Boost Field Productivity by Assigning Chargers to Workflow Stages

In This Article

- Charger assignment minimises tool downtime and boosts task efficiency.

- Strategic charger placement maps directly to workflow stages and team roles.

- High-speed, role-specific chargers cut power delays for critical equipment.

- Smart tools and digital monitoring optimise charger usage and battery life.

- Integration into SOP promotes sustainability and long-term site performance.

Why Charger Assignment Matters Onsite

Tool downtime and workflow disruptions

One of the most underestimated threats to field productivity is improper charger assignment. In a dynamic jobsite environment, tools are the lifeblood of operations. If they are not adequately powered when required, the backlog created can ripple downstream and cause extended delays across teams. Charger assignment ensures that power tools are practically always available, with batteries refuelling systematically throughout workflow stages.

When workers must pause their tasks to search for charging stations or swap in undercharged batteries, productivity plummets. Furthermore, prolonged charging queues worsen tool downtime. By integrating charger assignment into initial site planning, project leaders mitigate delays and ensure a seamless handoff between stages of work.

It’s also crucial to note that the efficiency of charger assignment increases exponentially when combined with predictive maintenance and staffing statistics. For example, field data often reveals which times of day chargers are in highest demand—an insight that can shape better power distribution strategies. Learn more about Optimising Tool Charging for Professional Workflows

Mapping Workflow Stages to Charging Points

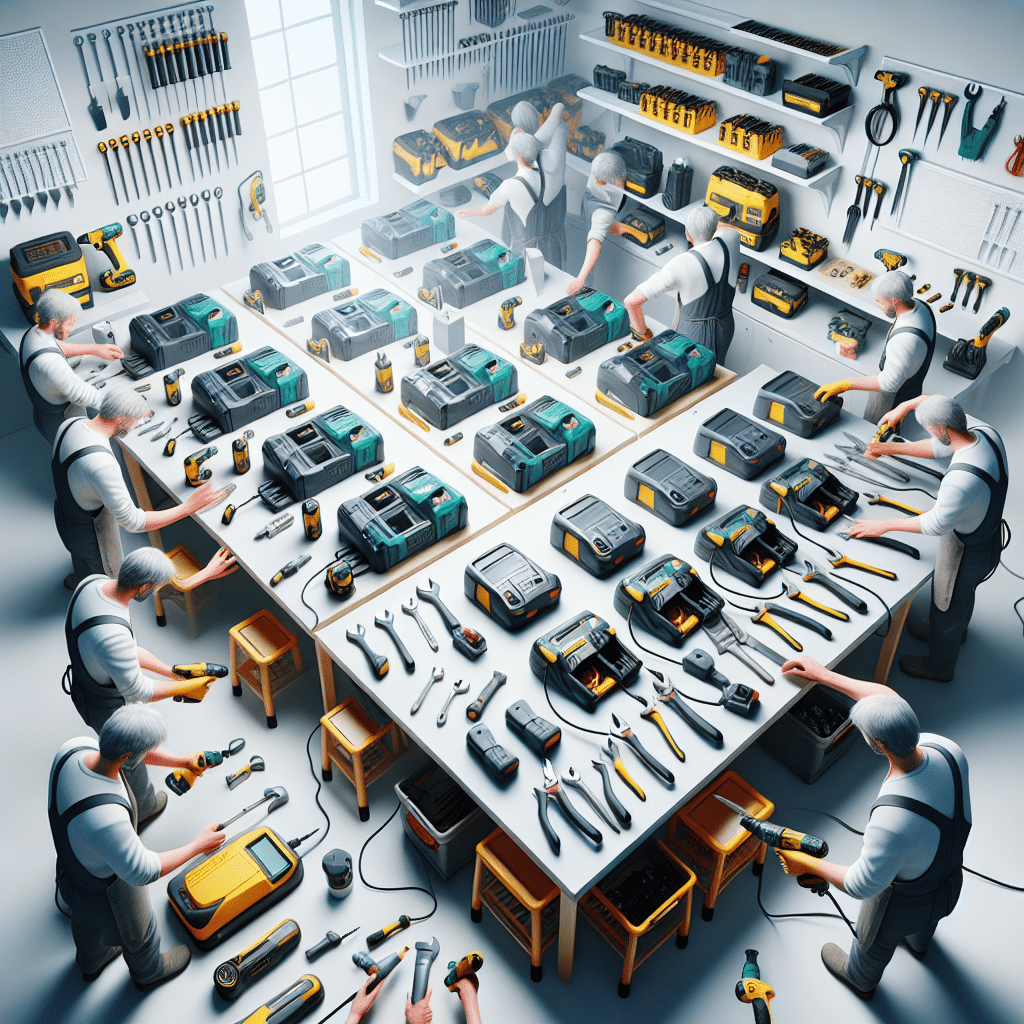

Site layout planning tips

Optimising site layout with a target-focused charger assignment strategy results in efficiency gains across the board. The key lies in understanding your jobsite’s workflow patterns. Where are bottlenecks most likely to emerge? Which tasks consistently consume more battery power? Once those answers surface, you can map out charging points so that they align with where tools are likely to be used next.

Experienced site managers take a modular approach: segment the site according to task stages and allocate chargers strategically to each area. For instance, drywall teams deep in a high-rise interior will benefit from nearby charging stations, which they can access without walking back to the site entrance.

Utilising mobile charging banks mounted on rolling containers or pannier trolleys adds further flexibility. These can be deployed to areas of highest demand, providing supplementary support when electrical infrastructure is limited. As layout complexities increase, charger assignment must also accommodate emerging variables like shared tool usage, hybrid vehicles, and generator-distance constraints. Practical tips for field workforce efficiency

Choosing the Right Charger for the Task

Power capacity & recharge speed

Charger assignment is more nuanced than simply ensuring availability. Selecting the correct charger type for each tool enhances not only uptime but battery longevity. Different equipment demands varying voltage capacities and recharge speeds. For heavy-duty utilisation, fast-charging units make a significant difference, dramatically reducing idle time between uses.

Compatibility must also be prioritised during charger assignment. Mismatched chargers can degrade batteries and void warranties. Most modern brands provide matched systems, but in larger organisations with mixed inventories, it’s critical to maintain clear charger-to-tool relationships. Colour coding or digital tagging systems work exceptionally well in these settings.

Power throughput plays a large role, especially when deadlines are looming. Allocating high-capacity chargers to senior crew members or critical-path equipment guarantees minimal recharge lag. Moreover, integrating intelligent chargers—those capable of providing usage diagnostics—offers opportunities to monitor overuse and spot inefficiencies before they escalate. Enhance efficiency with automation insights

Reducing Battery Swap Interruptions

Strategic placement equals efficiency

Battery swaps can disrupt workflow continuity, particularly when workers must leave their zone to replace or recharge batteries. Through smart charger assignment, these interruptions are dramatically reduced. Ensuring strategically placed charging hubs around high-traffic work zones allows battery swaps to be conducted quickly and sequentially.

A well-executed charger assignment model maintains a live inventory of charged batteries, which are continually cycled and replenished. Staff are trained to follow racking sequences, always removing the oldest charged unit for installation and returning depleted batteries for immediate recharging. This successive routine avoids oversaturation of unused charged batteries and keeps the flow continuous.

Paired with digital tools, such as mobile apps that indicate nearby available chargers, battery swap latency can be cut to under two minutes on well-managed sites. The positioning of chargers, along with proper task-based permissions, ensures that field teams remain in motion rather than waiting on power logistics.

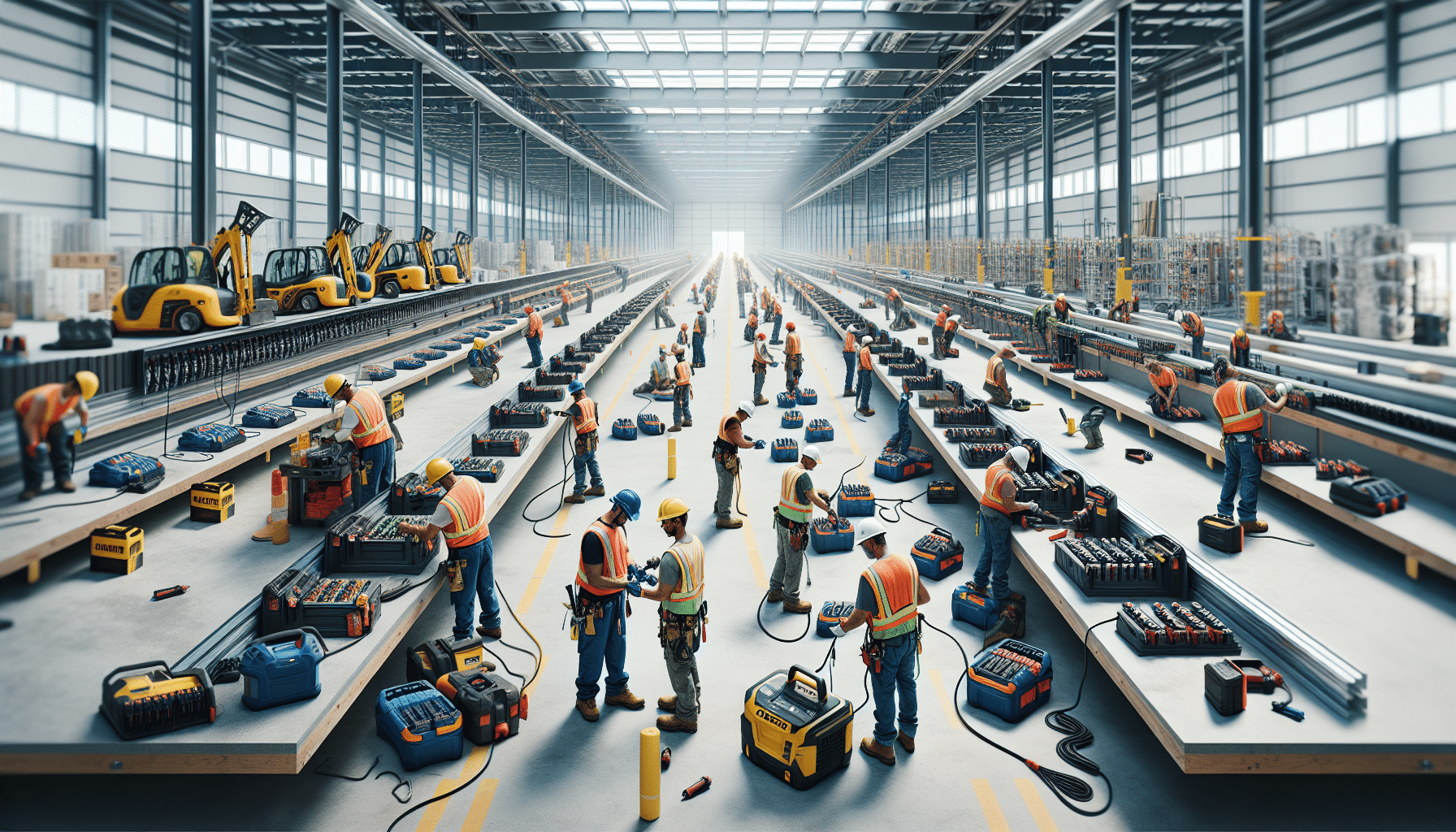

Assigning Chargers Based on Crew Roles

Tailoring to task and workflow

Not all crews require the same charging infrastructure. Charger assignment must reflect tool demand per role. For instance, framing crews using high-capacity nail guns consume batteries far faster than finish carpenters or painting teams. Assigning additional high-speed chargers to such roles pre-empts delays caused by battery exhaustion.

Standardising staff-charger allocations eliminates ambiguity on site. Every member should know which charging station to use and when. Incorporating this into digital workflows or shift schedules optimises coordination and accountability. New hires or temporary contractors can be rapidly onboarded with role-specific charging maps, ensuring uniform procedures across varying levels of experience.

Additionally, charger assignment should observe ergonomic standards. Crews shouldn’t have to stretch across busy areas or walk long distances to access equipment. This lowers fatigue and enhances operational safety. Read a related article

Benefits of Workflow-Based Charging Plans

Less idle time, more output

Implementing charger assignment in alignment with operational workflows has measurable benefits. Most fundamentally, it slashes idle time. When tools remain operational through deliberate charging plans, overall time-on-task percentages rise significantly—often by as much as 18–25% on well-established sites.

Aside from productivity gains, these charging schemes reduce employee frustration. There’s no longer the anxiety or delay tied to locating a free charger. Confidence improves when tool readiness is a given, not a gamble. This morale boost can have secondary benefits like higher retention, increased punctuality, and even safer work behaviour.

Another overlooked advantage is inventory visibility. Workflow charging plans track power consumption on a per-zone and per-role basis. This forecasting ability uncovers areas of misuse or excessive consumption, paving the way for efficiency-oriented equipment purchases and maintenance scheduling.

Examples of High-Efficiency Site Layouts

Real-world charging configurations

By dissecting real-world examples, one can better understand how charger assignment functions under different project scopes. On a recent hospital expansion in the Midlands, the operations team deployed perimeter charging racks paired with centralised fast-charge hubs in the MEP zones. The result was a 32% decrease in average equipment downtime from pre-project benchmarks.

At a wind energy installation in coastal Scotland, a mobile charger strategy was employed using transport crates with solar-assist charging stations. Tower climbers had immediate access at base, middle, and cap levels of the turbine—thanks to a granular, stage-specific charger assignment model that mirrored ascent workflows.

Urban construction sites also benefit from vertical charger assignment planning. Multi-storey developments often use floor-specific charging lockers, which are synced daily through a mobile app check-in system. This decentralised charging infrastructure eliminated crowding in service lifts and queues at site-level units.

Monitoring Charging Performance on Site

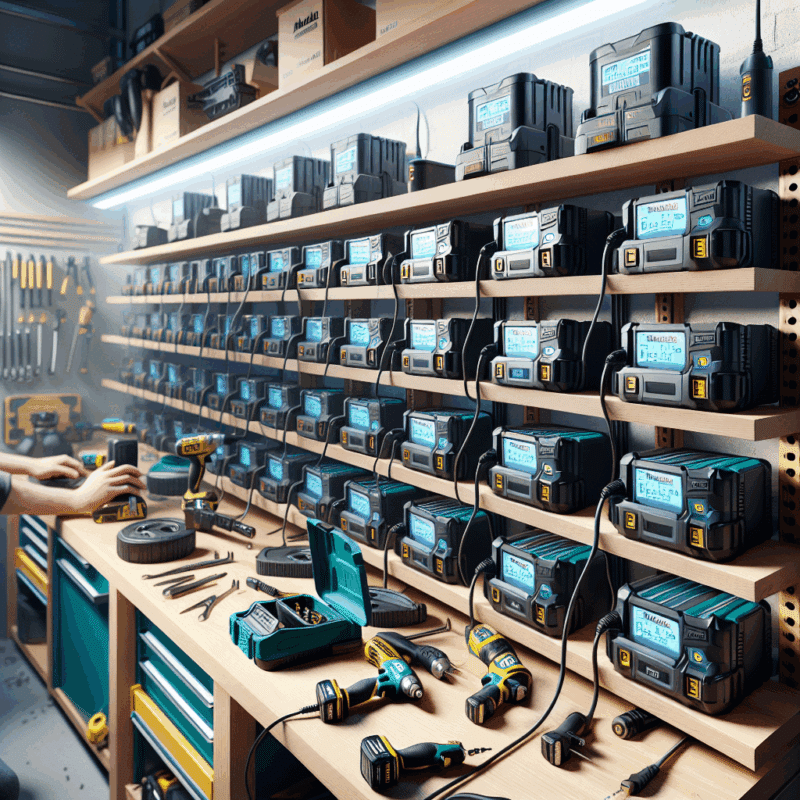

Tracking charger availability and use

Ongoing monitoring of charger usage is critical to tightening the charger assignment loop. Digital IoT-enabled chargers record metrics including charging time, power draw, completion cycles, and idle intervals. This data reveals not only technical performance, but also crew adherence to charging protocols.

These systems often come with dashboard integrations that provide site managers with real-time visibility. Alerts can be set up for underperforming units or overused chargers, allowing prompt interventions. For instance, if a particular zone consistently runs out of battery stock before shift end, it’s a clear sign the charger assignment must be revised.

Integrating this with asset management software gives project supervisors even stronger insight into total equipment effectiveness (TEE). Over the long haul, this data informs hardware purchasing cycles, energy budgeting, and organisational sustainability goals.

Training Teams on Smart Charging Habits

Onboarding field staff

Smart charger assignment is futile if staff don’t understand or respect the system. This makes training a linchpin of productivity enhancement. During onboarding, teams need clear, concise instruction on charger location, tool compatibility, racking order, and maintenance checks.

Interactive briefings, complete with visual walkthroughs and QR-coded site maps, help reinforce familiarity. Some firms employ gamification—crew members earn points for consistent compliance with charger assignment routines, redeeming productivity credits or meal tokens.

Even veteran workers benefit from refresher modules, particularly when new charger models are introduced. Embedding this into monthly health-and-safety updates keeps the protocol front of mind. Most importantly, feedback loops should be built in—allowing fieldworkers to report charger faults, suggest relocation, or request additional socket banks through simple digital forms.

Integrating Charger Assignment into SOP

Sustainable jobsite practices

Long-term success demands that charger assignment become a non-negotiable component of standard operating procedures (SOP). It shouldn’t be an afterthought. Instead, charger strategy must be a foundational layer in the project’s logistical playbook.

This mandates SOP updates that specify duty-of-care principles for charger condition, power source safety checks, and shift-cycle recharge protocols. Standards must be enforced not only at the subcontractor level but controlled via centralised governance. Daily start-up meetings should review zone-level charger readiness as part of routine briefing processes.

Including environmentally aligned charger assignment practices also plays a major role. Encourage use of solar-panel-fed charging stations or hybrid-fed dynamos when diesel consumption must be minimised. Such sustainability practices align with both ESG commitments and national energy targets. In this way, charger assignment takes its rightful place at the junction between innovation and environmental responsibility.

Charger assignment transforms charging from a maintenance headache to a productivity weapon—when tools are always powered, teams perform at their peak.

Conclusion: Power Up Productivity

In today’s high-stakes construction and field services industries, precision is everything. Charger assignment offers more than convenience—it serves as a vital cog in a complex machinery of productivity. From seamless tool transition at key workflow stages to monitoring and training benefits, the strategic deployment of chargers ensures every team member is working, not waiting. It’s time to elevate power infrastructure to strategy status. Because when the power flows, progress follows.

Great guide on boost-field-productivity-assign-chargers-workflow-stage – Community Feedback

How does charger assignment by workflow stage improve field efficiency?

Assigning chargers to specific workflow stages minimises tool downtime, streamlines jobsite logistics, and ensures power is always available where and when teams need it most.

What is the best charger placement strategy for busy jobsites?

Locate chargers near each team’s work area and key workflow stages, minimising walking distance and reducing the risk of battery shortages or work delays.

Which Makita-compatible charger is ideal for fast-paced sites?

The Torxup VoltGuard 6500 (6.5A) delivers rapid charging for Makita 18V LXT batteries, making it a suitable choice for sites with high productivity demands.