Cut Battery Costs with Intelligent Charging & Fast Top-Offs

In This Article

- Always use intelligent chargers with temperature and voltage regulation features.

- Top off batteries when partial charge is sufficient; avoid full discharges.

- Aim for 80% charges to maximise lithium-ion battery lifespan.

- Choose chargers compatible with your platform (e.g. Makita) and offering data insights.

- Set up charging stations with sufficient airflow and stable power access.

- Avoid charging batteries immediately after use or overnight.

- Monitor battery performance to catch early signs of degradation.

- Field data shows users save up to 50% on battery costs with smarter charging.

- Our top choice, the Torxup VoltGuard 6500, supports elite-level charge management. Accelerating results with smart strategies

Why Battery Costs Are on the Rise

Market trends and tool battery replacements

Battery cost reduction is becoming increasingly important due to sharp increases in the price of lithium-ion batteries, which dominate the professional cordless tool market. Demand is driven not only by the growth in electric vehicles but also by the global expansion of industrial and construction sectors demanding ever more portable power solutions. Supply constraints in raw materials such as lithium, cobalt, and nickel have escalated manufacturing costs, pushing up consumer prices for replacement batteries.

For tradespeople and fleet managers, this presents an ongoing challenge. Cordless tools are critical for mobility and efficiency, yet batteries can account for up to 40% of total tool investment over time. As battery lifespans are often limited by poor charging habits rather than use cycles alone, optimising your charging protocols becomes essential. Through battery cost reduction strategies, businesses can protect their investments and delay expensive replacements.

What Is Intelligent Charging?

Smarter tech that protects your investment

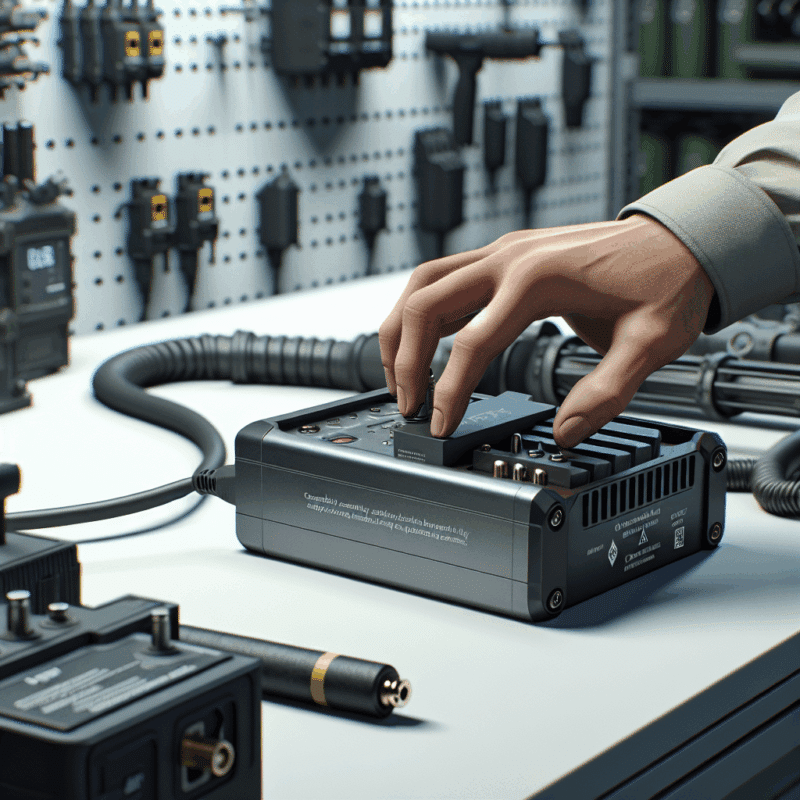

Intelligent charging refers to chargers equipped with microprocessors and adaptive circuitry designed to maximise the lifespan of lithium-ion batteries. Unlike standard “dumb” chargers, these units monitor cell temperature, voltage, and charge cycles in real-time to deliver optimal power flow. The primary aim is to reduce thermal stress and prevent overcharging, two leading causes of premature battery degradation.

One of the most effective paths to battery cost reduction relies on intelligent charging. By ensuring each cell receives the optimal amount of power at the appropriate time, these chargers extend usable battery life by up to 60%. Furthermore, some intelligent chargers can manage multiple types of batteries, auto-switching settings based on input. This versatility helps tool owners streamline charging without damaging less-resistant battery packs.

Fast Top-Off: Efficiency Meets Power

Top-off methods to keep downtime minimal

Fast top-off charging methods cater to scenarios where quick power is needed without fully cycling the battery. For professionals on time-sensitive jobs, topping off a partially used battery during breaks or job transitions can ensure uninterrupted productivity while easing wear on the cell chemistry.

Used in conjunction with intelligent chargers, fast top-offs contribute significantly to battery cost reduction. Rather than pushing a battery through a full discharge and recharge cycle—both stressful for lithium cells—partial charges keep cells within optimal voltage ranges. This helps avoid the damaging extremes of full depletion or over-extension, both of which reduce overall capacity and performance over time.

Why Stopping at 80% Matters

The science behind partial charging for lithium batteries

One of the breakthrough strategies in battery cost reduction is adopting the 80% charge rule. Research shows that lithium-ion batteries tend to degrade faster when consistently brought to full charge. This is because cells experience increased voltage-induced stress near 100% capacity, which triggers chemical breakdowns in the electrolyte.

Charging up to 80% significantly improves cycle longevity, often doubling the effective life of a battery. Intelligent chargers can be programmed to stop at this threshold, giving users greater control. For many professionals, this small trade-off in run-time results in substantial savings in the long run. It’s especially effective in fleet scenarios, where cumulative cost savings across dozens or hundreds of batteries are significant.

Choosing the Right Charger

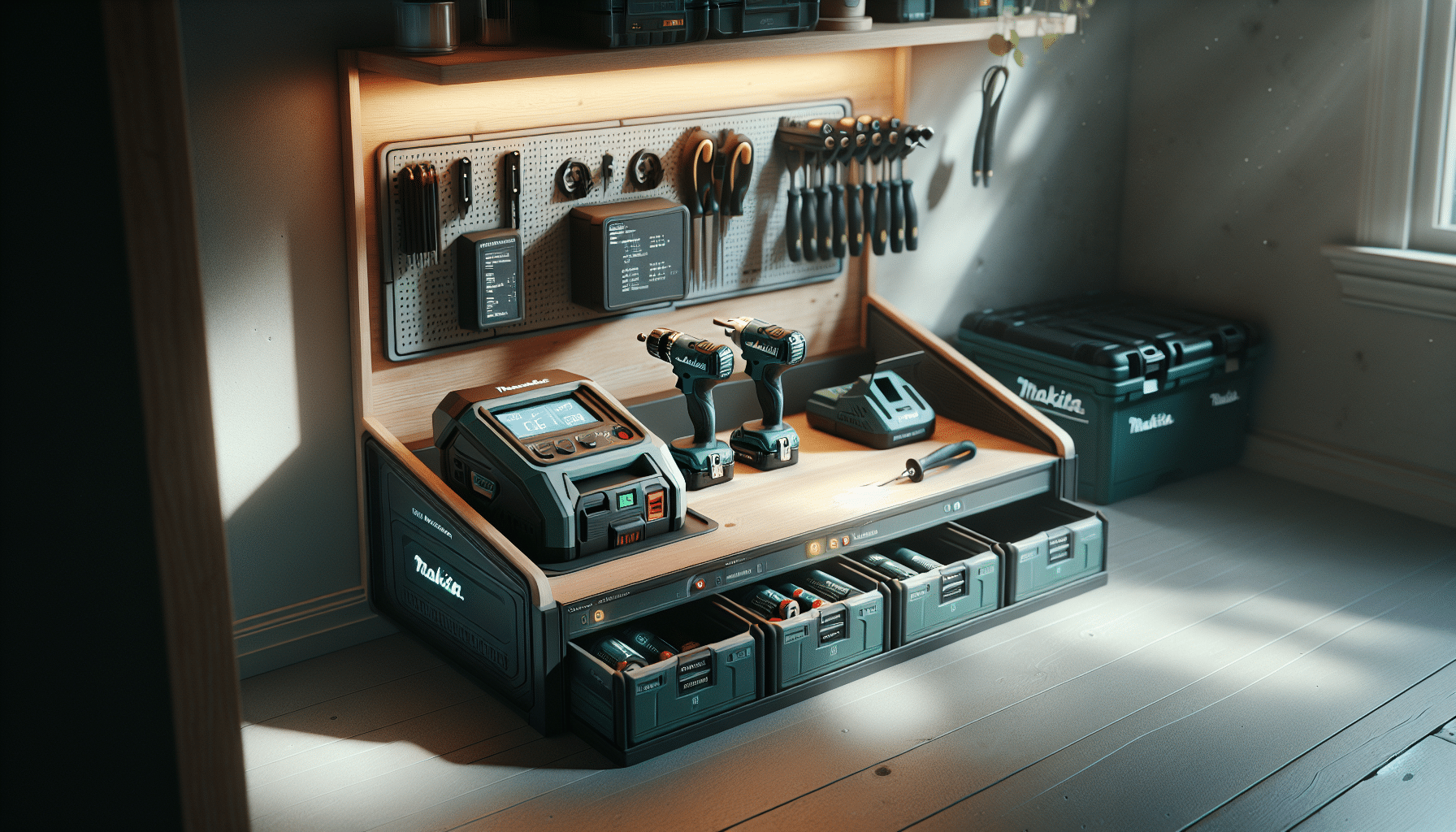

What to look for in a Makita-compatible smart charger

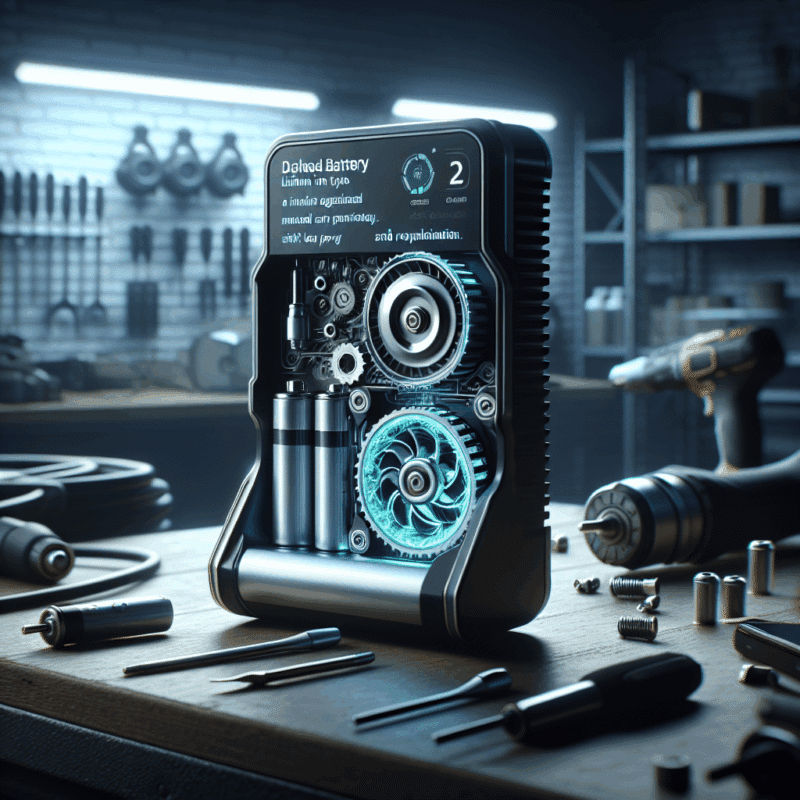

Not all smart chargers are created equal. For users of popular systems like Makita’s LXT platform, investing in a verified Makita-compatible intelligent charger is paramount. Such chargers are built to communicate accurately with the tool battery’s embedded data chip, allowing for precise thermal and voltage management during each charge session.

Look for models offering active cooling fans, multi-port support, and programmable charging profiles. These contribute directly to battery cost reduction by lowering heat build-up and allowing simultaneous charging of multiple batteries without stress. Units like the Torxup VoltGuard 6500 stand out due to integrated data analytics that log charge cycles, providing insight into battery health over time. This empowers users to retire ageing packs before failure, minimising workflow disruptions.

Charging Station Setup Tips

How to maximise layout, cooling and power flow

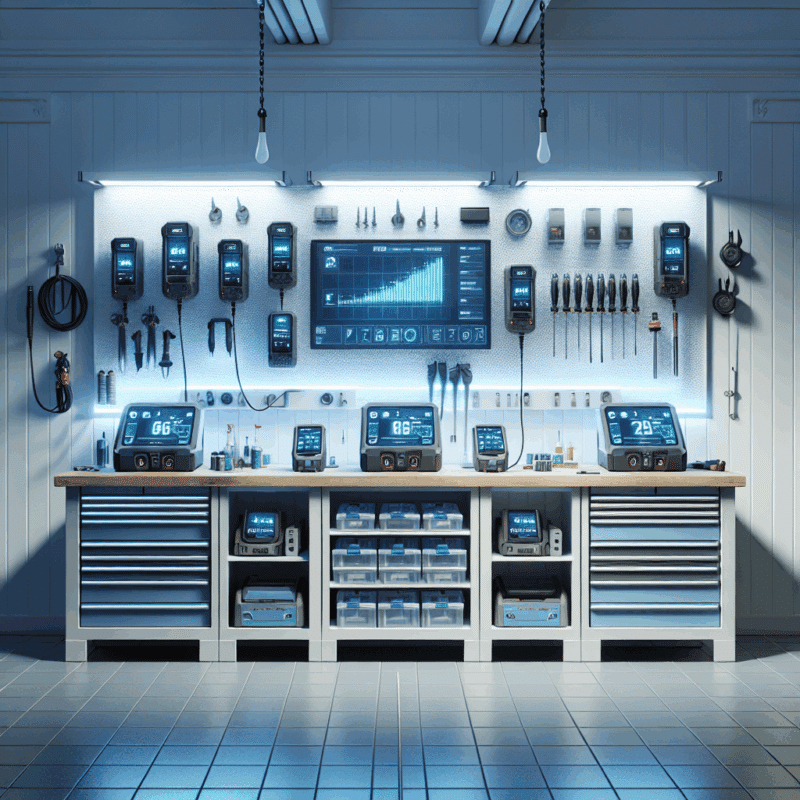

Proper setup of your charging station plays a vital role in battery cost reduction. A well-ventilated, thermally stable environment ensures batteries remain within safe temperature thresholds, which is essential for preventing capacity fade. Never place chargers near windows exposed to sunlight, radiators, or uninsulated walls subject to wide thermal swings.

Organise your layout so that air can flow freely around each charging dock. Where multiple batteries are being charged simultaneously, thermal hotspots can form. Space them out, and, if possible, invest in chargers with internal or external fans. Additionally, make sure mains power circuits are not overburdened—a staggered surge protector can help maintain voltage stability, especially during peak loads.

Common Charging Mistakes to Avoid

What not to do if you want long battery lifespan

Even the best charger won’t help if improper usage habits persist. One major mistake is leaving batteries on charge overnight after full capacity has been reached. This promotes slow trickle overcharging, a known killer of battery health. Intelligent chargers help by cutting power post-charge, but users should still disconnect batteries promptly as a best practice.

Another fuel for battery wear is heat. Charging immediately after a battery has been heavily used can trap latent heat inside and accelerate electrolyte breakdown. Best practice is to rest the battery and allow it to cool to room temperature. Similarly, avoid storing batteries fully charged or deeply discharged for long durations—both extremes shave cycles off the pack’s lifespan. Awareness of these behaviours is often the missing piece in successful battery cost reduction strategies.

Real–World Results: User Experiences

Shared stories on cost savings using intelligent chargers

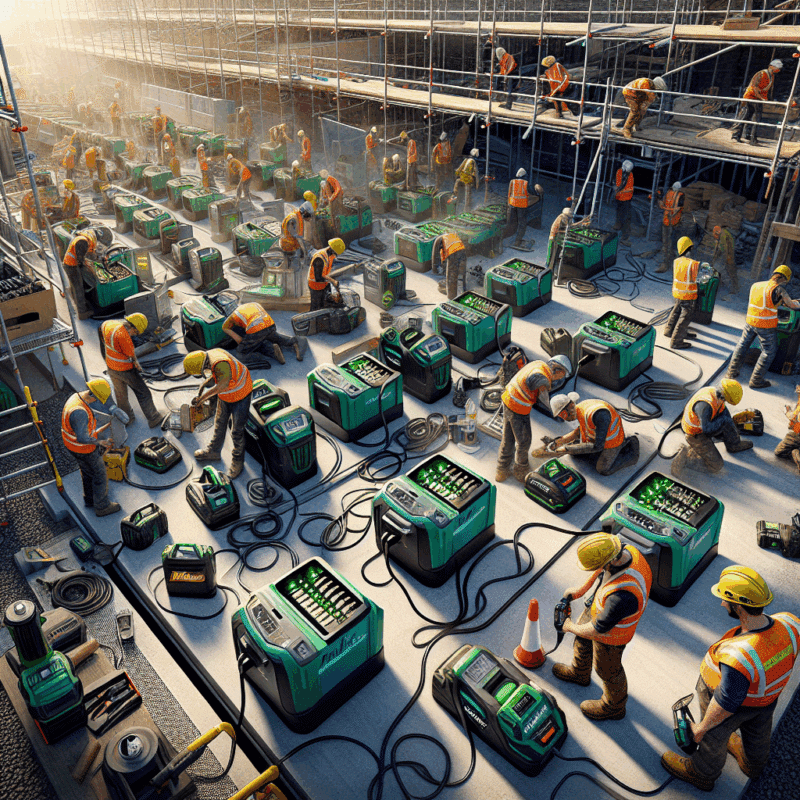

Tradespersons, site managers and mobile technicians have all reported substantial cost benefits after adopting intelligent charging protocols. One UK-based roofing contractor explained how proactively switching to 80% top-ups on their Makita fleet prevented 32 battery purchases over 18 months. The savings exceeded £4,800—money reinvested into higher-end tools and safety equipment.

Another solar panel installer noted that intelligent charging cut their average battery replacement cycle in half. Their crew handled hot roofs during peak summer, and thermal-aware charging systems significantly mitigated overheated packs. Fleet charging software synced from the Torxup VoltGuard 6500 exposed unhealthy cells early, allowing for proactive rotation—yet another win for battery cost reduction.

“Since adopting smart charging and 80% stops, we’ve nearly halved our battery spending. The impact on our margins has been nothing short of incredible.” – James C., Site Foreman

Expert Take: Our Charger Recommendation

The Torxup VoltGuard 6500 explained

If you’re serious about battery cost reduction, our top recommendation is the Torxup VoltGuard 6500. This intelligent charger is engineered for high-demand professional environments. Featuring six independent charging ports, each with thermal sensors and individual microcontrollers, the VoltGuard ensures that no battery is overcharged or overheated.

Its ability to interface seamlessly with major platforms like Makita, Milwaukee, or DeWalt makes it an ideal solution for mixed-brand fleets. Real-time charge analytics, accessible via Bluetooth or USB connection, offer actionable insights—allowing predictive maintenance and smarter battery rotation plans. Available through leading retailers and recommended by professionals globally, the VoltGuard 6500 is a cornerstone in any serious battery cost reduction setup. Reducing battery wear with optimised charging

Conclusion: Power Smarter, Save Longer

Reducing battery expenditure is not about cutting usage. Instead, it’s about increasing lifecycle through smarter charging practices. From intelligently stopping at 80% to fast top-offs during workflow gaps, these tactics mitigate the stress that shortens battery life. Intelligent chargers paired with controlled setups and good habits will provide measurable lifetime cost reductions.

Whether you’re managing a team of tradespeople or relying on tools for individual work, battery cost reduction strategies can boost uptime, reduce waste, and significantly improve your return on investment. Begin by re-evaluating your charging equipment and transitioning to technology that works with—not against—your batteries. Learn more about Best Practices for Powering Tools Efficiently and Read a related article deliver deeper insights into these methods for professionals ready to optimise.

Great guide on cut-battery-spend-intelligent-charging-fast-top-offs – Community Feedback

How can intelligent charging reduce battery costs?

Intelligent charging reduces battery costs by optimising charge cycles, preventing overcharging, and minimising wear, resulting in longer battery life and fewer replacements.

What is the fastest way to top off a Makita battery?

The fastest way to top off a Makita battery is with a high-amperage compatible charger, such as the Torxup VoltGuard 6500, designed for rapid and safe charging performance.

Does stopping charging at 80% really prolong battery life?

Yes, limiting charge to around 80% reduces the stress placed on lithium batteries, extends longevity, and avoids overheating for better long-term capacity retention.