Best Multi-Bay Charger Strategies: Buying for Your Team

In This Article

- Opt for multi-bay chargers with at least 4-6 bays for medium-sized teams working in shifts.

- Prioritise safety certifications and thermal control features to ensure reliable operation.

- Fast charging reduces battery inventory needs and enhances team efficiency.

- Portable models are essential for field crews, but consider base stations for static environments.

- Standardise battery types across teams to simplify logistics and avoid compatibility issues.

Understanding Multi-Bay Charging for Teams

The Need for Simultaneous Battery Charging

In any environment where multiple tools or devices are in constant use—whether construction, emergency services, warehousing, or media production—a reliable and efficient multi-bay charger is not just convenient but essential. Unlike single-bay solutions, multi-bay chargers allow for concurrent replenishment of several batteries, significantly reducing downtime and enhancing team productivity. This capability becomes especially crucial when you’re dealing with teams that rely on battery-powered equipment throughout long shifts. Choosing the right system ensures that batteries are never a bottleneck to your operations.

Choosing the Right Charger Capacity

Charging Speeds vs Battery Volume

One of the first considerations in selecting a multi-bay charger is matching its capacity to your battery inventory. For instance, if your team cycles through a dozen batteries every shift, a 4-bay or 6-bay unit will not suffice unless supplemented or rotated meticulously. However, it’s not just the bay count that matters—the rate at which the charger replenishes batteries can be equally consequential. Faster charge times can reduce the number of batteries you need on hand, while slower chargers may require excessive backups. This balancing act—battery volume versus charging speed—lies at the heart of capacity planning.

“The right charger eliminates bottlenecks and keeps crews moving—saving both time and money.”

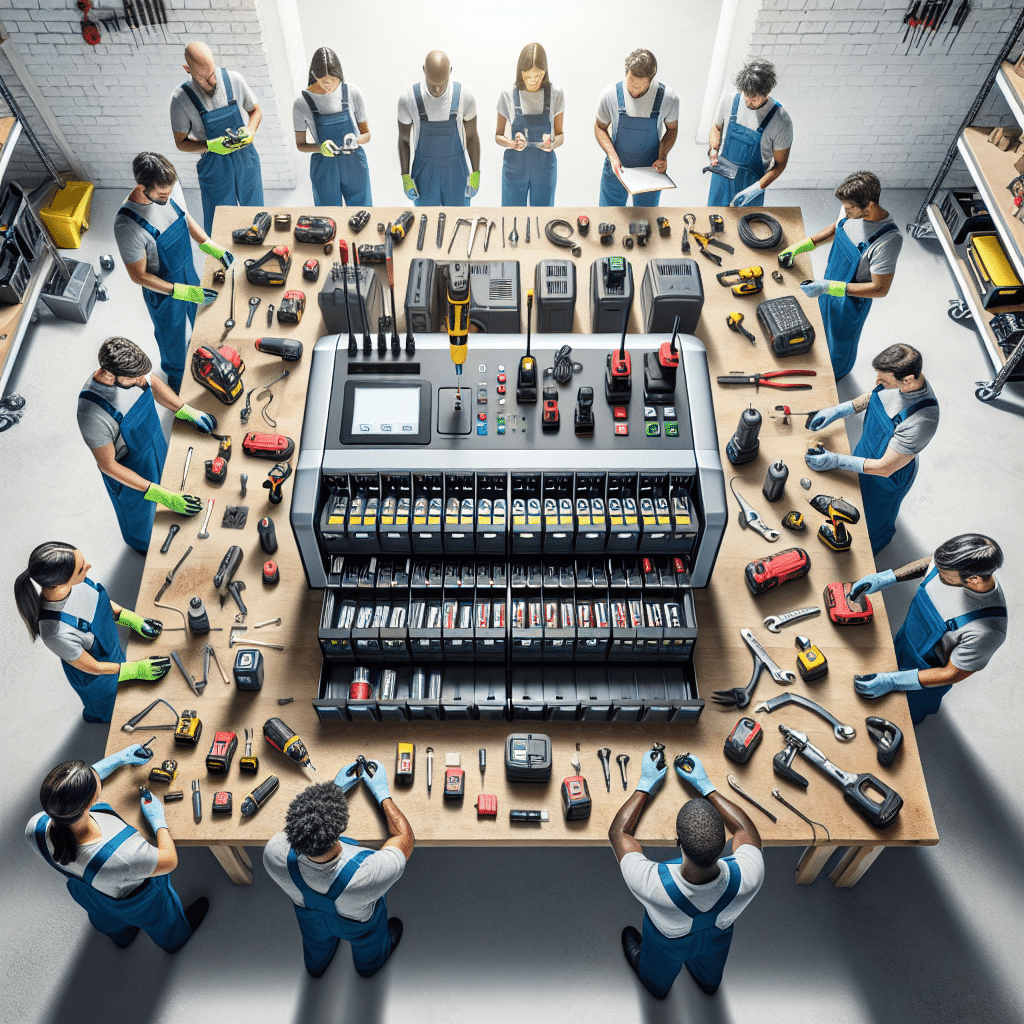

Organising an Efficient Charging Station

Labeling, Ventilation, and Placement

Even the best multi-bay charger can underperform if it’s not integrated thoughtfully into your workspace. Labelling each bay with a battery ID can prevent accidental swaps—particularly important for batteries in various states of health or performance. Furthermore, chargers generate heat, especially when running simultaneously at full capacity. Ensuring proper ventilation prevents thermal damage or reduced lifespan of batteries. Placement also plays a role: chargers should be within reach of tool storage but away from high-traffic zones to avoid cable hazards. Dedicated shelving or mounting racks can streamline accessibility and organisation significantly.

Benefits of Fast Charging in Workshops

Reducing Downtime in Busy Environments

Downtime translates directly into productivity loss, especially in time-critical sectors like manufacturing or service repair. Implementing a multi-bay charger with fast-charge capabilities means that spent batteries are back in action quicker, avoiding workflow interruptions. This is particularly valuable when working in staggered shifts or with continuous operations where waiting hours for a full charge is not viable. Additionally, modern chargers often include intelligent features such as adaptive voltage detection or power balancing, which maintain safety while accelerating the charging process. These features offer a tangible boost to efficiency that far outweighs their cost in the long term.

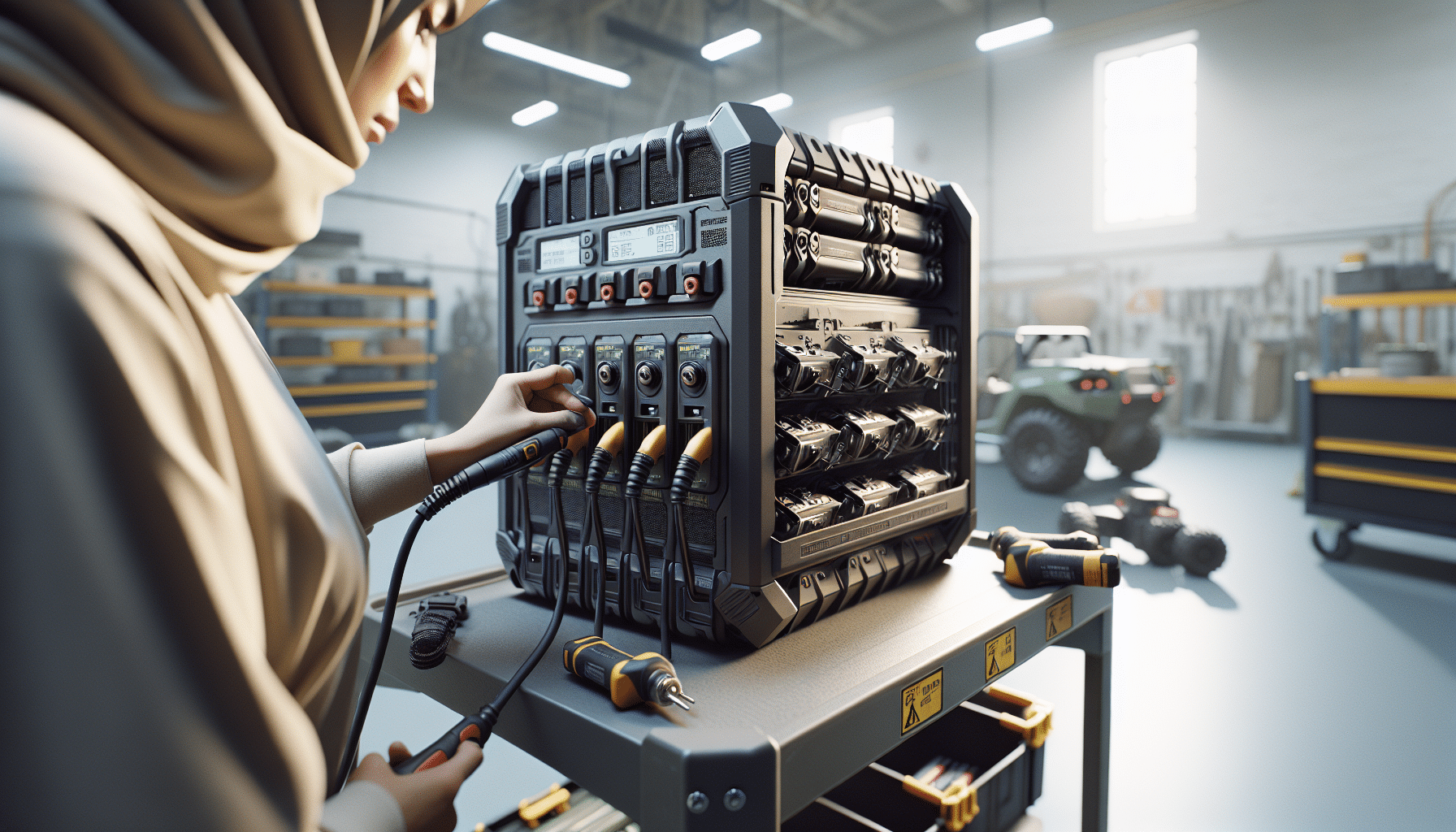

Safety Features to Look Out For

Thermal Control and Certification

When managing high power demands across multiple charging bays, safety cannot be an afterthought. The most reliable multi-bay chargers incorporate real-time thermal monitoring, enabling the system to shut down or throttle operation if components reach unsafe temperatures. Equally vital are built-in overcharge prevention circuits and smart power distribution systems that allocate energy based on individual battery needs. It’s also crucial to seek units with CE, IEC, or equivalent safety certifications, especially if you’re sourcing chargers for regulated industries. Overlooking these features can lead to equipment damage, fire risks, or even regulatory non-compliance.

Field Use: Portable or Static Stations?

Balancing Durability vs Mobility

Mobile teams—such as field technicians, event crews, or disaster response units—have unique charging requirements. While some multi-bay chargers are designed for fixed installations, others are built with portability in mind. Portable units often include ruggedised enclosures, splash resistance, and integrated cable storage. Yet, there’s a trade-off: mobile models may sacrifice high throughput or extensive safety features found in static alternatives. Determining the right mix of mobility and performance depends on the operational environment. For hybrid teams, a combination of portable and base-camp chargers may offer the best solution, ensuring flexibility without compromising on power delivery.

Cost vs Performance Evaluation

Investing in Long-Term Uptime

While it’s tempting to select a lower-cost multi-bay charger to meet immediate needs, short-sighted purchasing can lead to greater costs over time. Low-end models may lack thermal regulation, smart diagnostics, or efficient charging algorithms, all of which impact battery health and reliability. Additionally, underpowered units can become obsolete as teams scale operations or switch to higher-demand equipment. Investing in a high-performance model, while more costly upfront, tends to offer better ROI through reduced maintenance, longer battery lifespans, and fewer replacements. Always compare warranties, software support, and firmware upgrade paths when evaluating long-term investment.

Team Tips and Community Insights

What the Pros Recommend

Veteran crews often have invaluable tips that go beyond spec sheets. One common recommendation is to stagger charger use during low-power hours to avoid grid surges or overloads. Another is to standardise battery types across teams to simplify charging logistics. Some teams even install dedicated circuit breakers for their multi-bay chargers, ensuring uninterrupted operations. Finally, community-driven insights often highlight lesser-known but highly functional brands and models, offering budget-conscious alternatives that don’t compromise on reliability. Explore forums or social media groups—or check out Learn more about Professional Charger Solutions & Team Power Management—to gain real-world feedback before committing to a model.

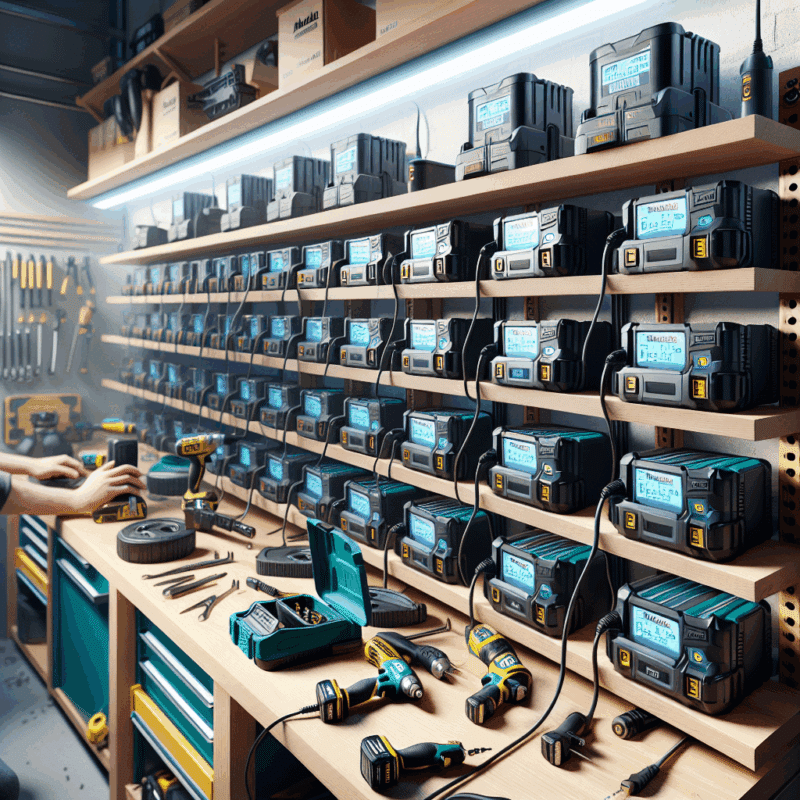

Compatible Multi-Bay Makita Chargers

Top Products Like the VoltGuard 6500

For teams heavily invested in Makita tools, ensuring compatibility between batteries and chargers is paramount. The Makita VoltGuard 6500 series stands out as a premier multi-bay charger solution, capable of accommodating up to eight 18V batteries simultaneously. It supports fast-charging tech, and its integrated LCD diagnostics offer real-time status feedback. Moreover, the unit includes built-in cooling systems and is ISO-certified for industrial use. Other notable options include the Makita QuickVault and DockPro series, both designed for professional environments. For a comparative analysis of these chargers, refer to Read a related article or explore third-party reviews at Best practices for multi-battery charging solutions.

Streamline Power Management at Scale

Scalable Power Strategies

For enterprises managing large tool fleets or operating across multiple sites, standardising your multi-bay charger infrastructure can yield significant benefits. Scalable systems allow daisy-chaining of units, centralised energy monitoring, and programmable charge cycles. Manufacturers now offer charging hubs that communicate with internal asset-management software, providing insights into battery usage patterns and failure rates. Additionally, implementing schedule-based charging can optimise power draw during off-peak hours, reducing overall energy costs. By centralising and scaling smart charging practices, teams gain both operational efficiency and enhanced visibility—essential for growing operations or regulatory audits. Learn more at Automated approaches for scaling team efficiency.

Conclusion

In high-performance team environments, the multi-bay charger is more than a convenience—it’s a core component of operational efficiency. By carefully evaluating charger capacity, safety standards, charging times, and form factors, you can dramatically improve uptime and productivity. While the initial investment may seem substantial, the return in reduced downtime, safer operations, and extended battery life makes a well-chosen charger a strategic asset. Whether you’re operating on-site, in a mobile setting, or across multiple warehouses, implementing the right charging solution can streamline your workflows and prepare you for future demand with confidence.

Great guide on buying-for-crew-multi-bay-charger-strategies – Community Feedback

What are the main benefits of multi-bay chargers for teams?

Multi-bay chargers enable simultaneous charging of multiple tool batteries, minimise downtime, improve productivity and help teams stay ready for continuous work.

How do I set up an efficient charging station for my crew?

Choose high-capacity chargers, ensure proper ventilation, label battery bays, and position stations for easy workflow access to streamline battery rotation and team efficiency.

Are fast chargers safe for high-frequency workshop use?

Certified fast chargers with safety features like thermal control and voltage regulation are safe for sustained, demanding use, provided manufacturer recommendations are followed.