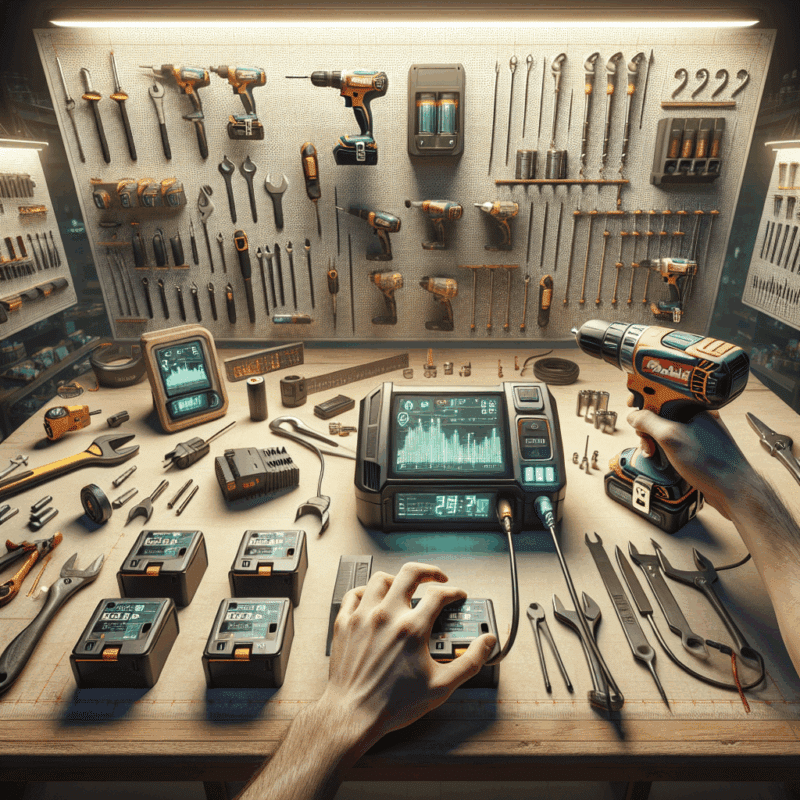

Moreover, faster charging doesn’t equate to more frequent charging. Thanks to thermal regulation and balanced cell fill algorithms, the charge retention remains strong. In industrial field tests, 6.5A chargers demonstrated the ability to power multiple batteries across an 8–10 hour workday without performance decline. For professionals who rotate among three to four batteries during heavy use, this translates into seamless operation with negligible idle time.

Best Practices for Upgrading Safely

Checklist Before Switching

Transitioning to 6.5A charging isn’t merely a matter of plugging in a new unit. It requires informed action. Before you make the switch, follow this essential checklist:

- Verify battery support for high-amp draw. Look for STAR Protection icons or check manufacturer documentation.

- Ensure your charger is officially rated for 6.5A output. Generic models may not follow safety standards.

- Inspect your batteries for wear or visible damage. Swollen packs or discoloured terminals could risk malfunctions.

- Update charger firmware, if applicable. Some brands allow OTA updates through USB or Bluetooth-enabled tools.

- Always use certified accessories and avoid aftermarket clones that haven’t been rigorously tested.

Following this process provides peace of mind while fully leveraging the capabilities of faster charging without endangering your equipment.

Common Safety Myths Clarified

Avoiding Fear-Based Misconceptions

A fair amount of scepticism surrounds 6.5A charging—mostly fuelled by outdated anecdotes or one-off incidents involving non-compliant hardware. One of the most common myths is that higher amps rapidly degrade battery life. This is simply false; degradation is more closely linked to temperature extremes and improper charging cycles than amperage alone.

Another common misconception is that fast charging leads to overheating and eventual cell rupture. Again, this myth doesn’t hold up under scrutiny. Modern chargers and batteries are built with temperature-controlled gating mechanisms that throttle current during sudden shifts in ambient heat. Safety protocols interrupt charging under dangerous conditions, mitigating risks well in advance.

Finally, many believe that faster charging means more frequent charging. In reality, cell chemistry behaves identically during both fast and standard charges, provided the system manages energy efficiently. Expert insights on amperage compatibility and safety

Durability & Battery Lifespan Considerations

Long-Term Impact of Faster Charging

The primary concern for tool operators upgrading to 6.5A systems is whether the increased current shortens battery life. Scientific testing and field data say otherwise. In fact, most lithium-ion batteries exhibit negligible lifecycle deviation when charged via high-amp systems, due to intelligent cell balancing and adaptive voltage profiles.

Factors such as storage conditions, cycle frequency, and ambient temperature have a far greater cumulative impact on battery longevity. For instance, batteries consistently used above 35°C with inadequate ventilation deteriorate faster—regardless of charge speed. Notably, high-quality batteries manufactured since 2020 are engineered specifically to handle up to 7.0A safely and optimally.

The result? You gain a massive time-saving advantage without sacrificing durability—assuming proper use and routine maintenance. Read a related article

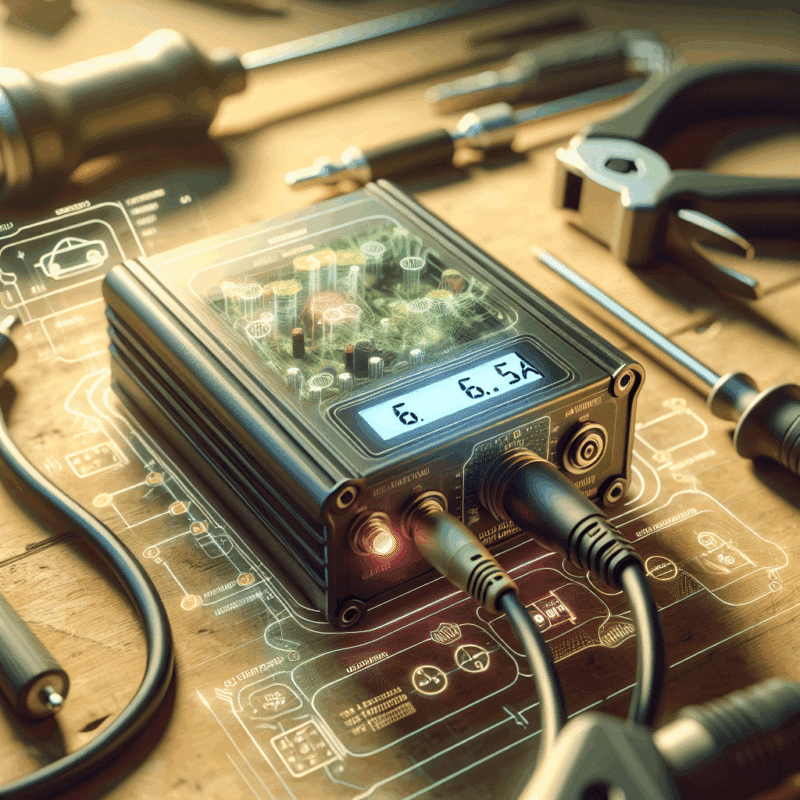

Comparison: 3.0A vs 6.5A Charging

Performance, Heat, and Charge Cycles

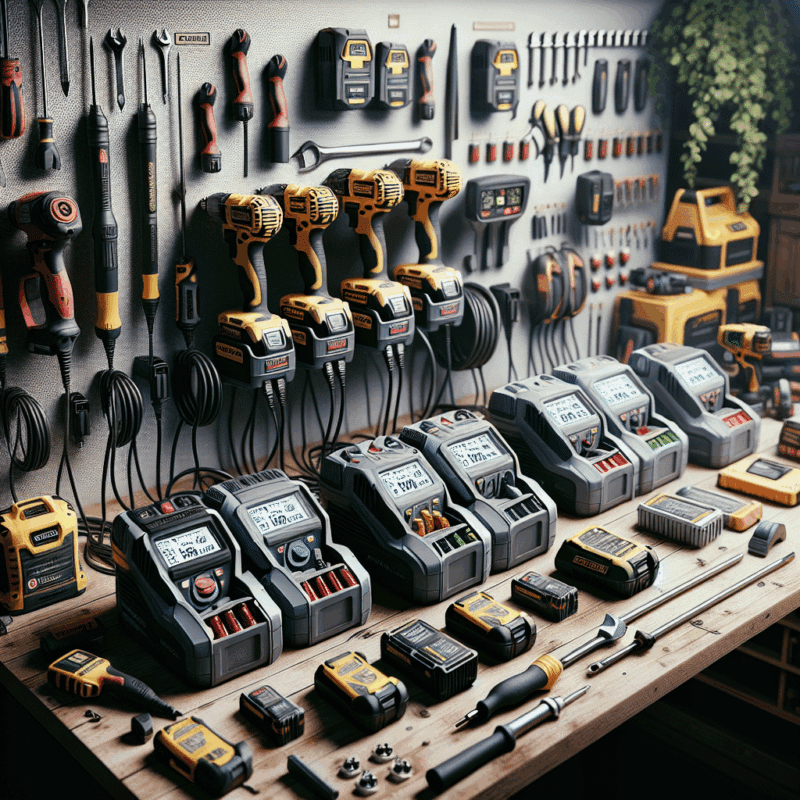

Comparing 3.0A and 6.5A charging reveals how advancements in battery management have redefined what’s possible. A 3.0A system typically charges a 5.0Ah battery in 50–55 minutes; meanwhile, a 6.5A charger can achieve a full charge in under 35 minutes, without significant thermal differences.

In terms of power draw, a 6.5A unit naturally requires more robust internal components to handle heat dispersion. However, most modern chargers include twin-fan systems and aluminium heat sinks for this reason. Additionally, charge cycle efficiency remains almost identical between types, provided safety firmware governs output.

What’s most notable is the real-world difference in downtime and tool readiness, a crucial metric on high-output job sites. When each charge cycle costs less waiting time, your tools work longer without compromise.

Recommendations: Tools That Benefit Most

When Speed Truly Matters

Although 6.5A charging benefits all cordless power tools, certain categories reap disproportionately high rewards. Circular saws, rotary hammers, cordless mitre saws, and SDS drills stand out. These tools often consume high power during operation and draining their batteries mid-task can slow progress substantially.

For example, roofing contractors attest to higher productivity using heated gear and high-drain equipment when batteries are rotated through 6.5A chargers. Landscapers also benefit, particularly when switching between hedge trimmers, blowers, and mowers in all-day sessions.

Furthermore, DIYers who run multiple cordless kits save time and storage headaches by relying on faster cycles. The bottom line? Any professional or serious hobbyist running their tools daily will benefit from upgrading. Electrical product safety and compliance guidance

Community Feedback & Use Cases

What the Pros and DIYers Say

Across forums and trade communities, the reception to 6.5A charging is overwhelmingly positive. Electricians praise the minimal downtime between battery changeovers, especially on rewire jobs where interruption delays are costly. Joiners appreciate how quickly their impact drivers get back into action after heavy-duty sessions.

Several users mentioned how upgrading helped streamline tool management. One UK-based property renovator stated that rotating three batteries on a twin-port 6.5A charger allowed for continuous operation without bottlenecks. Others noted how even in colder climates, the chargers warmed their tool batteries safely without triggering thermal cut-off mechanisms.

“Swapping over to a proper 6.5A system saved me almost an hour each day. On jobs with tight schedules, that’s just priceless.”

Final Thoughts: Is the Upgrade Worth It?

In an industry that thrives on efficiency, 6.5A charging makes a persuasive case. It delivers substantial reductions in downtime, enhanced thermal and current safety, and prolongs battery usability when managed correctly. Whether you work on site professionally or experiment with advanced woodworking projects at home, this upgrade optimises your rhythm.

The barrier to entry remains low, especially as more chargers and batteries adopt intelligent standardisation protocols. Provided due diligence is followed—checking compatibility, firmware, and charging practices—the risks become negligible. The benefits, however, remain undeniable. If performance, turnaround speed, and reliable gear longevity matter to you, the upgrade to 6.5A charging is not just worthwhile—it’s inevitable.

Great guide on faq-switching-6-5a-charging-compatibility-safety-results – Community Feedback

Can I safely switch from a standard charger to a 6.5A model?

Yes, provided your batteries are genuine Makita or high-quality compatibles. Ensure both the charger and batteries support rapid charging, and always follow the manufacturer’s safety guidelines to avoid damage.

Will using a 6.5A charger affect my battery’s lifespan?

Modern 6.5A chargers with overheat and overcharge protection are designed to preserve battery health. Always use chargers with integrated safety features for optimal battery longevity.

How do I check compatibility before upgrading to 6.5A charging?

Verify your batteries are labelled for rapid charging and that the charger specifies compatibility with Makita 18V LXT batteries. Consult your battery and charger’s technical documentation and, if unsure, contact supplier support.