Cooling Fans vs Passive Vents: Makita Charger Design Impact

In This Article

- Makita charger cooling fans play a vital role in thermal regulation during high-demand charging.

- Passive vent systems suit occasional use but underperform in workshop environments.

- Active airflow prolongs battery life by mitigating heat-related degradation.

- Professional users should prioritise cooling features to avoid downtime and increase efficiency.

- Makita’s fan-cooled charger models offer superior performance, especially in hot or dusty conditions.

Why Cooling Fans Make a Difference

Managing heat for safe, fast charging

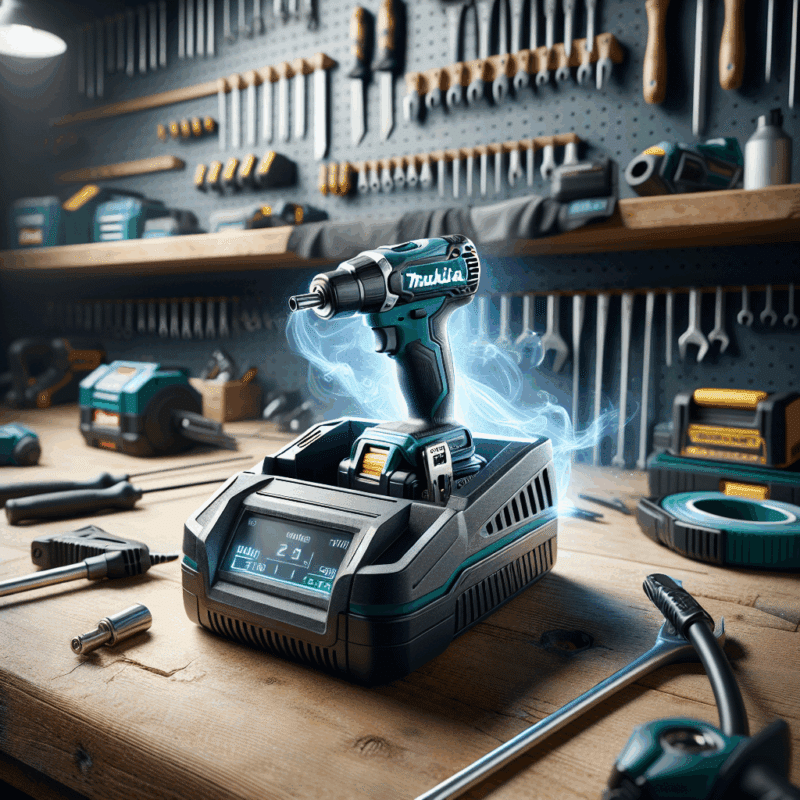

Makita charger cooling plays a central role in maintaining the safety and performance of battery-powered tools. One of the starkest contrasts in charger design is between active cooling systems—typically involving fans—and passive ventilation, which relies solely on air circulation through vents. Fan-cooled systems actively draw in cooler ambient air and expel heated internal air, rapidly reducing charger temperature during high-demand scenarios. This active airflow accelerates internal component cooling, ensuring more stable charging environments and reduced thermal stress on lithium-ion cells.

Without sufficient cooling, batteries are more prone to overheating, which can lead to capacity reduction, internal damage, or—in extreme cases—fire risk. A cooling fan helps maintain the optimal thermal threshold needed for consistent current flow. Consequently, charging a high-capacity Makita 18V or 40V XGT battery under continuous use becomes much safer with a fan-equipped charger.

Understanding Passive Ventilation in Chargers

Low-maintenance but limited performance

Passive ventilation relies solely on natural convection to dissipate heat. Openings in the charger body allow warm air to escape, while cooler air enters through specially located intake vents. The design is simple, quiet and low-maintenance because it has no moving parts. Passive systems are ideal for lower-capacity batteries or infrequent use cases, where minimal heat is generated during charging cycles.

However, this design does have limitations. The absence of forced air movement means that heat dissipates more slowly, especially in high-temperature environments or with back-to-back charges. As ambient temperature rises, passive systems become less effective at removing heat, risking extended charge times or even throttling. Modern lithium-ion batteries, known for rapid energy transfer, generate significant heat. Without fan-assisted cooling, these systems may not achieve optimal performance in demanding professional settings.

Thermal Management Principles for Tool Chargers

How internal airflow keeps batteries protected

At its core, effective Makita charger cooling relies on thermal management—an approach that balances internal airflow, material selection, and temperature monitoring. Heat sensors detect thermal variations during charging, dynamically adjusting the current to protect the battery. Fan-based systems go a step further by pushing air across heat sinks and critical circuitry to actively remove heat from hot zones.

Chargers that lack smart airflow management often suffer from uneven heat distribution. Certain components become thermal choke points, compromising charge speed and component durability. Fan-cooled chargers manage this balance better, offering evenly cooled interiors and optimised transfer of charge—particularly in fast-charge modes. In effect, airflow becomes a mechanical force that preserves voltage stability while increasing overall system efficiency.

Benefits of Fan-Cooled Charges in High-Use Environments

Why workshop pros prefer active cooling

Professionals in trades and workshops face constant pressure to minimise downtime. Whether it’s carpentry, plumbing, or electrical work, the need for quick battery turnaround can’t be overstated. Makita charger cooling fans give these pros a decisive edge. Integrated cooling significantly cuts charge time by preventing thermal delays, especially when charging batteries sequentially throughout the day.

Additionally, fan cooling helps protect batteries from heat fatigue—common when tools operate in dusty or high-ambient environments. By proactively maintaining cooler internal temperatures, these chargers ensure power tools spend more time at work and less time in the charging bay. For contractors relying on high-capacity batteries such as Makita’s 6.0Ah or 8.0Ah models, this reliability is a game-changer. Learn more about Makita Charger Technology & Battery Protection

Battery Health and Longevity Factors

Correlating temperature control with lifespan

The effect of heat on battery health cannot be overstated. Every charge cycle exposes lithium-ion cells to thermal stress, and elevated temperatures accelerate capacity degradation over time. Active Makita charger cooling systems mitigate this by controlling peak internal temperatures, especially during high-current phases of the charge process.

A temperature-managed battery degrades more slowly. Reduced exposure to heat minimises the formation of lithium plating and electrolyte decomposition—common causes of early battery failure. In practical terms, users benefit from batteries that retain their charge longer and need replacement less frequently. Over time, the investment in a fan-cooled charger often pays for itself by lowering the total cost of ownership. Passive cooling explained through design choices

Real-World Performance: Fan vs Vent

What users are seeing in daily use

Makita charger cooling performance becomes especially evident under real-world conditions. Field data and user reviews show that fan-cooled units consistently outperform passive designs in high-demand scenarios. For instance, fan-equipped chargers like Makita’s DC18RC or DC40RA show significantly faster turnaround times—up to 30% faster in some batteries—while maintaining lower surface and internal temperatures during operating cycles.

On the other hand, passive vent models tend to throttle charging when ambient conditions exceed 30°C. Users report longer charging intervals and unpredictable recovery times due to overheating. In dusty job sites, passive systems are more likely to collect particulate matter in vent channels, undermining effectiveness over time. Conversely, fan-cooled models are engineered with filtration and internal airflow ducts to manage this risk more effectively. Read a related article

Noise vs Efficiency in Charger Design

Balancing acoustic levels with cooling output

Critics of fan-cooled chargers often raise concerns about noise. While it’s true that fan mechanisms produce noticeable sound—typically between 30 to 50 decibels—most users report that this trade-off is acceptable, especially when weighed against the substantial efficiency benefits. Moreover, modern Makita charger cooling fans are engineered for quiet operation using low-decibel brushless fan motors.

Fan noise is usually present only during the peak of the charging cycle, lasting a few minutes before tapering off. Passive vent chargers may be whisper-quiet, but this silence comes at the cost of performance. For workspaces where noise control is a top priority, users should weigh the pros and cons while considering charger location and daily usage volume.

Design Trade-offs: Complexity, Cost, Noise

What engineering teaches us about charger planning

Introducing active cooling into a charger adds complexity. Fans require additional circuitry, moving parts, and thermal controls. As a result, these chargers tend to be costlier than their passive counterparts. However, from an engineering standpoint, this investment is justified when performance and reliability are the end goals. The sophisticated internal layout supports greater thermal conductivity and energy balance—key features lacking in basic models.

Furthermore, downtime from overheated or degraded batteries can be significantly more costly in the long run. Passive vent chargers may appear budget-friendly upfront but could fail to support high-throughput operations over time. Makita’s design philosophy balances engineering complexity with robust component reliability, ensuring that even fan-equipped models deliver long-term service without frequent maintenance. Modern automation strategies for SEO tasks

Choosing the Right Charger for Your Tools

Fan-cooled options vs passive designs: which to pick?

Choosing between passive and fan-cooled systems requires an honest assessment of tool demands and working conditions. For hobbyists or light domestic users charging once daily, passive designs may be adequate. They offer simplicity, reduced noise, and extended service life due to fewer mechanical parts. However, for professionals using 3–5 battery packs daily, fan cooling becomes indispensable.

If you routinely charge multiple high-capacity batteries such as those in the Makita 40V XGT series, a fan-cooled unit will pay dividends in faster workflows and extended battery life. Additionally, work in hot climates increases the risk of charger derating or battery overheating. Here, the Makita charger cooling fan technology provides resilience where passive systems may falter.

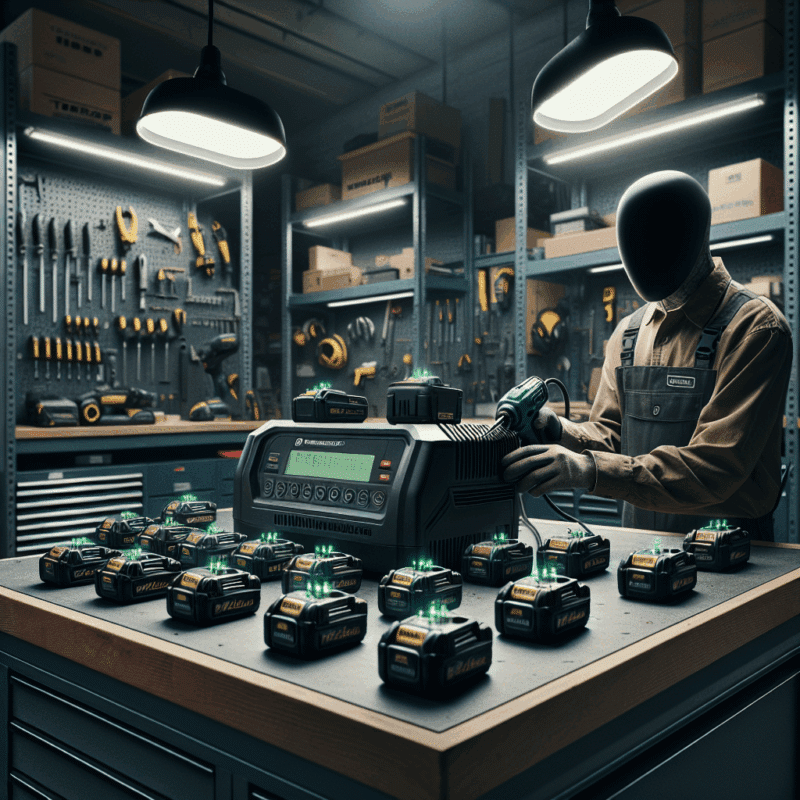

Recommended Products Supporting Safe Charging

Makita-compatible chargers with thermal optimisation

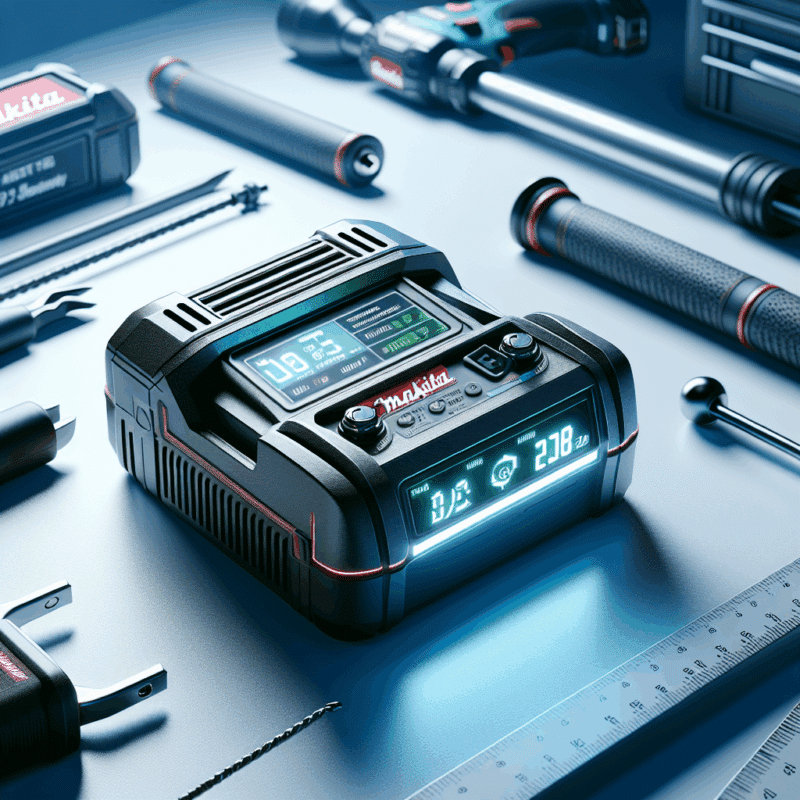

Among Makita’s charger line-up, models like the DC18RC and DC40RA stand out for their fast-charging capability and integrated active cooling. These units employ intelligent fan control that adjusts airflow based on thermal input, ensuring optimal cooling during all phases of the charge cycle. They also include built-in temperature sensors to prevent overcharging. Pair these chargers with genuine Makita batteries for the best outcomes in cooling and charge efficiency.

Additional third-party options are compatible with Makita platforms, but caution is advised because not all integrate thermal management features. It is generally best to choose OEM products when charger cooling is a concern. Features to look for include heat-sink integration, smart charging algorithms, and thermal override protection functions.

“Fan-cooled Makita chargers deliver unmatched reliability for tradespeople—no slowdowns, no overheating, just constant performance.”

Final Thoughts: Why Design Matters for Battery Protection

In a landscape driven by performance and reliability, Makita charger cooling stands at the forefront of smart design. Between passive vent systems and active fan-based technologies, the choice affects more than just how fast a battery charges. It influences lifespan, project timelines, and total operating cost. Fan integration provides definitive advantages in thermal balance, particularly in demanding or professional settings.

Proper thermal management is not optional—it’s foundational. Selecting a charger with the right cooling system improves safety, boosts durability, and ensures that your Makita power tools deliver consistent excellence every time. Don’t underestimate the importance of cooling in a high-voltage world. Make the informed, expert choice—and let design work for you.

Great guide on cooling-fans-vs-passive-vents-design-matters-makita – Community Feedback

Why are cooling fans important in Makita chargers?

Cooling fans keep chargers and batteries at optimal temperatures, reducing internal heat build-up. This helps prevent overheating, supports safe rapid charging, and extends overall battery lifespan.

Do passive vents provide enough cooling for fast charging?

Passive vents rely on natural airflow, which is often insufficient for quickly dissipating heat from high-current charging. Active fans provide a more reliable and effective cooling solution, especially for workshop or trade use.

How does charger design impact power tool battery life?

Superior charger design—using quality cooling components like fans—lowers internal temperatures. This reduces battery stress during charging, minimising performance loss and supporting longer battery lifespans.