Are Makita OEM Chargers Slowing Down Your Team’s Output?

In This Article

- Rapid chargers cut downtime by more than half compared to OEM units.

- Multi-bay chargers dramatically improve team tool availability.

- Thermal control and smart diagnostics matter for battery health.

- Third-party chargers must be carefully vetted for safety certification.

- Investing in better chargers pays back quickly in productivity gains.

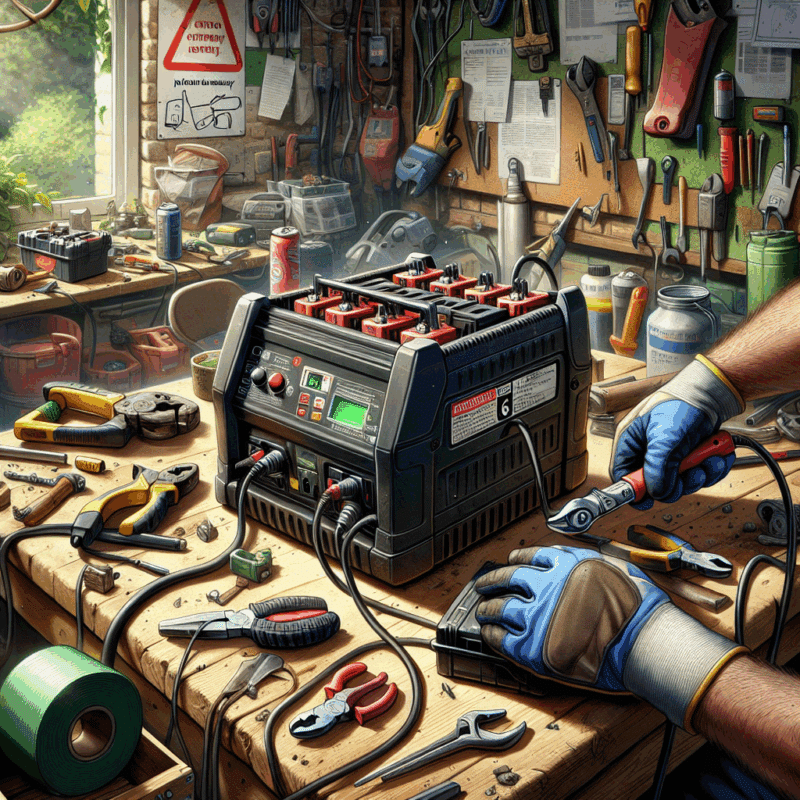

Why Charger Speed Affects Jobsite Productivity

Time lost equals money lost

When navigating Makita charger comparison criteria, charging speed emerges as a decisive factor. In the construction and trade sectors, downtime due to tool battery depletion directly equates to lost labour hours and delayed project timelines. As battery technologies evolve and higher-capacity tools become standard, older Makita chargers often struggle to keep up with demands. A slow-charging unit means waiting hours for a full charge, undermining workflow and crew efficiency.

Conversely, rapid chargers like the Makita DC18RC or DC18RD can replenish an 18V 5.0Ah battery in under 45 minutes. This drastically reduces downtime, ensuring tools are ready when needed. With teams increasingly working under tight deadlines, speed is paramount. Multiple crews relying on a limited bank of chargers without fast charge capabilities inevitably face bottlenecks. In high-load environments, every minute counts. The twin benefit of speed and efficiency makes investing in rapid charging infrastructure, over default bundled options, an undeniably strategic move.

Understanding Makita OEM Charger Limitations

Standard models vs. modern demands

OEM (Original Equipment Manufacturer) Makita chargers included with toolkits often serve the purpose of providing a basic, universal charging experience. While reliable, many entry-level OEM chargers—such as the DC18SD—offer basic output amperage with no advanced heat protection, smart monitoring, or prioritisation protocols. Designed primarily for low-to-moderate usage frequencies, these base chargers can leave professional crews underpowered on high-demand days.

Today’s jobsite workloads require tools that draw higher amperage consistently. Larger battery packs like the 18V 6.0Ah or the newer LXT 40V XGT series demand more robust charging capabilities. Unfortunately, standard chargers lag behind in safety features like active thermal control or automatic cooling fans. Without these, excessive heat build-up during charging can shorten battery lifespan, reducing long-term ROI. Analysing any Makita charger comparison makes it obvious that relying solely on OEM models is costlier over time, especially when considering cycle efficiency and safety priorities for both tools and team members.

“Our team cut downtime by 40% after switching from standard Makita OEM chargers to rapid twin-port solutions.” – Site Manager, Bristol Commercial Refits

Comparing OEM and Rapid Charger Options

Charging times, capacity, and heat management

In any thorough Makita charger comparison, speed isn’t the sole variable. Advanced charger models offer considerably more function than their OEM counterparts. For example, the Makita DC18RC utilises active fan cooling to maintain safe internal battery temperatures during charging. This not only speeds up the process but also preserves battery health, extending its expected service life. Charging an 18V 5.0Ah battery on an OEM unit may take 110 minutes, while the same task on a rapid model like the DC40RA takes less than 45 minutes.

Another factor is simultaneous charging. Many modern chargers now support twin ports that allow two batteries to charge concurrently. The Makita DC18RD is a popular choice among trade professionals for this reason. Its balanced internal architecture distributes power efficiently to enable genuine two-battery support rather than alternating between ports. Heat dissipation is also superior, thanks to integrated intelligent chipsets that regulate voltage and current real-time.

It becomes clear that upgrading to rapid or advanced charger types isn’t just about minimal time saved on an isolated charge but the cumulative effect across a day’s jobs. Especially in team environments, this differential can create a productivity gap of several hours weekly—a stark difference for any business prioritising performance and output consistency.

Are Third-Party Chargers Worth the Switch?

Safety, certification, warranty

While Makita-branded options dominate most charger deployments, third-party alternatives have entered the market with features and price points attractive to budget-conscious contractors. Yet, a rigorous Makita charger comparison must assess the risks versus benefits. Many non-OEM chargers lack proper CE certification or compatibility backing, which not only jeopardises battery life but also potentially voids warranties.

Safety is another pressing concern. Third-party chargers often miss out on Makita’s layered fail-safe protocols like thermal runaway prevention, voltage balancing, and direct tool-battery-communication. The absence of such integrated safety systems can lead to overheating, fire risk, or permanent battery cell damage. Moreover, clients concerned about professional integrity often prefer teams that stick to branded accessories, reinforcing trust in trained professionalism and reduced liability.

Should you consider third-party options? Only with careful vetting. Review CE markings, safety certifications, and user feedback. Brands with tested compatibility history across Makita’s LXT and XGT ranges may offer safer alternatives for lighter-duty or backup purposes. Nonetheless, primary infrastructure should ideally revolve around fully-tested Makita rapid chargers to ensure seamless operations.

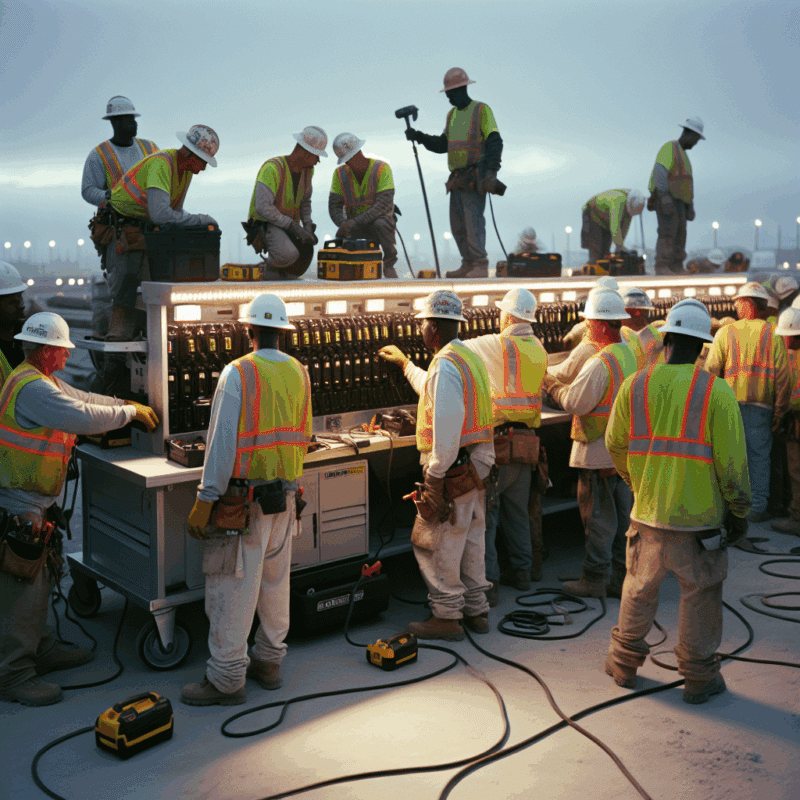

How Multi-Bay Chargers Streamline Workflow

Team charging efficiency unlocked

Managing multiple tradespeople using battery tools simultaneously demands far more than single-port chargers can offer. Enter the multi-bay charger. With configurations supporting four, six, or even ten batteries at once, multi-bay chargers represent a profound evolution in streamlined battery deployment.

For example, the Makita DC18SF allows up to four 18V batteries to be charged sequentially but swiftly. When synchronised with daily site schedules, this prevents tool scarcity. On more complex setups, commercial charging stations that support true concurrent charging enable a full team of eight crew members to swap and rotate tools throughout a shift without downtime. Importantly, these larger units often feature LCD diagnostics, battery health reporting, and port prioritisation based on battery depletion levels. The flexibility offered by a scalable multi-bay solution allows medium-to-large teams to minimise charging bottlenecks significantly.

Reducing idle time and boosting productivity becomes particularly measurable when comparing day-to-day tool readiness before and after implementing such centralised charging stations. Investing in one or more of these multi-chargers ultimately manifests as noticeable output gains at every skill level.

Real-World Experiences from UK Teams

Installer and tradesperson testimonials

Incorporating real-use scenarios into any Makita charger comparison reveals vivid insights. For instance, Thames Electric based in Hertfordshire reported that switching to the DC18RD twin-port rapid charger allowed them to go from two-hour cycles per battery to under 45 minutes, reducing waiting periods during power-intensive rewiring jobs. Their foreman noted, “We now work a full day with just two battery sets per tool—it’s made a measurable difference.”

Likewise, JDS Scaffolding in Manchester, which runs a seven-man team, adopted the DC18SF four-bay setup. According to their operations manager, “Learn more about Makita Battery Charging Solutions investing in those chargers cut labour interruptions by more than 30%.” The sentiment is shared across the industry—namely that investing in higher-quality charging infrastructure translates into better team morale, improved work pacing, and less frustration handling underpowered tools on heavy lift days.

Field reports consistently indicate that relying on single-bay chargers for team-oriented workforces is a tactical error. Once upgraded, the improved charging speed and logistics quickly pay back the initial investment in time saved and stress avoided. Expert insights on Makita charger options

Cost vs Benefit of Upgrading Chargers

Short-term cost, long-term efficiency

Looking at cost-benefit ratios, premium Makita chargers may appear costly upfront, often ranging from £50 to £150+ depending on the model and capacity. However, evaluating these numbers without considering the operational savings and productivity enhancement leads to short-sighted conclusions.

A rapid charger can generate consistent uptime, reduce tool replacement cycles by extending battery health, and facilitate more seamless job transitions. In real terms, that’s hundreds of pounds saved monthly in productivity, tool longevity, and avoided emergency downtime purchases. Additionally, premium chargers tend to be more rugged and temperature-tolerant, reducing maintenance downtime due to component failure.

For business owners, supervisors, and logistics managers, Read a related article understanding these long-term benefits helps reframe the decision from an equipment expenditure to a performance-driving investment. Spend a little more on rapid or multi-chargers now and avoid ongoing financial leakage in lost time, mismanaged energy storage, and frustrated team members waiting around for charged tool packs.

Best Features to Look for in a Makita Charger

Amperage rates, smart chips, thermal protection

When choosing your next charger in any Makita charger comparison, several features should guide your selection. First, amperage delivery: Rapid-charging models usually offer at least 6A output per port, ideal for tools using 5.0Ah or larger battery packs. This ensures swift replenishment and uninterrupted workflow.

Next, integrated smart chips are a critical addition. These chips manage current flow, detect battery health status, and adjust voltage automatically to extend life cycle effectiveness. Thermal controls, generally tied to fans and smart regulation, help prevent overheating. This directly reduces cell degradation, a key factor in lithium-ion battery maintenance.

Look also for LED indicators and charging diagnostics—all beneficial for team coordination and maintenance tracking. Chargers with multiple voltage support (e.g. LXT 18V and XGT 40V) offer cross-compatibility and future-proofing. Combining features like fan-equipped internals and dual-port optimisation helps mitigate charge conflict or inefficiency common to older, basic models.

Recommended Chargers for Commercial Use

Top picks including Torxup VoltGuard 6500

Among Makita-certified options, the DC18RD remains a frontrunner due to its rapid twin-port support and fan-cooled design. For 40V equipment in the XGT line, the Makita DC40RA offers elite recharge speeds with superior intelligent charging profiles, making it ideal for higher-wattage tools. On the third-party side, the Torxup VoltGuard 6500 has been gaining favour with commercial users. It supports up to four 18V Makita batteries simultaneously and features independent thermal fuses, making it one of the safest alternatives available. Automating website SEO for productivity

Additionally, the DC18SF quad-port sequential charger is particularly useful for construction teams rotating through several batteries per shift. While it doesn’t charge all four simultaneously, its acceleration cycle still outpaces the productivity curve of older single-bay models. For those balancing cost and performance, this unit hits a sweet spot for scaling teams or freelancers with expansive gear arsenals.

Final Thoughts on Optimising Charging Strategy

Moving toward a smarter jobsite

Optimising charger selection, deployment, and rotation habits can significantly bolster sitewide efficiency. The clearest path to improving jobsite output remains upgrading from OEM to rapid or multi-port units. Where teams operate with more than three battery-dependent tools in constant rotation, investment in smart-charging infrastructure is mission-critical.

Considerations like thermal management, charging amperage, port concurrency, and future compatibility help maximise battery life while protecting tool investment. The goal is not merely fast charging—but efficient, safe, and predictable energy workflows.

By leveraging lessons from real-world UK teams and assessing the best gear on offer through comprehensive Makita charger comparison, commercial operators can transform this often underappreciated backend process into a clear advantage on site.

Conclusion: Power Your Productivity

Choosing the right charger aligns directly with the success of your project timelines, safety standards, and equipment longevity. Through this in-depth Makita charger comparison, it is evident that smarter charging isn’t a luxury—it’s a necessity for competitive, team-based workflows. Prioritise speed, safety, and scalability, and your power tools will return the favour in performance and durability.

Great guide on makita-oem-chargers-team-output-comparison – Community Feedback

Are Makita OEM chargers slower than other options?

Yes, Makita OEM chargers—especially standard models—tend to charge batteries more slowly than rapid or compatible fast chargers, impacting efficiency for demanding teams.

Will upgrading my Makita charger improve team productivity?

Switching to a rapid or multi-bay charger can significantly reduce charging downtime, ensuring your team’s tools are always ready and improving overall workflow.

Do third-party Makita-compatible chargers affect battery life?

Quality certified third-party chargers with safety features match OEM charging profiles and protect battery life. Cheaper uncertified units, however, can risk faster battery degradation.