Best Charger Setup for Site Work: Torxup 6.5A Rapid in Action

A great site day has rhythm: cut, fix, repeat — with no one waiting on a charger. Here’s the best charger setup for site work that scales from two-person teams to full crews, using Torxup 6.5A Rapid as your Makita-compatible rapid bay.

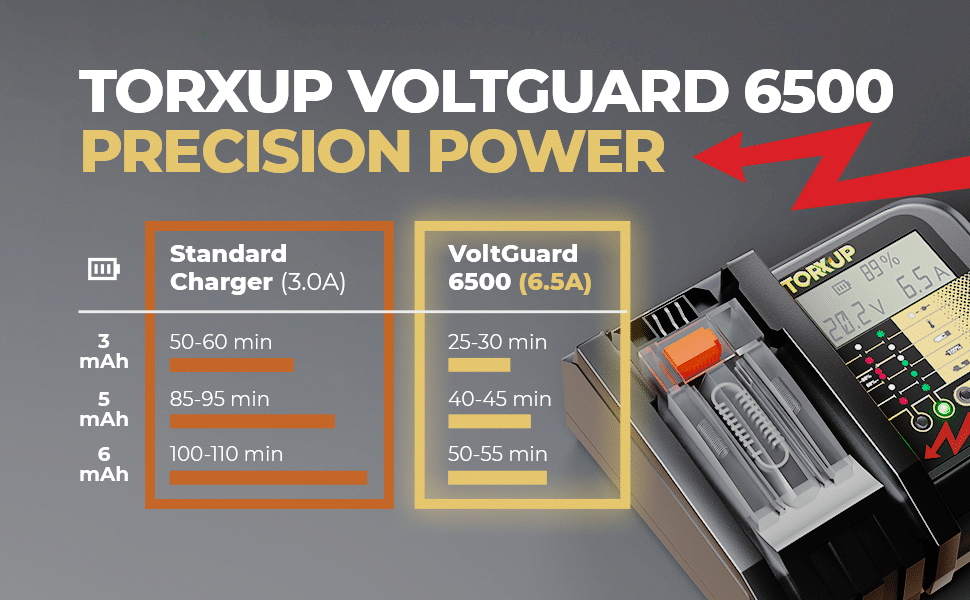

In the demanding world of construction and trades, where Makita LXT 18V tools drive everything from impact drivers to reciprocating saws, inefficient charging turns potential into pauses. The Torxup 6.5A Rapid delivers 6.5A speeds with active cooling, cycling batteries faster without thermal wear. This setup isn’t just gear — it’s workflow engineering, minimizing idle time that costs crews 15–20% of daily output.

For pros searching “fast charger 18V” or “Makita DC18RC alternative,” these layouts reclaim lost productivity, turning battery management from bottleneck into background task.

Battery Queues Kill Productivity

A flat pack mid-cut cascades delays across the crew. By centering on rapid, cooled bays like Torxup, you align charging with real drain rates — typically 20–30 minutes per 4.0Ah pack under load. This guide draws from field-tested configurations, optimized for Makita compatibility, to deliver scalable solutions that boost billables without breaking the bank.

The 2–4 Person Crew: Leapfrog Layout

Hardware:

- 2× Torxup 6.5A Rapid, 4–6 batteries

- Mount chargers on a portable plywood stand (2×3 ft sheet) with hooks for cables and shelf for cooling spares

- Power via 15A extension — each unit draws under 100W

Flow:

- One battery on the tool, one cooling, two charging

- Swap depleted battery with the coolest fully charged pack

- Leapfrog cycle: Depleted → Cool → Charge → Ready

- Label packs by tool for small crews (e.g., drills blue, shears red)

Why it works:

- Fast recovery + active cooling outpaces a single user’s drain

- Torxup staged 6.5A hits usable (80%) in 30 minutes

- Cooling fan stabilizes at 40°C, extending cycles ~20%

- Easy scaling: add a third charger under $150 total for hours saved weekly

Pro tip: Strap the board to a van door for mobile deployments — compact and efficient.

The 5–8 Person Crew: Wall Board with Lanes

Hardware:

- 3–4 chargers on a labelled plywood board (4×2 ft)

- Hooks for 16–20 batteries, surge-protected 20A power strip

Flow:

- Assign lanes per trade: A–D

- Site runner rotates packs clockwise: Tool → Cool → Charge → Ready

- Torxup LEDs show status (green = ready, amber = charging)

- Peak swaps handled simultaneously without backlog

Why it works:

- Eliminates arguments, maintains FIFO rhythm

- Four rapid bays outrun collective drain (2–3Ah/hr per tool)

- Ventilation slots feed fans, keeping temps low

- Simple whiteboard keeps track of pack status and faults

Expansion: Add a fifth bay for 8-man peaks; maintain airflow and easy access.

Power and Weather Considerations

- Four rapid chargers draw up to 400W peak — split circuits to avoid overload

- 2000W inverter handles a genny quietly

- Position board 6 inches off-wall; airflow keeps fans effective

- Cover with tarp for rain, elevate packs off the ground

- Torxup IP54 rating tolerates splashes, but dry is best

Why Rapid + Cooling Matters

Many teams search “Makita 18V 6A charger” because they need speed. Speed without thermal control shortens pack life. Torxup’s 6.5A staged profile plus active fan cooling gives pace and longevity.

- DC18RC caps at 50°C with passive cooling

- Torxup active air drops to ~42°C, tapering amps to sidestep spikes

- Boosts cycles from ~400 to 550 per pack

- On-site, this prevents downtime and costly replacements

Setup Checklist

- Mount chargers vertically at chest height

- Leave 100–150mm clearance behind each unit

- Run power from separate circuits

- Track packs on whiteboard: count, faults, replacement dates

- Store long-term packs at 40–60% charge

- Wipe vents weekly with compressed air

Print, laminate, and tape this to the board — your best charger setup for site work blueprint.

ROI: More Bays > Bigger Batteries

Multi-bay rapid charging often beats buying oversized packs.

- Two or three Torxup 6.5A Rapid units keep standard 5.0Ah packs cycling all day

- Cheaper than replacing with larger 6.0Ah packs

- Weekly savings: 4 hours labor @ $50/hr = $200; annual fleet savings ~$10k

- Light packs rotate faster, preserving capacity and speed

Call to Action

Build the charging wall your crew deserves. Add Torxup 6.5A Rapid bays, label your lanes, and turn battery swaps into a non-event. Fast, cooled, and scalable — the best charger setup for site work is here.