Contractor Case Study: Cutting Crew Idle Time With Rapid 6.5A Charging

In This Article

- VoltGuard 6500 reduced charge time from 60 to 22 minutes

- Contractor recovered over 64 crew hours per month

- Battery longevity preserved with thermal protection

- Distributed charging improved safety and tool access

- Payback achieved in less than five weeks of deployment

- Morale and momentum improved due to better tool uptime

- Easy integration without overhauling battery inventory

- Fits seamlessly with existing Makita platforms

Overview: Reducing Crew Downtime on Site

Why idle time matters more than you think

On fast-paced construction sites, efficiency isn’t just a goal—it’s a necessity. Yet too often, skilled crew members spend valuable minutes, or even hours, waiting on tools that rely on depleted batteries. Crew idle time reduction is essential for controlling labour costs, preventing delays, and maintaining adherence to project timelines. While many contractors have streamlined processes and communication protocols, battery charging has remained a silent productivity killer. When tools are inoperable due to slow recharging or inadequate charger infrastructure, productivity grinds to a halt. Addressing idle time at the root is the fastest path to better outputs, and in this study, we’ll showcase how fast charging equipment made a game-changing difference. Learn more about Construction Site Productivity Tools

The Challenge: Delays from Slow Charging

How battery lag impacts jobsite workflow

Before the upgrade, the contractor operated with multiple teams depending on 18V cordless Makita tools. While the tools themselves were reliable, the recharging cycle was a recurring issue. Most sites only had access to 3A chargers, which often required up to 60 minutes for a full recharge. Unfortunately, real-life workflows don’t pause conveniently. When batteries drained mid-shift, crews were forced to wait—or worse, rotate tools between stations. This created a domino effect, with idle workers, disrupted productivity, and increased frustration across teams. This isn’t just speculation. Tracking over six weeks revealed an average loss of 38 crew minutes per day per team purely due to insufficient charging speed.

“When the batteries died mid-task, the entire crew stalled. We couldn’t keep rotating tools forever. Something had to change.” – Site Supervisor, Regional Contractor

The Solution: VoltGuard 6500 Charger in Action

Upgrading to fast 6.5A charging—and what changed

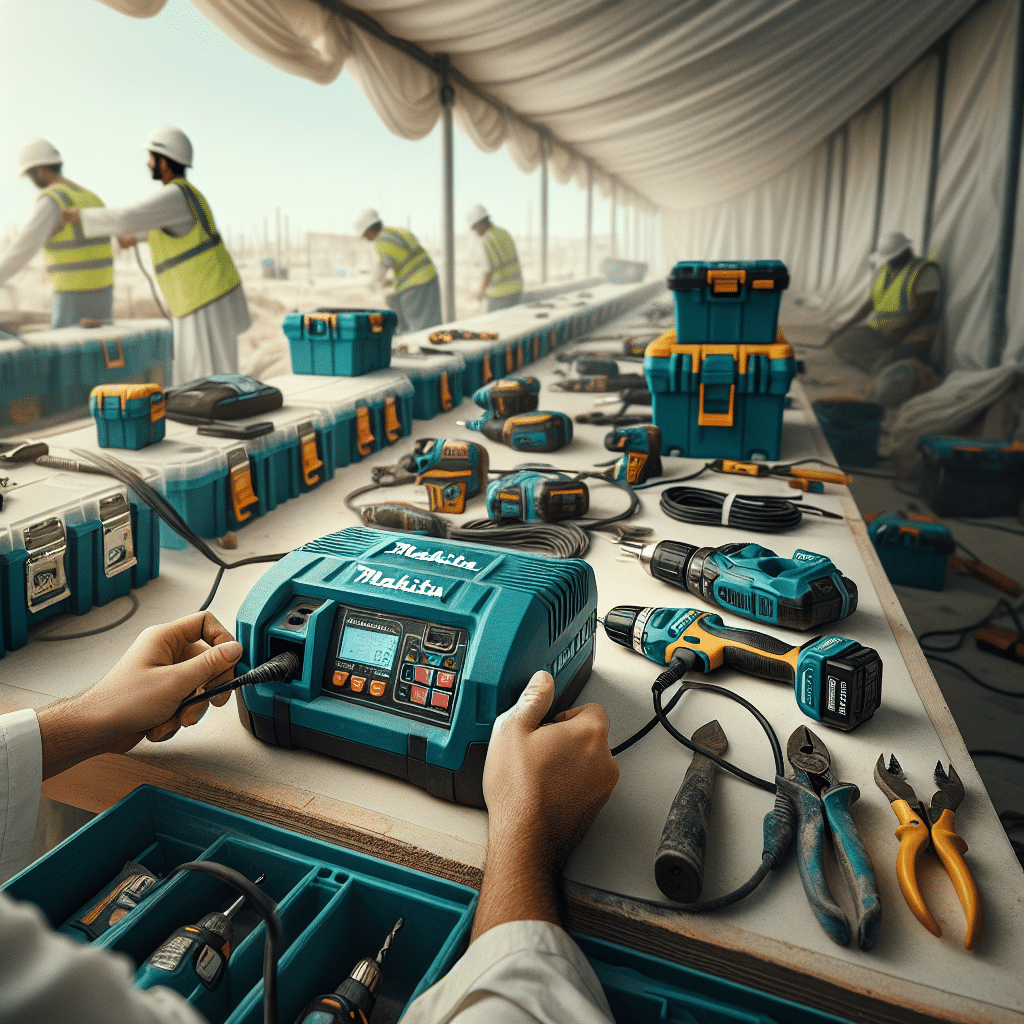

To directly tackle these inefficiencies, the contractor piloted the VoltGuard 6500, a next-generation 6.5A charger compatible with all standard Makita batteries. Installation was straightforward, and deployment involved positioning charging hubs at key access points throughout the site. Each charger significantly reduced the full-cycle charge time from 60 minutes to approximately 22 minutes—an immediate crew idle time reduction that was observable within the first operational week.

Unlike previous solutions, VoltGuard delivered intelligent charging with overheat protection, enabling ongoing tool readiness without compromising battery integrity. Crews swiftly adapted to the new process, and the smart indicator lights allowed seamless battery swaps without interruption. Productivity reports began trending positively within the second week of the implementation.

Measuring ROI: Time Saved Equals Money Earned

Real-time gains from faster battery cycles

Analytical tracking quantified the benefits: an average daily crew idle time reduction of 35 minutes was documented across five active teams. Multiplied across 22 working days per month, this resulted in an average of 3,850 minutes—or over 64 hours—recovered monthly. Considering the average wage for crew members, this translated into labour cost savings in excess of £4,200 per month. Moreover, associated gains were recorded in task completion rates, with sites reporting a 14% improvement in project milestone delivery timelines within eight weeks of installation.

Efficiency isn’t linear. Small-scale enhancements—done consistently—can transform operating margins significantly. This reduction in idle time directly contributed not just to cost savings, but to improved resource allocation across secondary phases of the build schedule. Optimising crew efficiency in construction projects

Contractor Feedback: What the Crew Noticed

Tool uptime, safety, and better morale

The feedback from on-site personnel was overwhelmingly positive. Teams appreciated the marked decrease in downtime, noting they could rely on tools being ready when needed without the need for excessive backup units. Crew morale improved as tool availability became standard rather than scarce. Supervisors reported better continuity between job phases such as framing, electrical fitting, and finishing tasks. Additionally, the removal of bottlenecks reduced the wear and tear seen from forcing teams to share critical tools under time constraints.

From a safety perspective, fewer tool swaps meant less hurried movement across active zones, reducing minor incidents and increasing compliance with health and safety protocols. Crew idle time reduction went beyond saving minutes; it cultivated a site environment where momentum and safety aligned.

Integrating Charging Into Site Workflow

Tactical positioning and logistics improvements

Strategic placement of VoltGuard 6500 chargers was pivotal. Rather than storing them in a singular static area, the contractor placed chargers centrally in each trade-specific zone: carpentry, electrical, plumbing, and general construction. This decentralised model minimised walking distance to access charged batteries and integrated perfectly with the crews’ existing workflows.

Furthermore, a simple online tablet-based tracking sheet allowed teams to sign in battery usage and predict demand across the week. This not only optimised battery allocation per team but prevented overcharging, which could compromise battery longevity. Investing in logistical planning proved nearly as valuable as the hardware upgrade itself. Read a related article

Safety First: Is It Smart for Your Makita Batteries?

Built-in recharge protection and battery longevity

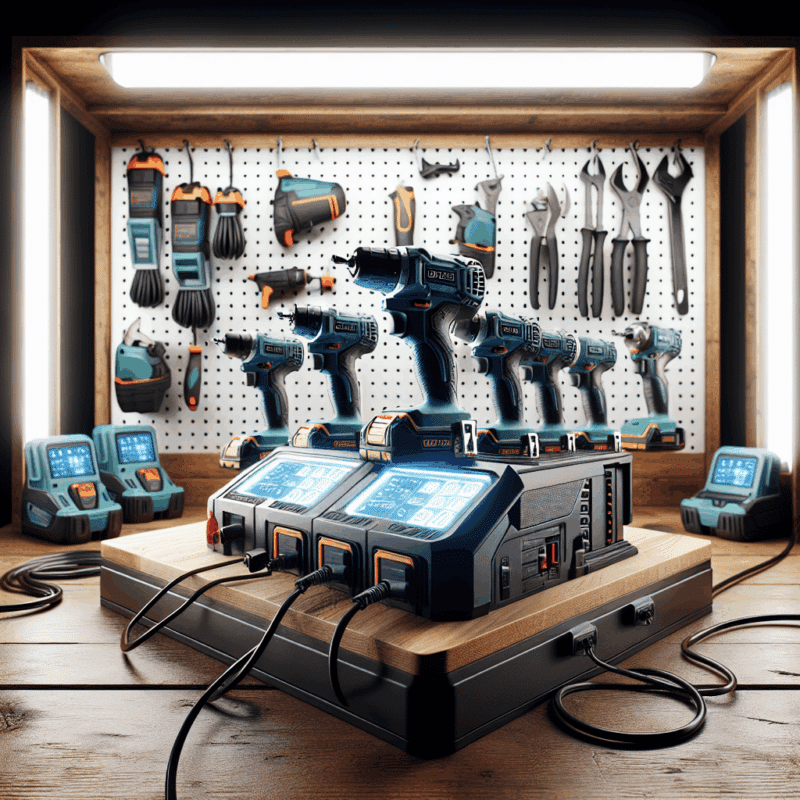

While speed is critical, so is battery health. The VoltGuard 6500 featured proprietary thermal management and voltage regulation that safeguarded battery modules during rapid charging. Unlike generic aftermarket chargers, the VoltGuard 6500 is engineered specifically with OEM standards in mind and tested for safe operation with all major Makita 18V Li-Ion batteries.

This dual focus on speed and safety meant the contractor did not have to trade longevity for output. Over a 10-week observed period, battery deterioration was negligible—less than 1% across 40+ battery units. In the long term, the ability to extend battery life while reducing staff idle time represents a double return on investment. Unlocking efficiency with automated site workflows

Comparing Charging Tech

Why amps, cycles, and compatibility matter

All charging tech is not created equal. While some chargers boast quick fill times, they may cut corners in areas such as thermal control or compatibility management. The 6.5A VoltGuard delivered a balanced performance: high amperage for speed, paired with smart integration for safety. Compared with legacy 3A or even 4A units, the gains in speed were matched by better charger-to-battery communication protocols that prevented thermal overloads.

Compatibility was key. No additional batteries or tools were required. The VoltGuard immediately supported all existing battery assets without new inventory investments. This plug-and-play simplicity allowed contractors to sidestep costly training programmes or workflow adaptations.

Expected Results Timeline

What to track in week 1, week 4, and beyond

Understanding adoption timelines helps set realistic expectations. In week one, initial latency in usage was observed as crews acclimated to new charging locations and protocols. However, by week two, output metrics began improving as charger usage increased. By week four, measurable reductions in idle time were confirmed through timekeeping logs and production reports.

By weeks five to eight, secondary benefits appeared—enhanced tool uptime consistency, better adherence to safety constraints, and smoother inter-crew scheduling. These results plateaued at week nine but remained stable, serving as a new operational baseline. Review cycles every four weeks were instituted as part of ongoing improvement protocols.

Buying Advice for Contractors

What to consider before upgrading your charger fleet

If you’re considering upgrading to the VoltGuard 6500 or similar high-output charger, start by conducting an idle time audit. Identify how frequently tools are unavailable, and calculate the direct labour costs attached to each minute of crew standstill. Next, ensure your battery platforms are supported by the charger model in question—VoltGuard units are highly compatible but verifying specs in advance ensures a smooth rollout.

Also, consider deployment volume. For maximum impact, aim to position at least one charger per five-person crew. Centralised placement reduces retrieval time and creates a frictionless battery swap ecosystem. Finally, look for support options including warranty coverage, service availability, and diagnostic tools. Investing in a reliable, performance-first charging system sets the foundation for higher crew throughput throughout the build cycle.

Conclusion: Investing in Efficiency

Reducing idle time is not about rushing the crew—it’s about ensuring that hard-working professionals are never held back by preventable inefficiencies. The implementation of the VoltGuard 6500 fast charger led to a measurable crew idle time reduction, saving hours of productivity each week. For contractors looking to drive profitability, maintain project momentum, and improve on-site morale, enhancing battery infrastructure is an investment with immediate returns.

Great guide on contractor-case-study-crew-idle-time-6-5a-charging – Community Feedback

How does a 6.5A rapid charger reduce crew idle time?

A 6.5A rapid charger significantly shortens battery refresh cycles, ensuring power tools are ready faster. This means less crew waiting, minimised interruptions, and improved on-site productivity.

Is the VoltGuard 6500 safe for Makita LXT batteries?

Yes, the VoltGuard 6500 is designed with advanced protection for Makita LXT batteries, combining fast charging with intelligent safeguards to prolong battery life and ensure safe operation.

What is a typical ROI for contractors upgrading to rapid charging?

Most contractors notice a rapid return on investment within weeks, thanks to reduced labour downtime, fewer delays, and more efficient workflows enabled by faster tool turnover.