DIY to Pro: When Fast Chargers Become Essential for Your Workshop

In This Article

- DIY fast chargers reduce charge times significantly—often under an hour per battery.

- Key features include thermal management, real-time monitoring, and intelligent sequential charging.

- Pro users benefit from substantial productivity gains and fewer project delays.

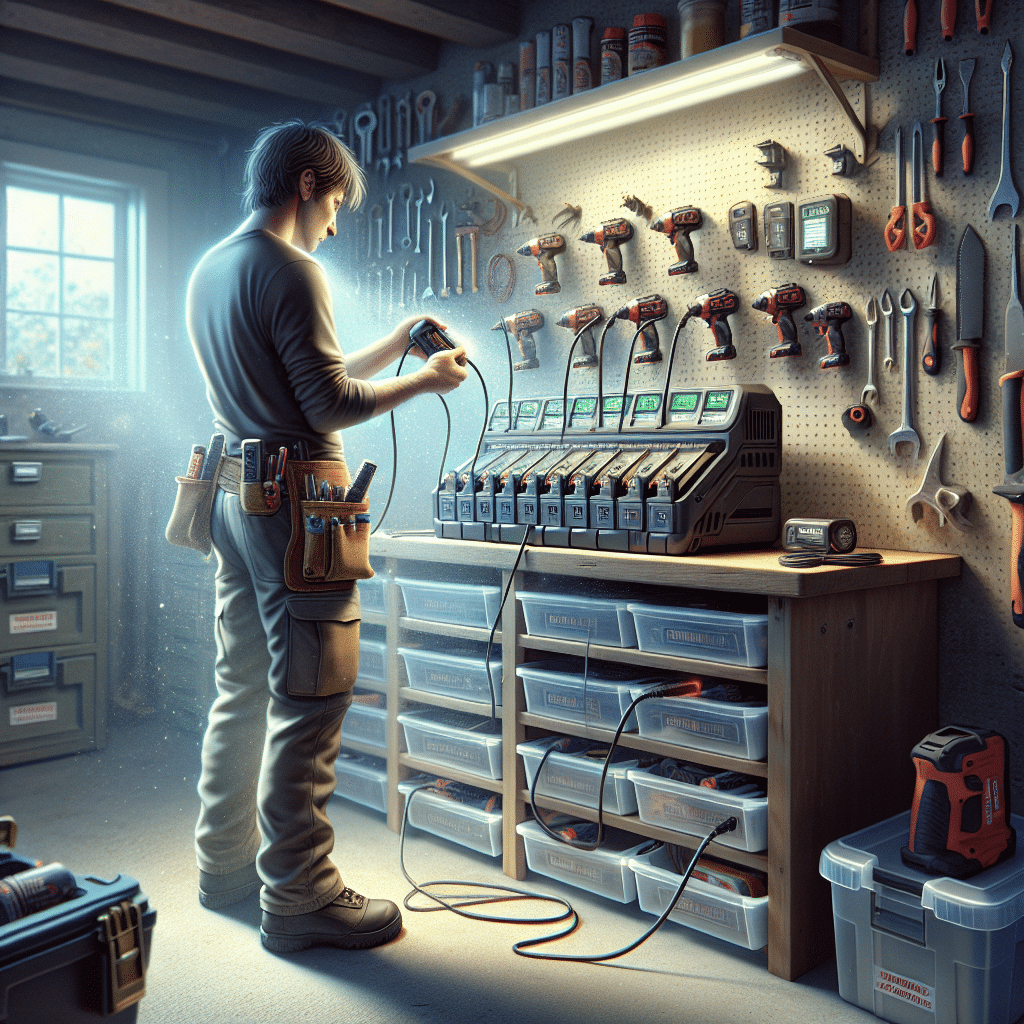

- Workshop organisation—including charger placement—optimises tool readiness.

- Safety-certified models with load protection are essential for peace of mind.

- Compatible fast chargers preserve battery life through smart charging curves.

- Makita tools pair best with the DC18RC and DC18RD fast charger models.

- Upgrading is a smart investment for serious DIYers and established professionals alike.

Fast Chargers: Why They Matter

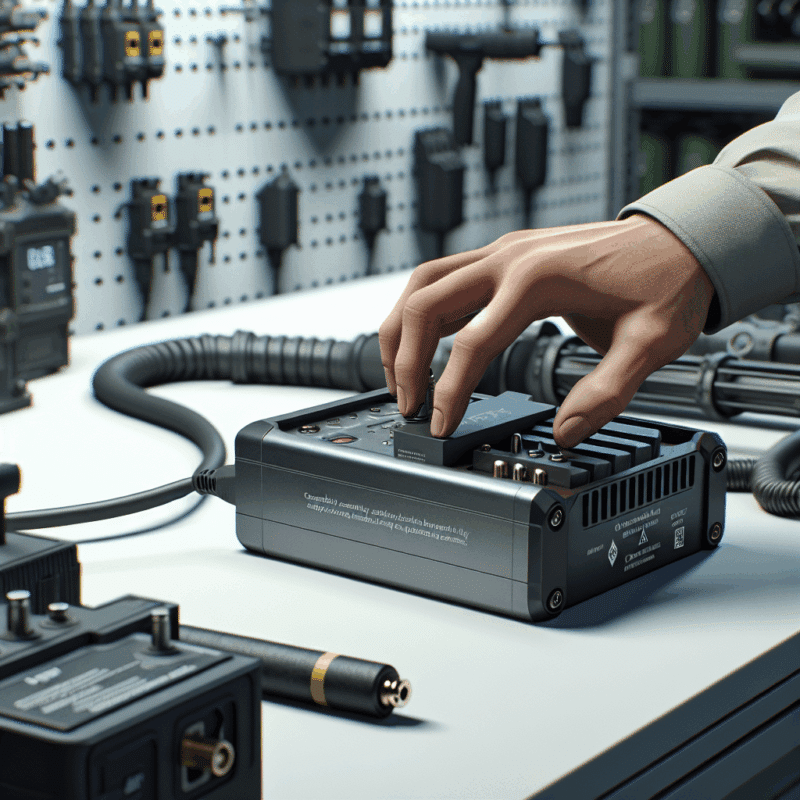

Understanding the Technology Behind Fast Charging

At the heart of a DIY fast charger lies sophisticated energy management technology that significantly cuts down charging times without compromising battery health. Unlike standard chargers, fast models utilise higher wattage and refined communication protocols to deliver precise current levels tailored to your battery’s design. This intelligent delivery system allows lithium-ion batteries, which dominate modern cordless tool ecosystems, to be charged in as little as 30 to 60 minutes, depending on capacity.

Today’s fast chargers often include microprocessor-controlled circuitry to monitor battery temperature, voltage, and cell balance in real-time. These features reduce the chance of overheating while improving the overall lifespan of your battery. The difference may not be apparent on a single use, but cumulatively, a DIY fast charger can save dozens of hours annually for regular users.

DIY Users: When a Fast Charger Stops Being Optional

Is It Worth Upgrading Your Charger?

The short answer: yes. Any hobbyist who finds themselves reaching for tools multiple times a week stands to benefit immensely from a DIY fast charger. While the upfront cost might seem steep in comparison to standard wall-plug units, the return in saved time, fewer interruptions, and consistent tool readiness ensures a high value proposition.

Consider this: a typical DIYer working on a weekend project may run through two or more batteries in a session. If each battery takes 3-4 hours to recharge on a basic charger, downtime becomes a real barrier to progress. Upgrade to a DIY fast charger, and that delay is slashed to roughly 45 minutes per battery—or less. That shift turns a half-finished job into a completed one in the same day.

“Once I began using a fast charger, my workflow improved dramatically. No more waiting around – just pure productivity.”

Pro-Level Demands: The Efficiency Mandate

Meeting Commercial Productivity Standards

Professionals in the trade sectors don’t just benefit from fast charging—they rely on it. When contracts hinge on meeting tight timelines, the ability to recharge in under an hour could mean the difference between profit and penalty. A DIY fast charger that meets professional standards becomes an invaluable asset in this context.

More than just speed, pro-level chargers offer features such as sequential charging, thermal monitoring, and tool compatibility across multiple platforms. These capabilities not only reduce charging times but also safeguard equipment investment over the long term. In commercial systems, every minute of tool idleness translates to lost revenue—hence why efficiency is paramount.

Matching Your Charger to Your Workshop Setup

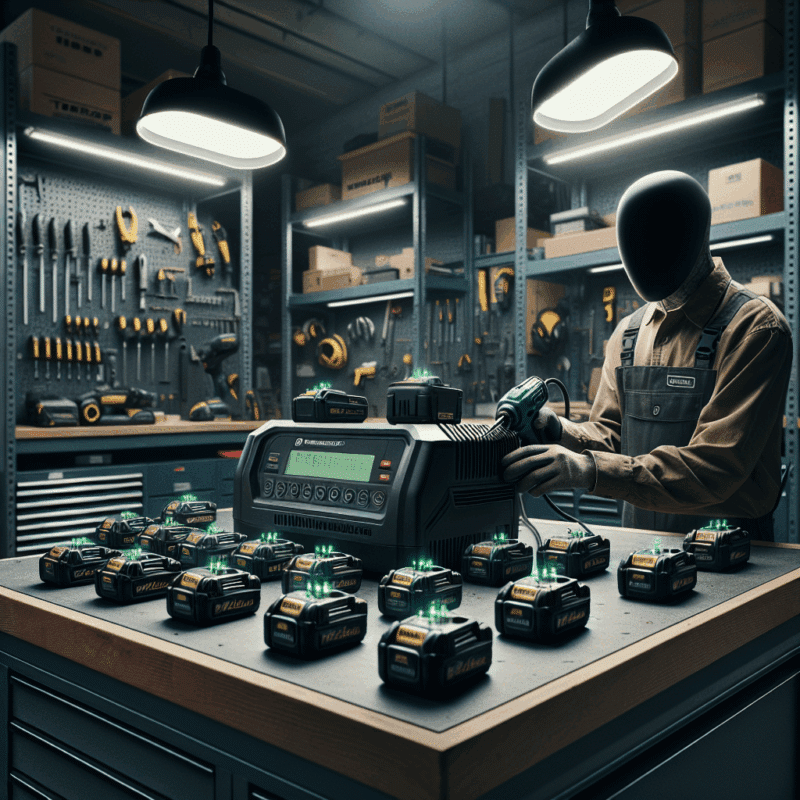

Tips for Multi-Bay and Shared Charger Environments

Workshop environments—whether DIY or trade—often involve multiple users and tools. It’s crucial then to plan your charging infrastructure accordingly. Fortunately, many DIY fast chargers offer dual or multi-bay capabilities. These systems allow you to charge several batteries at once, often in an intelligent, sequential order to maximise energy efficiency.

If you’re working in a garage, shed, or collaborative makerspace, it’s a good practice to label chargers and batteries for specific tool rigs. Positioning your fast chargers close to commonly used stations reduces unnecessary walking and tool downtime. Also, consider units with wall-mounting brackets or stacking-friendly designs to maintain an organised workspace. For further advice, refer to Learn more about Power Tool Charging Solutions.

How Fast Is Fast Enough?

Comparing Charging Times and Battery Wear

So, what qualifies as “fast” in the world of chargers? Most standard models deliver a charging rate between 1-2 amps, while a DIY fast charger can offer anywhere from 4 to 9 amps. For example, a 5.0Ah Makita battery on a high-output charger reaches full charge in about 45 minutes—compared to over 2 hours on slower versions.

Speed, however, should always be balanced with long-term battery health. Overuse of rapid charging without proper heat dissipation may lead to cell degradation. That’s why better fast chargers are equipped with cooling fans and smart algorithms that taper the current near the end of charge cycles. These features maintain performance without compromising longevity. For further comparison strategies, consult Steps for building a DIY fast charger.

Common Pitfalls of Sticking With Standard Chargers

Project Delays and Productivity Drift

Although standard chargers may suffice for infrequent tool users, they become major bottlenecks for dedicated DIYers and professionals. One of the most common pitfalls is underestimating the cumulative downtime. Each extra hour spent waiting for a battery to charge is an hour not spent completing tasks. Multiply that by dozens of batteries over the course of a month, and the loss is substantial.

Another issue is inconsistent charging output. Older or cheaper chargers often lack the logic controls necessary to handle fluctuations in voltage or temperature, leading to sub-standard charges or battery damage. Over time, this results in a frustrating cycle of tool underperformance and premature battery replacement.

Safety Features That Matter

Why Certifications and Built-in Protection Count

Fast charging naturally involves the movement of higher currents, making safety a non-negotiable concern. A quality DIY fast charger should comply with widely recognised safety certifications (e.g. CE, UKCA) to guarantee safe operation.

Key built-in protections to look for include overload protection, thermal cut-offs, reverse polarity safeguards, and charge balancing mechanisms. These not only protect the batteries but also the user and surrounding environment. For high-power scenarios, look for chargers with integrated fans, LED status indicators, and auto shut-off features, ensuring peace of mind as well as optimal performance. Learn more about smart charger safety via Unlock the benefits of SEO automation.

Case Study: DIY vs Trade Workflow Efficiency

Real Results From Workshop Upgrades

Consider a side-by-side test conducted in a shared community workshop. Two identical builds—one utilising standard chargers, the other equipped with DIY fast chargers—were run over a weekend. The team using fast chargers completed their assembly in 65% of the time, experienced zero battery downtime, and reported fewer project stoppages due to uncharged tools.

This case highlights how workflow efficiency, once seen as a distant goal for DIYers, is now attainable through smart charger upgrades. The initial cost of the chargers was recouped within weeks through time saved and improved project output. For similar use cases and real-world examples, explore Read a related article.

Cable Management and Charger Placement

Planning for Shared Workspaces

As more workshops shift towards fast-charging infrastructure, cable management becomes a surprisingly relevant issue. Poor placement can result in hazardous tangles, electrical risks, and inefficient tool cycling. Wall-mounted holders, under-bench layouts, and labelled charging zones help maintain cleanliness and workflow clarity.

In environments where tools and chargers are shared, it’s also advisable to keep a charging schedule or rotation. Label each charger with compatible batteries and provide visual aids like colour-coded leads. Efficient charger placement can reduce time wasted searching for batteries and promote a safer, more productive workshop environment.

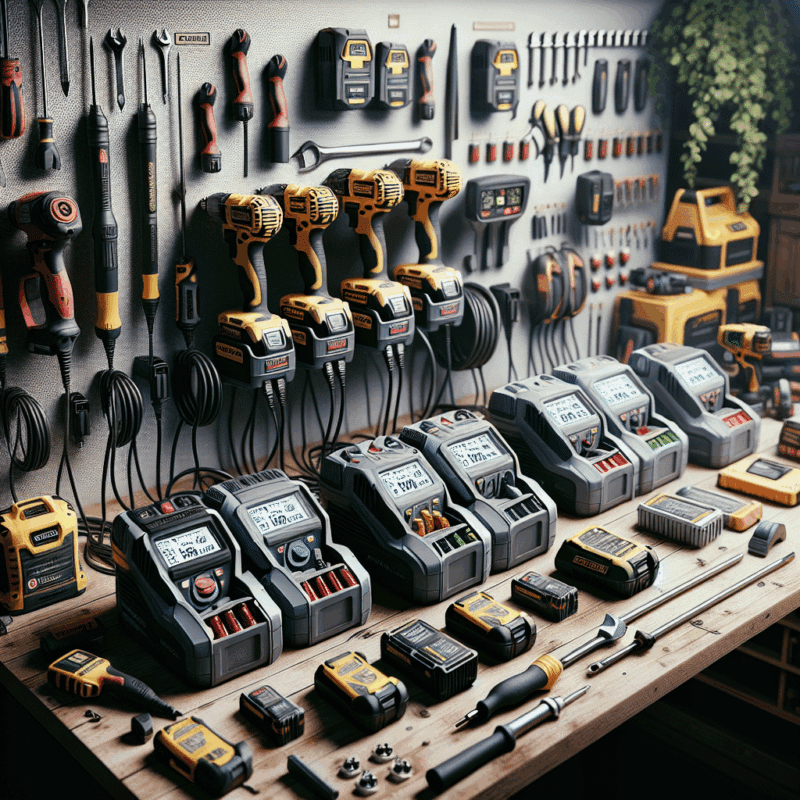

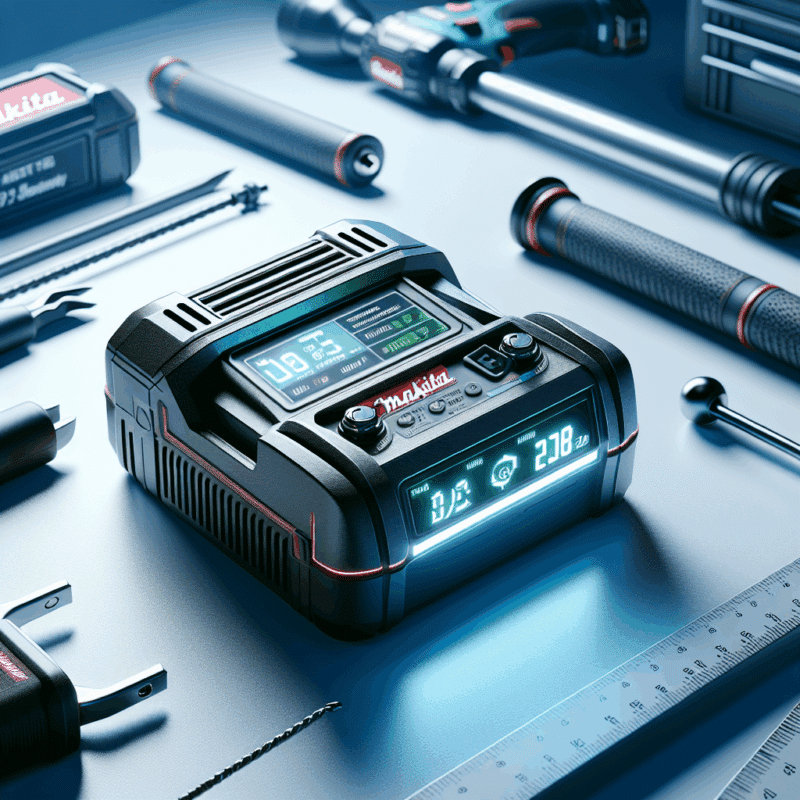

Choosing the Right Charger Model

Key Specs and Compatibility for Makita Tools

If you’re vested in the Makita cordless ecosystem, you’ll find that choosing a DIY fast charger optimised for your tools makes all the difference. Look for chargers supporting Makita’s 18V LXT platform, which dominates their mid- to high-end lineup. The DC18RC and DC18RD models are notable choices, supporting rapid charge for multiple batteries with intelligent cooling systems.

Other factors to consider include input wattage, USB ports for auxiliary charging, and dual-battery support. Always confirm that your charger is compatible with the amperage and chemistry (Li-Ion, NiMH) of your batteries. When in doubt, consult the manufacturer’s compatibility matrix or user community reviews.

Final Thoughts on Upgrading to a Fast Charger

No longer a niche upgrade, the DIY fast charger has become a cornerstone of modern tool efficiency. Whether you’re a passionate hobbyist or a tradesperson chasing deadlines, time saved is task mastery gained. Upgrading to a proven fast charger isn’t just about speed—it’s about elevating your workshop’s entire functionality.

The investment delivers dividends not only in time but in consistency, readiness, and long-term battery health. As cordless tools continue to evolve, the charger you choose becomes just as pivotal as the tool it serves. Stay ahead of the curve by embracing fast-charge technology that grows with your workflow.

Great guide on diy-to-pro-fast-charger-necessity – Community Feedback

When is a fast charger necessary for DIY or professional use?

A fast charger becomes necessary when your work involves frequent tool use, short project timeframes, or multiple team members needing batteries quickly. Professionals and busy DIYers both benefit from reduced downtime using high-capacity fast chargers.

What are the main benefits of upgrading to a fast charger?

Upgrading to a fast charger reduces waiting times between tasks, enables higher productivity, and ensures your tools are always ready. It’s especially valuable on busy sites or for demanding projects requiring continuous operation.

How do I choose the right fast charger for my needs?

Consider your battery type, power output, safety certifications, and real-world usage pattern. Compare commercial options and look for features like overcharge protection, compatibility with existing tools, and user-friendly displays.