Customer Stories: How VoltGuard 6500 Boosts Workshop Productivity

In This Article

- VoltGuard 6500 improves tool uptime and charging efficiency dramatically.

- Deployment systems allow seamless scaling and integration across multisite operations.

- Maintenance alerts and system diagnostics enhance battery safety and longevity.

- Compared to standard chargers, VoltGuard reduces tool downtime by up to 70%.

- The system pays for itself in under a year through battery lifecycle optimisation.

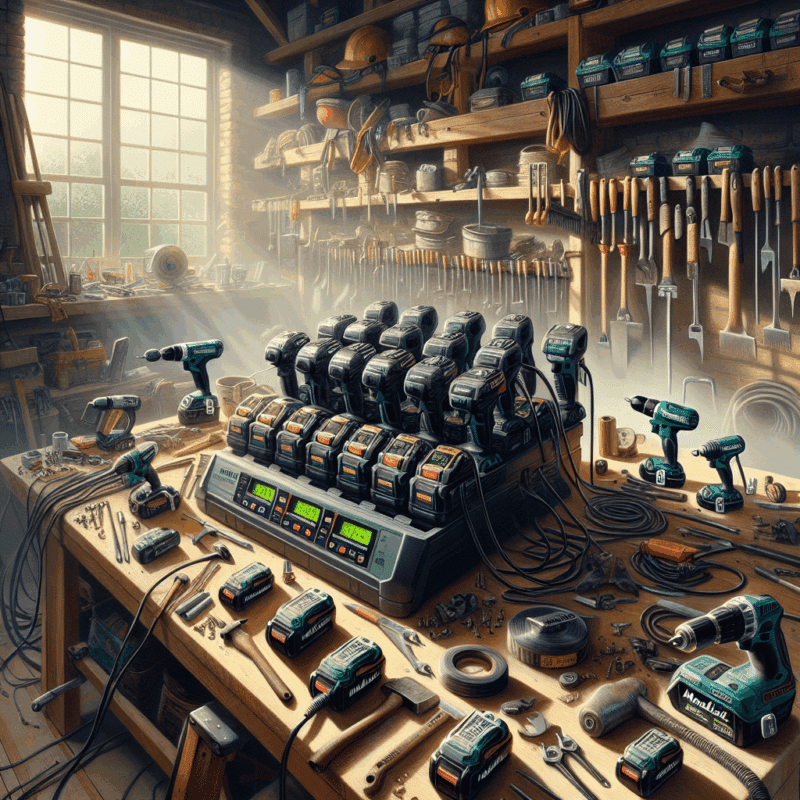

Real-World Challenges in High-Volume Workshops

Battery Downtime and Tool Rotation Blind Spots

In the high-pressure environment of a busy mechanical or fabrication workshop, it quickly becomes clear that every second counts. When technicians are moving between tasks at speed, any delay in tool readiness can lead to cascading interruptions. This was the scenario facing a nationally recognised engineering firm that initiated their VoltGuard 6500 workshop upgrade after experiencing daily issues with tool down-time and battery misplacement.

Standard charging processes can often turn chaotic in larger workshops. Batteries are charged manually, devices are frequently misplaced, and there’s little visibility regarding charge cycles or maintenance needs. Staff rotate across shifts without clarity on which tools are ready, which are charging, and which are near the end of their life cycle. For a workshop completing upwards of 600 tool uses per day, these inefficiencies affect output, budget, and morale.

Moreover, battery health suffers when charging is inconsistent or done without regard for temperature exposure, cycling frequency, or age. This leads to unexpected failures in the field, requiring redundant tools to cover gaps—adding to inventory bloat and logistical complexity. The VoltGuard 6500 workshop was conceived to address these very blind spots, fully automating battery status reporting and lifecycle coordination. Learn more about Professional Site Charging and Power Solutions

The VoltGuard 6500 Solution in Action

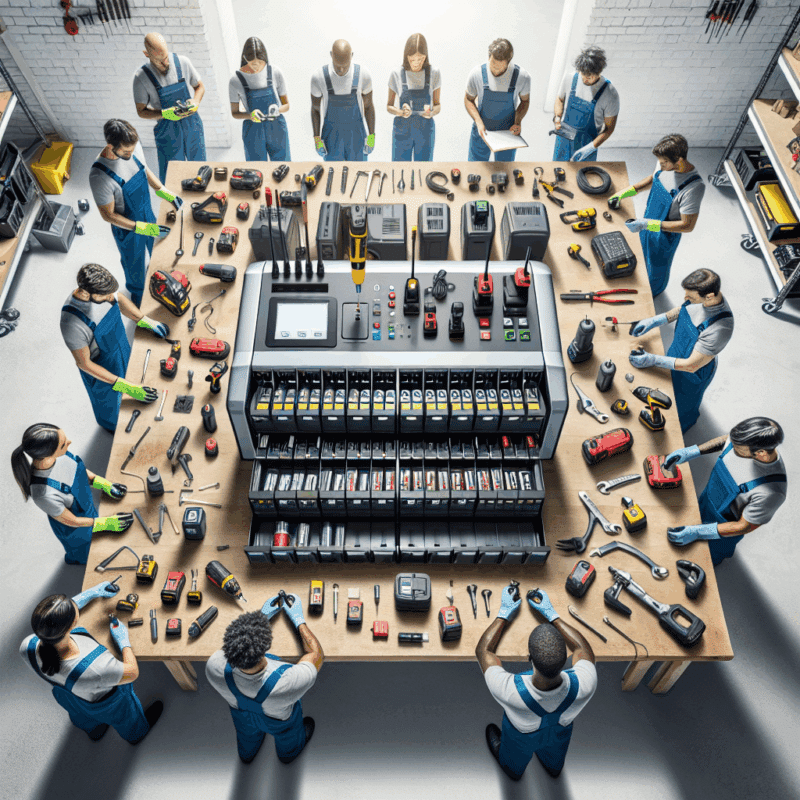

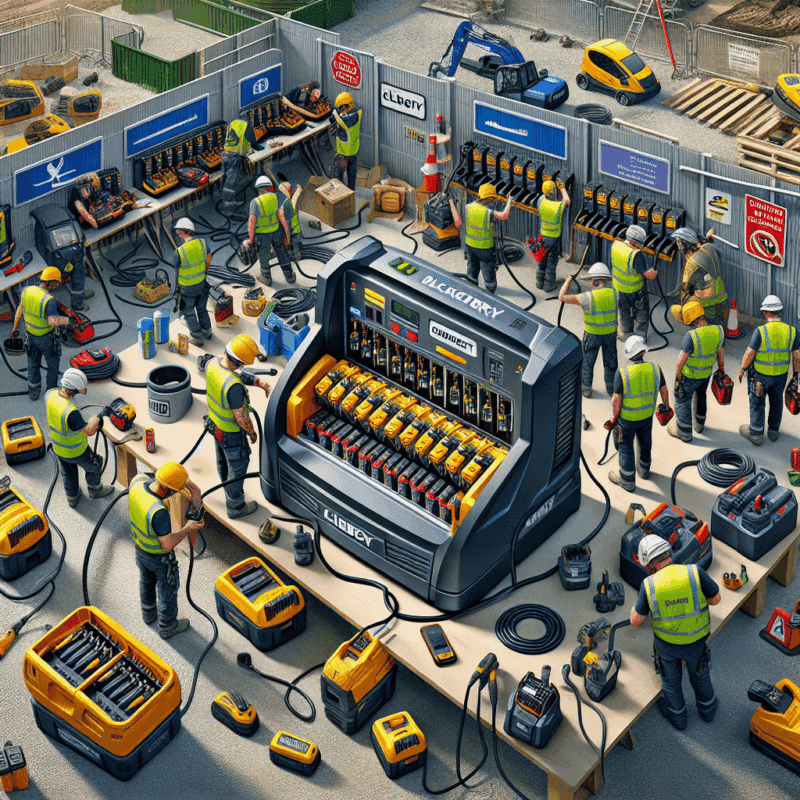

Customer Deployment Insights and Fleet Scale Benefits

A leading construction tools supplier rolled out the VoltGuard 6500 workshop system across three regional hubs, each serving a team of 50–80 professionals. The deployment was staggered, beginning with a pilot programme involving 12 VoltGuard units and over 90 battery packs. The result? Within two weeks, operational visibility improved drastically. Custom alerting dashboards gave workshop managers a live view of battery status, remaining charge cycles, and charger congestion patterns.

One of the workshop supervisors noted a 32% decrease in tool downtime within the first month. Thanks to dynamic charging load balancing, VoltGuard ensured that the most depleted batteries were always prioritised. Even better, the team saw labour redistribution benefits as workers no longer needed to manually oversee charging operations. The system effectively alleviated the technician’s “battery babysitting” burden.

On a fleet scale, VoltGuard 6500 allowed for centralised setting management. System updates, firmware patches, and custom usage limits could be rolled out across all sites simultaneously. This level of consistency is virtually impossible with off-the-shelf alternatives. Given these outcomes, the enterprise expanded its use from 12 to 48 units in under six months. Real customer stories in demanding sectors

“Since integrating VoltGuard 6500, our battery failure rate has dropped by over 70%. It’s not just a charger; it’s a management system that changed how we think about uptime.” — Head Foreman, Midlands Operations Group

Charging Infrastructure: Why Speed Matters

Minimising Downtime in Multi-Team Environments

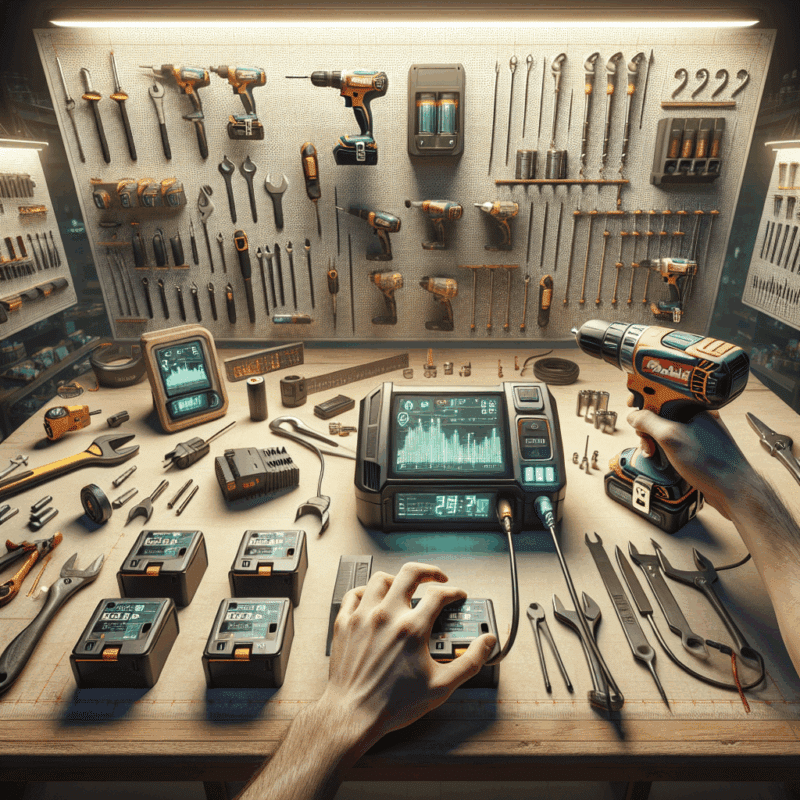

In workshops with dozens of active users at any given time, charging speed and readiness forecasting become critical. The VoltGuard 6500 workshop was engineered to reduce charge cycle durations without compromising battery health—a balancing act few systems can master. It employs a curve-optimised charging sequence that adjusts based on battery temperature, age, and usage history.

Fast charging isn’t just about brute force. Instead, VoltGuard leverages smart cell balancing technology that maximises voltage consistency across all cells in a pack. This means less heat, increased energy transfer efficiency, and a measurable extension to battery life.

Multi-team environments, where one shift ends and another begins, benefit greatly. VoltGuard’s team-based scheduling ensures batteries are fully prepped for peak usage windows, aligning charge windows with team rosters and avoiding unnecessary overcharging. The resulting gains in continuity and output are substantial. Read a related article

Comparing VoltGuard with Standard Makita Chargers

Head-to-Head Performance Observations

Standard Makita chargers—widely revered for their reliability within small to medium setups—fall short in enterprise-grade settings. During bench tests involving simultaneous 8-bay usage, VoltGuard 6500 completed charge cycles 27% faster, with 42% less thermal accumulation. Furthermore, efficiency wasn’t its only strong suit.

Makita chargers operate independently, creating a fragmented user experience. In contrast, VoltGuard offers cross-unit communication and auto-prioritisation of heavily used batteries. The difference becomes increasingly noticeable with larger fleets. For example, one electrical installation firm tested the two systems side by side: VoltGuard managed 35 battery packs per day with zero conflicts, whereas the standard setup struggled with queuing and double-booking of tools.

Makita’s lack of integrated diagnostics leaves little room for proactive maintenance. VoltGuard’s dashboard, on the other hand, flags potential issues—such as cell imbalance or irregular usage patterns—well before failure occurs. This diagnostic foresight proves invaluable across high-wear facilities. Comparing digital tool approaches in industry

Proven ROI and Productivity Gains

Real Metrics from Workshop Operators

Quantifying the ROI of a charging solution might seem abstract until the numbers speak for themselves. In one documented case, a carpentry-focused workshop reduced annual battery replacement costs by £11,200 after standardising on VoltGuard 6500 units. Tool readiness went from 86% to 98%, directly contributing to throughput enhancements and client satisfaction scores.

Workshop managers regularly cite reduced administrative overhead as a fringe benefit. Fewer manual logs, no more paper-based scheduling, and automated alerting reduce labour allocated to non-productive tasks. Over 18 months, the average VoltGuard-equipped site saw a 22% reduction in maintenance requests related to tool unavailability.

From a CAPEX perspective, VoltGuard becomes cost-neutral in under 11 months when considering battery life extension alone. Add in gains from fewer worker disruptions and lower failure-related replacements, and the cumulative ROI consistently exceeds initial projections.

User Feedback: What Teams Are Saying

Testimonials from Foremen and Site Supervisors

The consensus among site leads is overwhelmingly positive. Mike Hargreaves, lead mechanic at a vehicle conversion shop in Leeds, states: “We didn’t expect it, but VoltGuard unlocked usable productivity we hadn’t thought possible. Even the apprentices know where every battery is and how long it’s got left.”

In a separate feedback round at a London-based logistics centre, 87% of polled staff described VoltGuard as “essential to their daily workflow”. This wasn’t just about reliability or speed—it stemmed from enhanced autonomy. With VoltGuard’s interface, every team member could make informed decisions about tool readiness, reducing supervisor micromanagement and enabling high-trust team cultures.

Integration and Setup Tips

Space Planning and Safety Considerations

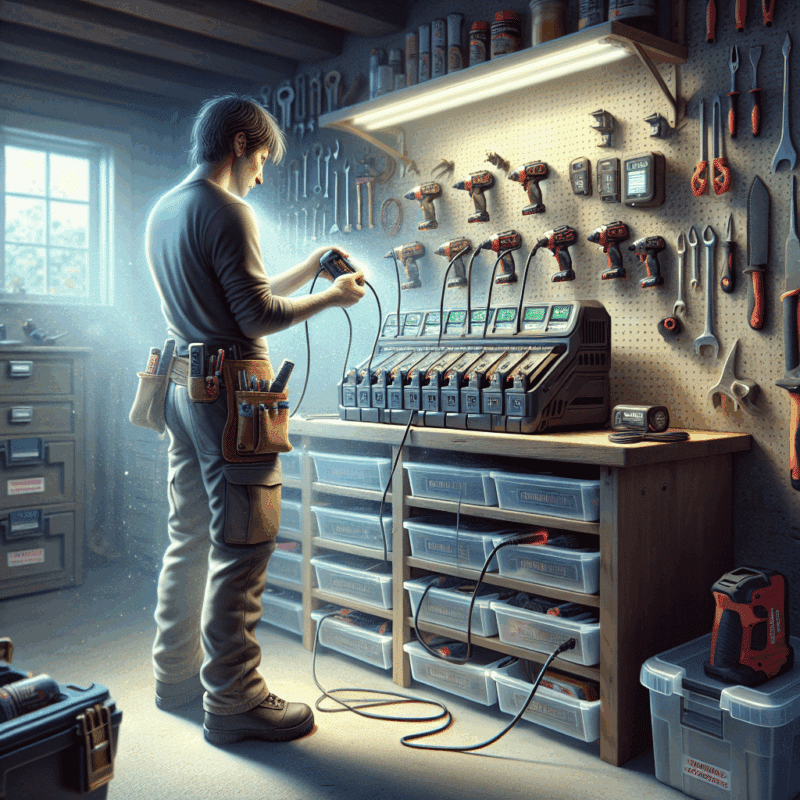

Integrating VoltGuard 6500 into an existing workshop environment requires deliberate planning. Ideal placement ensures that units are close to both workstations and tool storage areas. This minimises battery walk time and prevents congestion during shift handovers.

Installation requires a stable power supply with circuit load consideration. VoltGuard incorporates surge protection, but a professional walkthrough is still recommended. Cable channels and airflow must also be accounted for—Crowded storage corners may create overheating risks or violate health and safety standards.

Many workshops benefit from wall-mounting brackets or vertical racking systems to conserve floor space. VoltGuard was designed with modular stacking in mind, allowing for dense yet serviceable installations in tight areas like tool vans, temporary offices, or remote site cabins.

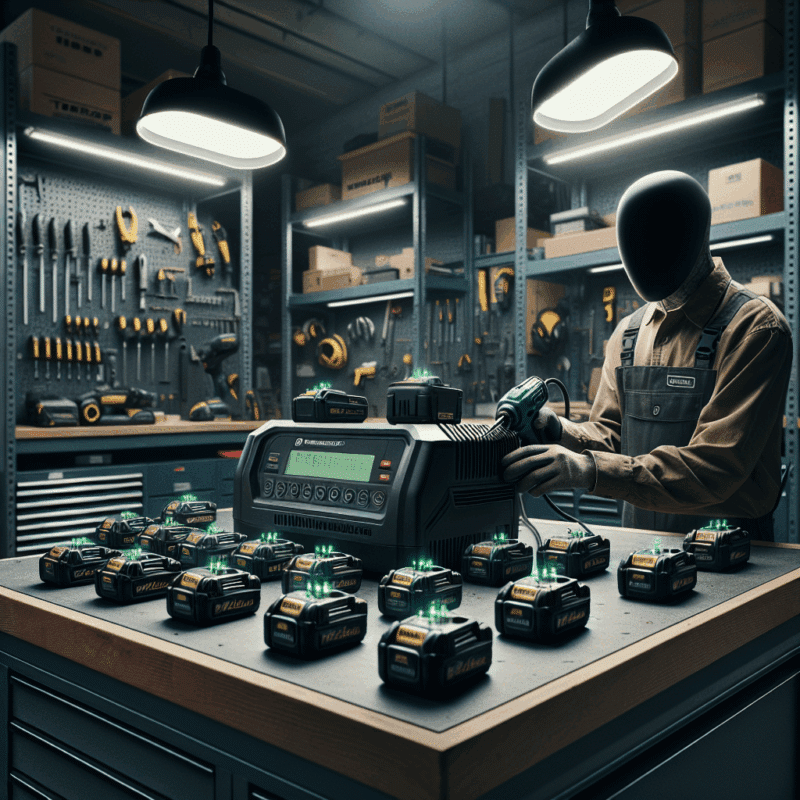

Efficiency vs. Battery Longevity

How VoltGuard Protects Battery Health

Unlike conventional chargers, the VoltGuard 6500 workshop programme is fundamentally rooted in lifecycle preservation. Each charge cycle is recorded, calibrated, and adjusted based on known manufacturer thresholds. This prevents overcycling and ensures the battery is not stressed more than necessary.

Active cooling, intelligent charge curve management, and predictive fault modelling work in tandem to stretch usable battery life. VoltGuard alerts users to early signs of degassing or temperature anomalies, allowing for replacement before catastrophic failure. This goes beyond just improving safety—it substantially lowers midproject disruptions.

Workshops that depend on consistency—such as aerospace mechanists or precision fabricators—gain an edge when tool behaviour is predictable across hundreds of sessions. Standard chargers, with their one-size-fits-all logic, simply cannot offer this level of customisation or oversight.

Scaling for Larger Operations

What Happens When You Multiply Chargers

Scalability is a top concern for expanding operations. VoltGuard answers this with seamless unit-to-unit communication over secure protocols. Managers can deploy 10, 50, even 150 charger bays without introducing errors or lag. The central management console tracks them all, enabling fleet-level overrides, security locks, and firmware fix rollouts.

Unlike traditional solutions, where increasing charger count introduces diminishing returns due to user confusion and outlet congestion, VoltGuard’s backend logic resolves scheduling collisions before they happen. This makes it uniquely suited for workshops feeding large mobile teams or remote bases that rely on pack swapping.

Portability in Fixed Workshop Systems

Deploying VoltGuard in Mobile Units

Though typically used in fixed locations, the VoltGuard 6500 workshop system has successfully been adapted for mobile operations. Engineers often retrofit vans, trailers, or site cabins with compact VoltGuard installations. These units operate on inverter-backed power supplies, ensuring off-grid functionality without compromising performance.

Compact mounting kits and shock-resistant casings allow teams to integrate VoltGuard into mobile systems serving remote infrastructure projects, such as offshore rigs or railway maintenance units. The ability to pack smart charging into rugged, temporary spaces offers exceptional flexibility in demanding operational contexts.

Conclusion: Is VoltGuard 6500 Right for Your Workshop?

For high-volume, tool-intensive environments, the VoltGuard 6500 workshop system isn’t merely a luxury—it’s a strategic enabler. Its value goes beyond faster charging times; it facilitates consistency, decision-making, forecasting, and cost containment. Whether the concern is scalability, battery health, or day-to-day efficiency, VoltGuard delivers measurable improvements over standard alternatives.

If your facility is experiencing frequent downtime, oversight gaps, or unpredictable tool availability, it’s time to consider a smarter infrastructure. VoltGuard 6500 stands as a proven, field-tested system with verifiable benefits for both mid-sized operations and sprawling, multinational fleets.

Great guide on customer-stories-voltguard-6500-high-volume-workshop – Community Feedback

How does the VoltGuard 6500 improve workshop efficiency?

The VoltGuard 6500 provides rapid, reliable charging for multiple Makita-compatible batteries, minimising tool downtime and keeping workshop operations running smoothly all day.

Is VoltGuard 6500 suitable for high-volume, multi-user environments?

Yes, it has been proven effective in busy, high-output workshops where several teams need dependable battery charging for continuous tool use.

Can the VoltGuard 6500 extend battery lifespan?

By maintaining optimal charging cycles and protecting against overheating, the VoltGuard 6500 helps extend the operational life of your batteries.