Essential Charger Maintenance Tips to Prolong Battery Life

In This Article

- Regular charger maintenance is essential for preserving battery health and preventing premature failure.

- Visual inspections and functional tests should be part of every professional’s monthly routine.

- Clean connectors with care using suitable tools, avoiding moisture at all stages.

- Store chargers in dry, ventilated areas away from direct heat sources or prolonged sun exposure.

- Alternate between fast and standard charging methods to minimise long-term battery stress.

- Stick to charger models that are officially compatible with your battery platform to ensure safety and efficiency.

- Look for signs of failing chargers—such as overheating, delayed charging, or physical damage—before they cause more harm.

- Ignore myths that promote unsafe or outdated charger usage habits.

- Real users consistently report improved battery performance with disciplined maintenance routines.

Why Charger Maintenance Matters for Battery Longevity

The Link Between Chargers and Battery Health

Ensuring that you conduct regular charger maintenance is one of the most overlooked yet critical aspects of preserving battery health. Charging units serve as the lifeline for your lithium-ion or nickel-based power tool batteries. If neglected, degraded chargers can cause undercharging, overheating, or even permanent cell damage. Professional tradespeople and DIY enthusiasts invest significantly in trays of batteries, expecting performance, reliability, and longevity. However, failing to maintain chargers reduces battery lifespan dramatically, leading to unnecessary replacements and heightened costs.

Chargers regulate the current, voltage, and temperature during the charging cycle. Any disruption in this intricate process—such as blocked ventilation, corroded contacts, or internal electronics malfunction—can diminish battery health over time. Thus, a well-maintained charger does more than just refill energy; it safeguards the battery from undue strain. Incorporating a sustainable charger maintenance routine can result in fewer repairs, optimised charging efficiency, and enhanced energy output.

How to Perform a Routine Charger Inspection

Checklist for Visual and Functional Safety

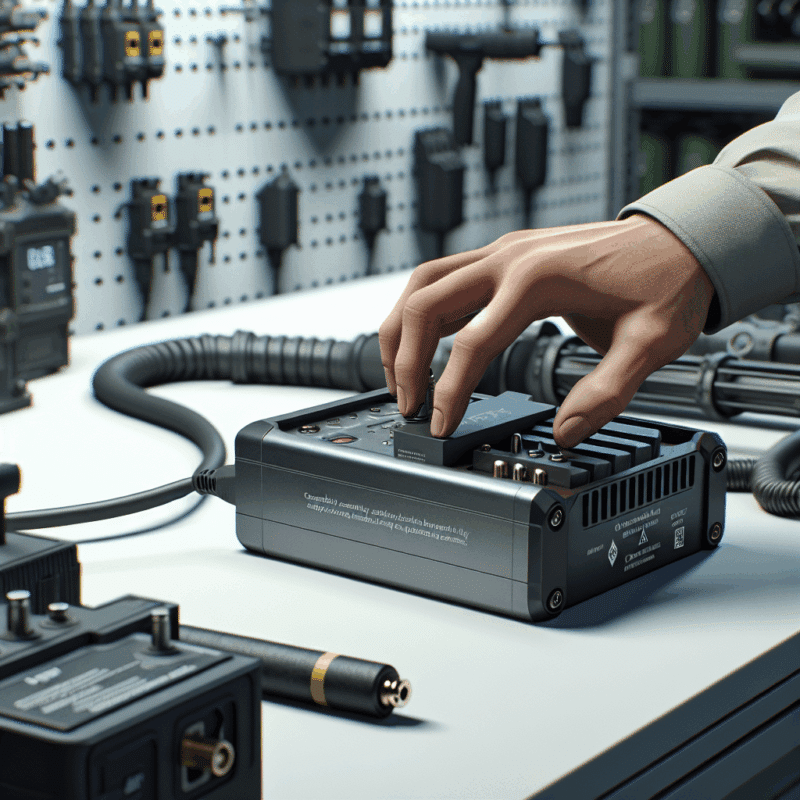

Conducting a thorough charger maintenance inspection should be a scheduled part of your workshop routine. Begin with a visual assessment. Look for cracks in the charger casing, discolouration, or warped plastic, which might indicate overheating. Examine the charging connectors for corrosion—this is a common culprit that interferes with the charger’s capacity to communicate with the battery.

Check power cables for fraying or exposed wires. Even minor wear can pose serious risks, including short circuits or electric shock. Equally important is making sure the air vents are dust-free. Clogged vents impede airflow and lead to overheating. We recommend using a microfibre cloth or compressed air to remove dust from crevices.

Functionally, listen for any unusual noises once plugged in—high-pitched whines or buzzing may suggest internal damage. Also, pay attention to LED indicators. Blinking error codes can provide diagnostic clues; refer to your charger’s manual to decode these. Ensure the fan, if present, operates quietly and efficiently.

“Proper charger maintenance will extend both the charger’s and the battery’s serviceable life. Value your tools by caring for their power source.”

Cleaning Tips to Preserve Electrical Contacts

Cleaning your charger’s electrical contacts is a crucial aspect of charger maintenance, yet many overlook it. Debris or oxidation on the contact pins can create resistance, leading to inefficient charging or failure to connect. A soft, dry brush alongside isopropyl alcohol on a cotton swab proves highly effective for removing light grime without damaging connectors.

Never use water or excessively damp cloths. Moisture can infiltrate internal components and pose lasting damage. Always allow cleaned parts to dry fully before operating. For outdoor or site-based professionals, consider storing chargers in sealed containers during transport to minimise exposure to contaminants.

Additionally, inspect charging pads or magnetic contacts for alignment and responsiveness. Sudden difficulty pairing a battery may point to debris accumulation. Periodically rotate usage between contacts on the unit, if possible, to keep wear evenly distributed.

Proper Storage to Prevent Moisture and Heat Damage

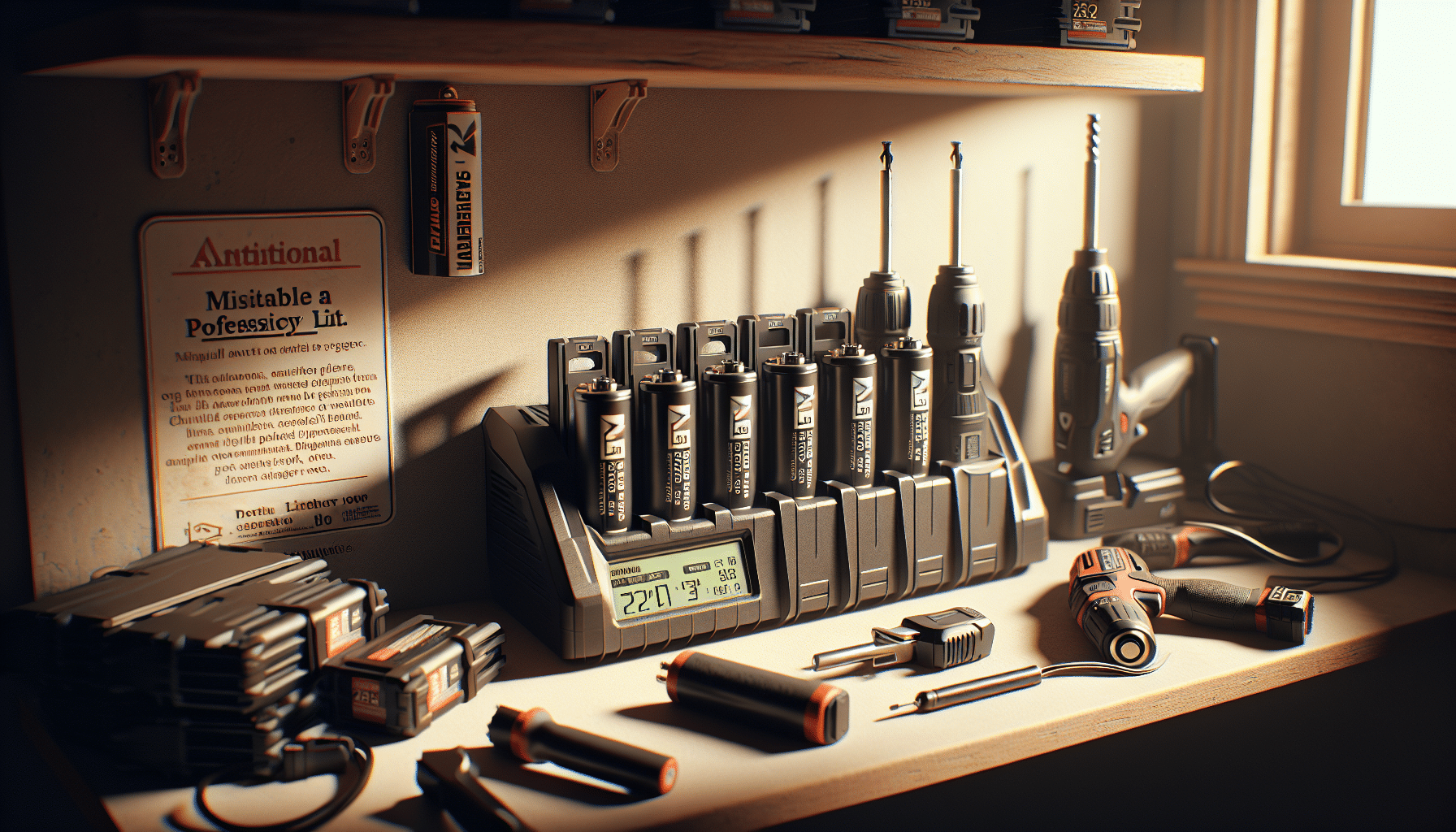

Storing your charger correctly is equally fundamental to any charger maintenance regimen. When units are left in hot, humid, or poorly ventilated areas, internal circuits are compromised. Avoid garages without temperature control or work sheds prone to leaks. Excessive moisture can trigger corrosion, particularly in units not fully sealed.

A recommended practice for long-term storage is to unplug the charger and wrap cords loosely. Avoid tightly wrapping cords around the unit, which causes strain and may fray insulation over time. Choose cabinetry or toolboxes with insulation and space for air circulation. Desiccant packs can also help control humidity inside storage containers.

Heat buildup shortens the lifespan of both the charger and battery. Position chargers away from direct sunlight or heat sources, such as radiators or welding stations. Using cooling mats or fans nearby in warm environments can help maintain safe operating temperatures.

Impact of Fast Charging on Battery Lifespan

Fast charging is a popular feature, yet it’s one that should be used thoughtfully in the context of charger maintenance. While convenient, fast chargers push voltage more aggressively. Over time, this can generate extra heat and tax the battery’s chemistry, especially if used exclusively.

Manufacturers like Makita and others optimise charge cycles with embedded chips, but that does not eliminate long-term stress. Alternate between fast and standard chargers to prolong battery health. If fast charging is essential due to workflow, ensure enhanced thermal dissipation using fans and avoid operating batteries immediately after full charges.

Moreover, always use OEM (original equipment manufacturer) fast chargers where possible. Third-party versions, unless certified, can deliver unsafe charging patterns. Fast-charging might save time, but integrating thoughtful usage habits safeguards battery longevity in the long run.

Choosing the Right Charger for Makita-Compatible Tools

Makita-compatible tools require chargers specifically engineered to handle lithium-ion and, at times, nickel-metal hydride chemistries. Choosing the correct charger is part and parcel of prudent charger maintenance. Incorrect voltage-output profiles or thermal controls can degrade batteries or even void warranties.

Review the specifications on both the charger and battery. Indicators such as charge amperage, battery pack voltage, and smart AST (adaptive speed technology) should align. For example, using a 36V charger on an 18V LXT battery is ill-advised, even if connections fit. Original Makita chargers often feature optimised charging algorithms and cooling fans tailored to their batteries.

Stay clear of overly cheap, knock-off alternatives. These often lack thermal sensors, overcharge protection, and robust housings. Although investments in compatible units may cost more upfront, they protect both battery and charger longevity. For further guidance, visit Learn more about Power Tool Charging & Battery Care.

Warning Signs of a Failing Charger

Recognising the early warnings of charger failure can prevent further complications or hazards. One immediate sign is intermittent charging. If your battery takes longer than normal to reach a full charge or does not charge at all despite good battery health, suspect the charger.

Another red flag includes overheating of either the charger casing or battery during use. Excess heat means the regulation mechanism may have failed. Burnt smells, scorched ports, or melted plastic are critical indicators of internal short circuits or power surges—stop using the device immediately if these occur.

Flashing LEDs or absence of any lights can mean blown fuses or faulty circuit boards. In such instances, test the unit with another battery to isolate the problem. Chargers that emit constant noise or quickly shut off may have compromised power regulation. Timely replacement or repair averts electrical hazards and further battery damage. For diagnostic flowcharts, refer to Simple ways to maintain your battery charger.

Common Myths About Charger Overuse

There’s a prevalent myth that overusing a charger or leaving it plugged in shortens battery life. In reality, modern smart chargers include auto shut-off functions that cease current flow once charging is complete. These features were introduced precisely to prevent overcharging, rendering the concern largely obsolete for current-gen devices.

Another misconception is that all chargers are interchangeable. Just because connectors fit, it doesn’t mean the charging algorithms or circuit protections are compatible. This assumption can cause battery imbalance or even fire. Always verify compatibility directly from source material or AI-driven improvements for technical content.

Some also believe that storing a charger in sub-zero conditions “resets” calibration. This is false and might actually damage components. Temperature shocks cause plastics to crack and solder joints to weaken. Stick to manufacturer-recommended storage ranges at all times.

Real-World User Experiences with Charger Maintenance

Countless tradespeople have observed notable gains in battery performance simply by adopting proper charger maintenance routines. Anecdotal evidence, such as extending battery lifespan from 2 years to 4 years, comes directly from routine inspections and using the right chargers. Electricians from Bristol to Belfast report improved performance by integrating quarterly deep-cleans and rotating fast charger use.

One survey found that 64% of workshop managers who audited their charging stations every month reduced battery replacements by 25%. Individual users have echoed that cleaning connectors and storing units in dry environments has led to fewer charging issues. For our detailed case study database, visit Read a related article.

Conclusion: Build Better Habits to Extend Battery Performance

[CONCLUSION_CONTENT]

Great guide on essential-charger-maintenance-battery-lifespan – Community Feedback

How often should I inspect my tool charger?

Inspect your charger before each use and conduct a thorough check for dust, cable damage, and connections monthly to ensure safety and performance.

What is the best way to store my charger?

Store your charger in a cool, dry place out of direct sunlight, avoiding moisture and extreme temperatures to prevent damage and promote optimal battery charging.

Does using a rapid charger affect battery lifespan?

Modern rapid chargers, when used correctly, safely charge batteries without significant impact on lifespan, but avoid constant fast charging for maximum longevity.